Concrete pipe with steel fibers

A technology of fiber-reinforced concrete and concrete pipes, applied in the field of concrete pipes, can solve the problems of reducing the profit margin of enterprises and increasing the cost of pipes, and achieve the effects of light weight, saving the total cost of the project, and reducing the laying of auxiliary roads

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

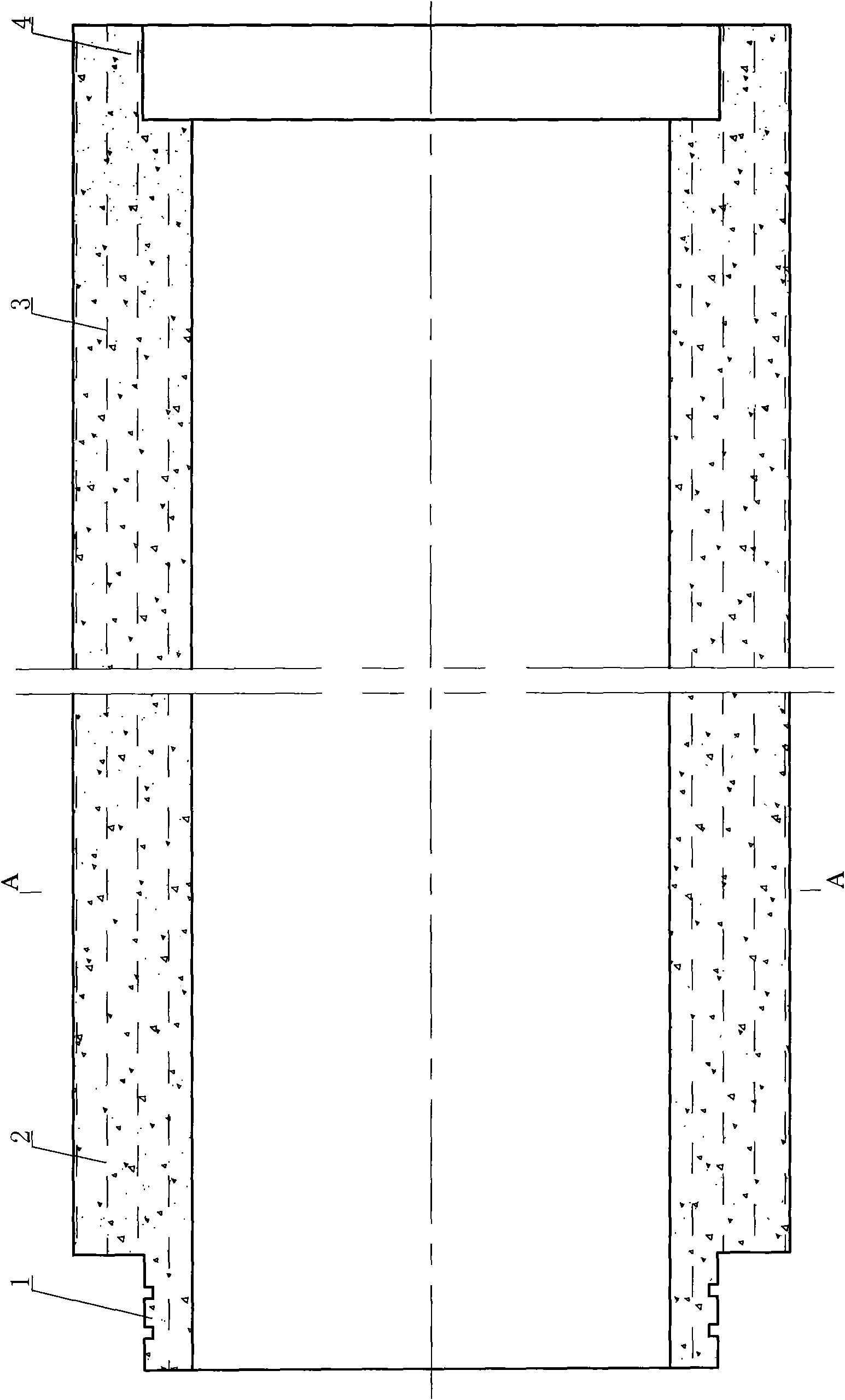

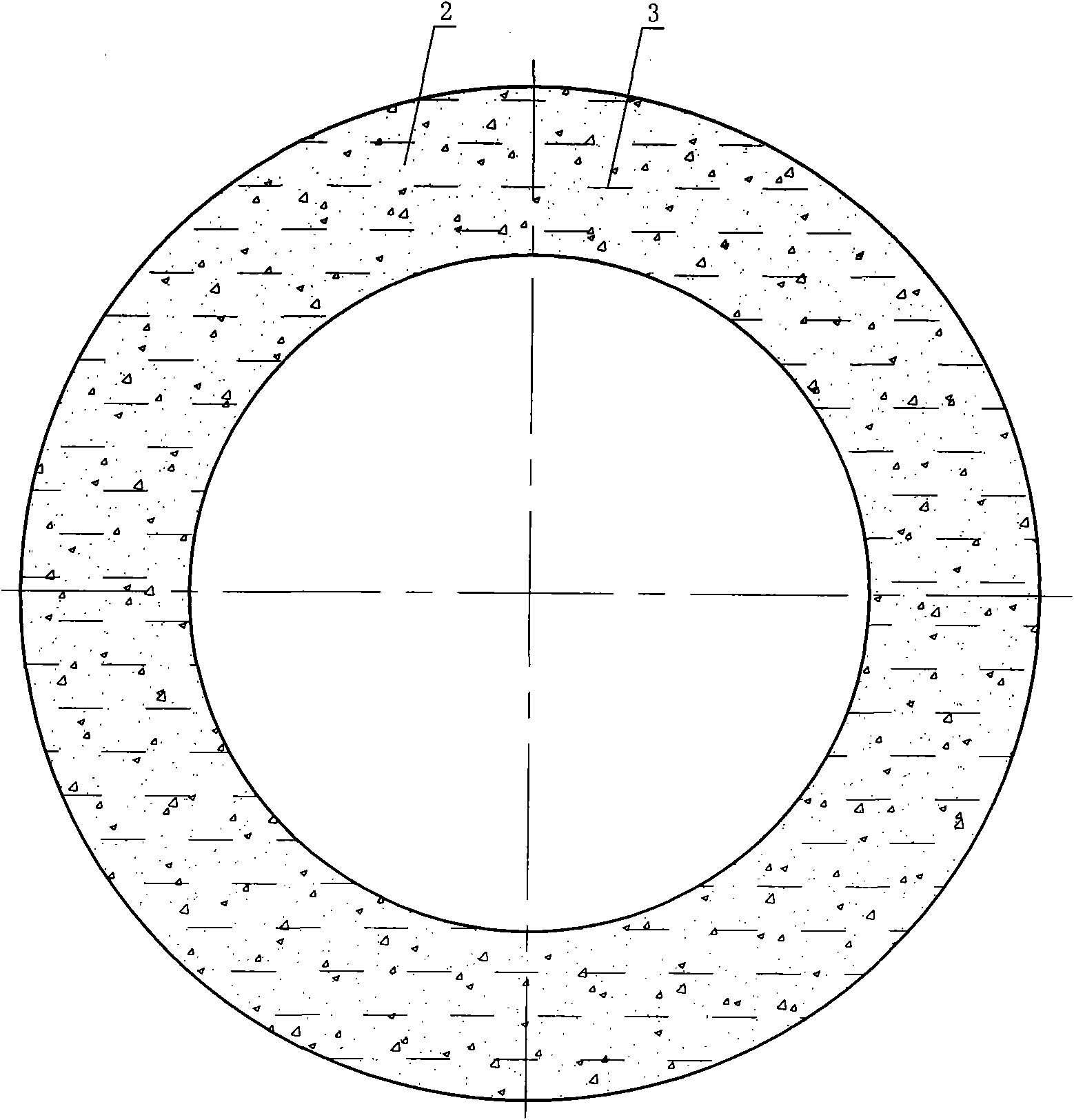

[0023] A concrete pipe with steel fibers, its overall structure is composed of a pipe material 2 and a socket 4 and a socket 1 coaxially formed at its two ends respectively. The pipe is mixed with cement, water, sand and stones that meet the concrete strength ratio, and steel fiber 3 is added to continue stirring evenly. The length of the steel fiber is 15mm, the diameter is 0.3mm, and the cross section is circular. The steel fiber concrete that constitutes the pipe The components and their weights are respectively:

[0024] Cement 322Kg;

[0025] Water 140Kg;

[0026] Sand 475Kg;

[0027] Stone 864Kg;

[0028] Steel fiber 20Kg.

Embodiment 2

[0030] A concrete pipe with steel fibers. Steel fibers are added to the pipe concrete. The length of the steel fibers is 60 mm, the diameter is 1.2 mm, and the cross section is circular. The components and weights of the steel fiber concrete constituting the pipe are:

[0031] Cement 540Kg;

[0032] Water 220Kg;

[0033] Sand 828Kg;

[0034] Stone 1306Kg;

[0035] Steel fiber 140Kg.

[0036] Others are the same as in Example 1.

Embodiment 3

[0038] A concrete pipe with steel fibers, adding steel fibers in the concrete, the steel fibers have a length of 43mm, a diameter of 0.7mm, and a circular cross section, wherein the components and weights of the steel fiber concrete constituting the pipe are:

[0039] Cement 431Kg;

[0040] Water 180Kg;

[0041] Sand 650Kg;

[0042] Stone 1100Kg;

[0043] Steel fiber 80Kg.

[0044] Others are the same as in Example 1.

[0045] The interface form of the concrete pipe with steel fiber can be tongue and groove, flat mouth, socket or steel socket, and what is shown in the accompanying drawing of this embodiment is a tongue and groove pipe.

[0046] Further verify the advanced nature of the present invention below by application example:

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com