Reconstituted tobacco coating liquid and preparation method thereof

A technology of reconstituted tobacco leaves and coating solution, which is applied in the preparation of tobacco, tobacco, application, etc. It can solve the problems of unfavorable substrate absorption, fouling of concentrators, and stickiness of sheets, so as to avoid high slag content and alleviate scaling , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The invention provides a method for preparing a coating solution for reconstituted tobacco leaves. The method is suitable for preparing a low-nicotine and low-viscosity coating solution in the process of papermaking reconstituted tobacco leaves.

[0038] The preparation process of the reconstituted tobacco leaf coating liquid in this application comprises the following steps:

[0039] 1) extracting the tobacco raw material with water, and separating the solid and liquid to obtain the tobacco extract.

[0040] Specifically, the tobacco raw materials are tobacco stems, tobacco sheets and tobacco powder, and the three raw materials are mixed according to the mass ratio of (4-8): (1-4): (1-4), and then the total weight of the raw materials is added 4-7 times of water, soak and extract at 40-80°C for 30-60 minutes, and then separate solid-liquid to obtain tobacco insoluble matter and tobacco extract.

[0041] 2) Adding a strong base to the tobacco extract to obtain an alkal...

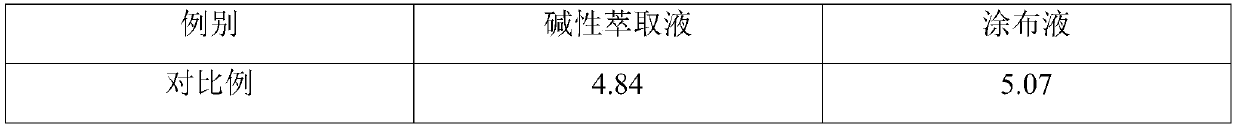

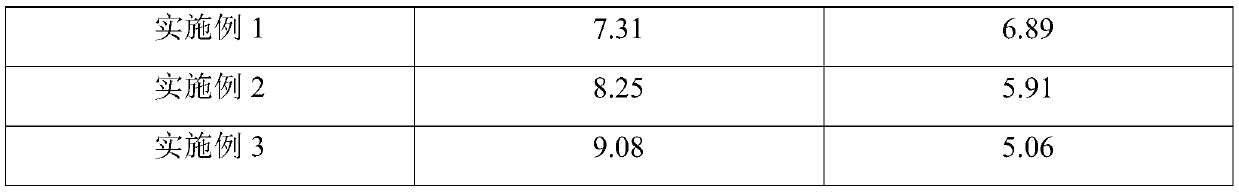

Embodiment 1

[0050] 1) After the tobacco raw material is extracted with an extractant, solid-liquid separation is obtained to obtain tobacco insoluble matter and tobacco extract. The tobacco raw material is tobacco stem, tobacco sheet and tobacco dust, and the mass ratio of tobacco stem, tobacco sheet and tobacco dust is 5: 3:2, the extraction agent is water, the amount of water is 5 times the total weight of tobacco raw materials, the extraction temperature is 70°C, and the extraction time is 30 minutes;

[0051] 2) adding potassium hydroxide to the tobacco extract obtained in step 1), controlling the weight ratio of potassium hydroxide and tobacco extract to be 0.6:100 to obtain an alkaline extract;

[0052]3) Centrifuge the alkaline extract that step 2) obtains with a centrifuge, the centrifuge speed is 3000r / min, and the centrifugal time is 5min to obtain a refined extract;

[0053] 4) concentrating the refined extract obtained in step 3) under reduced pressure, the concentration tempe...

Embodiment 2

[0056] 1) After the tobacco raw material is extracted with an extractant, solid-liquid separation is obtained to obtain tobacco insoluble matter and tobacco extract. The tobacco raw material is tobacco stem, tobacco sheet and tobacco dust, and the mass ratio of tobacco stem, tobacco sheet and tobacco dust is 5: 3:2, the extraction agent is water, the amount of water is 5 times the total weight of tobacco raw materials, the extraction temperature is 70°C, and the extraction time is 30 minutes;

[0057] 2) adding potassium hydroxide to the tobacco extract obtained in step 1), controlling the weight ratio of potassium hydroxide and tobacco extract to be 0.8:100 to obtain an alkaline extract;

[0058] 3) centrifuge centrifugal purification step 2) to obtain the alkaline extract, the centrifuge speed is 4000r / min, and the centrifugation time is 5min to obtain a refined extract;

[0059] 4) concentrating the refined extract obtained in step 3) under reduced pressure, the concentrati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com