Subcritical steam auxiliary power gasoline engine

A gasoline engine, subcritical technology, applied in the direction of mechanical equipment, engine operation, engine components, etc., can solve the problems of increased possibility of knocking, high exhaust temperature, power consumption, etc., to suppress the formation of nitrogen oxides, increase output torque and Power, the effect of increasing the burst pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: refer to each accompanying drawing.

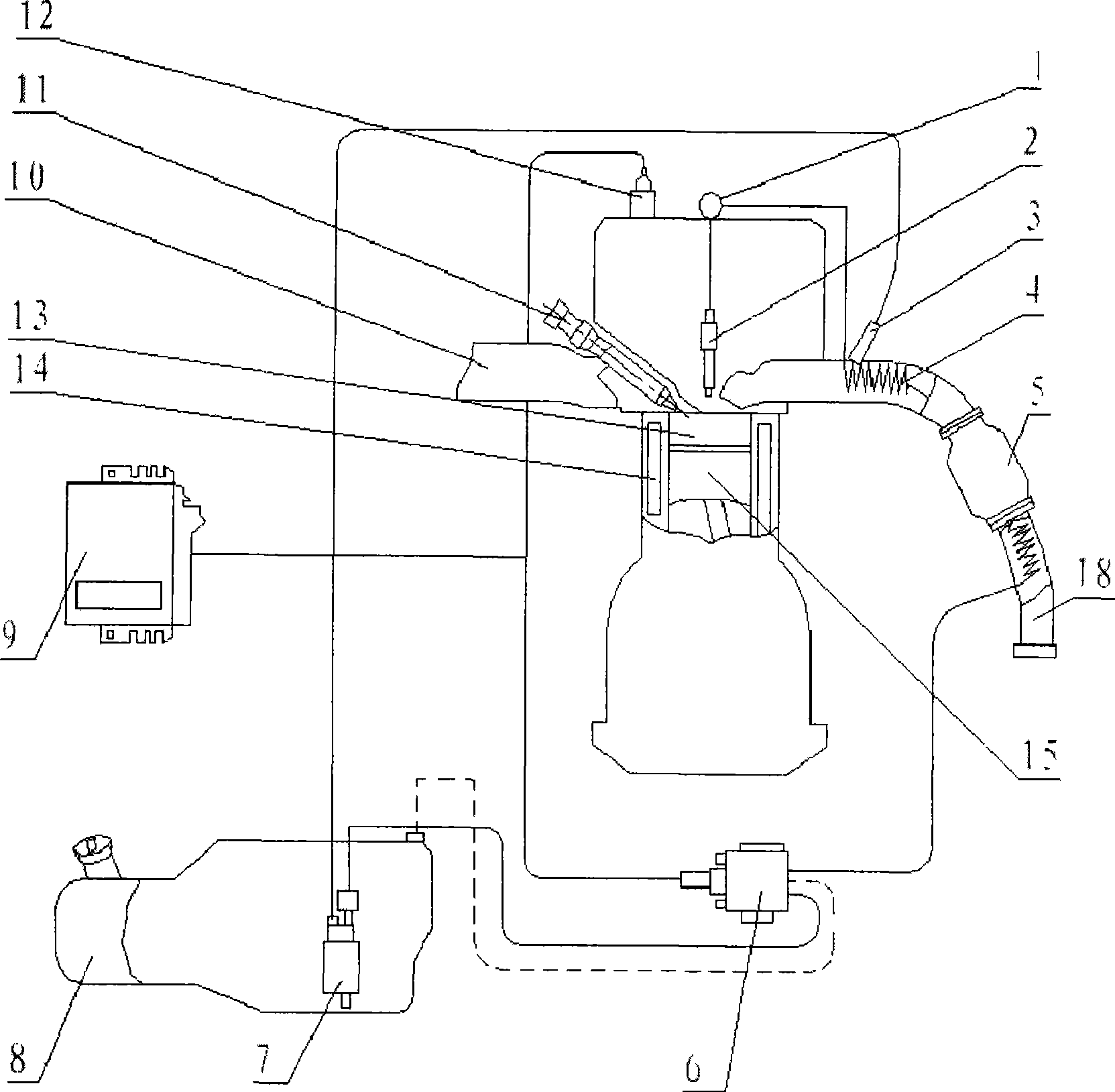

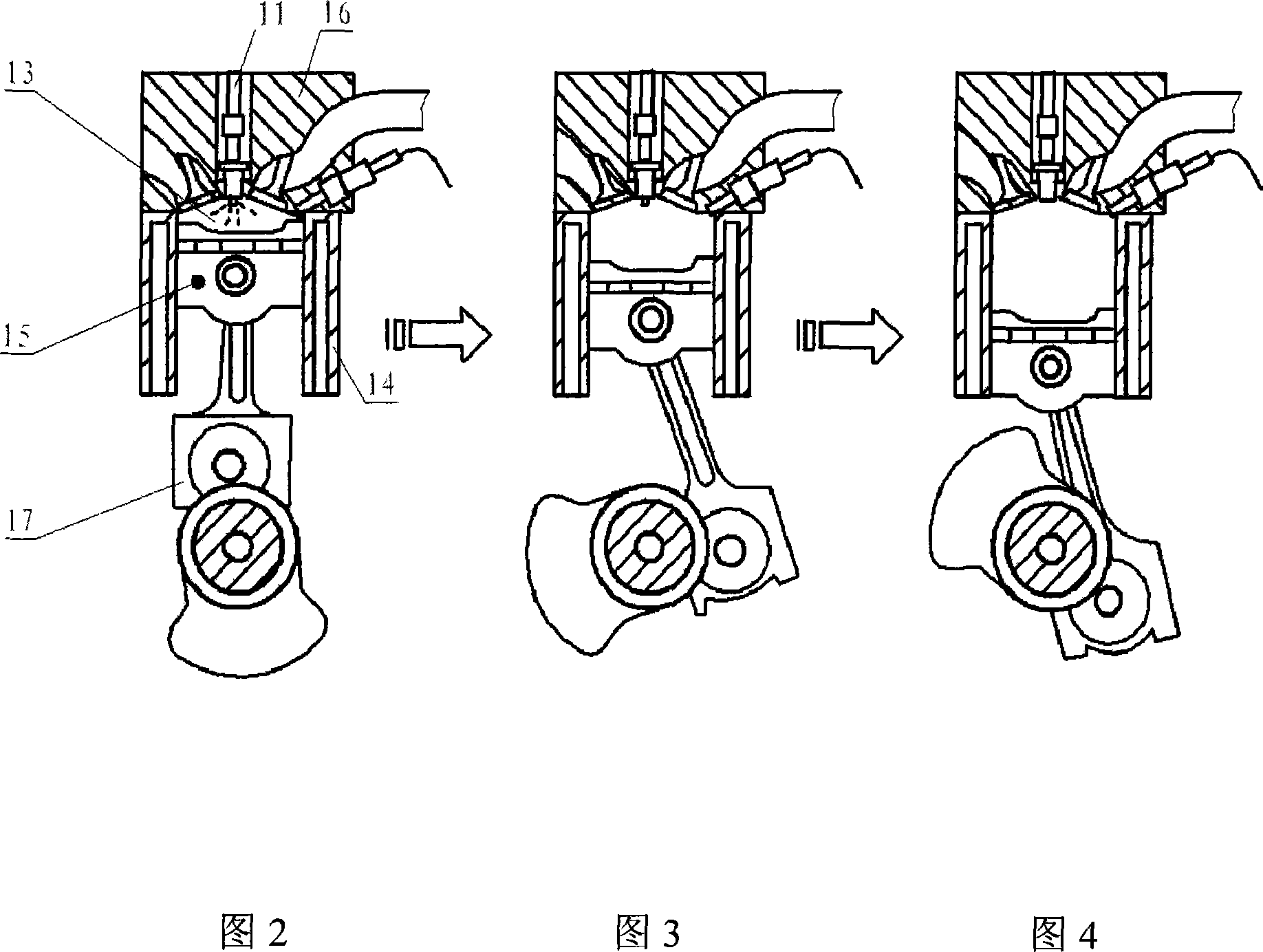

[0027] A subcritical steam-assisted working gasoline engine (four-stroke gasoline engine), including a gasoline engine cylinder water spray device; the gasoline engine cylinder water spray device includes: a water tank 8, an electronic control unit 9 (similar to the gasoline engine cylinder direct injection in the prior art) The structure and function of the electronic control unit of the system are similar, or called ECU or ECM, to manage the water injection time and water injection volume, a single ECU or ECM can be used, or it can be shared with the ECU or ECM that manages air intake and oil supply) , the water pump that is electrically connected with the electronic control unit 9 and controlled by the electronic control unit 9, the water rail 1 (similar to the oil rail structure and function of the high-pressure common rail diesel engine in the prior art), the water spray nozzle 2 (installed on the cylinder head 16 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com