Beam splitting double-focus-point laser processing head

A dual-focus, point laser technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve the problems of unstable welding pool volume and geometry, deterioration of final weld quality, and excessive temperature gradient. Achieve the effects of reducing plasma volume, reducing the evaporation effect of molten pool, and reducing energy concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

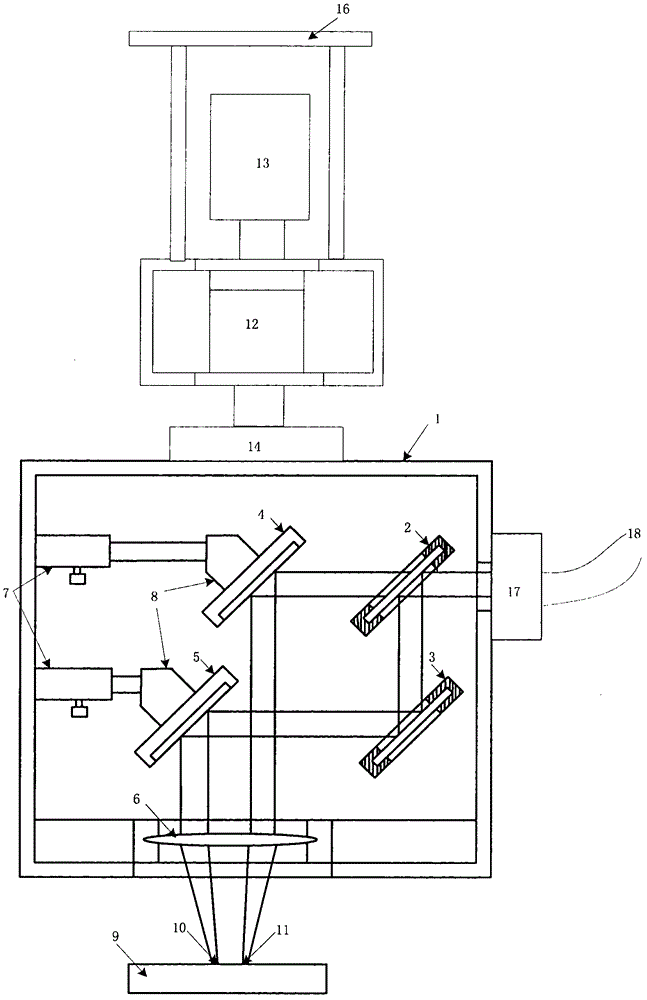

[0025] Such as figure 1 As shown, the present invention provides a beam-splitting double-focus point laser processing head, including an optical path cavity 1, a cavity connection box 12, a servo motor 13 and an external flange 16;

[0026] The optical path cavity 1 is connected to the output shaft of the servo motor 13 through a coupling; the servo motor 13 can drive the optical path cavity 1 to rotate around its own axis.

[0027] The cavity connection box 12 is fixedly connected to the external machine tool through the external flange 16, and the servo motor 13 is connected to the cavity connection box 12 (the gravity of the servo motor 13 is supported by the cavity connection box 12, and the cavity connection box 12 is supported by the external flange 16 is connected with the external machine tool to maintain the structural stabi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com