Waste gas catalytic combustion equipment for garbage disposal

A technology of catalytic combustion and waste treatment, applied in combustion methods, combustion types, lighting and heating equipment, etc., can solve the problems of water vapor recycling, incomplete waste gas treatment, waste of water resources, etc., to increase the contact area and time , the effect of accelerating catalytic combustion efficiency and accelerating incineration efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

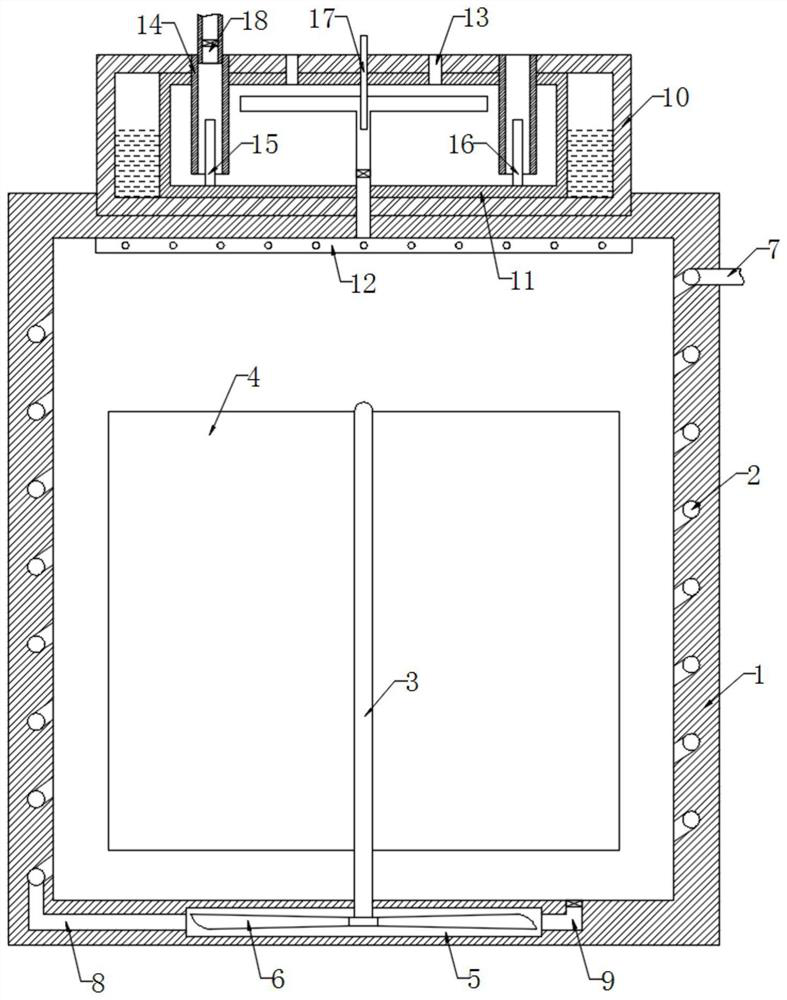

[0023] refer to figure 1 , a kind of exhaust gas catalytic combustion equipment for waste treatment, comprising a combustion chamber 1, the inner wall of the combustion chamber 1 is provided with a spiral heating chamber 2, further, the spiral setting of the spiral heating chamber 2 increases the contact area with the catalyst in the combustion chamber 1, and at the same time extends The flow time of the exhaust gas in the spiral cold spiral heating chamber 2 is shortened, and the catalyst can be preheated well. The bottom of the combustion chamber 1 is rotatably connected to the rotating shaft 3, and the side wall of the rotating shaft 3 is fixedly connected to a plurality of stirring blades 4. Combustion The lower end of the chamber 1 is provided with a circular chamber 5, the lower end of the rotating shaft 3 runs through the lower end of the combustion chamber 1 and extends into the circular chamber 5, the lower end of the rotating shaft 3 is fixedly connected with the wind...

Embodiment 2

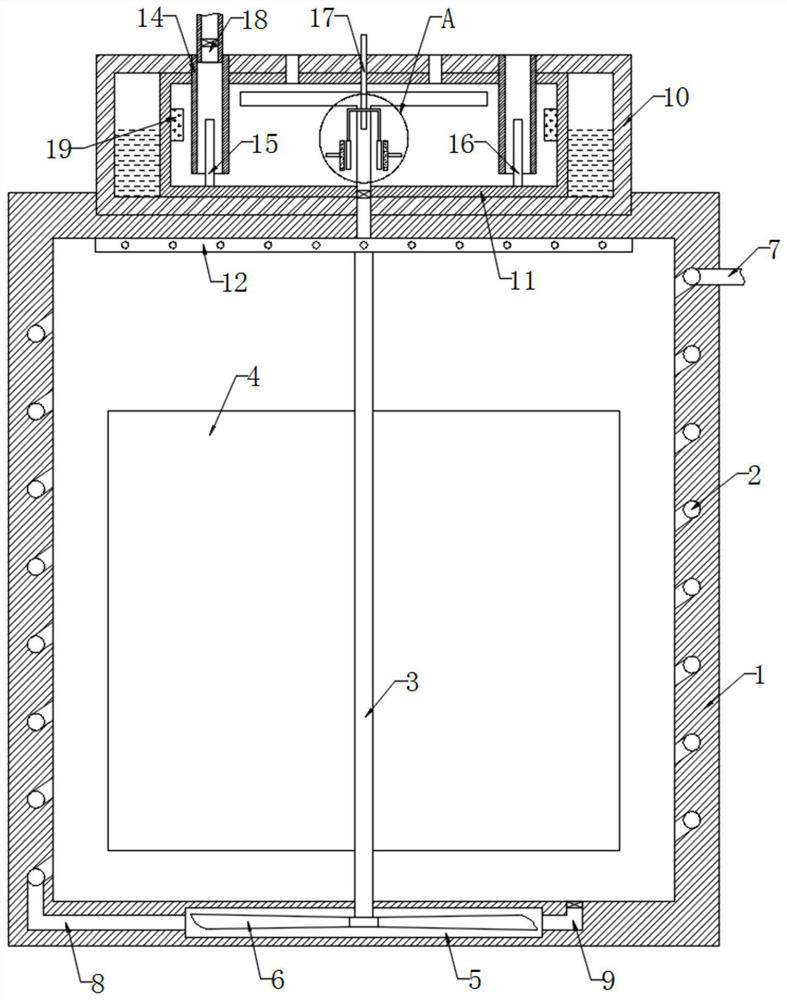

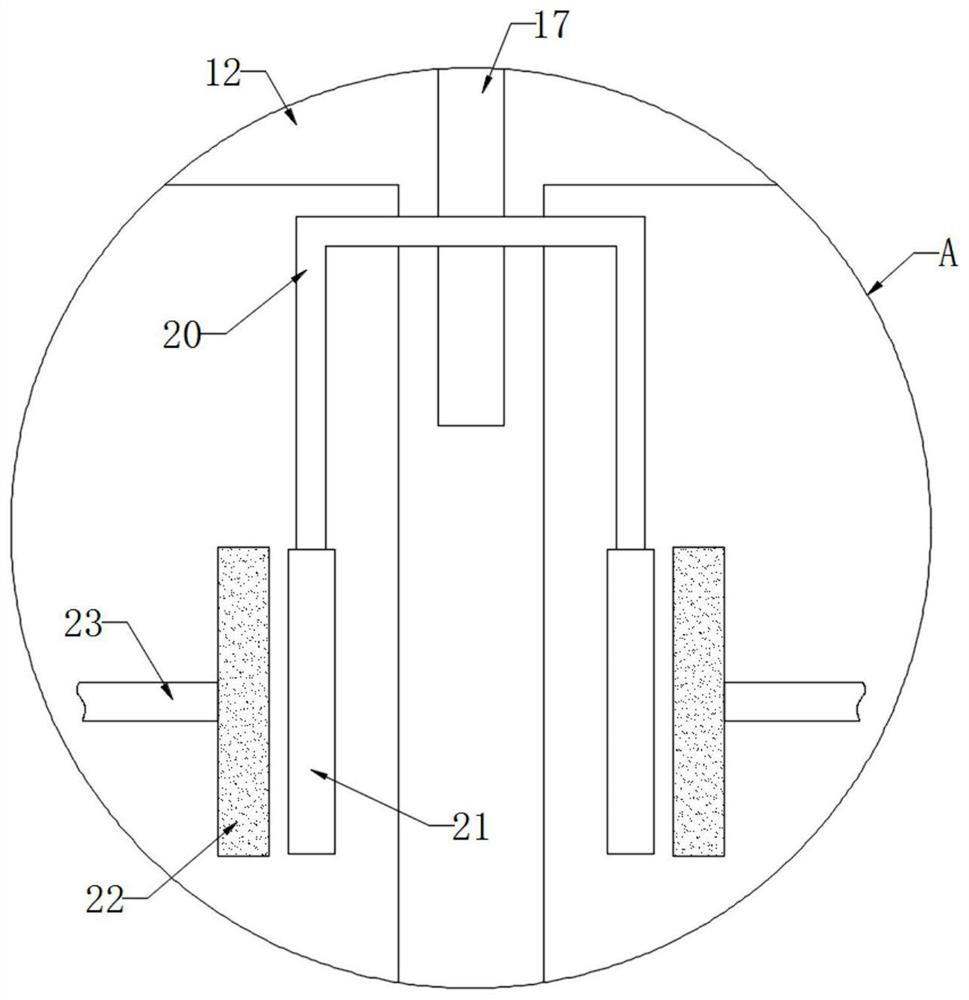

[0028] refer to Figure 2-3 , different from Embodiment 1, the one-way exhaust pipe 12 is rotationally connected with the combustion chamber 1 and the side wall of the liquid storage tank 11, the upper end of the rotating shaft 3 is fixedly connected with the lower end of the one-way exhaust pipe 12, and the inner wall of the liquid storage tank 11 is symmetrically fixed Two permanent magnets 19 are connected, and the magnetic poles of the two permanent magnets 19 facing each other are opposite, so that a magnetic field circuit is formed between the two permanent magnets 19, and then the cutting of the magnetic induction line can be realized. The one-way exhaust pipe 12 is located at Part of the side wall of the liquid storage tank 11 is plugged with a coil 20, and both ends of the coil 20 are fixedly connected with an arc-shaped piece 21, and the inner wall of the liquid storage tank 11 is symmetrically fixedly connected with a brush 22, and the arc-shaped piece 21 is attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com