Flexible Assembly Induction Heater

An induction heater and flexible assembly technology, applied in the direction of induction heating, coil devices, etc., can solve the problems that fixed or closed induction coils cannot be used, the heating temperature is difficult to meet the requirements, and the heating time is long, etc., so as to achieve safe and reliable use , fast heating, simple installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

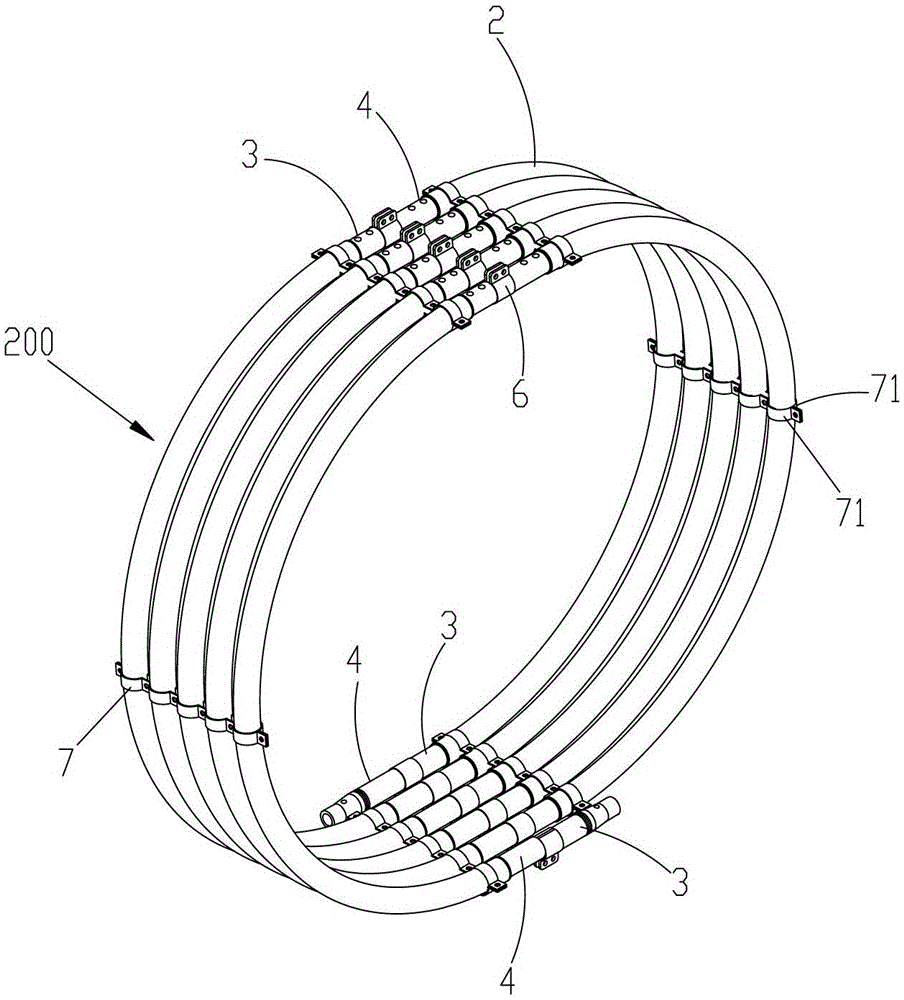

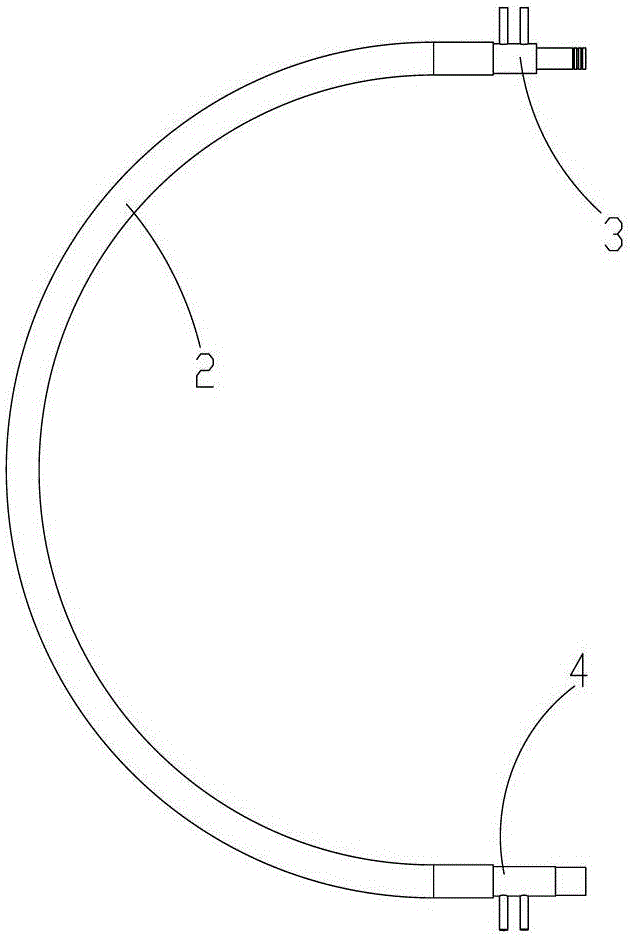

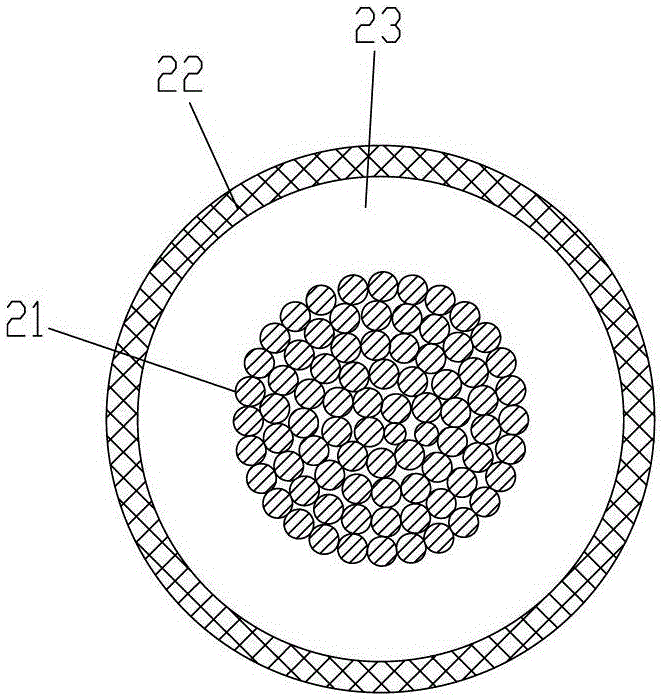

[0038] Such as figure 1As shown, the flexible assembled heating inductor in a preferred embodiment of the present invention is especially suitable for inductively heating the weld seam positions of large workpieces such as jacket platforms in offshore oil platforms, and it is understandable that it does not Heating of small workpieces is ruled out. The flexibly assembled heating sensor includes several flexible cables 2, and the number of flexible cables 2 in this embodiment may be but not limited to ten. Both ends of each flexible cable 2 are respectively connected with a first joint 3 and a second joint 4, and the first joint 3 and the second joint are matched. Specifically, the two ends of each flexible cable 2 are respectively mechanically and electrically connected to the first connector 3 and the second connector 4; They are all matched and connected with the second joint 4 on the previous flexible cable 2, and connected in sequence to form an induction coil 200, that ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com