Van type vacuum drying device for urban sludge

A vacuum drying device and sludge technology, which is applied in the direction of dehydration/drying/concentrated sludge treatment, etc., can solve the problems of poor drying effect, odor overflow, etc., and achieve good drying effect, small vaporization latent heat, and good social and economic benefits.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

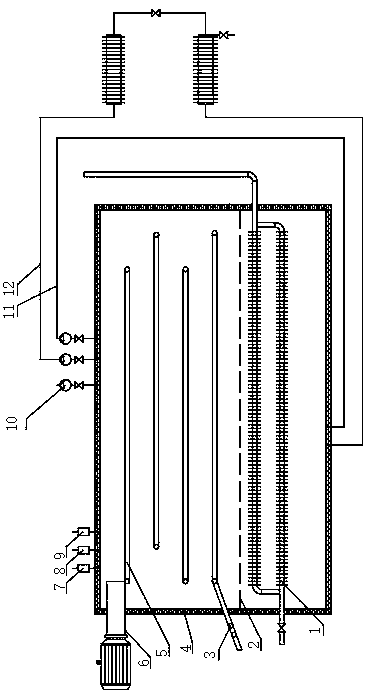

[0034] Such as figure 1 As shown, a box-type vacuum drying device for urban sludge of the present invention includes a drying box 4, and the box body of the drying box 4 is an insulated box body. The drying box 4 is connected with a vacuum pump 10, and the vacuum pump 10 is used to control the vacuum degree in the drying box 4.

[0035] An air distribution plate 2 is arranged inside the drying box 4 to divide it into an upper material delivery area and a lower air supply area, and the air distribution plates 2 are evenly arranged with air distribution channels. There is a material conveying system in the material conveying area, and a finned heat exchanger 1 is installed in the air supply area. The gas entering the air supply area is heated by the finned heat exchanger 1 and then introduced through the air distribution channel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com