Process method for recycling acetone from exhaust gas

A process method and acetone technology, which are applied in chemical instruments and methods, preparation of organic compounds, separation/purification of carbonyl compounds, etc., can solve the problems of high energy consumption, poor stability, and difficult separation of acetone recovery.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

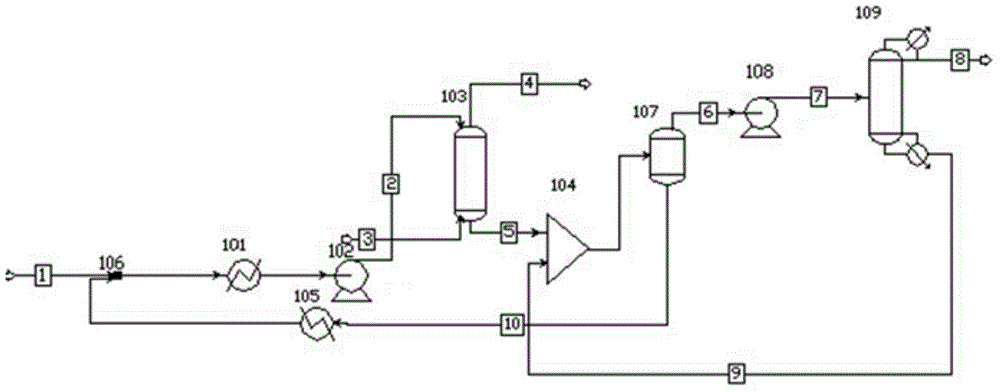

[0041] The acetone to-be-treated gas 3 containing about 1.79% mole fraction enters from the bottom of the absorption tower 103, and the feed temperature is 20°C. The gas 3 to be treated rises continuously in the absorption tower 103 and meets the condensed absorption water 2 entering from the top of the absorption tower 103 countercurrently. The condensed absorption water 2 enters the tower at a temperature of 10°C and sprays down from the top of the tower. After the trace amount of acetone is condensed and absorbed by the absorption water 2, it falls to the bottom of the tower to form diacetone water 5, which is extracted from the bottom of the absorption tower 103 at a temperature of 15°C and the mass fraction of acetone is 3.8%. The tail gas is discharged from the top of the tower, the temperature is 10.5°C, and the acetone content is lower than 0.07‰.

[0042] Dilute acetone water 5 enters the liquid-liquid phase separator 107 through the first mixer 104 for preliminary co...

Embodiment 2

[0045] The gas to be treated 3 containing mole fraction of about 1.79% acetone enters from the bottom of the absorption tower 103, and the feed temperature is 25° C. The absorption water 2 meets countercurrently, and after condensation, the temperature of the absorption water 2 entering the tower is 7°C, and it is sprayed down from the top of the tower. After the trace amount of acetone is condensed and absorbed by the absorption water 2, it falls to the bottom of the tower to form diacetone water 5, which is extracted from the bottom of the absorption tower 103 at a temperature of 18°C and the mass fraction of acetone is 3.9%. The tail gas is discharged from the top of the tower, the temperature is 8.6°C, and the acetone content is lower than 0.07‰.

[0046] Dilute acetone water 5 enters the liquid-liquid phase separator 107 through the first mixer 104 for preliminary component separation, and the liquid-liquid phase separator 107 separates the feed liquid I6 and the feed l...

Embodiment 3

[0049] The gas to be treated 3 containing mole fraction of about 1.79% acetone enters from the bottom of the absorption tower 103, and the feed temperature is 15° C. The absorption water 2 meets countercurrently, and after condensation, the temperature of the absorption water 2 entering the tower is 9°C, and it is sprayed down from the top of the tower. After the trace amount of acetone is condensed and absorbed by the absorption water 2, it falls to the bottom of the tower to form diacetone water 5, which is extracted from the bottom of the absorption tower 103 at a temperature of 14.3°C and the mass fraction of acetone is 4.0%. The tail gas is discharged from the top of the tower, the temperature is 12°C, and the acetone content is lower than 0.07‰.

[0050] Dilute acetone water 5 enters the liquid-liquid phase separator 107 through the first mixer 104 for preliminary component separation, and the liquid-liquid phase separator 107 separates the feed liquid I6 and the feed li...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com