Vertical sliding lead-down forming method for plate glass chute

A vertical sliding, flat glass technology, applied in the vertical drawing of glass liquid, glass forming, glass manufacturing equipment and other directions, can solve the problems of glass surface damage, difficulty in producing ultra-thin glass, easy oxidation and consumption of tin liquid, etc.

Inactive Publication Date: 2015-07-08

徐林波

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] However, float glass also has its shortcomings that are difficult to overcome, such as complex molding control process, easy oxidation and consumption of tin liquid, glass plate is easily polluted by tin liquid, glass surface is easily damaged when the glass ribbon is pulled out of the tin bath, and ultra-thin glass is produced. very difficult etc.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

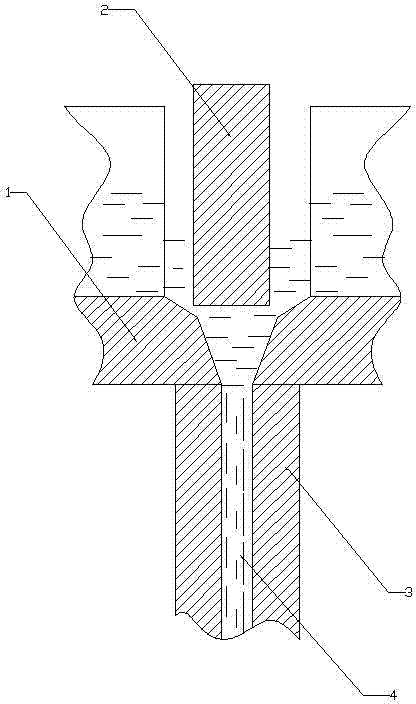

[0013] figure 1 , the molten glass flows into the vertical chute (3) through the lip brick (1) under the control of the gate (2), and forms a glass ribbon of required thickness, which is hardened, annealed, and cut to make glass plate.

[0014] Above-mentioned vertical chute (3) is built by laying bricks or stones with graphite material, and can compensate or replace.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a vertical sliding lead-down forming method for a plate glass chute. The vertical sliding lead-down forming method for the plate glass chute is characterized by comprising the following steps: with a solid material which is low in friction coefficient, high in heat conductivity coefficient, small in expansion coefficient, good in chemical stability, low in permeability and heat-resistant, and has a polishing function as a vertical chute, carrying out vertical sliding lead-down forming on glass metal in a slot, and pulling and leading out a glass tape with required thickness and width.

Description

technical field [0001] Flat glass forming process. Background technique [0002] As we all know, since the float glass process came out in the 1950s, it has become the mainstream process of flat glass production. The forming process of float glass production is completed in a tin bath filled with protective gas (N2 and H2). The molten glass flows continuously from the tank kiln and floats on the surface of the tin liquid with high relative density. Under the action of gravity and surface tension, the glass liquid spreads and flattens on the tin liquid surface to form a flat upper and lower surface, hardens and cools Afterwards, it is led to the transition roller table. The rollers of the roller table rotate, and the glass ribbon is pulled out of the tin tank and enters the annealing kiln. After annealing and cutting, the flat glass product is obtained. Compared with other forming methods, the float method has the following advantages: It is suitable for high-efficiency ma...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C03B15/02

Inventor 徐林波

Owner 徐林波

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com