Draining device of extracting tube

A liquid discharge device and extraction tube technology, applied in the direction of solid solvent extraction, etc., can solve the problems of low liquid level in the extraction tube, overflow of solvent, easy blockage of the liquid discharge tube, etc., and achieve the goals of preventing discharge, prolonging contact, and reducing slag content Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

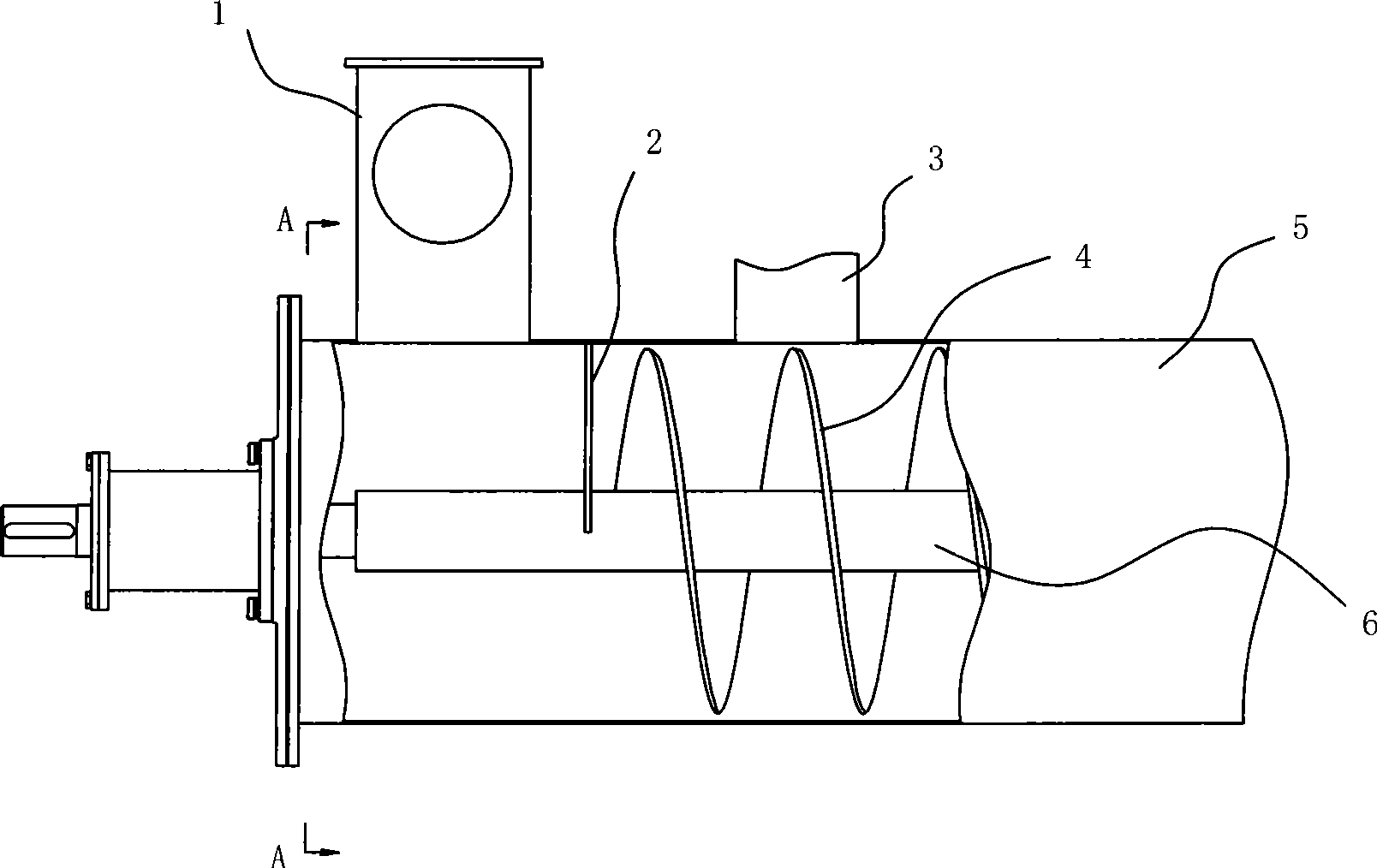

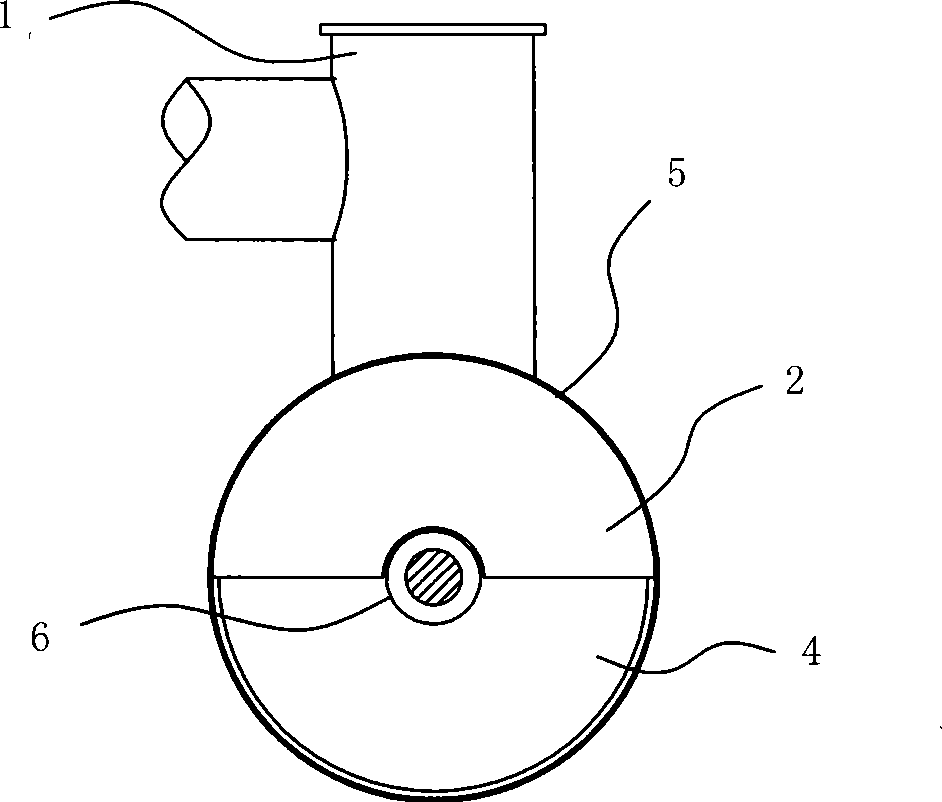

[0009] In order to clearly illustrate the technical features of the solution, the solution will be described below through a specific implementation mode combined with the accompanying drawings.

[0010] As can be seen from the accompanying drawings, the liquid discharge device of the extraction tube of this program has an extraction tube 5 and a screw propeller composed of a propulsion shaft 6 and a helical blade 4 fixed on the propulsion shaft 6 in the extraction tube 5. One end of 5 has feed pipe 3, and this scheme has liquid outlet pipe 1 on the top of extraction pipe 5 between described extraction pipe 5 side end and feed pipe 3, and the upper part liquid pipe of extraction pipe 5 lumens A baffle plate 2 is fixed between the feed pipe 1 and the feed pipe 3, and the baffle plate 2 is located at the end of the spiral blade 4. The material baffle plate 2 is semicircular fan-shaped, and the arc at the upper end of the material baffle plate 2 is the same as the inner cavity ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com