Modified methanol and preparation method thereof

A denatured methanol and production method technology, applied in the petroleum industry, liquid carbon-containing fuels, fuels, etc., can solve problems such as corrosion swelling, formaldehyde emissions, etc., and achieve the effects of reducing emissions, increasing power performance, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] The denatured methanol described in the embodiment of the present invention is made of the following components in parts by weight: 80 parts of methanol, 3.16 parts of methanol denaturing additive, wherein the methanol denaturing additive is made of the following components in parts by weight: isopropyl 50 parts of alcohol; 11 parts of cyclohexylamine; 10 parts of No. 1 aviation kerosene; 0.5 parts of zinc peroxide; 6 parts of dimethyl carbonate; 9 parts of isooctyl nitrate; 7 parts of fatty acid methyl ester; 0.5 parts of p-cresol.

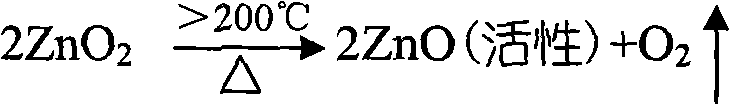

[0055] The production method of methanol denaturation described in the present embodiment comprises the following steps: 1) production active agent: 50 parts of isopropanol and 7 parts of fatty acid methyl esters are allotted; 1 part is formulated with 0.5 part of zinc peroxide; 3) production of catalytic combustion agent: the catalytic combustion auxiliary agent produced in step 2) is formulated with 6 parts of dimethyl carbonate and 9 pa...

Embodiment 2

[0057] The denatured methanol described in the embodiment of the present invention is made of the following components in parts by weight: 85 parts of methanol, 9.27 parts of methanol denaturing additive, wherein the methanol denaturing additive is made of the following components in parts by weight: isopropyl 70 parts of alcohol; 3 parts of cyclohexylamine; 5 parts of No. 1 aviation kerosene; 0.1 part of zinc peroxide; 1 part of dimethyl carbonate; 4 parts of isooctyl nitrate; 3 parts of fatty acid methyl ester; 0.1 parts of p-cresol.

[0058] The production method of methanol denaturation described in the present embodiment comprises the following steps: 1) production of active agent: 70 parts of isopropanol and 3 parts of fatty acid methyl ester are allocated; 2) production of catalytic combustion agent auxiliary agent: No. 1 aviation kerosene 5 parts 1 part and 0.1 part of zinc peroxide; 3) production of catalytic combustion agent: the catalytic combustion auxiliary agent ...

Embodiment 3

[0060] The deformed methanol described in the embodiment of the present invention is made of the following components by weight: 90 parts of methanol, 15.38 parts of methanol denaturing additive, wherein the methanol denaturing additive is made of the following components by weight: isopropyl 90 parts of alcohol; 20 parts of cyclohexylamine; 5 parts of No. 1 aviation kerosene; 0.9 parts of zinc peroxide; 10 parts of dimethyl carbonate; 15 parts of isooctyl nitrate; 10 parts of fatty acid methyl ester; 0.9 parts of p-cresol.

[0061] The production method of methanol denaturation described in the present embodiment comprises the following steps: 1) production of active agent: 90 parts of isopropanol and 10 parts of fatty acid methyl ester are allocated; 2) production of catalytic combustion agent auxiliary agent: No. 1 aviation kerosene 5 10 parts and 0.9 parts of zinc peroxide; 3) production of catalytic combustion agent: the catalytic combustion auxiliary agent produced in st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com