Combustion of ultra-low concentration combustible gas and its thermal energy step utilization system

An ultra-low concentration, gas technology, applied in the direction of combustion, combustion method, combustion type, etc. using catalytic materials, can solve the problems of different catalytic reactions, and achieve the effect of increasing specific surface area, high working temperature, and convenient and fast transformation methods.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

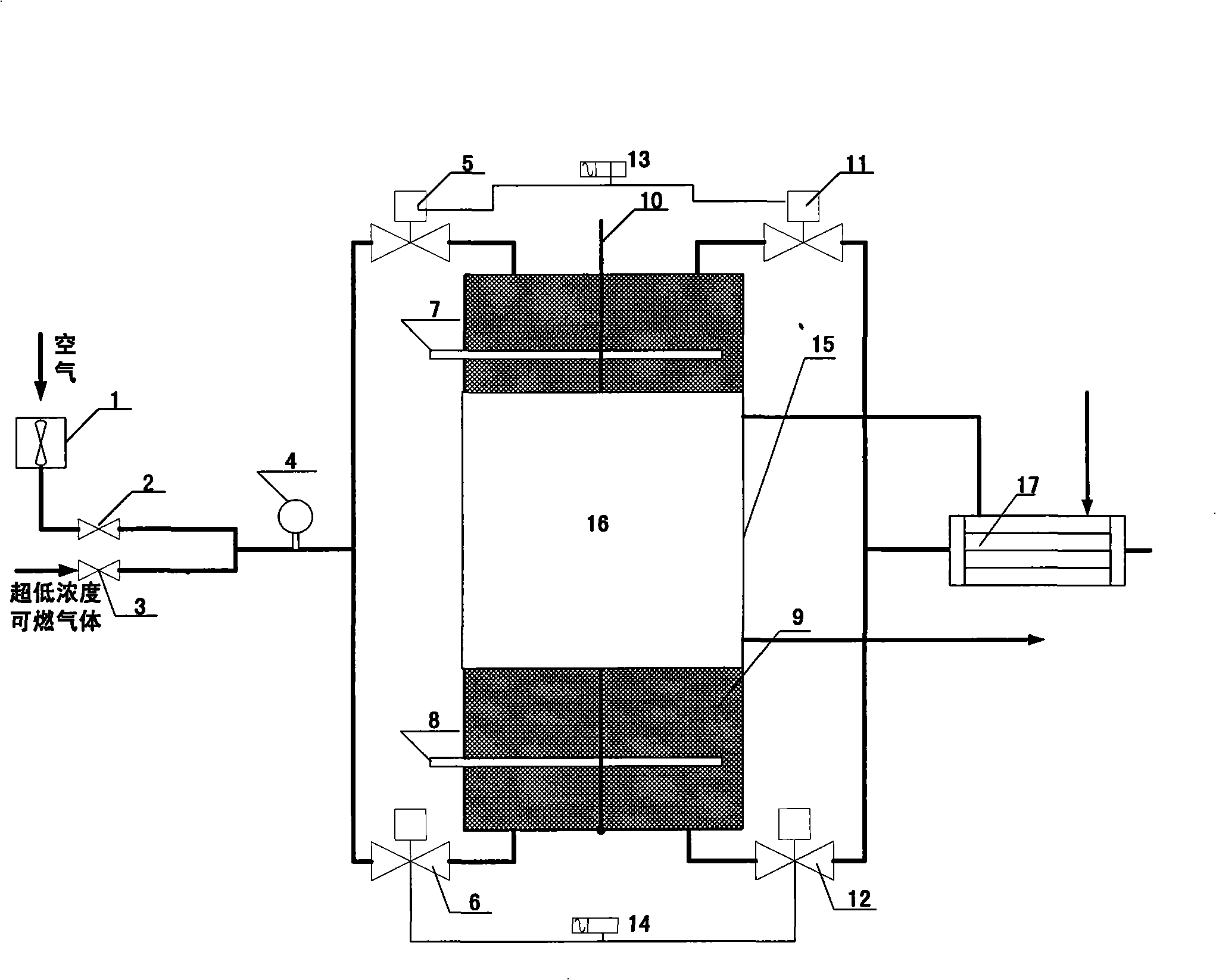

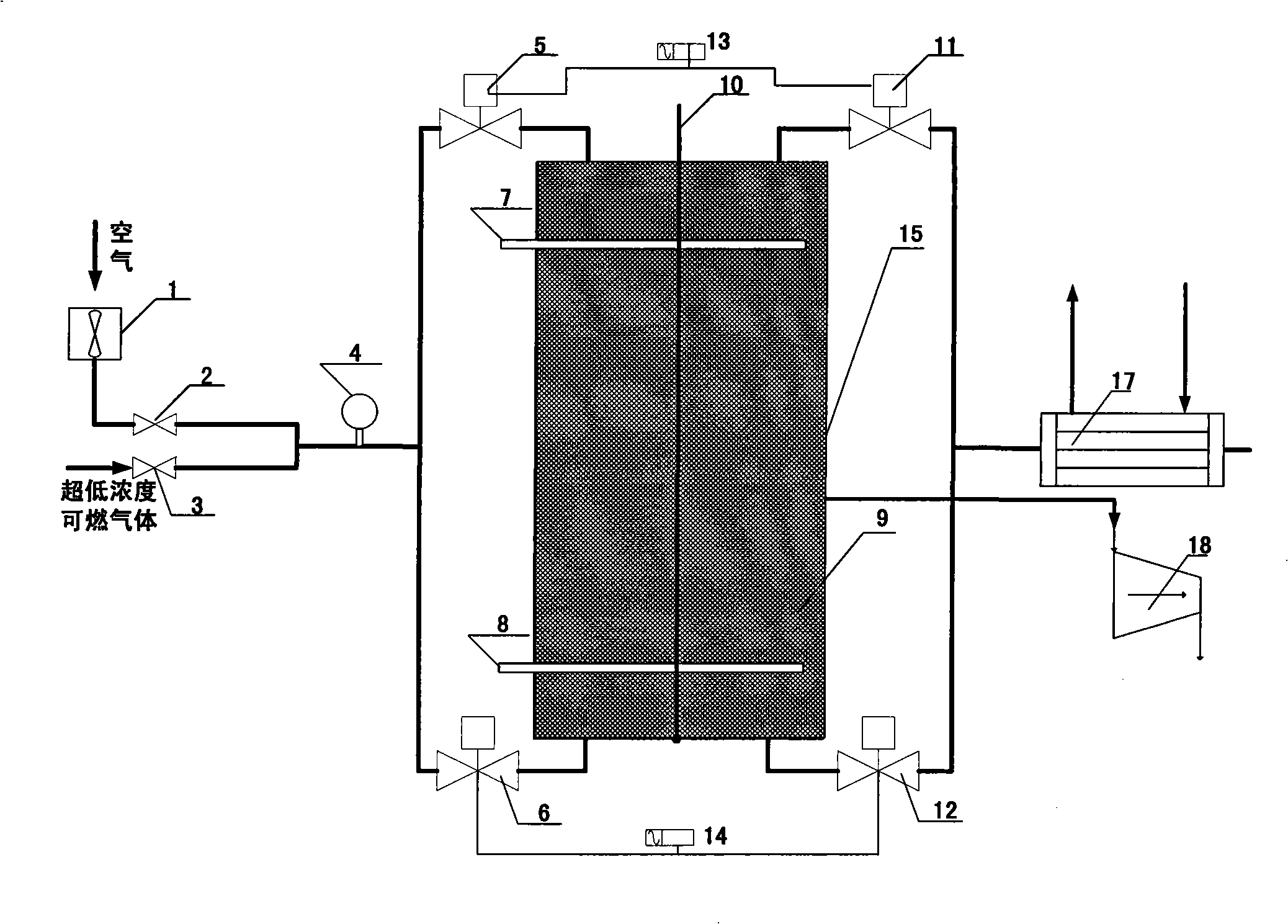

[0025] Such as figure 1 As shown, its system mainly includes:

[0026] The fan 1 is connected to the flow control valve 2 via a pipeline; the flow control valve 2 and another flow control valve 3 are connected to the concentration monitoring meter 4; the concentration monitoring meter 4 is connected to the first electromagnetic valve 5 and the second electromagnetic valve 6; the first The solenoid valve 5 is connected to the second solenoid valve 6; the third solenoid valve 11 is connected to the fourth solenoid valve 12; the time relay 13 is connected to control the first solenoid valve 5 and the third solenoid valve 11; the time relay 14 is connected to control the second solenoid valve 6 and the fourth solenoid valve 12; the first solenoid valve 5, the second solenoid valve 6, the third solenoid valve 11, and the fourth solenoid valve 12 are connected to the reactor 15; the reactor 15 has a built-in electric heating element 7 and another electric heating element Component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com