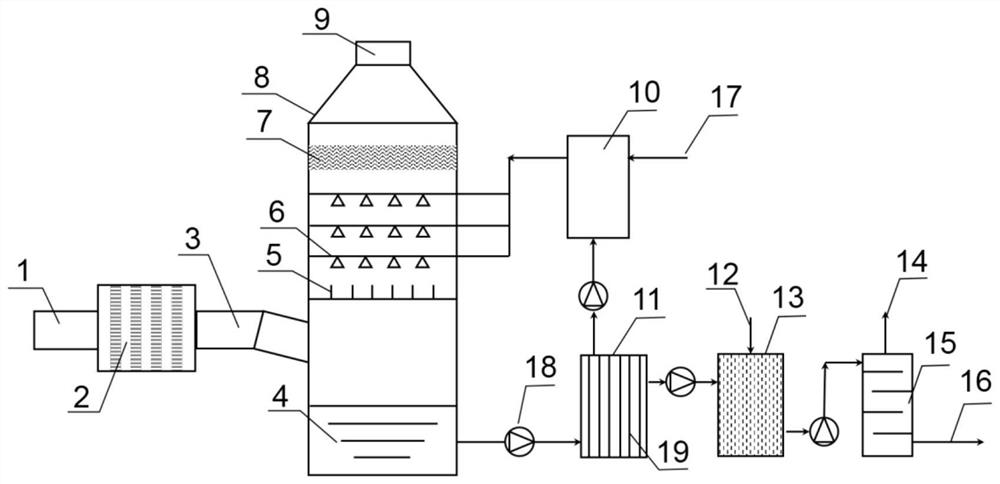

Method and system for preparing urea by coupling denitration with electrocatalytic reduction

A technology coupled with electricity and electrocatalysis, applied in chemical instruments and methods, preparation of organic compounds, separation methods, etc., can solve problems such as the combination of nitrogen oxide removal process without consideration, and achieve the effect of enhancing the absorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] A cement kiln, after adopting a flue gas circulation process, the flue gas emission is 660000m 3 / h, the flue gas temperature is about 200°C; the concentrations of sulfur dioxide and nitric oxide in the flue gas are 800mg / Nm 3 ,300mg / Nm 3 . Ozone is used to oxidize nitric oxide, calcium hydroxide solution is used as alkaline absorption liquid, nanofiltration membrane is used to filter nitrate and nitrite, and copper-palladium alloy is used as a catalyst for electrocatalytic reduction.

[0103] The specific process is:

[0104] The exhaust gas first enters the oxidation device 2, according to the molar ratio O 3 Ozone is added at a ratio of / NO=1.5 to oxidize NO to NO 2 and N 2 o 5 . Contains NO 2 and N 2 o 5 The flue gas enters the spray absorption tower 8, and after contacting with the calcium hydroxide solution as the alkaline absorption liquid, it is absorbed by the absorption liquid. due to NO 2 The absorption coefficient is relatively low, and a gas-liq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com