Sludge drying and incinerating system, sludge drying machine and sludge drying method

A sludge drying and sludge technology, applied in combustion methods, dewatering/drying/concentrating sludge treatment, incinerators, etc., can solve the problem of high operating costs, large investment in infrastructure, and ineffective sludge problems. Solve and other problems to achieve the effect of improving drying rate, reducing water content and avoiding secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

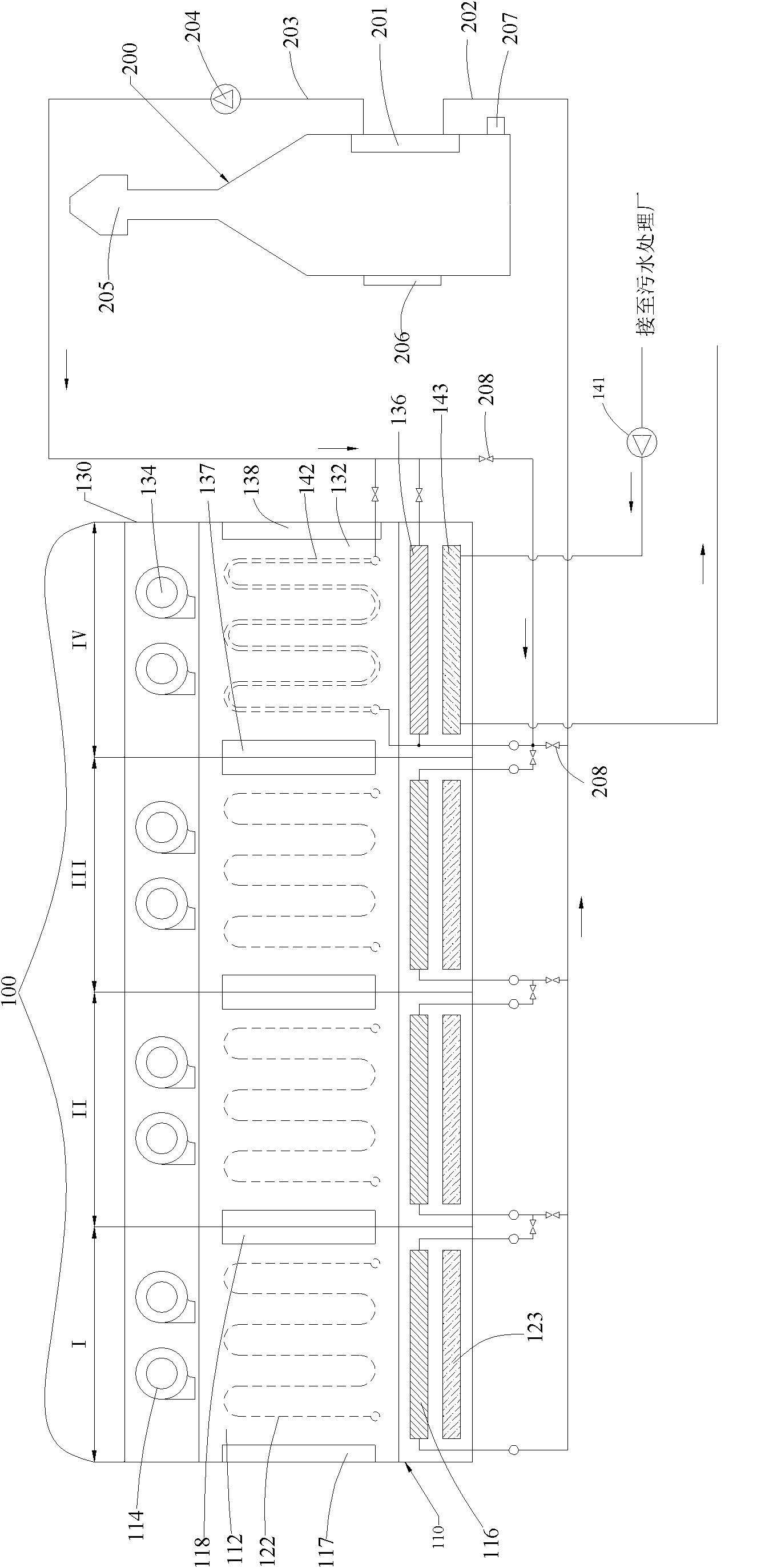

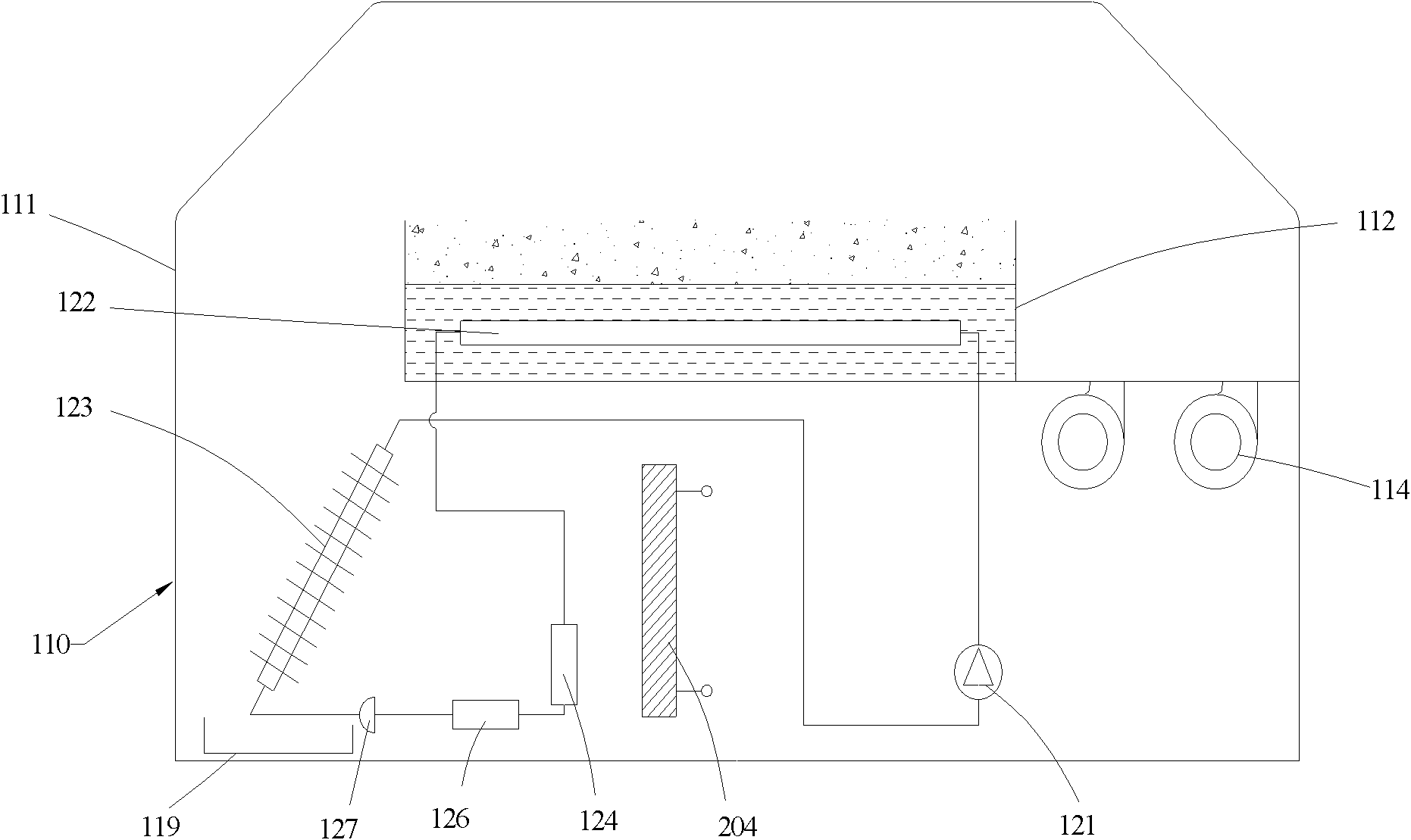

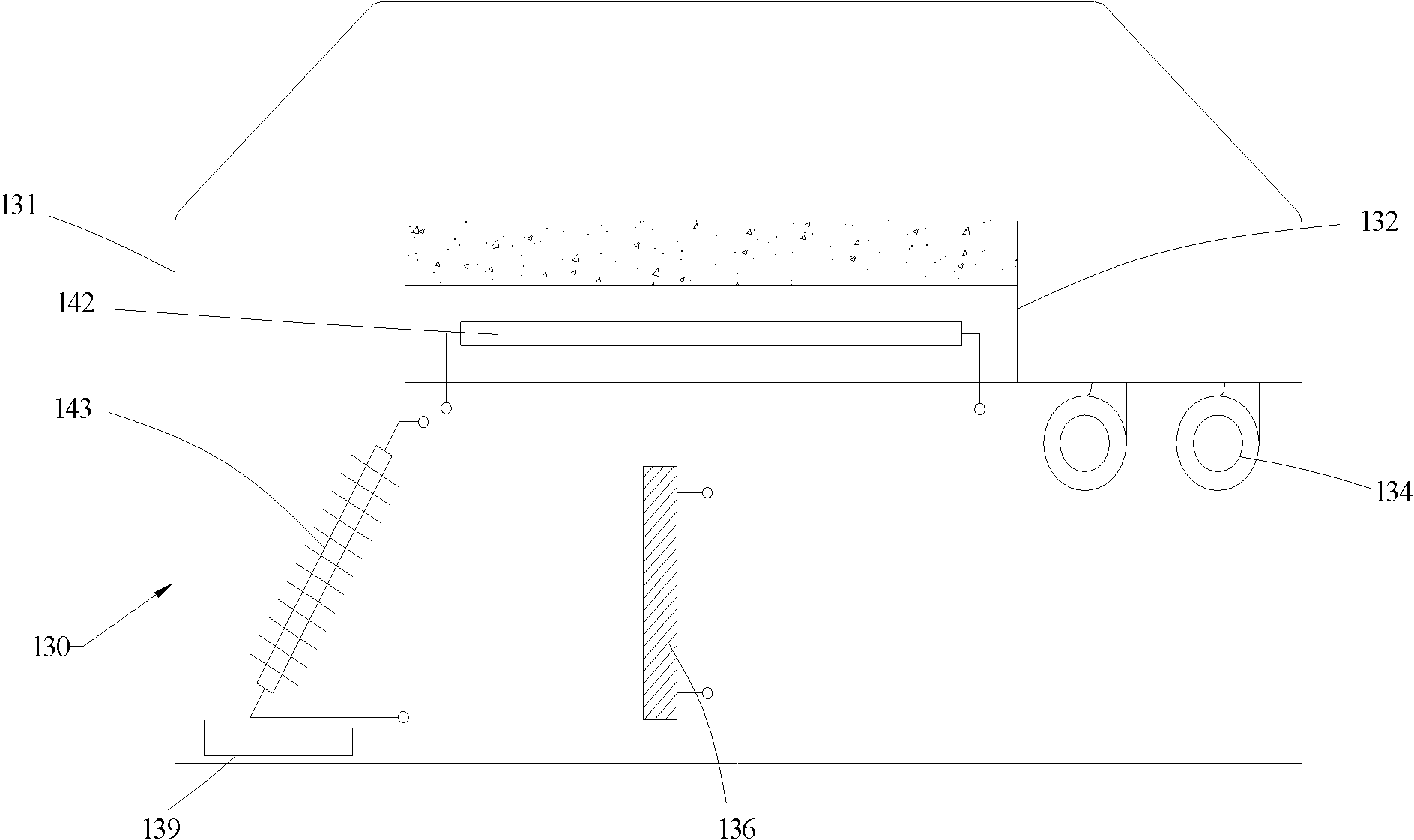

[0038] Such as Figure 1 to Figure 4Shown is an embodiment of the sludge drying and incineration system of the present invention, which can be used for sludge treatment in urban sewage treatment plants; of course, it can also be applied to sludge drying treatment in other occasions. The system includes a sludge dryer 100 and a heat source; of course, a sludge uniform feeder, an electrical control system, etc. are also provided. The sludge uniform feeder can choose the appropriate equipment according to the needs; and the electrical control system is used to control the operation of the electrical components of the entire system. It can be understood that the sludge dryer 100 can be used separately, as long as an appropriate heat source is selected to provide heat.

[0039] In this embodiment, the heat source is a sludge incinerator 200 , especially a waste heat recovery sludge incinerator 200 . The sludge incinerator 200 is provided with a heat recovery device 201 , and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com