A method for pasting facing bricks in prefabricated concrete floor and wall panels

A prefabricated concrete and concrete technology, applied in the field of pasting bricks, can solve the problems of not doing a good job in the protection of the face bricks, the face bricks are prone to scratches, and the quality is difficult to control, etc., and achieves good viewing effect, saves the paste process, and reduces the effect of material consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

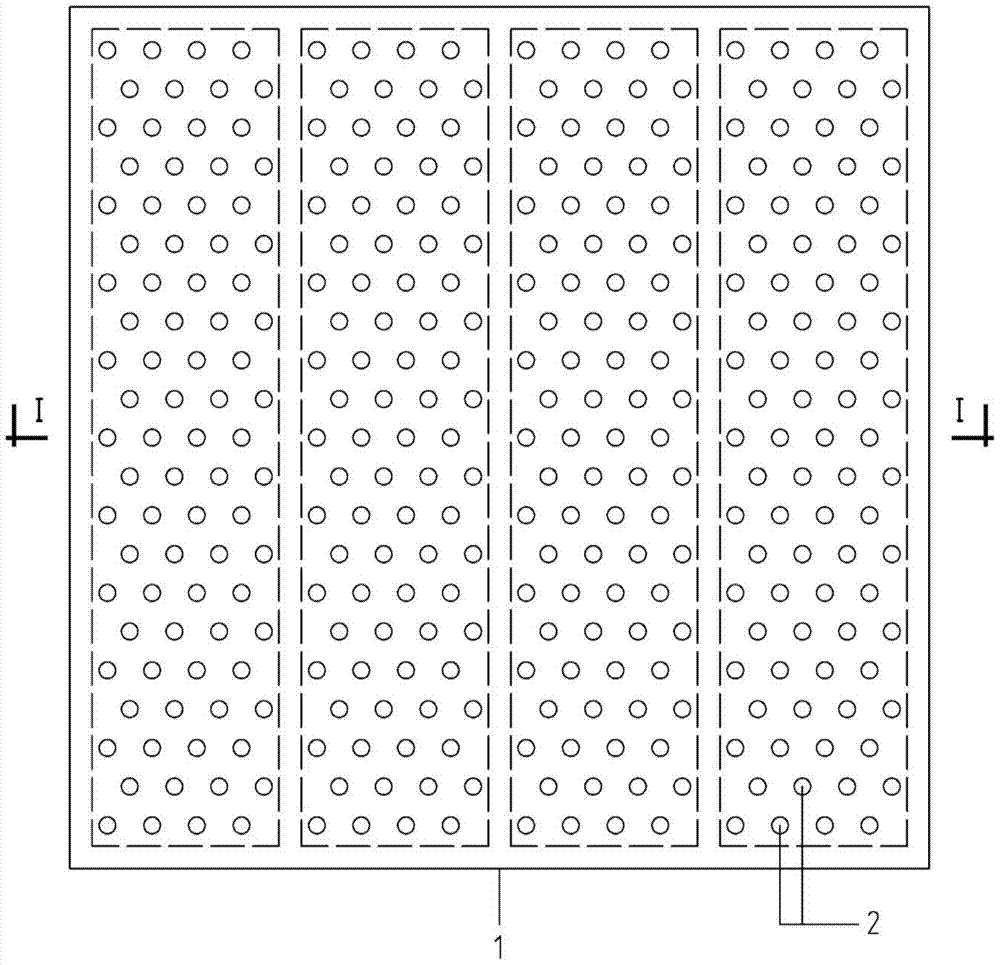

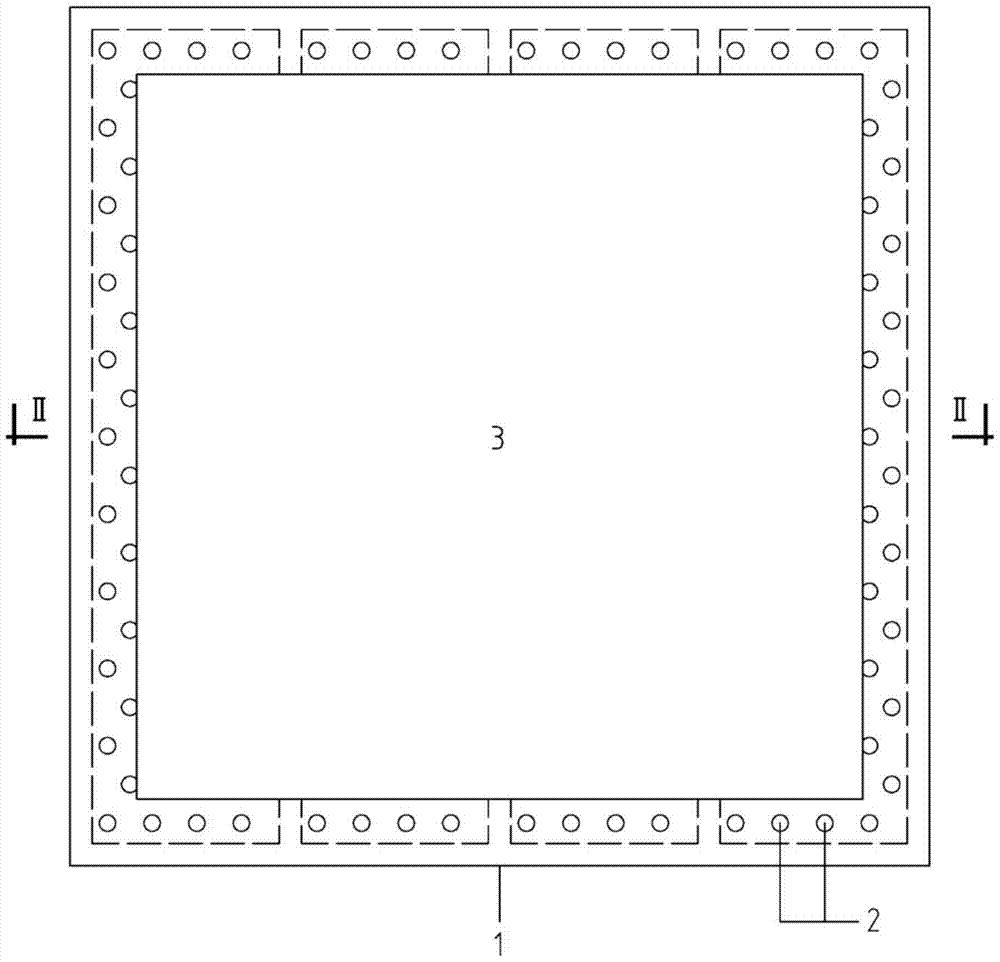

[0032] A method for pasting facing bricks when prefabricating concrete floors and wall panels, the pasting bricks are integrated when pouring the precast concrete floor or wall concrete, such as Figure 1 to Figure 12 Shown, the operating steps of the concrete implementation of the present invention are as follows:

[0033] Step 1, making the base form 1 of the precast concrete floor or wall panel, the working surface of the base form 1 of the precast concrete floor or wall panel has vent holes 2, adjusting the base form 1 of the precast concrete floor or wall panel to the level and clean the surface;

[0034] Step 2, use a water spray tool to evenly spray a thin layer of water on the bottom form 1 of the precast concrete floor or wall panel, and then lay single-sided adhesive plastic on the bottom form 1 of the precast concrete floor or wall panel Film 3, the adhesive side of the single-sided adhesive plastic film 3 faces upwards, and the non-adhesive side faces downward. Wh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com