Novel manufacture method of iron-aluminum thermal spraying powder core wire

A technology of thermal spraying and powder core wire, applied in coating, melting spraying, metal material coating process, etc., can solve the problems of poor performance, insufficient metallurgical reaction, low content of coating compounds, etc., and achieve moderate cost. , Easy to implement, good effect of high temperature vulcanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

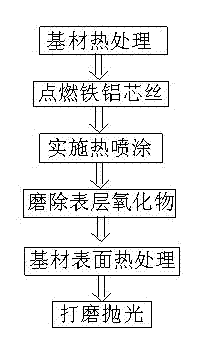

[0018] The specific preparation process of the novel iron-aluminum thermal spraying powder core wire mentioned in the present invention is as follows:

[0019] a) Material selection and mixing, the main components and percentage ratios of the prepared iron-aluminum thermal spraying powder core wire are as follows: aluminum powder 50%, magnesium powder 12%, iron oxide 35%, potassium chloride 2%, and the rest It is Mn, Si, S, P impurities; the raw materials are ground in an abrasive machine, and the particle size of the obtained aluminum powder is about 50 mesh, the particle size of magnesium powder and potassium chloride is about 60 mesh, and the particle size of iron oxide is about 40 mesh. ;During the mixing process, firstly, divide the aluminum powder into two parts with a mass ratio of about 1.8:3.2, and then mix the lesser part of the aluminum powder with potassium chloride, magnesium powder and iron oxide as material A , use the remaining aluminum powder as material B; th...

Embodiment 2

[0025] The specific preparation process of the novel iron-aluminum thermal spray powder core wire mentioned in the present invention is as follows:

[0026] a) Material selection and mixing, the main components and percentage ratios of the prepared iron-aluminum thermal spraying powder core wire are as follows: aluminum powder 45%, magnesium powder 13%, iron oxide 38%, potassium chloride 3%, and the rest It is Mn, Si, S, P impurities; the raw materials are ground in an abrasive machine, and the particle size of the obtained aluminum powder is about 50 mesh, the particle size of magnesium powder and potassium chloride is about 60 mesh, and the particle size of iron oxide is about 40 mesh. ;In the mixing process, first, divide the aluminum powder into two parts, the mass ratio is about 2:3, and then mix the aluminum powder with potassium chloride, magnesium powder and iron oxide as the A material , use the remaining aluminum powder as material B; then, send material A into the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com