Hydrogen catalytic burner

A catalytic burner, hydrogen technology, applied to gas fuel burners, burners, combustion methods, etc., can solve problems such as danger, hydrogen loss, and reduced combustion efficiency, and achieve high catalytic combustion efficiency, low "leakage" probability, The effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

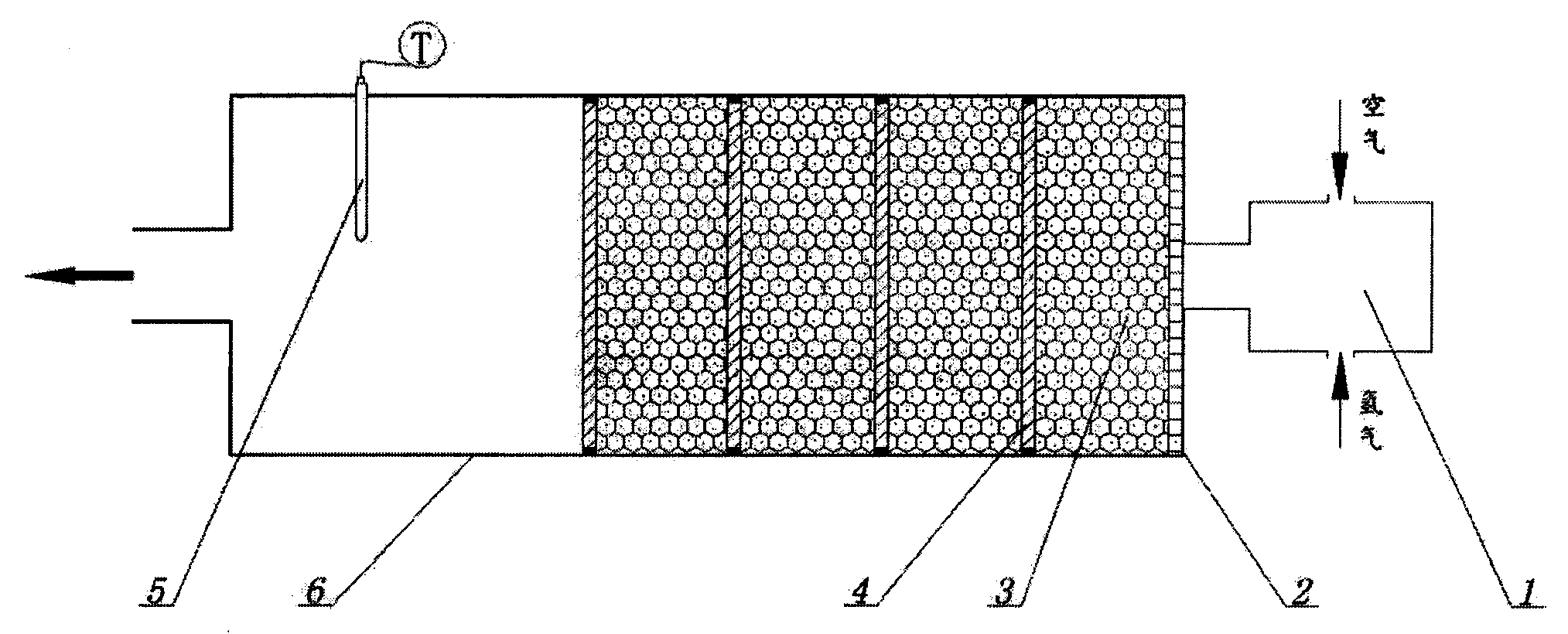

[0019] A hydrogen catalytic burner is provided with a hydrogen / air gas mixing chamber 1 and a porous liner 2, and the porous liner 2 is placed at the bottom of the hydrogen catalytic burner. The catalyst layer 3 has a multi-layer structure, and separators 4 are arranged between the catalyst layers, and the separators 4 are flanged porous separators. The separator 4 is sealed with the wall of the hydrogen catalytic burner 6 through interference fit. The hydrogen / air mixture from the gas mixing chamber 1 enters the first catalyst layer 3 through the porous liner 2 , and then enters the second catalyst layer through the holes on the separator 4 . Since the partition 4 is tightly sealed with the wall of the hydrogen catalytic burner 6 , the hydrogen / air mixture will not pass through the wall of the burner 6 .

[0020] There are three catalyst layers, the catalyst layer is ceramic powder loaded with precious metals, and the catalyst carrier is γ-Al 2 o 3 The ceramic powder, the ...

Embodiment 2

[0022] A hydrogen catalytic burner is provided with a gas mixing chamber, a porous liner, a catalyst layer, a partition and a temperature sensor. The porous liner is placed at the bottom of the hydrogen catalytic burner, the catalyst layers are multi-layered, and partitions are arranged between the catalyst layers. The partition is a flanged porous aluminum alloy plate, and the partition is sealed with the wall of the catalytic burner through interference fit.

[0023] There are six catalyst layers in total, and the catalyst layer is a glass fiber mat loaded with precious metals. The catalyst carrier is glass fiber felt, the catalyst is noble metal ruthenium, and the catalyst load is 1% of the carrier mass. When the hydrogen / air mixture with a fuel-air ratio of 1 / 25 passes through the catalytic burner, hot air at 280°C (measured temperature) is obtained, and the hydrogen concentration in the tail gas is less than 10PPM.

Embodiment 3

[0025] A hydrogen catalytic burner is provided with a gas mixing chamber, a porous liner, a catalyst layer, a partition and a temperature sensor. The porous liner is placed at the bottom of the hydrogen catalytic burner, the catalyst layer has a multi-layer structure, and partitions are arranged between the catalyst layers. The partition is a flanging porous red copper plate, and the partition is sealed with the wall of the catalytic burner through interference fit.

[0026] There are six catalyst layers in total, and the catalyst layer is a glass fiber mat loaded with precious metals. The catalyst carrier is a glass fiber mat, the catalyst is three composites of Pd, Pt and Ru, and the catalyst load is 0.8% of the carrier mass. When the hydrogen / air mixture with a fuel-air ratio of 1 / 25 passes through the catalytic burner, hot air at 280°C (measured temperature) is obtained, and the hydrogen concentration in the tail gas is less than 5PPM.

[0027] This embodiment has the ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com