Cyclonic coal mine ventilation air methane (VAM) catalytic oxidization reactor

A catalytic oxidation and reactor technology, applied in chemical instruments and methods, dispersed particle separation, separation methods, etc., can solve problems such as environmental pollution and energy waste, and achieve the effects of reducing costs, increasing residence time, and avoiding maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

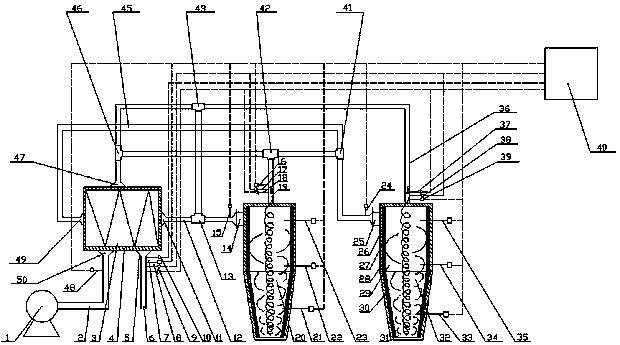

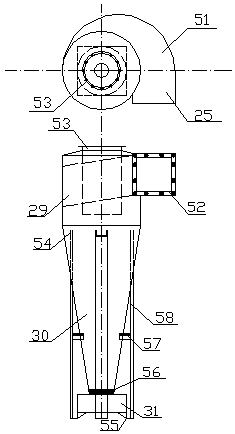

[0040] Such as figure 2 As shown, the exhaust air enters the reactor through tangential entry of the volute, the inner wall of the inlet pipe is tangent to the cylinder, and the outer wall adopts an involute form with an involute angle of 180°. The reactor shell is composed of an air inlet, a volute type air inlet pipe, a cylinder, a cone, an ash storage hopper and an air outlet. The air inlet is arranged on the cylinder and connected by flanges, the reactor is supported by a bracket and a support plate, and the bracket is connected with the base, so that the reactor is more stable.

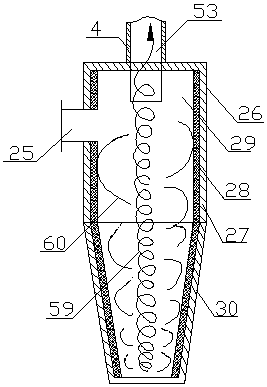

[0041] Such as image 3 As shown, the gas flow direction in the reactor is mainly divided into outer vortex and inner vortex. After the gas enters the reactor, it rotates from top to bottom along the outer wall of the reactor, that is, the outer vortex. At this time, the gas reacts with the catalyst coated on the inner wall of the reactor. At the same time, the dust particles contained in the...

Embodiment 2

[0048] Preheat the reactor to 500°C with a gas flow rate of 1.2m 3 / h, the flow rate is 0.04m / s, the methane concentration is 0.8%, the reversing period is 5min, the methane conversion rate can reach more than 85%, and the outlet temperature is only 35°C.

Embodiment 3

[0050] Preheat the reactor to 500 °C with a gas flow rate of 1.2 m 3 / h, the flow rate is 0.04m / s, the methane concentration is 0.3%, the reversing period is 5min, the methane conversion rate can reach more than 80%, and the outlet gas temperature is below 45°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com