Patents

Literature

49results about How to "Focus spot is small" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

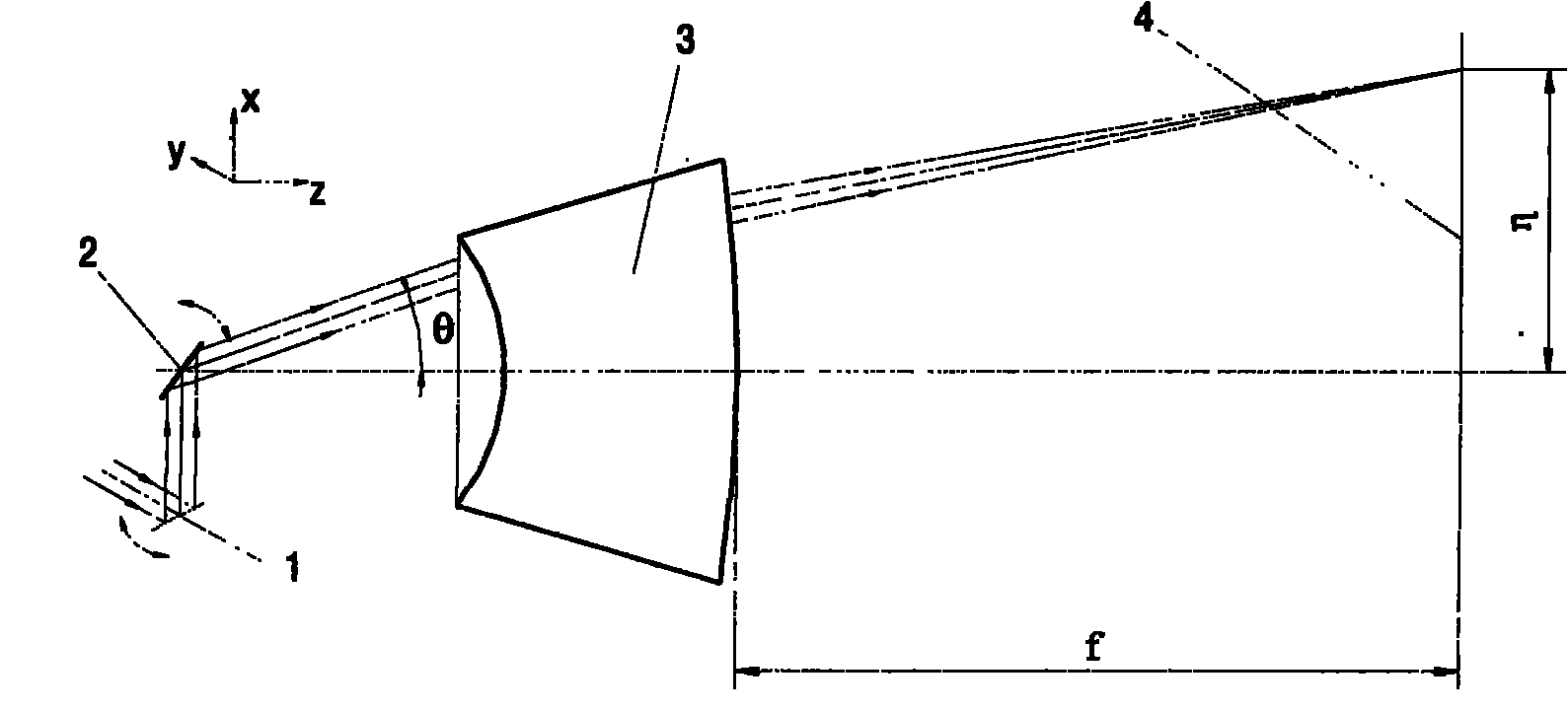

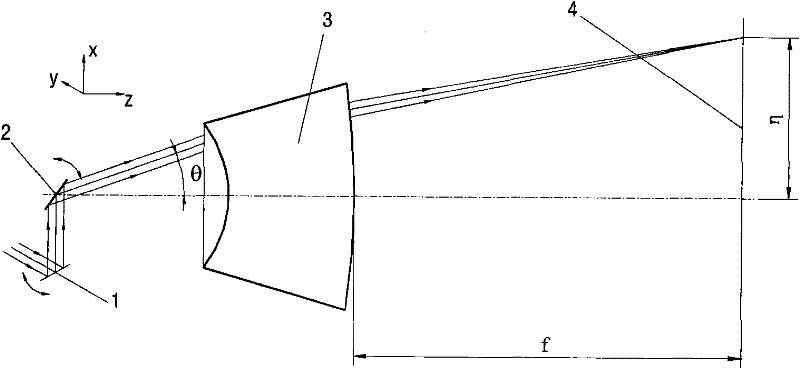

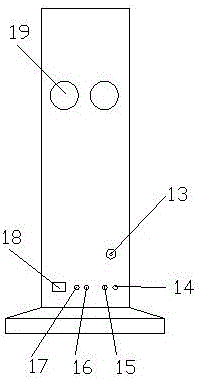

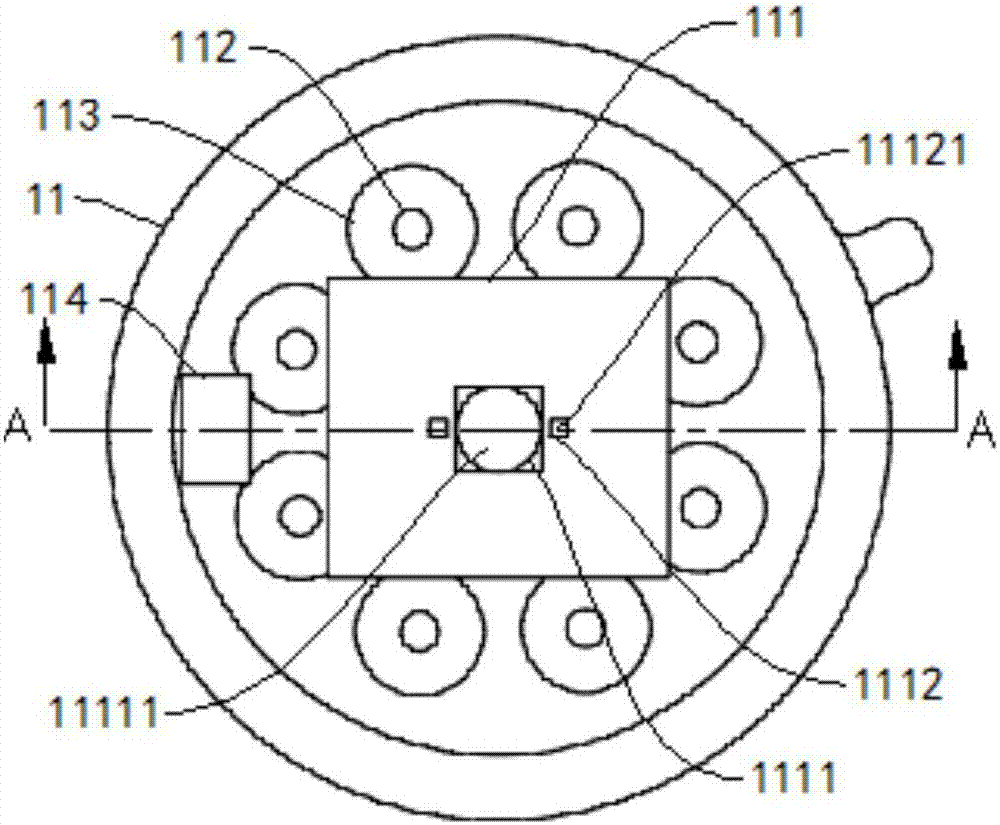

Silicon chip surface defect detector capable of classifying defects and defect classifying method

InactiveCN101672801AEasy to detectImplement classificationScattering properties measurementsOptically investigating flaws/contaminationPhotovoltaic detectorsSilicon chip

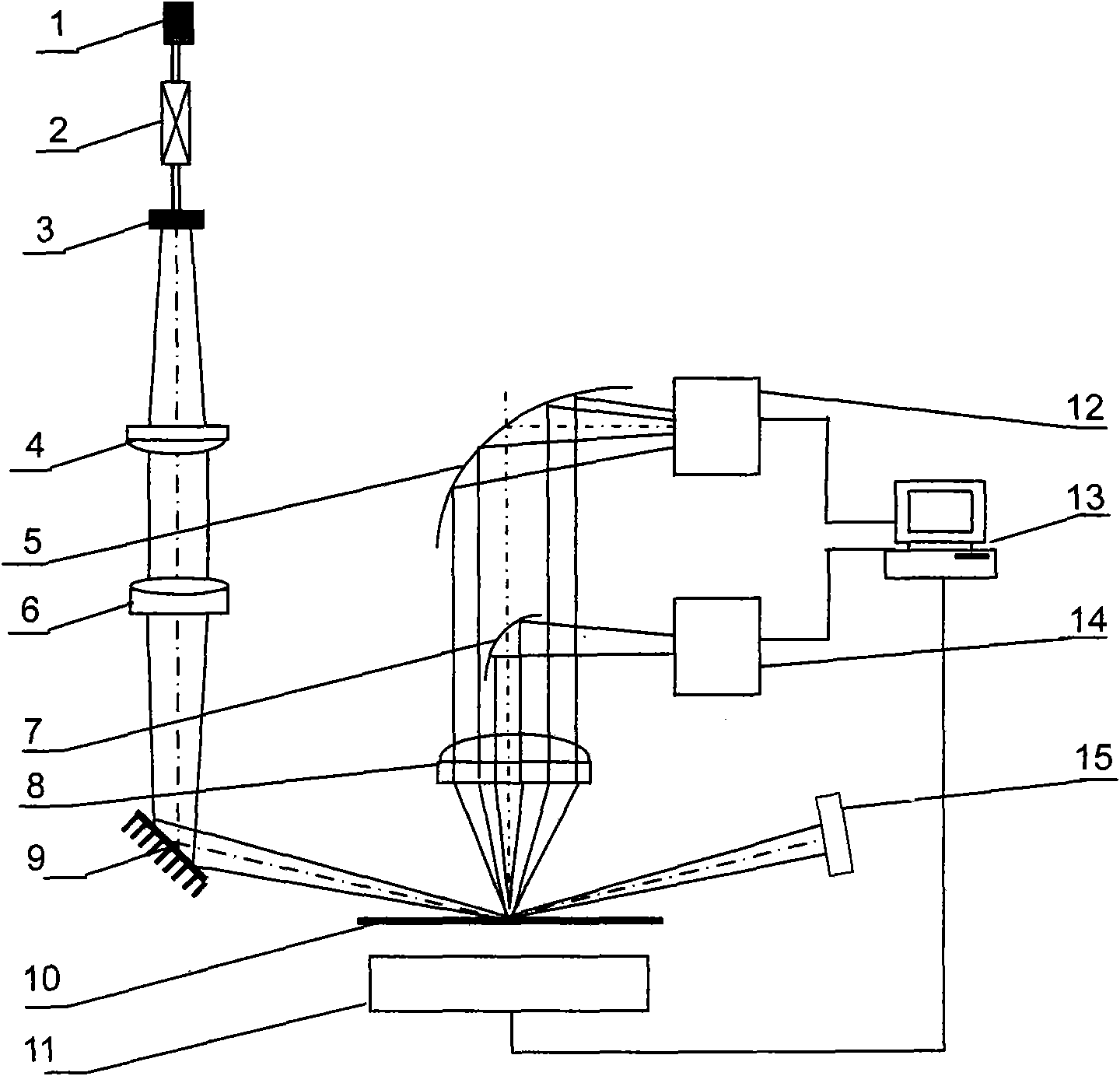

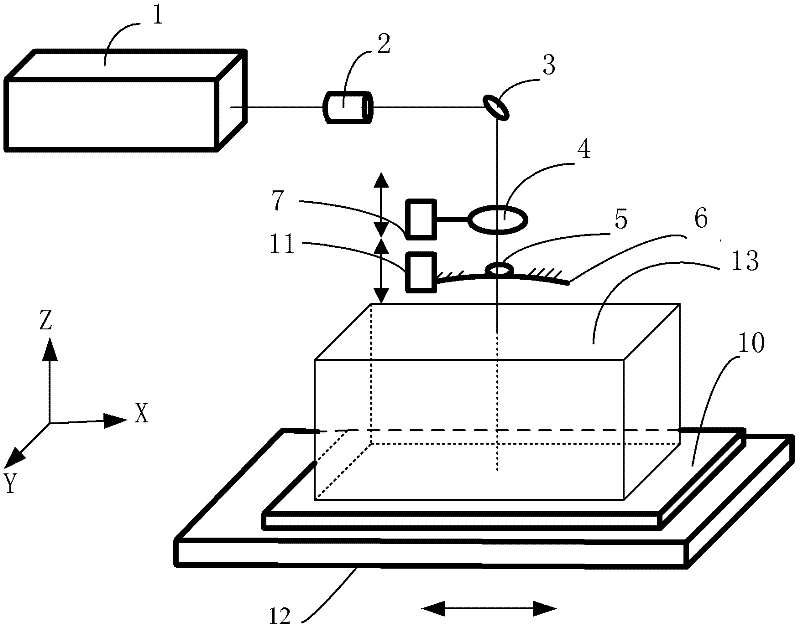

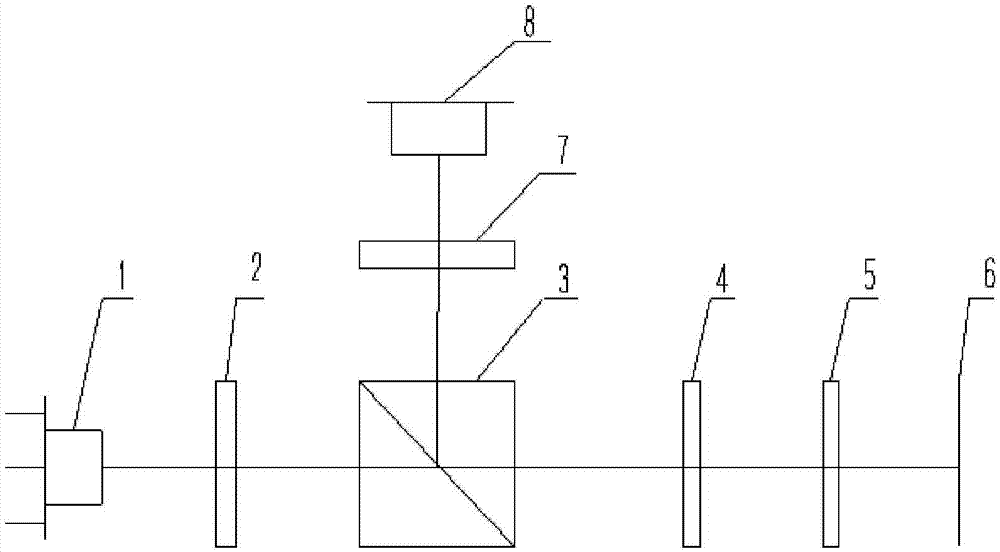

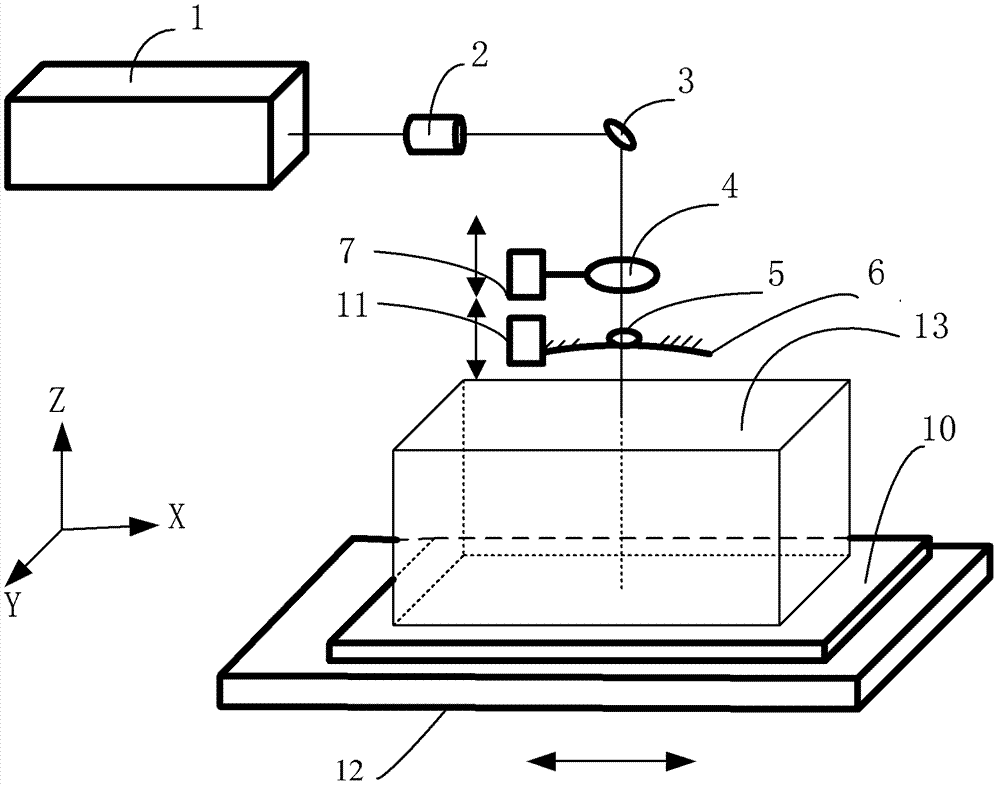

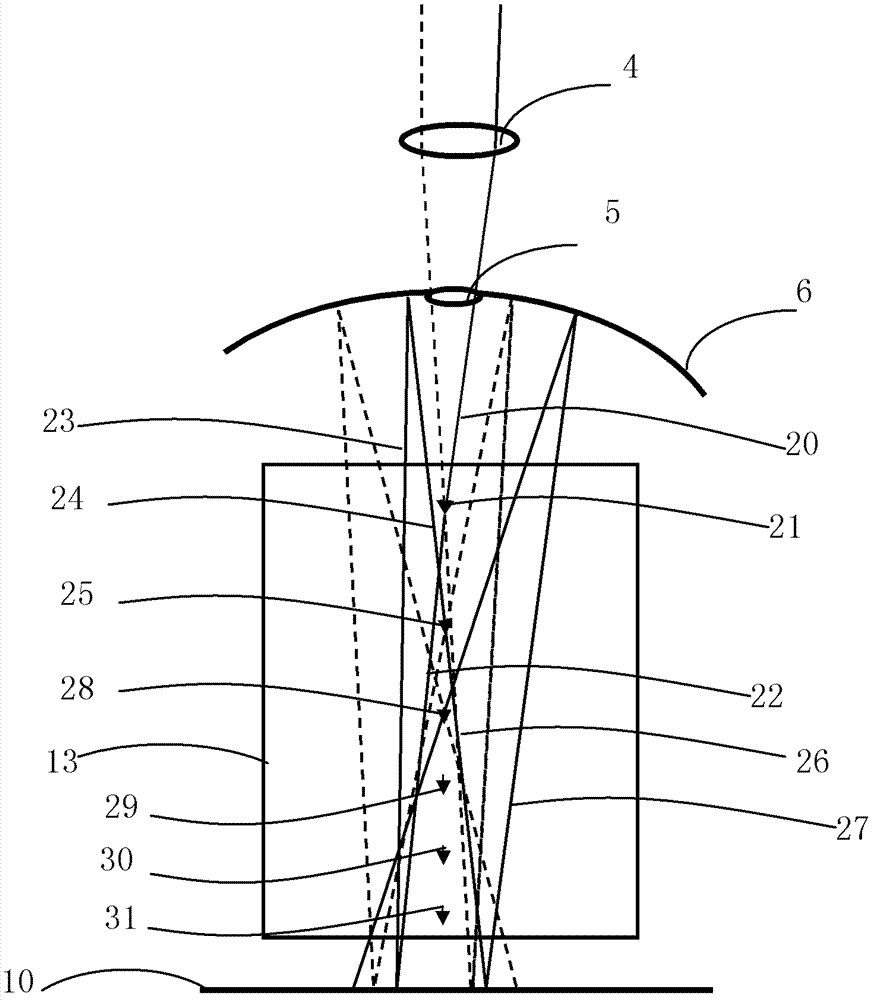

The invention relates to a silicon chip surface defect detector capable of classifying defects and a defect classifying method. The flat surface of the silicon chip to be detected on a highly reliablesilicon chip working platform is irradiated by a laser from an inclination direction. Circular narrow channel collection and annular narrow channel collection are carried out on scattered lights produced by the silicon chip surface defect by two paraboloidal mirrors with different calibers in a direction near the silicon chip face normal and parallel with silicon chip face. Two photoelectric detectors detect intensities of the collected electrooptical signals in two channels respectively and then take a ratio of two intensities, then compare the ratio with a given threshold value, and at lastthe silicon chip surface defects can be classified. The defect detector has the advantages of simple structure, high sensitivity, fast detecting speed, capability of classifying the defects on the silicon chip surface, etc.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

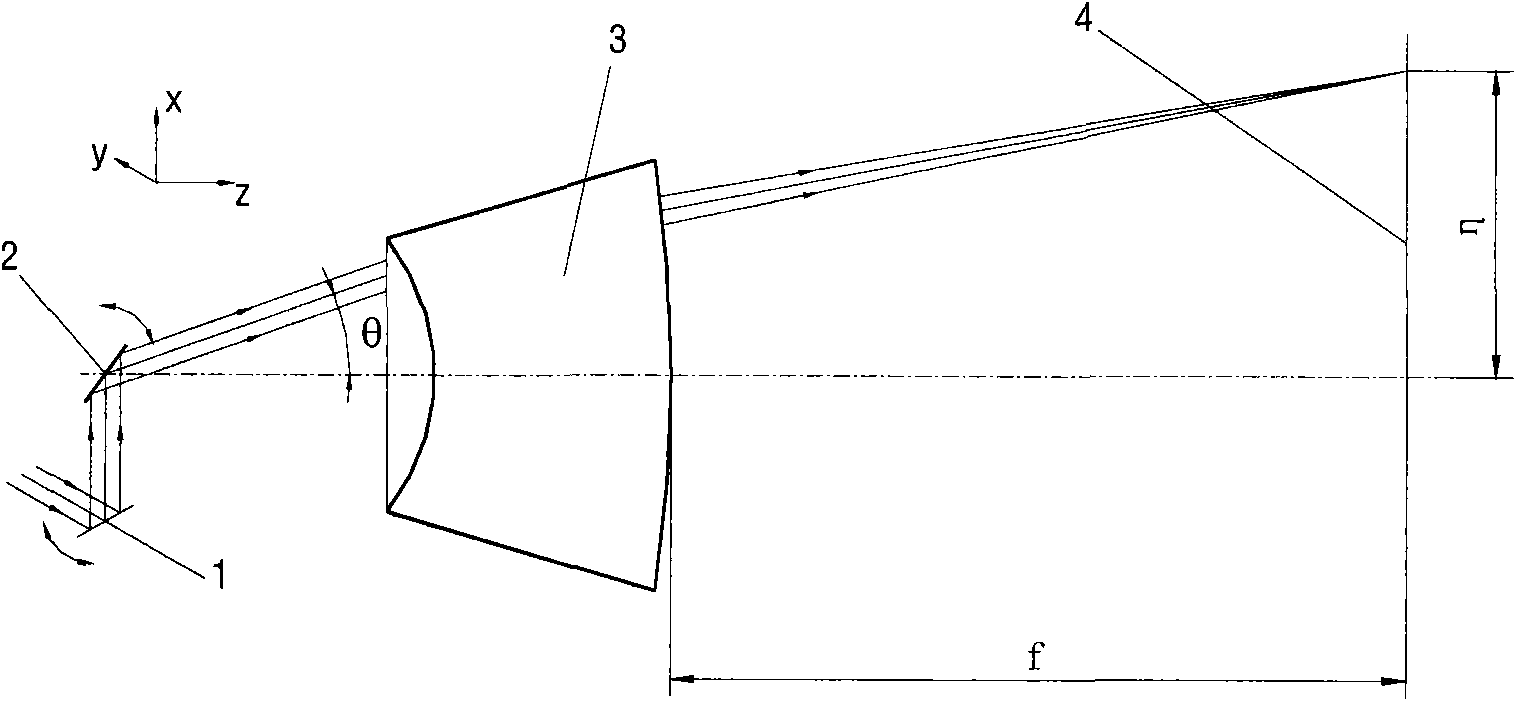

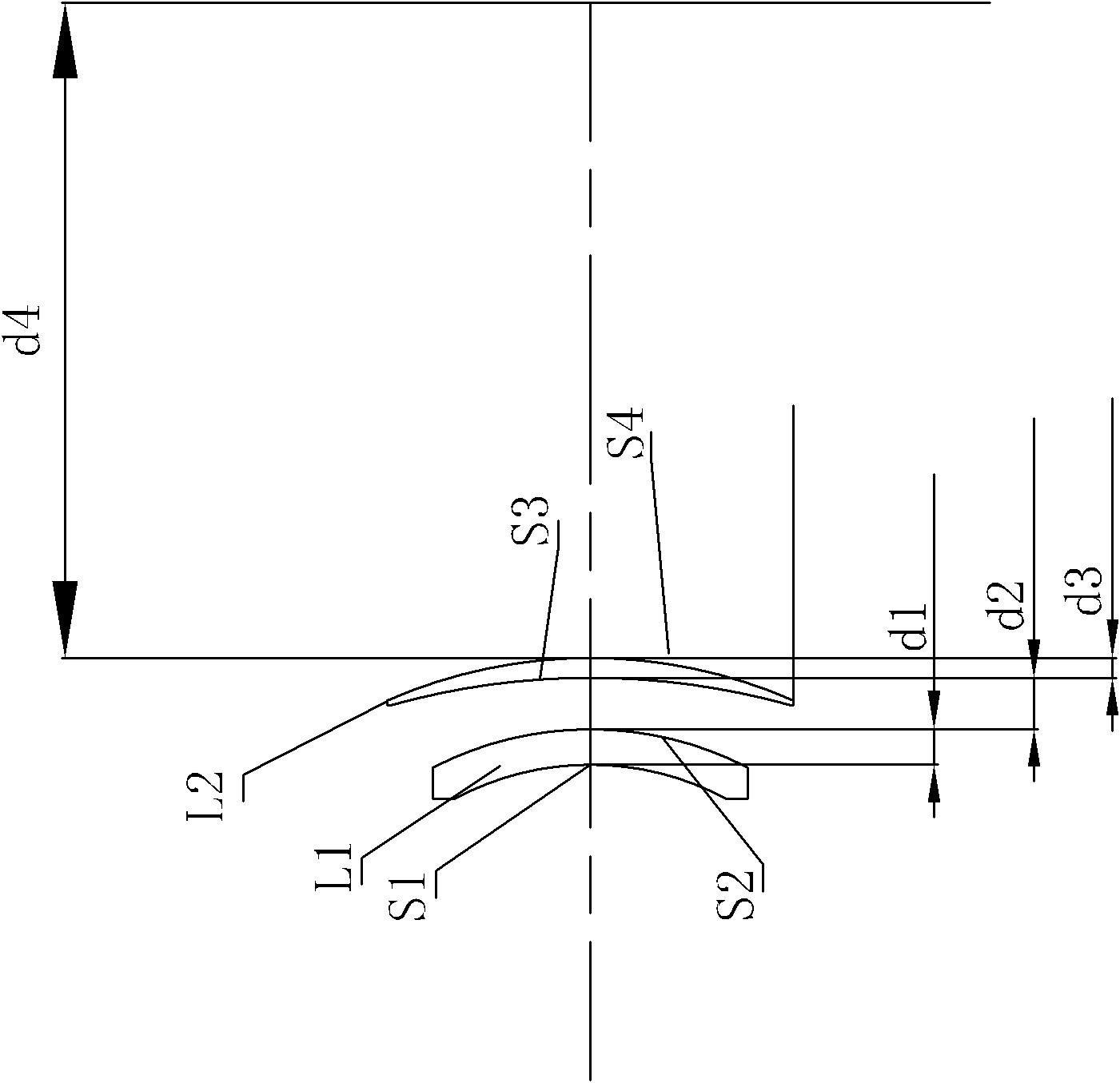

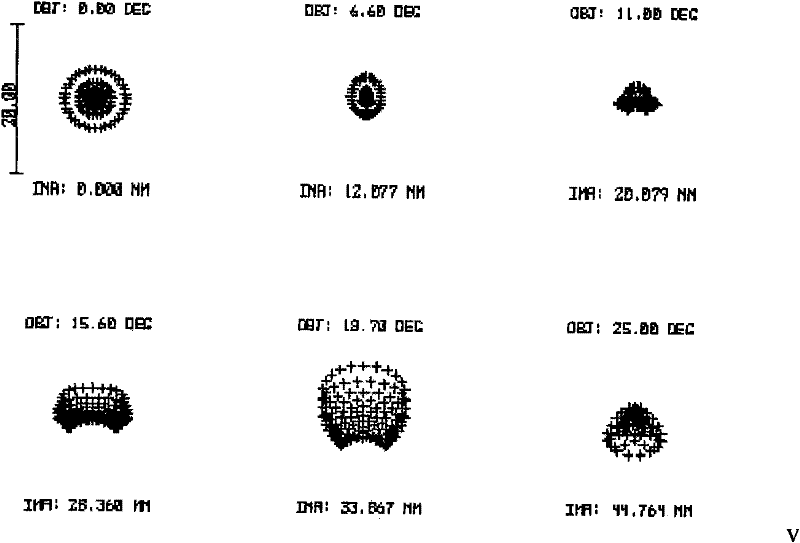

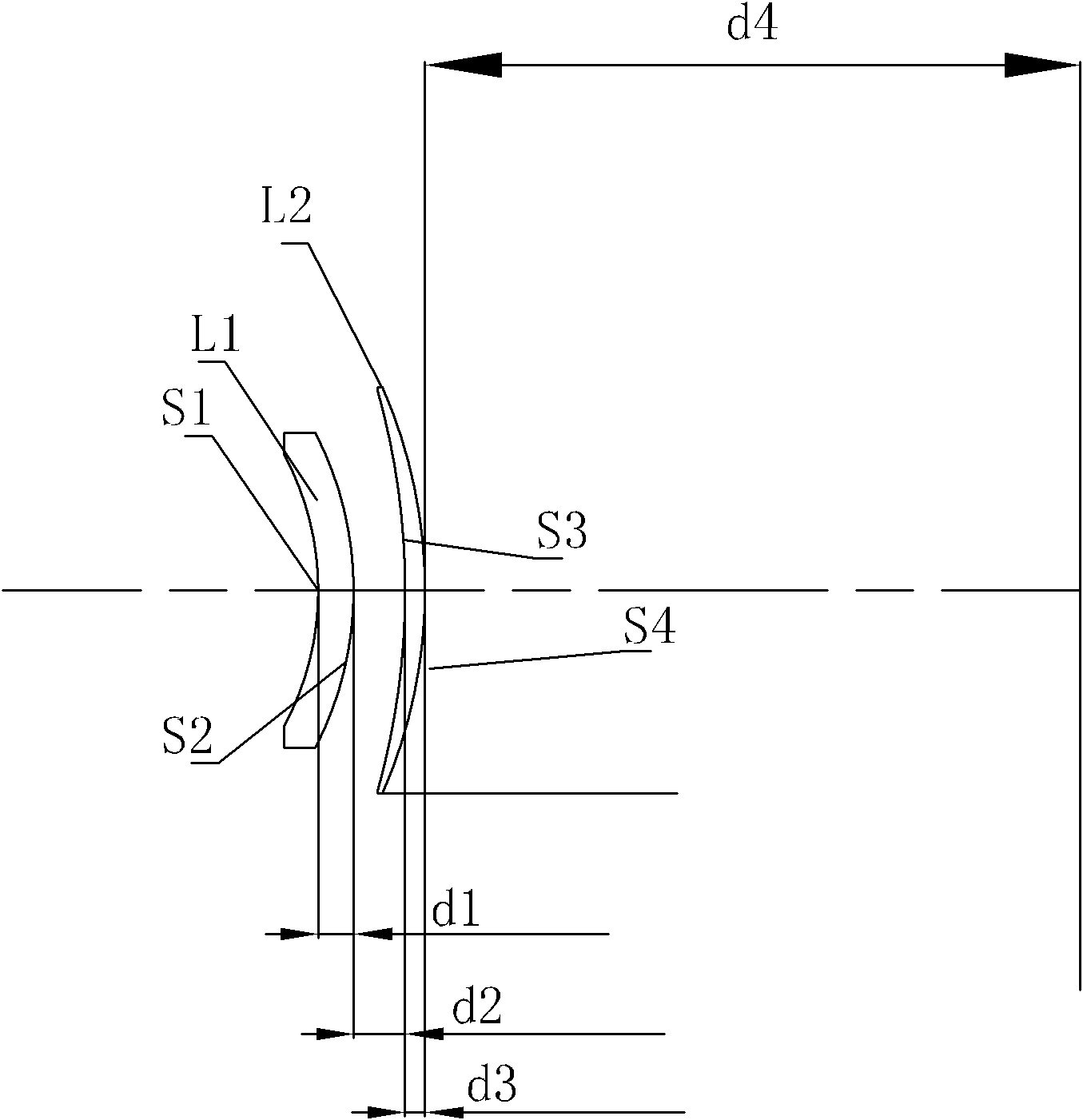

Optical lens applied to ultraviolet laser

The invention discloses an ultraviolet laser-applied f-theta optical lens. The optical lens comprises a first lens, a second lens, a third lend and a fourth lens which are positioned in the incident directions of light beams and arranged in order, wherein the first lens is a biconcave lens; the second lens is a meniscus lens, of which the curved surface bends towards the incident directions of the light beams; and the third lens is a planoconvex lens; and the fourth lens is a biconvex lens, wherein the optical lens is applied to the ultraviolet laser with the angle of vision of the lens of 50 degrees, the focal distance of 100mm, and the wavelength of 355nm in a processing range of 50mm*50mm. The ultraviolet laser has small focal spot and concentrated energy through the lens, and can mark or carve some processed special materials with superfine effects.

Owner:HANS LASER TECH IND GRP CO LTD

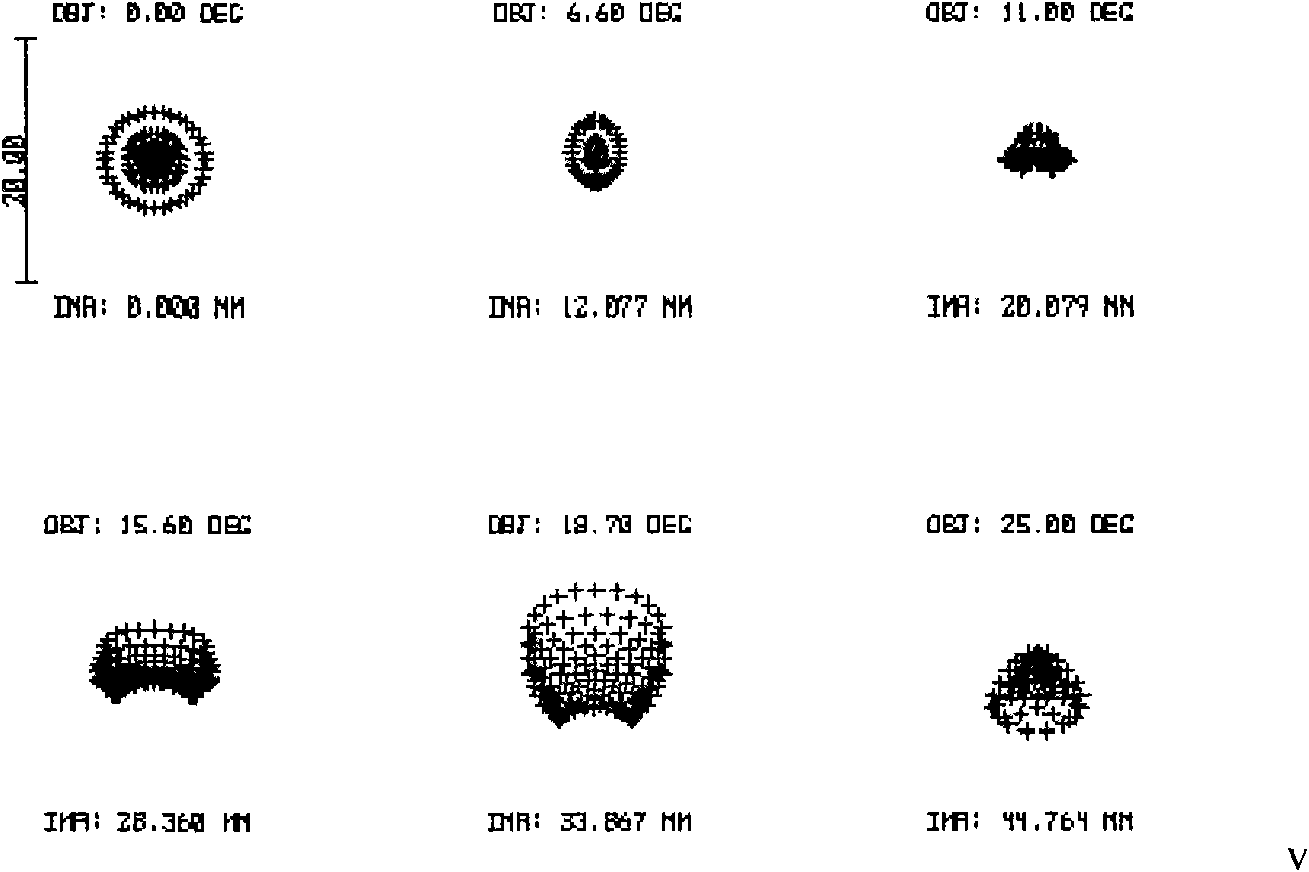

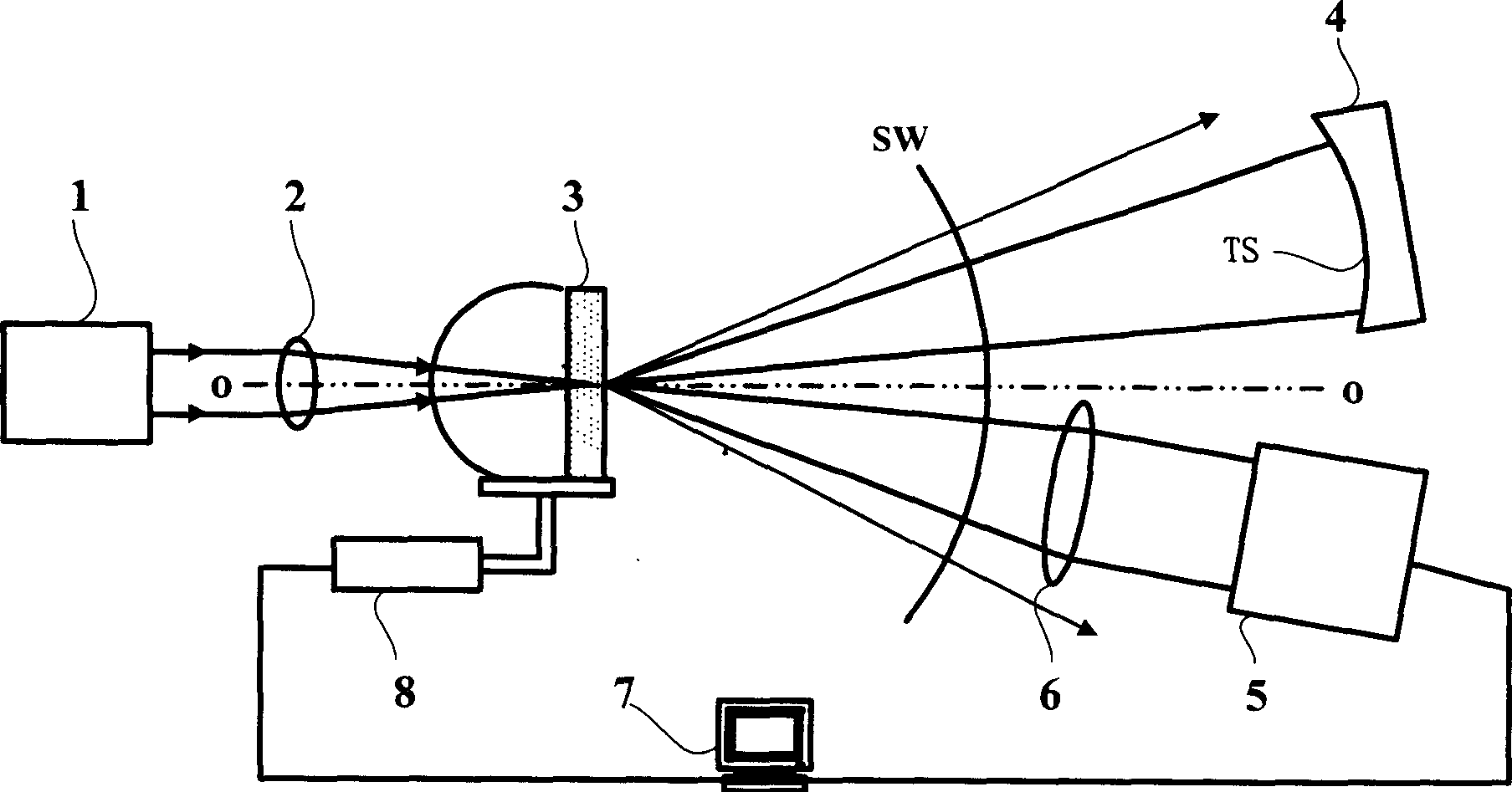

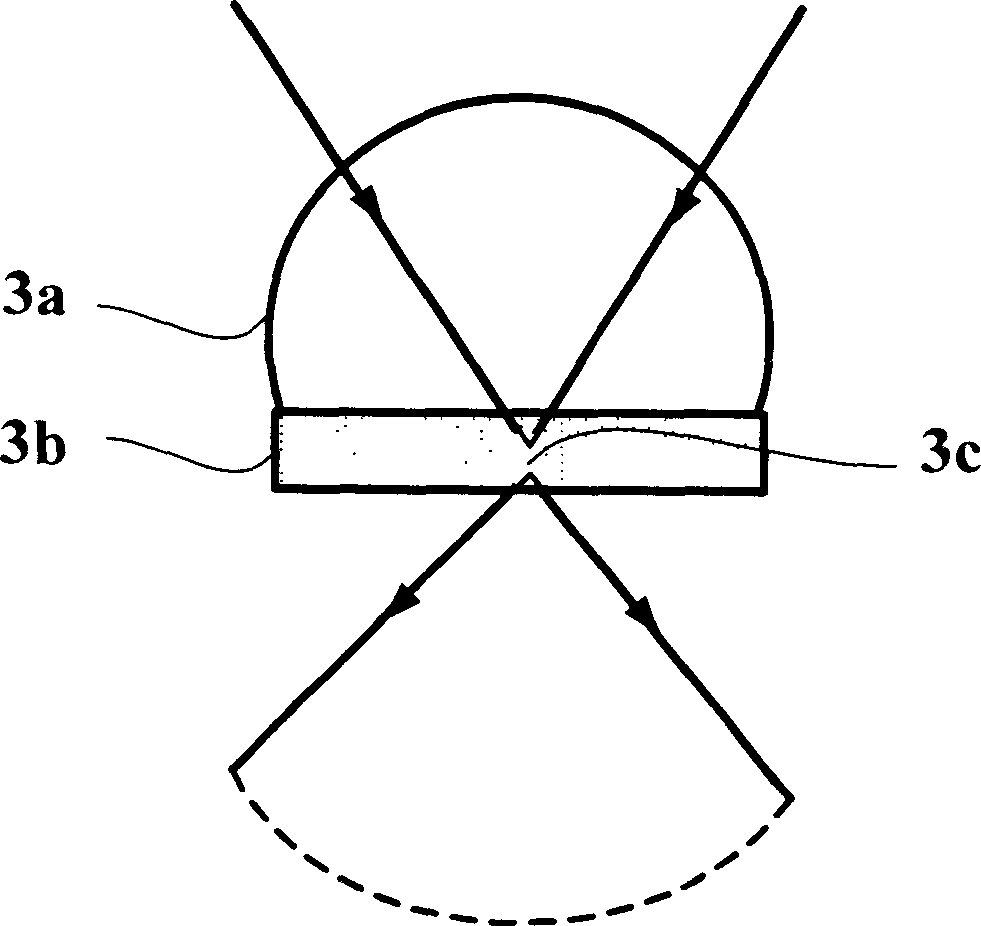

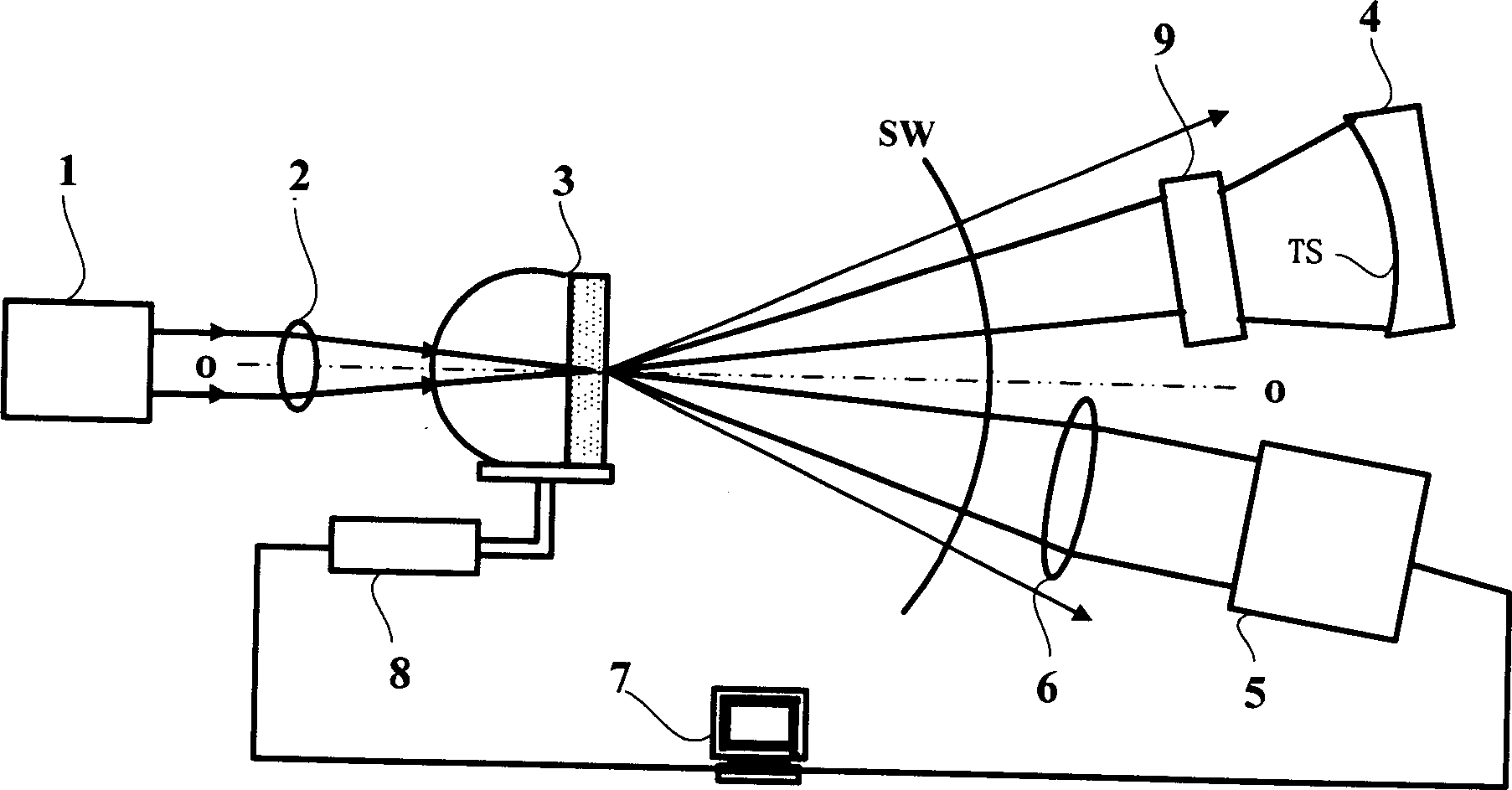

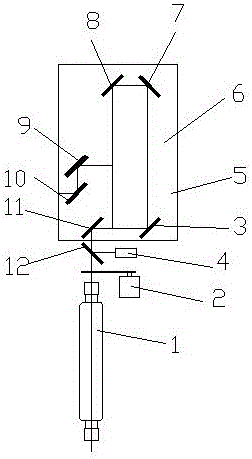

Spot diffraction interferometer for measuring surface shape

InactiveCN1431477AFocusEasy to assembleInterferometric spectrometryPhase-affecting property measurementsData acquisitionOptoelectronics

The interferometer includes the optical part and the data acquisition, process and control parts. The optical part includes the laser, the convergent lens, the lens soaked by the solid coated with super resolving power mask arranged in optical axis in sequence along the traveling direction of the laser beam. The part to be measured is positioned above the optical axis and the image lens is in lower part. The data acquisition, process and control parts include the CCD camera, the computer and the displacement controller. The key technique in the invention is the lens soaked by the soild and the mask with supper resolving power. Thus, the smaller pinhole can be obtained as the ideal light source with spherical wave. The position and size of the pinhole are adjustable, providing high transmittance of light and low requirement for the quality of the light beam.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

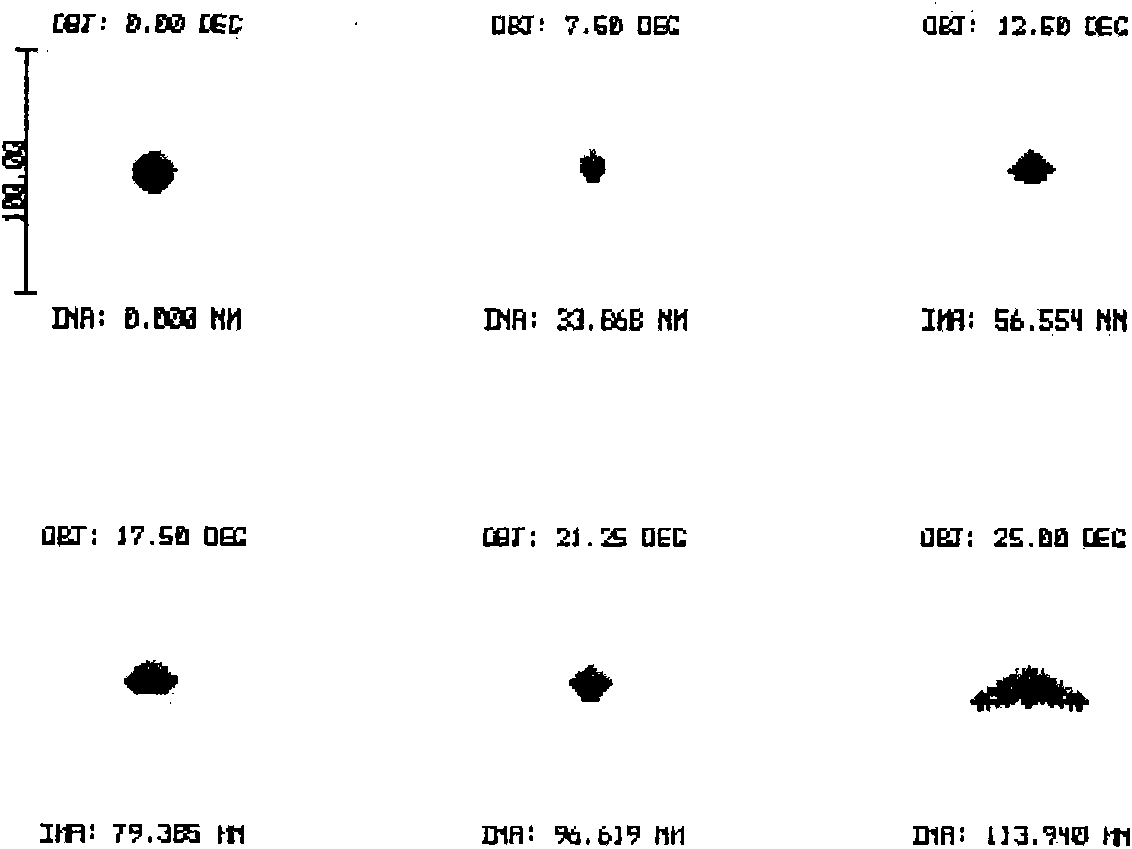

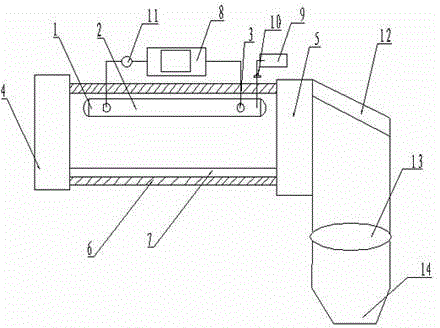

Laser multipoint focusing processing system

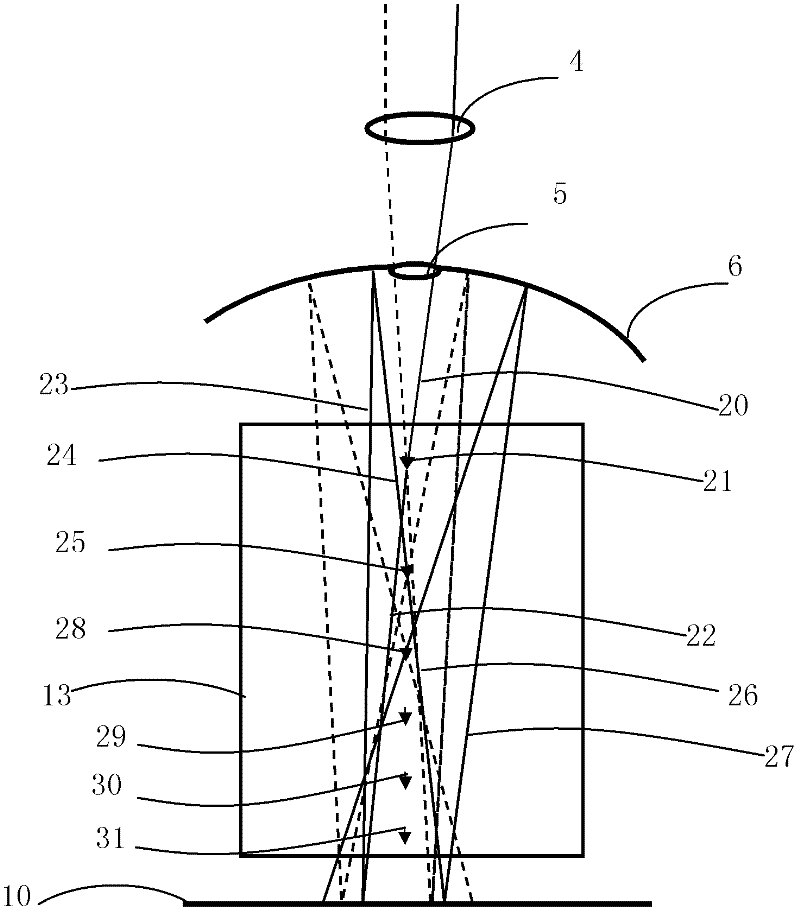

ActiveCN102653032AFocus spot is smallSmall requirementsGlass severing apparatusLaser beam welding apparatusOptical pathOptoelectronics

The invention discloses a laser multipoint focusing processing system, wherein the structure of the system is as follows: a laser, a beam expander, a light guide lens, a focusing lens and first and second total reflection mirrors are sequentially located on the same light path, the first total reflection mirror is a spherical mirror or non-spherical mirror processed with a minipore at the middle part, and the curvature radius of the first total reflection mirror is smaller than a half of the minimal distance between the two total reflection mirrors; at work, the concave surface of the first total reflection mirror faces to an xy two-dimensional work table, and the optical axis of the first total reflection mirror is overlapped with the optical axis of the laser; the centre of the minipore is overlapped with the optical axis of the laser; and the position of the focusing lens is adjustable up and down, and the distance between the two total reflection mirrors is adjustable. The system can convert a single focusing point introduced by the laser to a transparent material into a plurality of focusing points with the same optical axis, thereby improving the laser energy absorption uniformity of the cut and separated transparent brittle material along the thickness direction so as to reinforce the heating uniformity of the transparent material along the thickness direction and sharply reduce the stress difference along the thickness direction to cut and separate the transparent brittle material in high quality, high efficiency and high success rate.

Owner:武汉飞能达激光技术有限公司

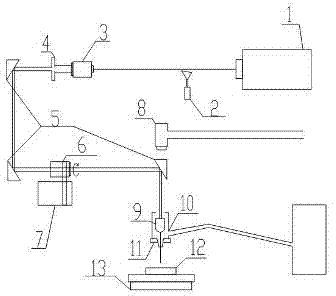

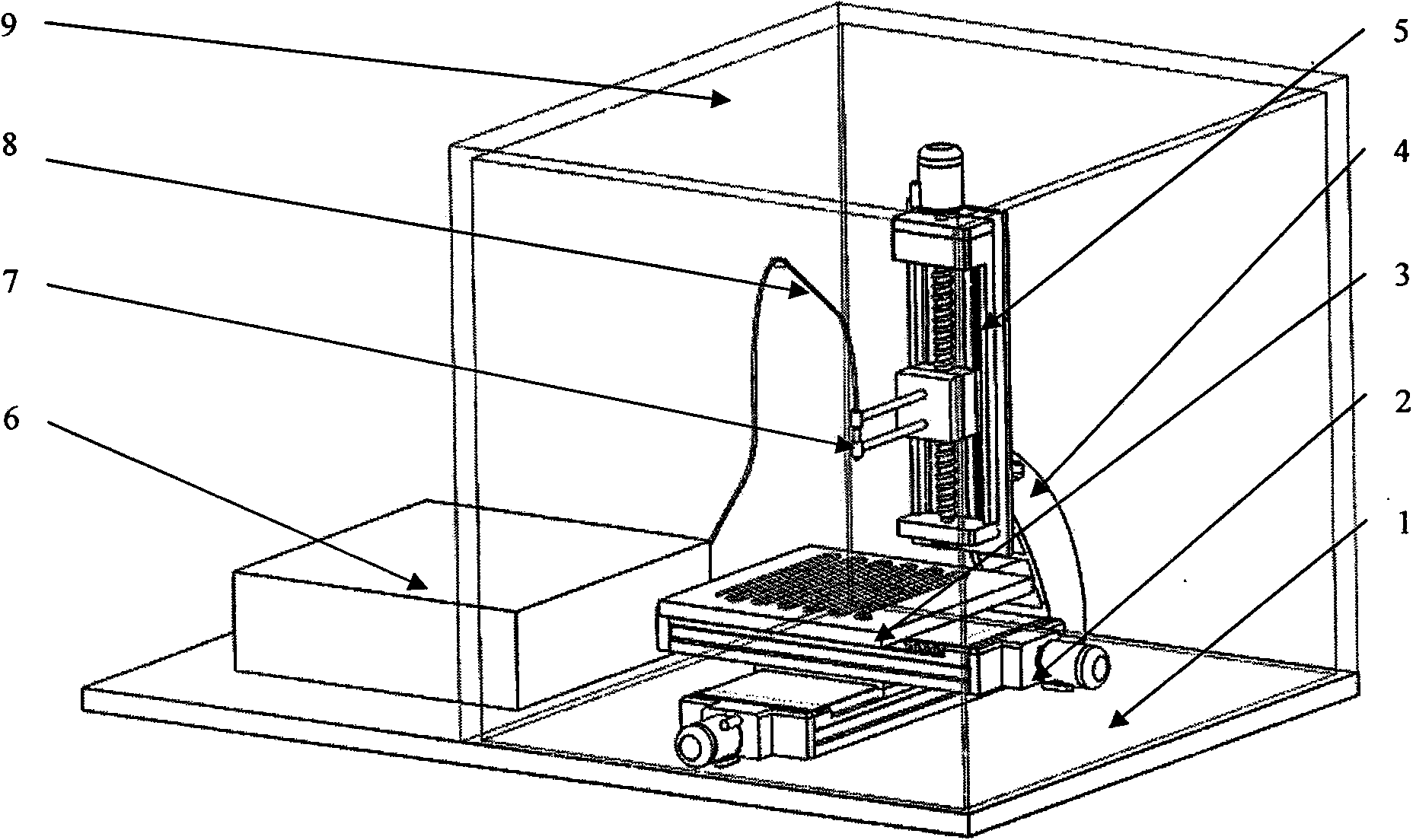

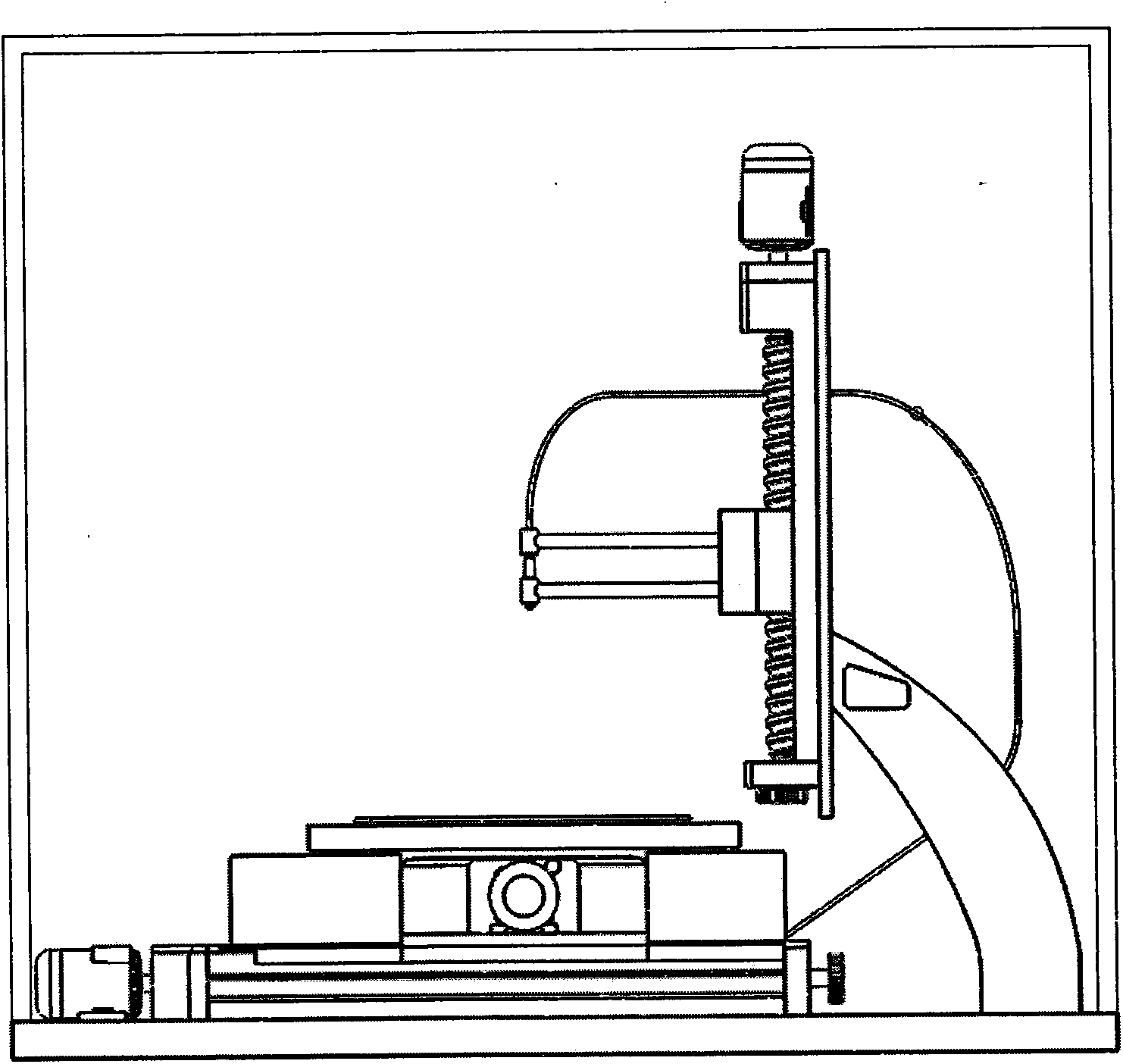

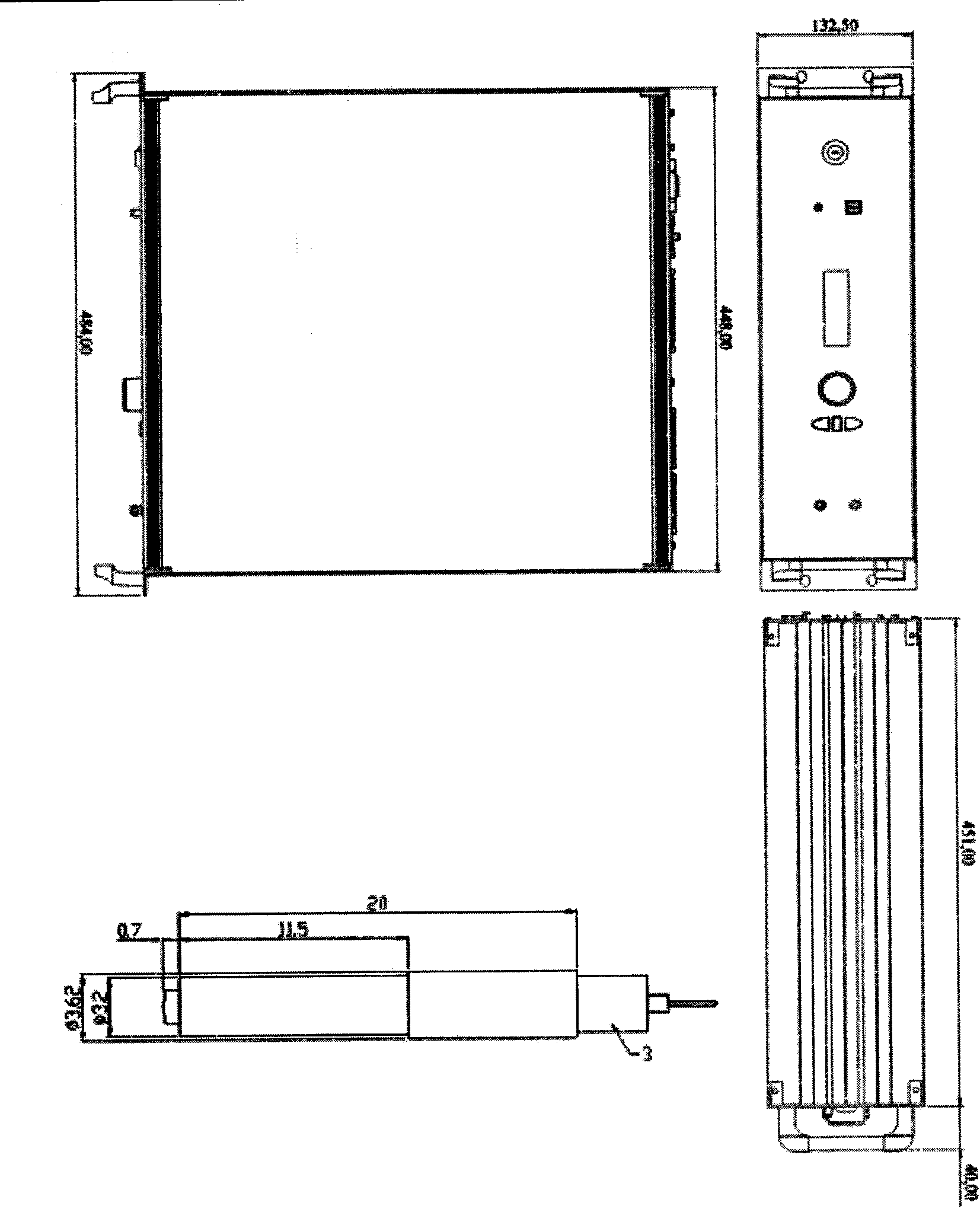

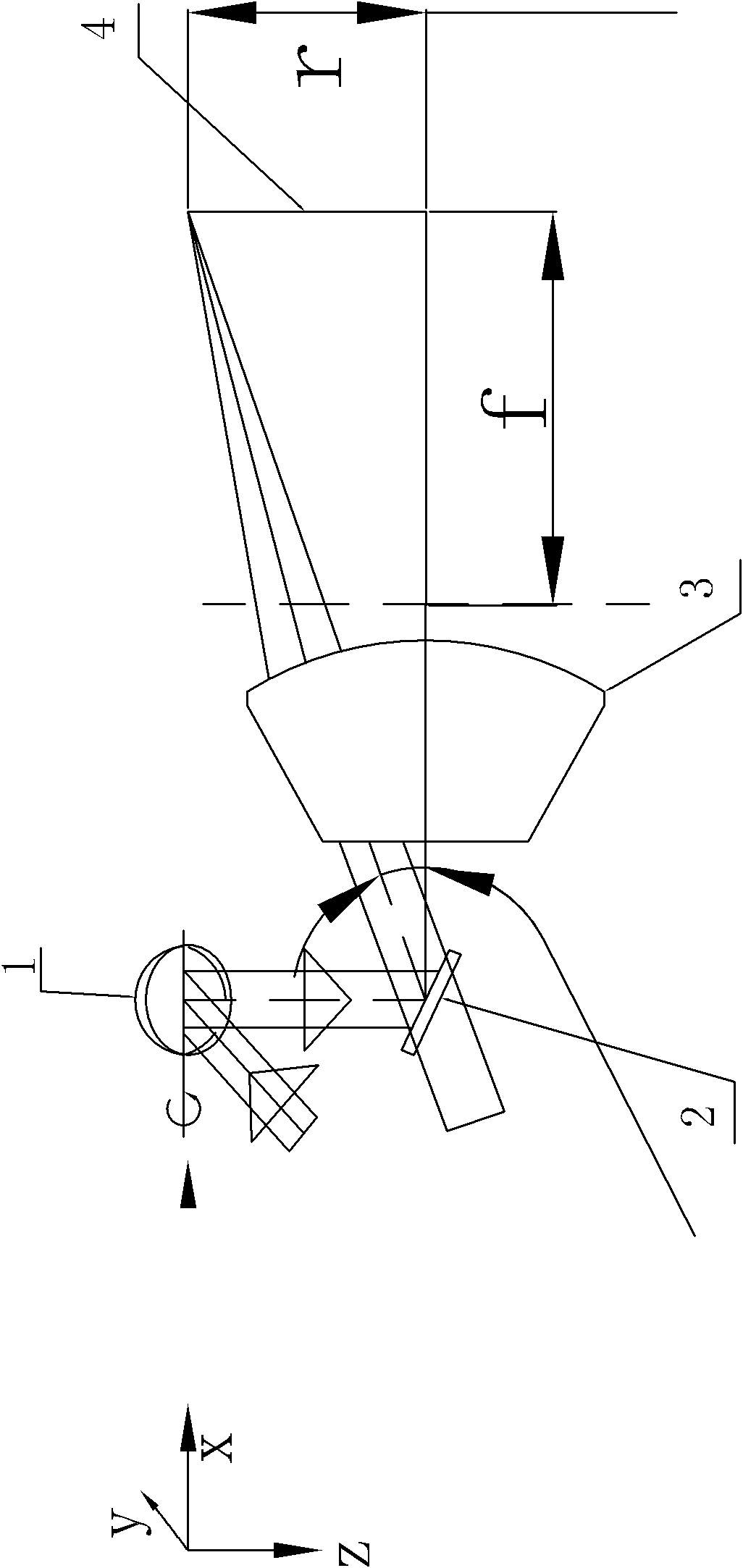

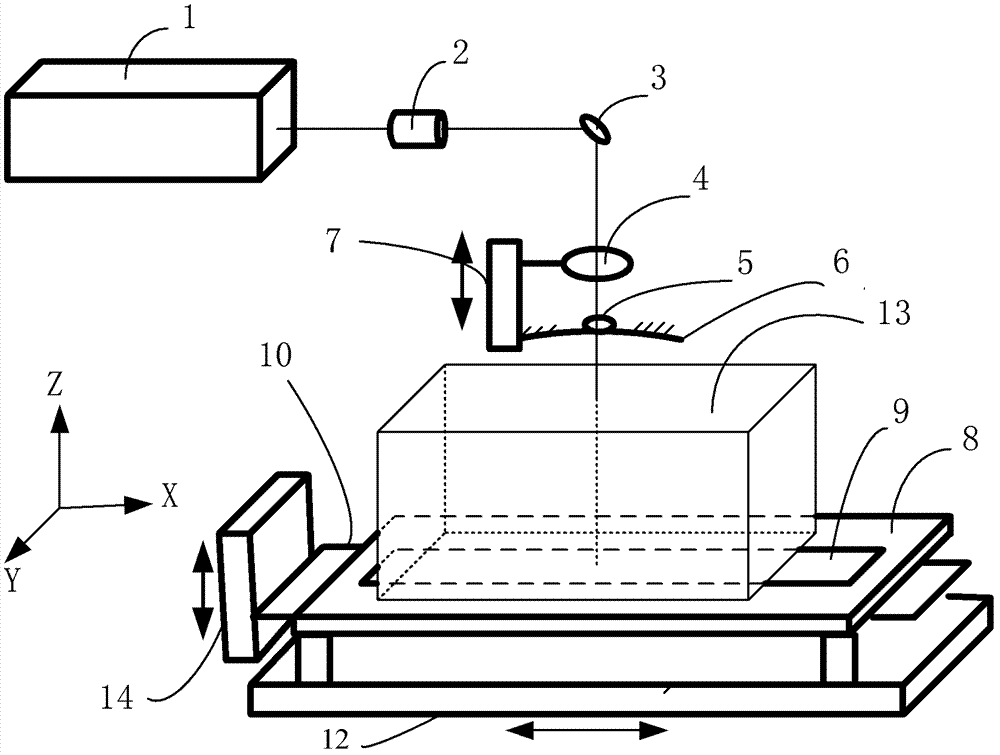

Laser processing device of silicon glass bonding slice and method thereof

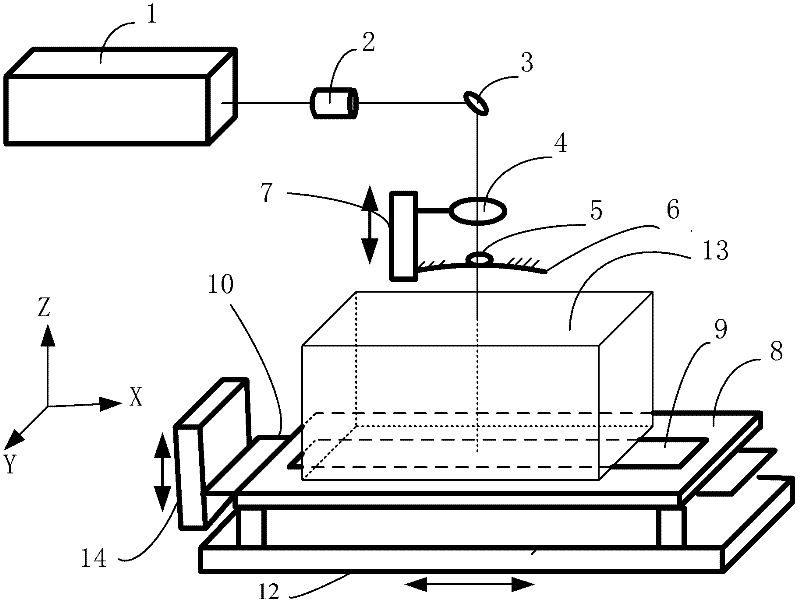

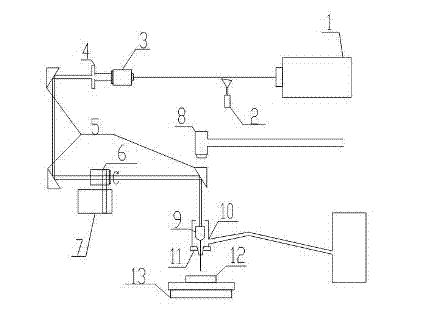

ActiveCN102310285AImprove divergence angleReal-time observation of processing progressLaser beam welding apparatusBeam expanderLaser processing

The invention relates to a laser processing device of a silicon glass bonding slice and a method thereof. An output end of an ultraviolet high-frequency ultrashort pulse laser is provided with an optical gate, a beam expander and an aperture diaphragm, an output end of the aperture diaphragm is provided with a pair of 45-degree completely reflecting mirrors, output ends of the 45-degree completely reflecting mirrors are provided with deflection lenses, an output end of the deflection lens is provided with a 45-degree completely reflecting mirror, an output end of the 45-degree completely reflecting mirror is provided with a focus lens, the focus lens is right opposite to a three-dimensional movable platform, a CCD (Charge Coupled Device) illuminating lamp is arranged under the focus lens, and a coaxial CCD (charge coupled device) para-position observation system is distributed above the three-dimensional movable platform. Light beams sent by the ultraviolet high-frequency ultrashort pulse laser chemically focus a focal point on the upper surface of glass material, a spiral deflection lens controls the width of a once-cut cutting track, adjusts the cutting track into the cutting track with proper width, accurately positions the cut cutting track, and controls the focal point to correspondingly descend along with the increase of the cutting depth to orderly cut each cutting track on the silicon glass bonding slice.

Owner:SUZHOU DELPHI LASER

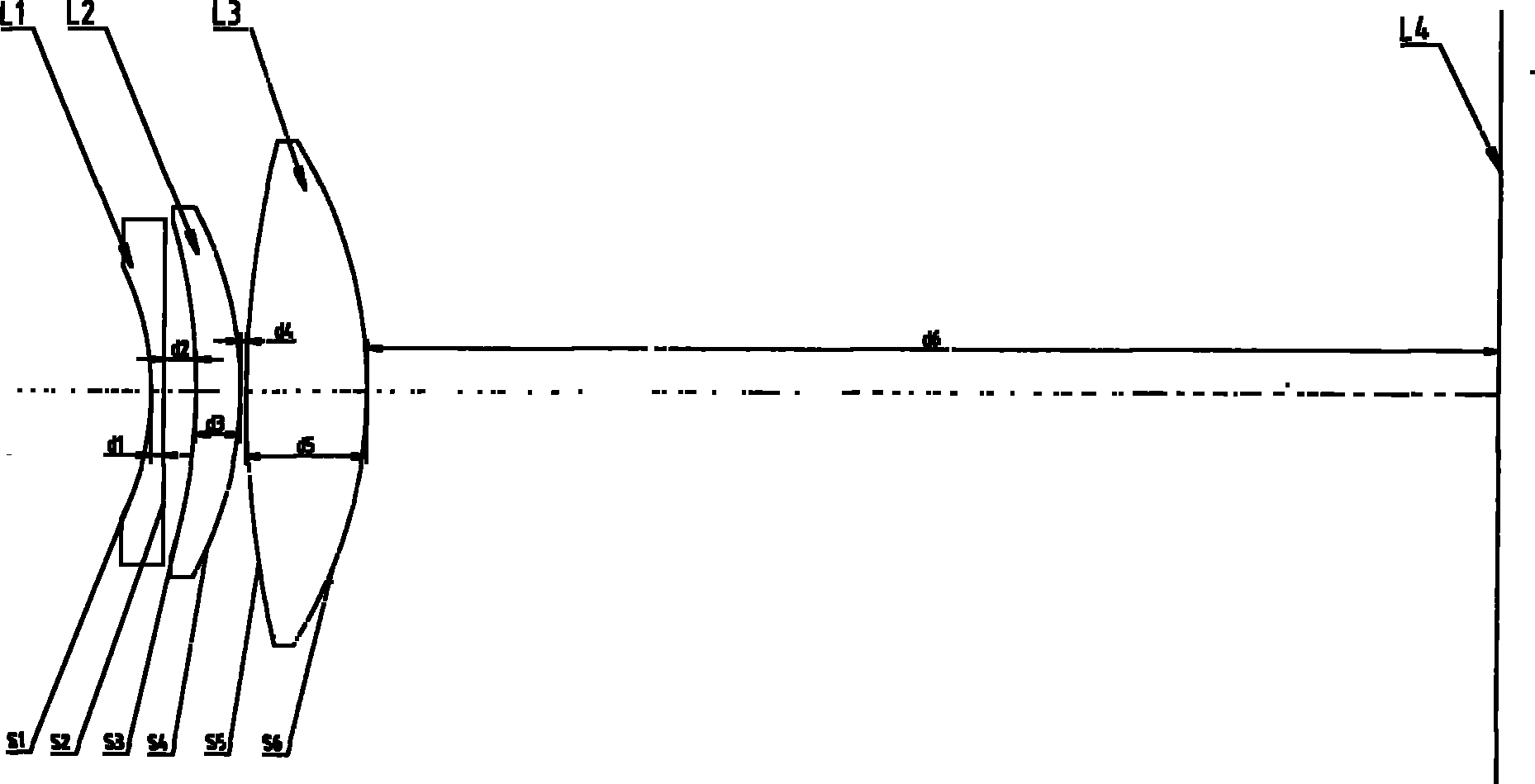

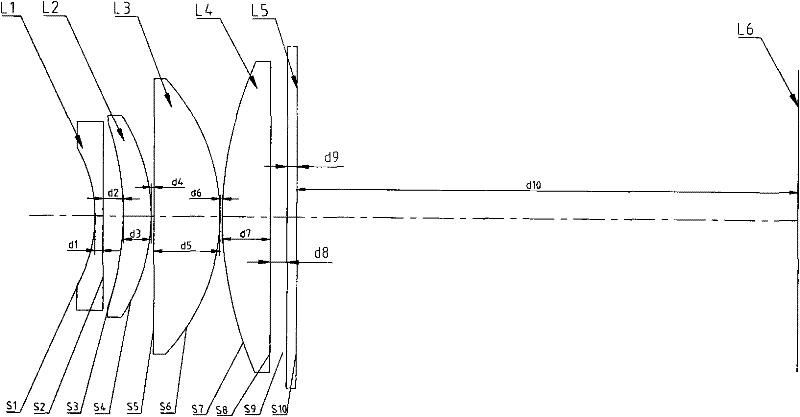

Optical lens for ultraviolet laser

ActiveCN101866043AIncrease in sizeFocus spot is smallLaser beam welding apparatusOptical elementsLight spotUltraviolet

The invention relates to an optical lens for an ultraviolet laser. The optical lens is characterized by comprising a first lens, a second lens and a third lens which are sequentially positioned in the incident direction of beams, wherein the first lens is a biconcave lens, the second lens is a crescent lens, and the curved surfaces of the first and second lenses both bend towards the incident direction of rays; and the third lens is a biconcave lens. The optical lens is used for the ultraviolet laser with focal length of 254mm and wavelength of 355mm and a processing area with processing range of 160mm<2>*160mm<2>. A concept of high-order aberration mutual compensation is adopted in aberration correction so as to obtain good effect; the ultraviolet laser after being focused by the lens has small light spot and concentrated energy and can perform superfine processing; and the processed product is finer and clearer.

Owner:HANS LASER TECH IND GRP CO LTD

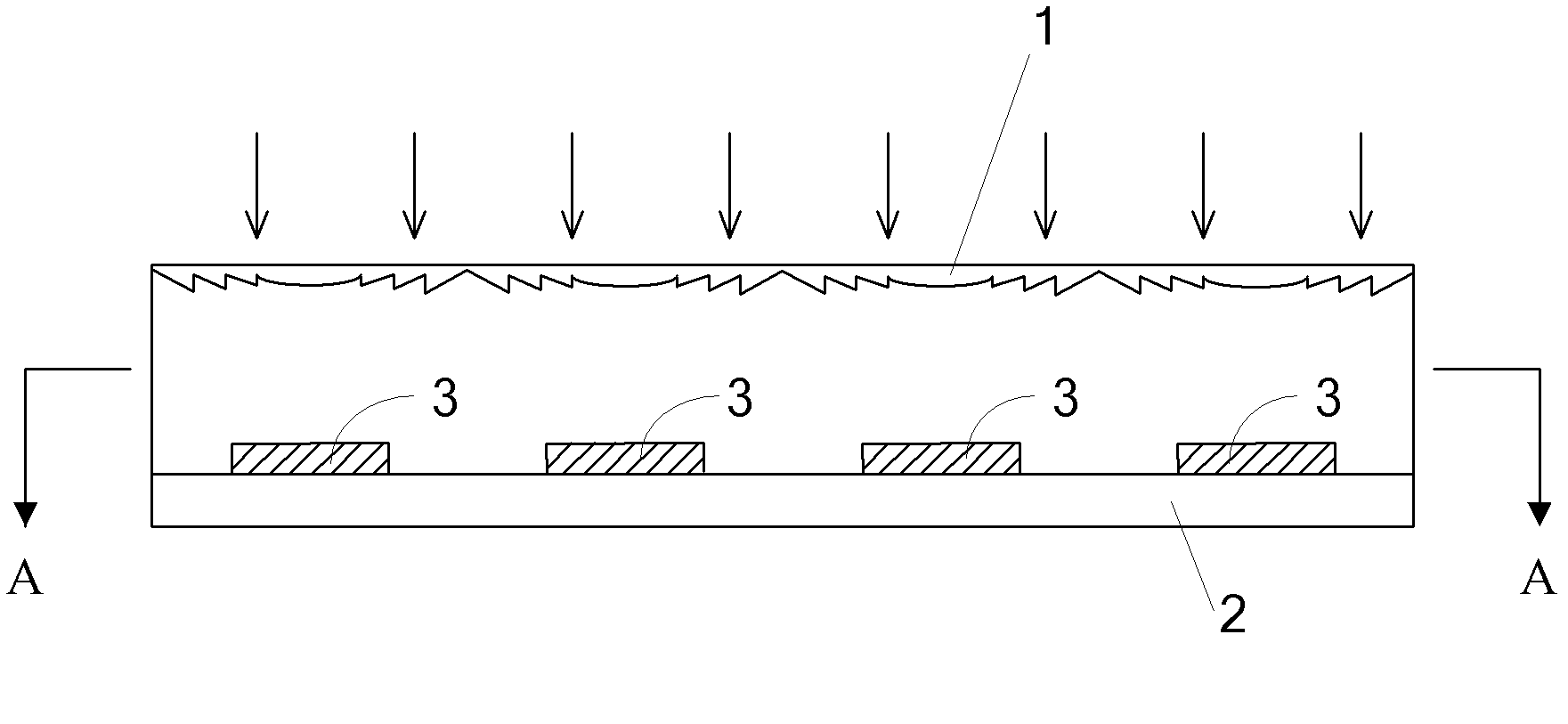

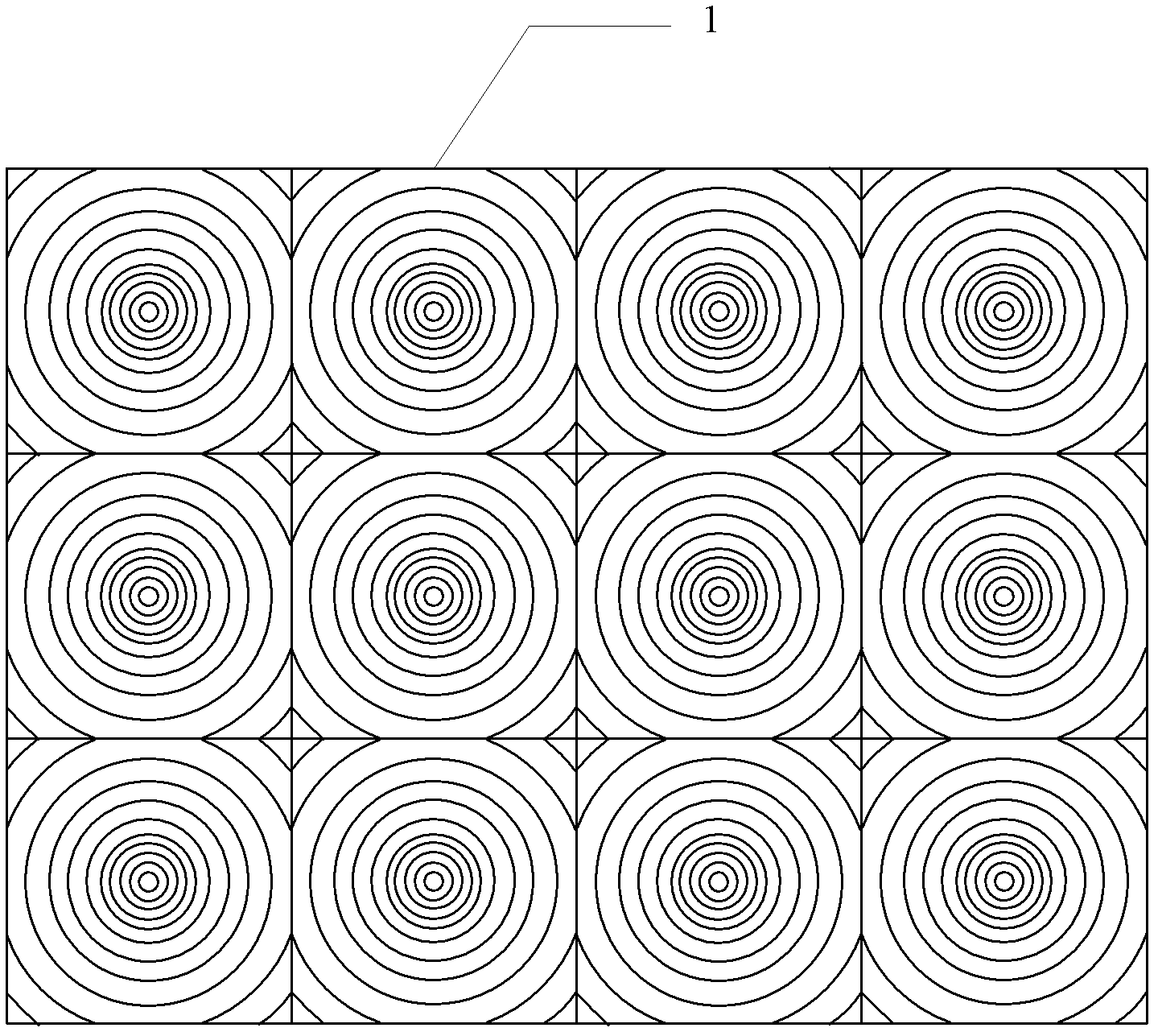

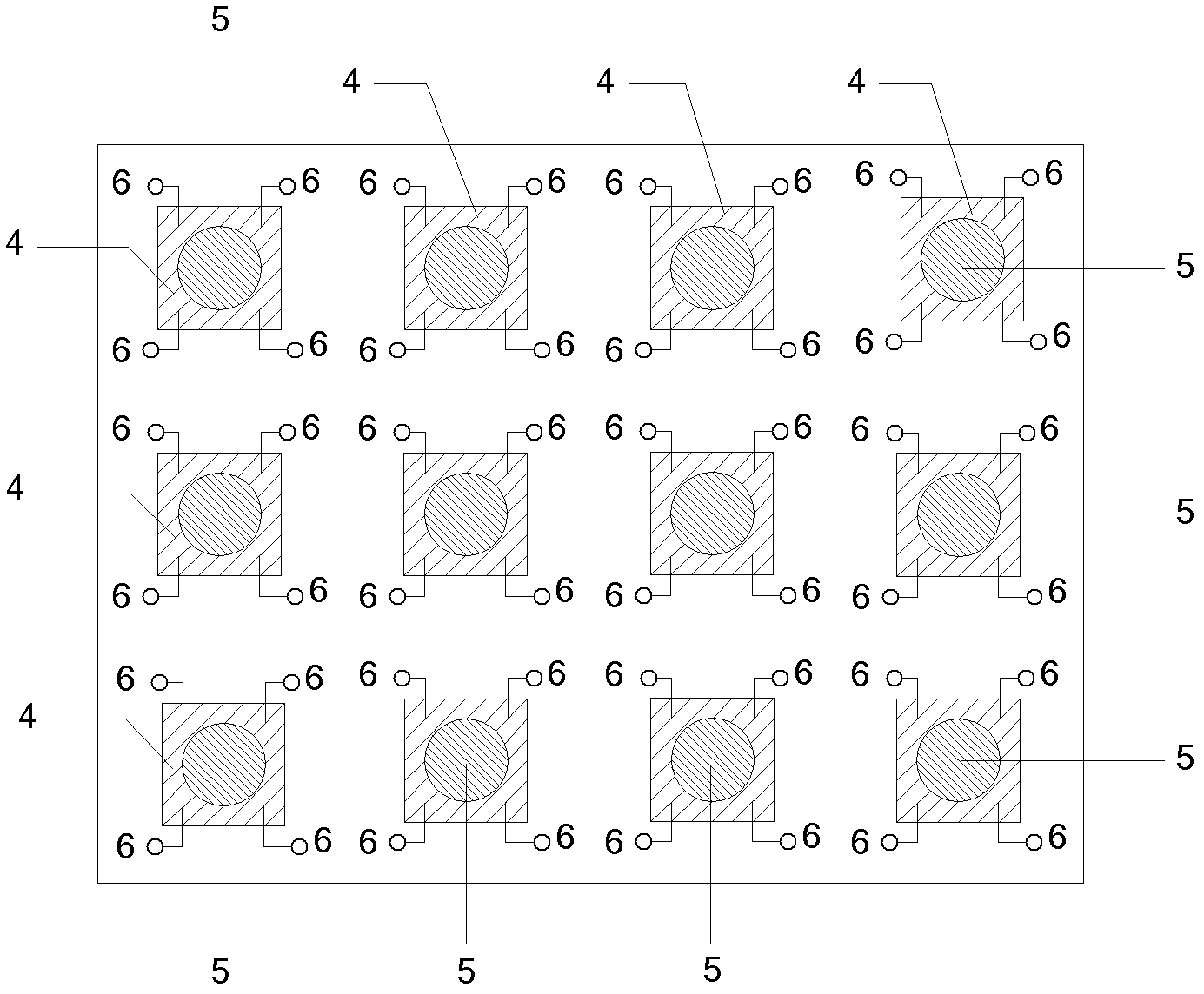

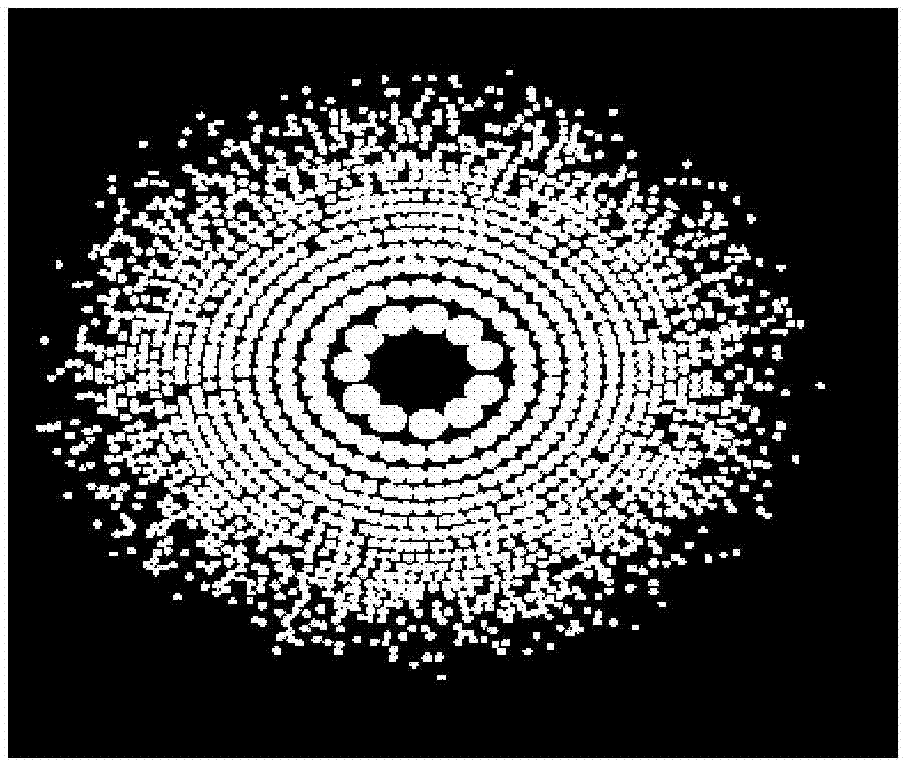

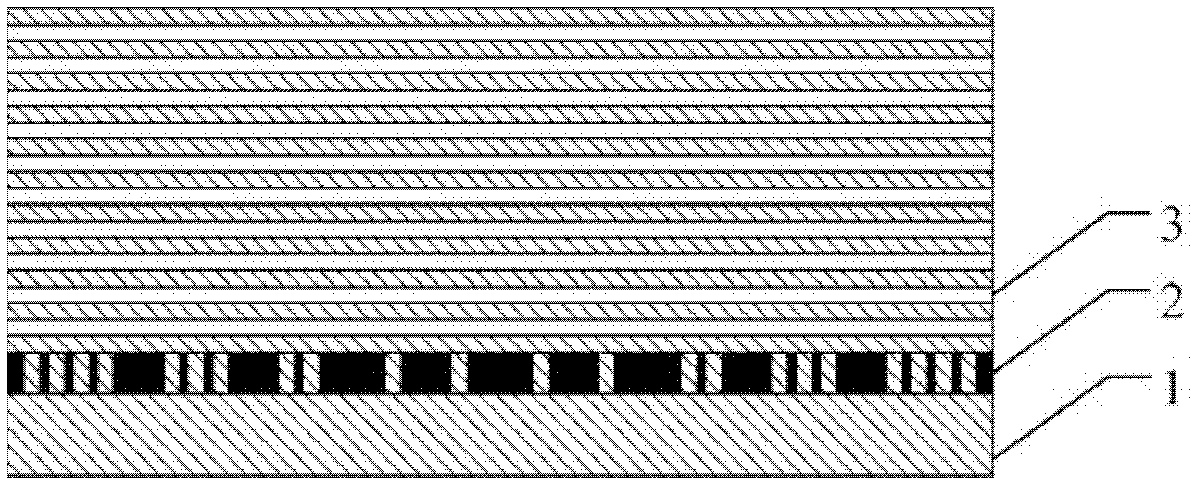

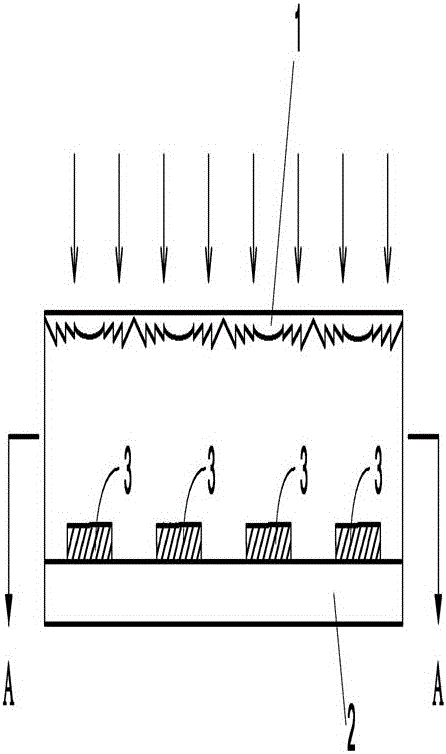

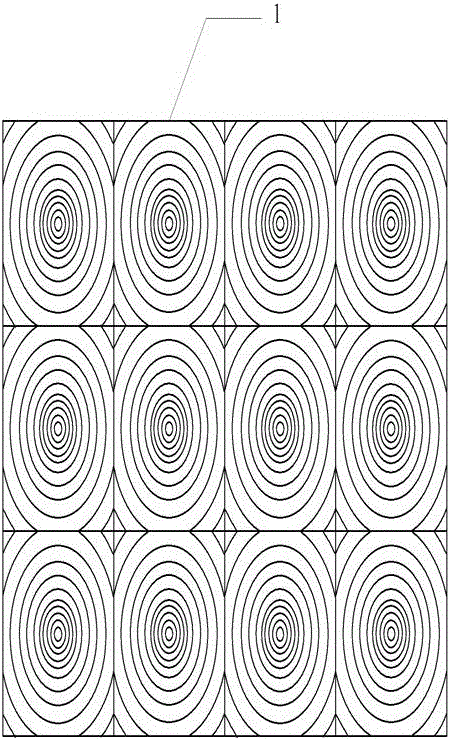

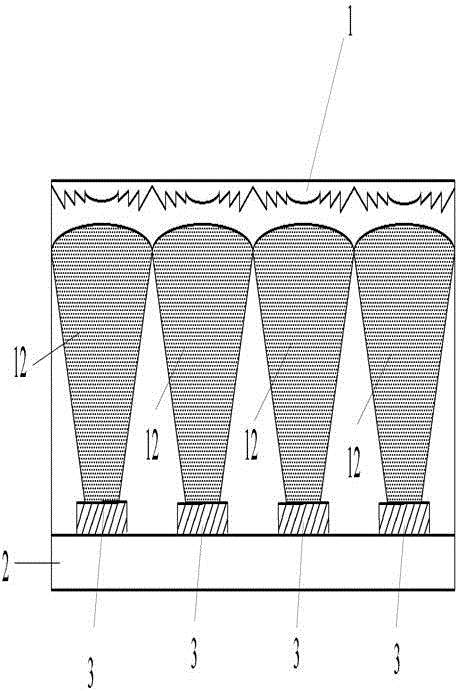

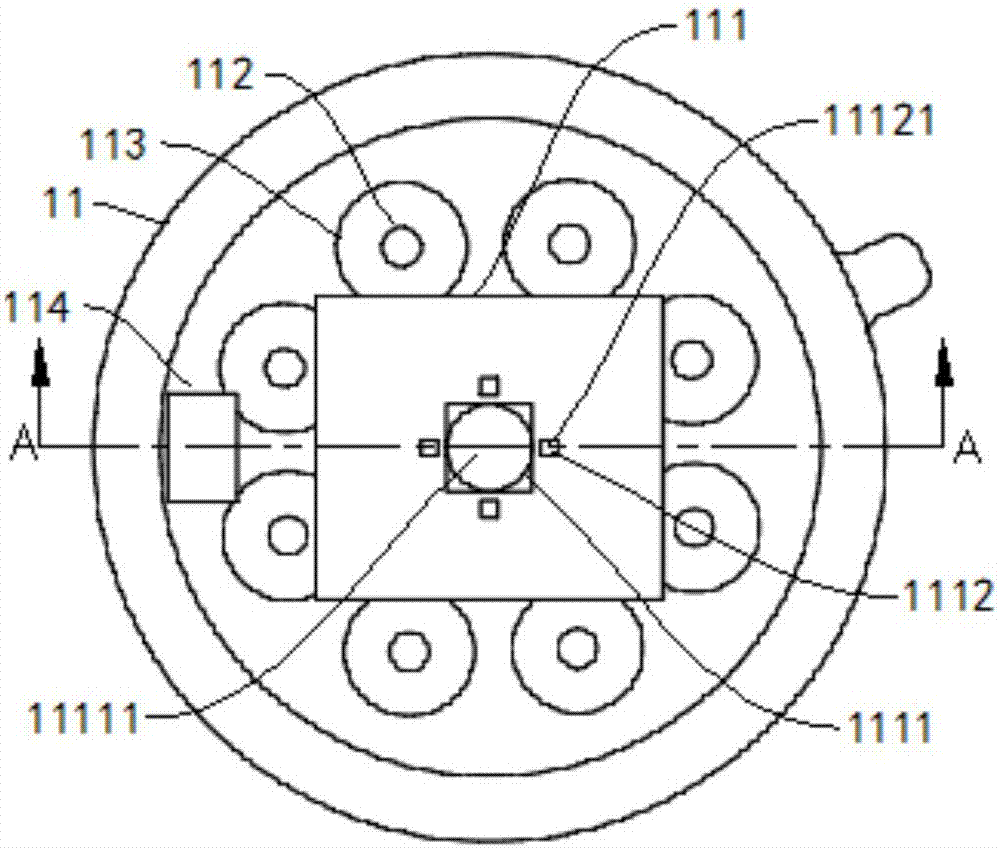

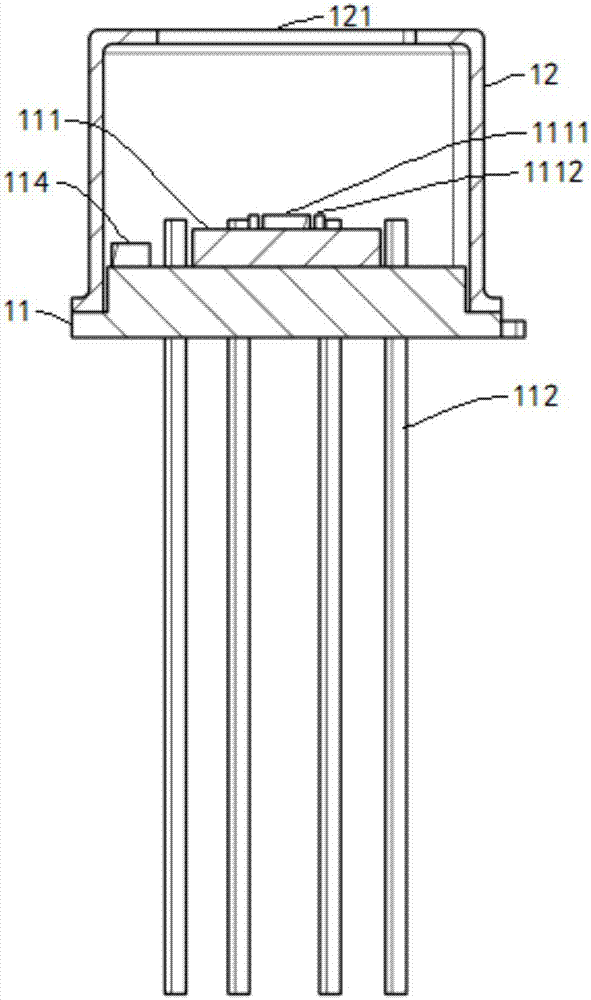

A dense array concentrated solar photovoltaic device

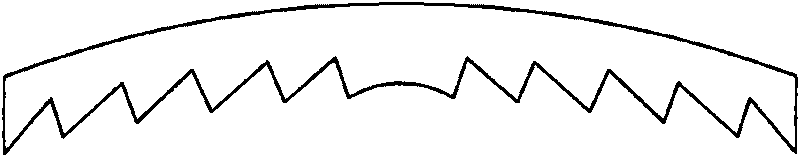

ActiveCN102280511AFocus spot is smallReduced accuracy requirementsPhotovoltaic energy generationSemiconductor devicesCell chipConcentric ring

The invention relates to a dense array concentrating solar energy photovoltaic device, and belongs to the field of photovoltaic. The dense array concentrating solar energy photovoltaic device comprises a Fresnel lens array, a plane substrate and at least two photo cells, wherein the Fresnel lens array is arranged at a top layer and is an integrated lens; the upper surface of the Fresnel lens is a plane and the lower surface of the Fresnel lens is provided with at least two groups of concentric ring-shaped saw teeth; each group of concentric ring-shaped saw teeth forms a Fresnel lens; the Fresnel lenses are arranged in an array mode; the plane substrate is arranged at a bottom layer; the at least two photo cells are arranged on the upper surface of the plane substrate and in a photo cell array mode; the number of the photo cells in the photo cell array is the same as the number of the Fresnel lens in the Fresnel lens array; and each photo cell corresponds to one Fresnel lens. The array concentrating solar energy photovoltaic device is simple in heat dissipation, short in concentrating focus and high in solar energy utilization rate, and does not require electrode arrangement inside a photo cell chip.

Owner:REDSOLAR NEW ENERGY TECH

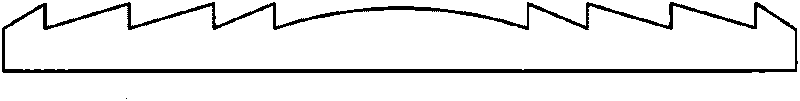

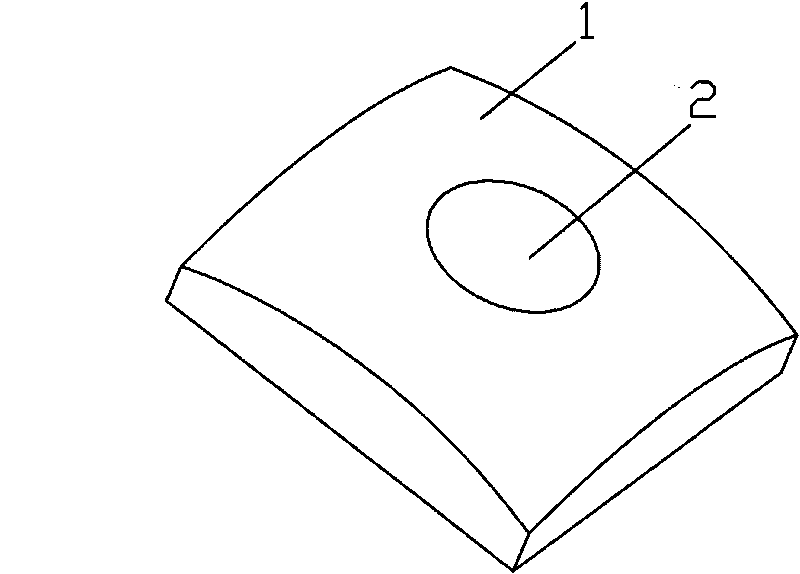

Solar energy condensing electricity-generating device with summit-cutting curve condensing lens

InactiveCN101710804AReduce lossesHigh Geometric Concentration RatioPhotovoltaic supportsMountingsElectricityFresnel lens

The invention discloses a solar energy condensing electricity-generating device with a summit-cutting curve condensing lens, which comprises a plurality of solar energy condensing electricity-generating modules and a sun-pursuing track bracket system for installing the solar energy condensing electricity-generating modules a, wherein the solar energy condensing electricity-generating modules comprise a plurality of solar energy condensing electricity-generating units which are arranged in a matrix way, the solar energy condensing electricity-generating units comprise summit-cutting curve condensing lenses and condensing cells which are arranged in the condensing areas of the summit-cutting curve condensing lenses; and each condensing cell of the solar energy condensing electricity-generating modules is connected with each other in series to outwards output electric energy. By adopting the summit-cutting curve condensing lens, the solar energy condensing electricity-generating device leads the solar energy condensing lens not only to have the optical advantage of a curve fresnel lens but also to have the machining advantage of a plane fresnel lens, which is simpler than that of the curve fresnel lens, thereby reducing the machining cost, improving the condensing effect, and greatly increasing the cost performance thereof.

Owner:SUNTRIX CO LTD

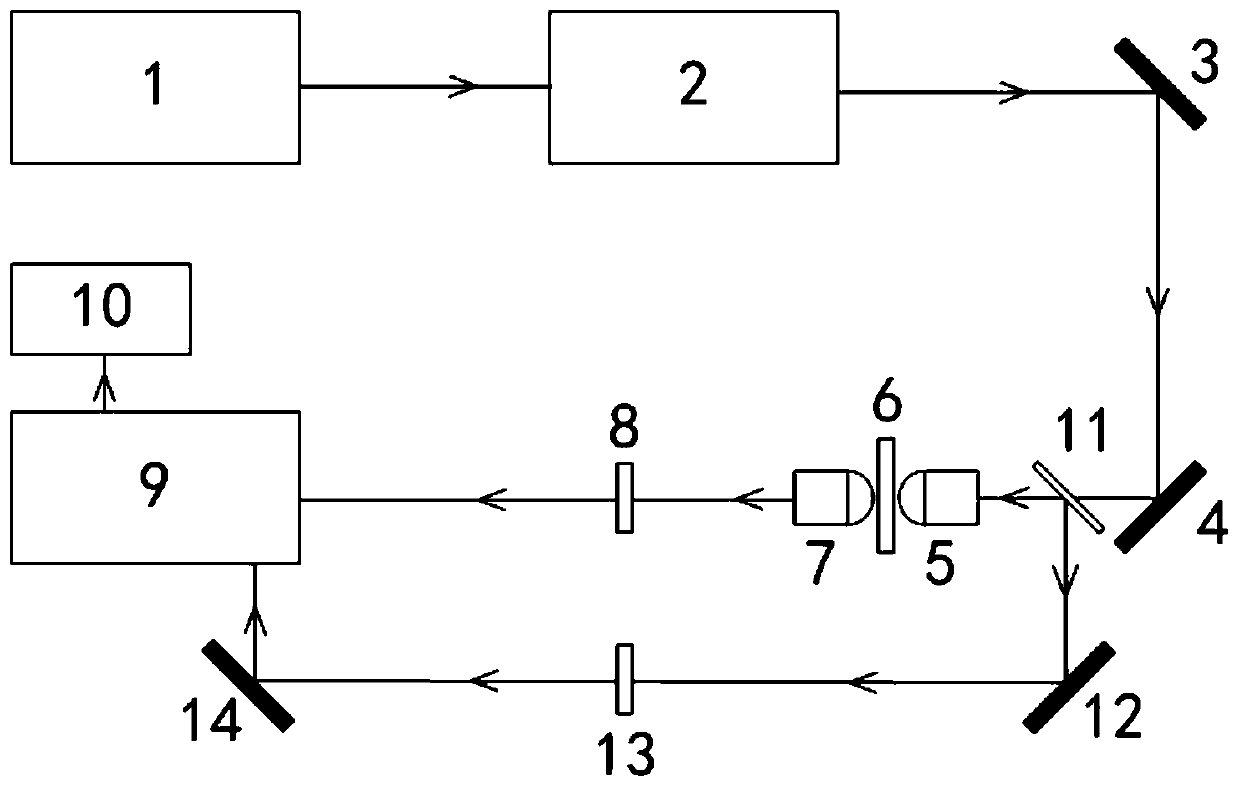

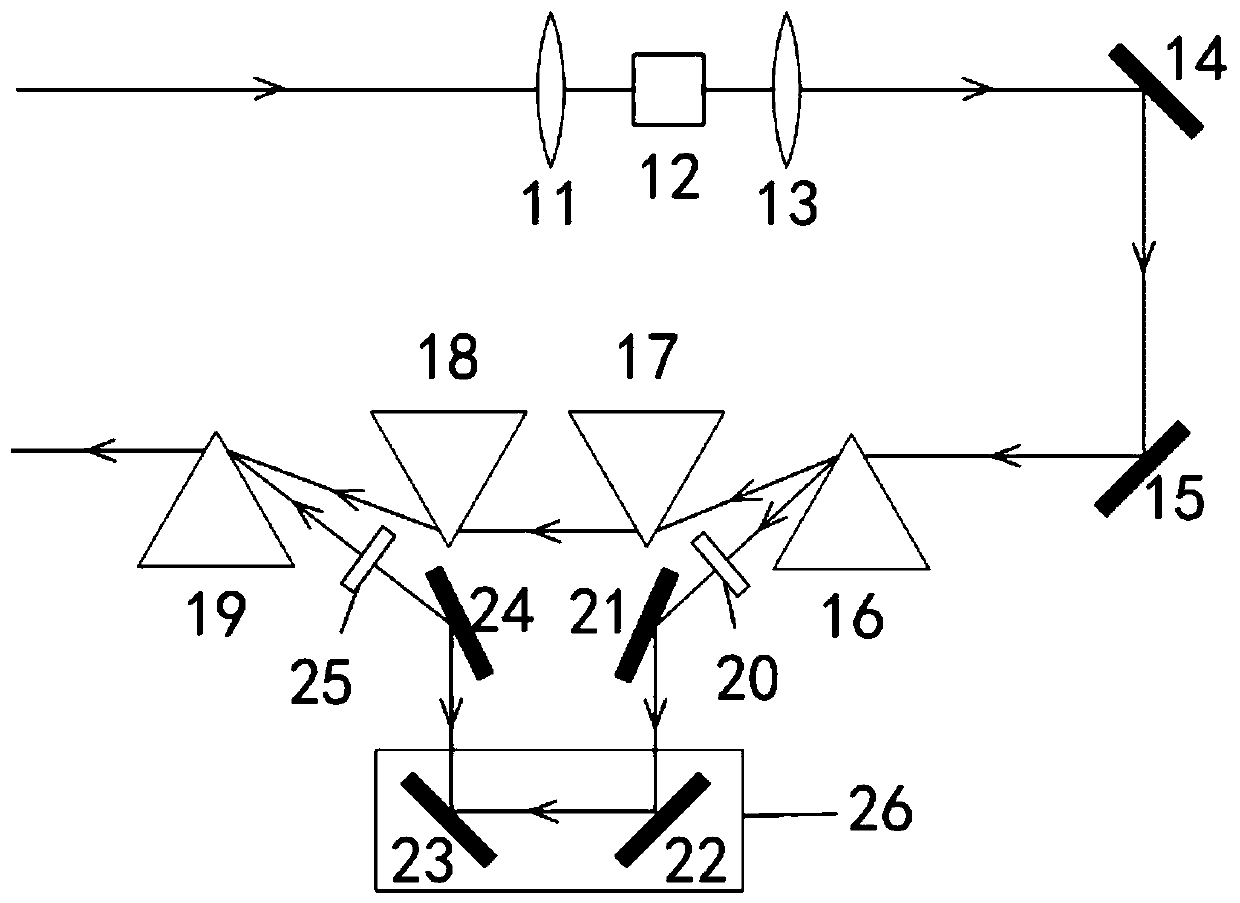

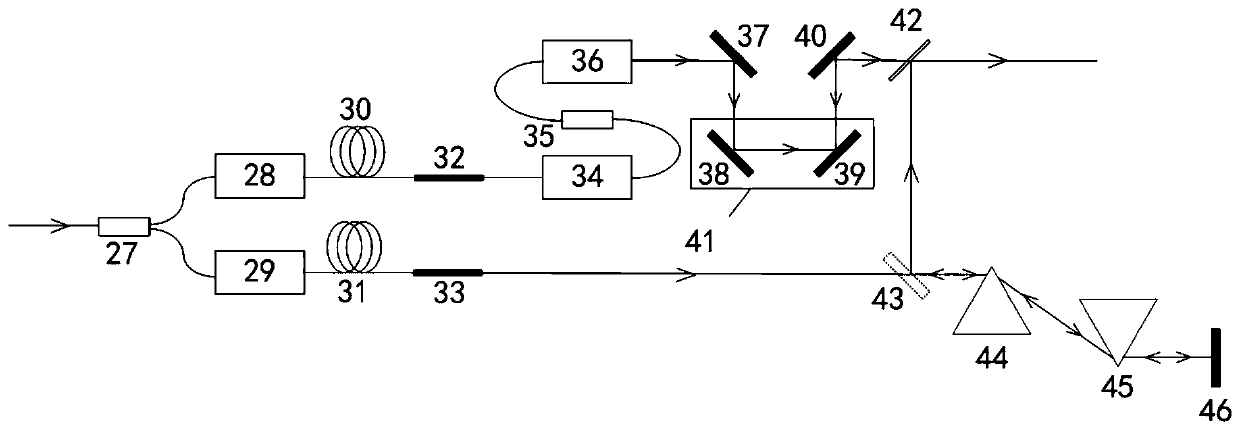

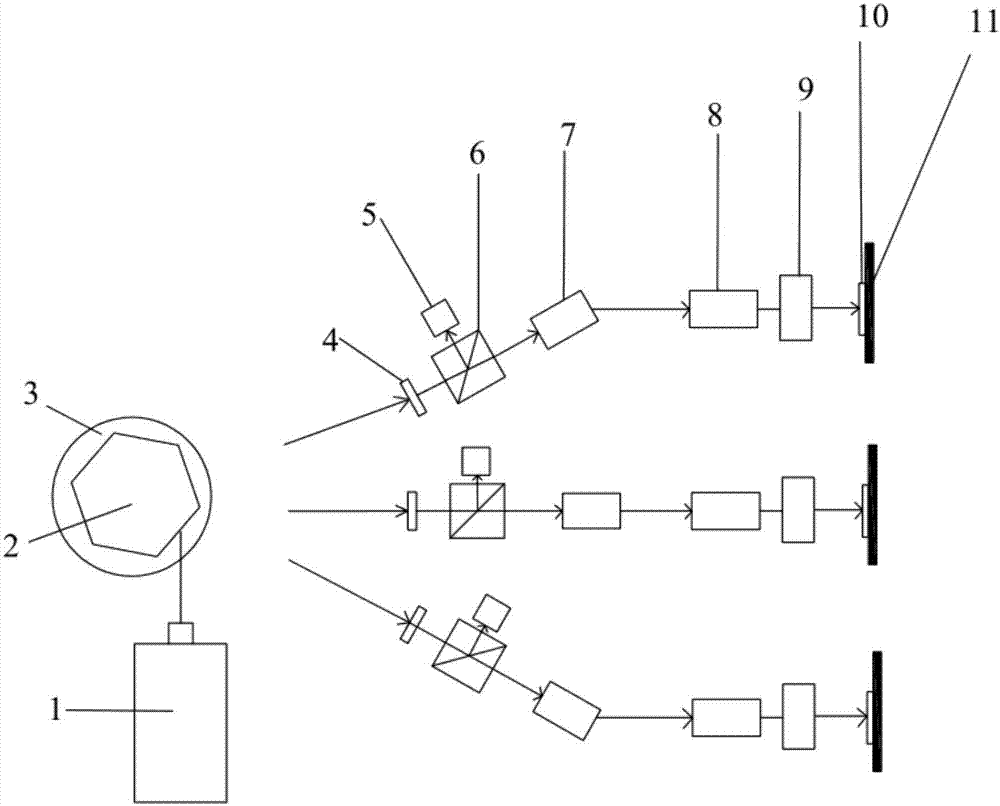

Time-resolved wide-spectrum CARS spectral imaging device based on high-repetition-frequency femtosecond laser

ActiveCN110579462ARealize synchronous mechanical scanningRealize data collectionRaman scatteringOptoelectronicsFundamental frequency

The invention discloses a time-resolved wide-spectrum CARS spectral imaging device based on high-repetition-frequency femtosecond laser. The device comprises a high-repetition-frequency femtosecond laser device, a double-pulse laser generation module and a spectral imaging platform. The high-repetition-frequency femtosecond laser device is used for generating fundamental frequency light with the high repetition frequency and inputting the fundamental frequency light into the double-pulse laser generation module. The double-pulse laser generation module is used for generating fundamental frequency light and frequency shift light which are suitable for coaxial transmission of the time-resolved CARS imaging technology. And the spectral imaging platform is used for realizing scanning type Raman spectral imaging of a to-be-detected sample. According to the invention, the wide-spectrum femtosecond laser is used as pump light and Stokes light at the same time and coherence among multiple energy levels can be established at one time, so that hyperspectral imaging of various molecules can be realized at the same time. A coherent excitation process and a detection light excitation process which are jointly realized by the pump light and Stokes light are separated in time and narrow-spectrum light is adopted as the pump light, so that a non-resonance background is effectively suppressed,and the detection sensitivity is greatly improved.

Owner:HUAZHONG UNIV OF SCI & TECH

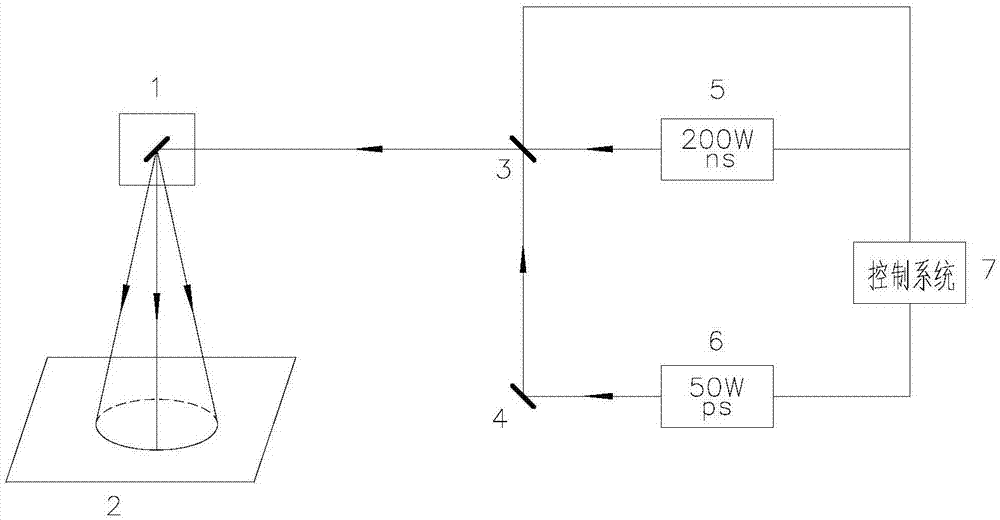

Laser cutting system and cutting method thereof

ActiveCN107234345AFast cutting speedExpand the cutting rangeLaser beam welding apparatusGalvanometerLaser power density

The invention provides a laser cutting system and a laser cutting method thereof. The laser cutting system comprises a galvanometer system, a variable reflector, a fixed reflector, a first laser, a second laser and a control system. The control system is connected with the first laser, the second laser and the variable reflector. The cutting mode is the front focusing cutting mode. According to a rear focusing cutting mode adopted by existing pole piece cutting, the focusing spot of front focusing is smaller than that of rear focusing, the laser power density at the focusing spot is larger, cutting speed can be increased, through matching with a three-axis galvanometer, the cutting range is large, large-breadth cutting and small-breadth batch cutting can be conducted, cutting efficiency is improved, and cost is reduced.

Owner:HANS LASER TECH IND GRP CO LTD

Optical fiber laser three dimensional printer for preparation of nano-ceramic bone tissue engineering scaffold

InactiveCN104276826AFocus spot is smallImprove stable outputBone tissue engineeringBiomedical engineering

Owner:CENT SOUTH UNIV

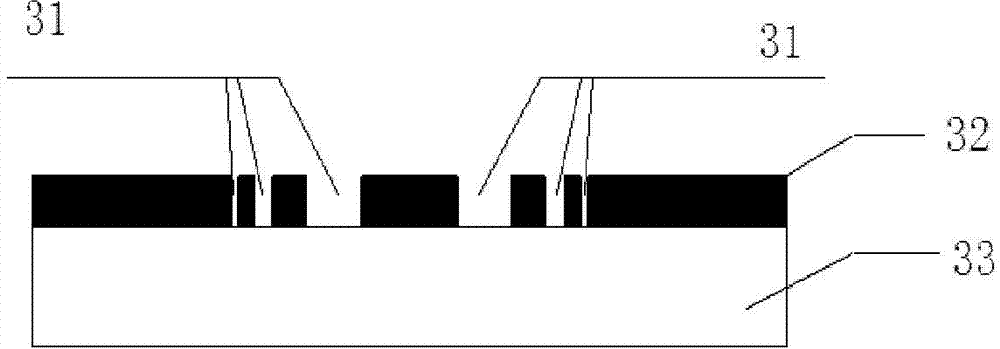

Photon sieve-based blue-ray optical head

InactiveCN102737664AWith super-resolution focusing characteristicsImprove resolutionRecord information storageOptical beam guiding meansBeam splitterWavelength

The invention discloses a photon sieve-based blue-ray optical head, which comprises a blue-ray laser diode, a collimating lens, a polarized beam splitter, a polaroid, a photon sieve, an optical disk, a cylindrical lens and a photoelectric detector. Light emitted by the blue-ray laser diode is focused on a surface of the optical disk through the photon sieve after being subjected to beam shaping and is transmitted to the photoelectric detector through a light path after being reflected. The optical head has high compatibility, the blue-ray disc can be read and written only by substituting the photon sieve for a focusing objective lens under the condition that a system structure is not required to be changed, and the length of a light source can be further reduced, so that a large number of data can be stored.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Laser generator

InactiveCN104953462ABeam quality is stableFocus spot is smallLaser detailsEngineeringElectrical and Electronics engineering

The invention discloses a laser generator. The laser generator comprises a discharge tube, an internal discharge pipe gas cavity is arranged in the discharge tube and is filled with mixed gas of CO2, N2, HE and the like, two discharge tube electrodes are arranged at two ends of the discharge tube and are connected with a power source via leads, and a controller is arranged between the power source and the discharge tube electrodes.

Owner:张家港市旭华激光有限公司

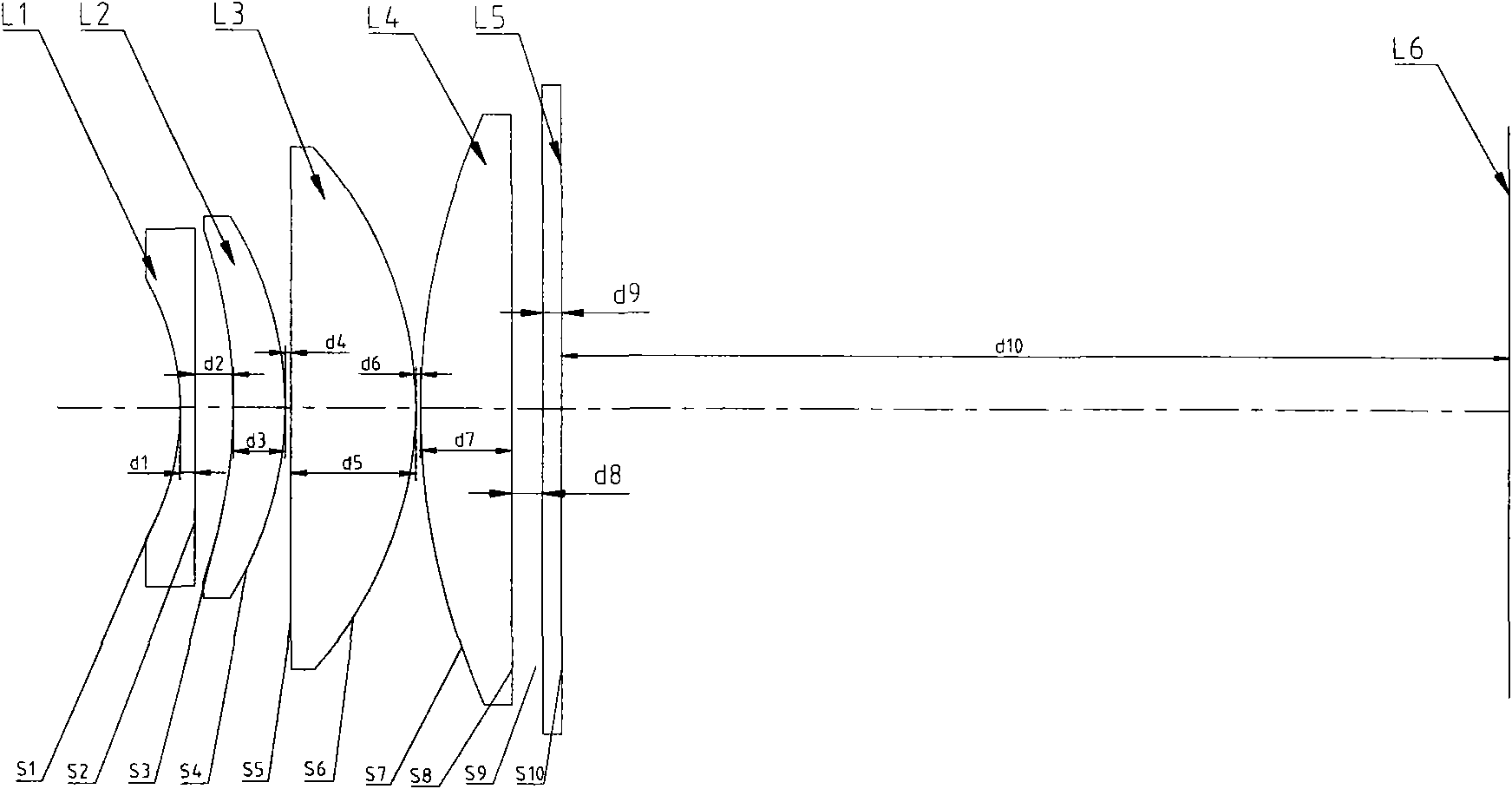

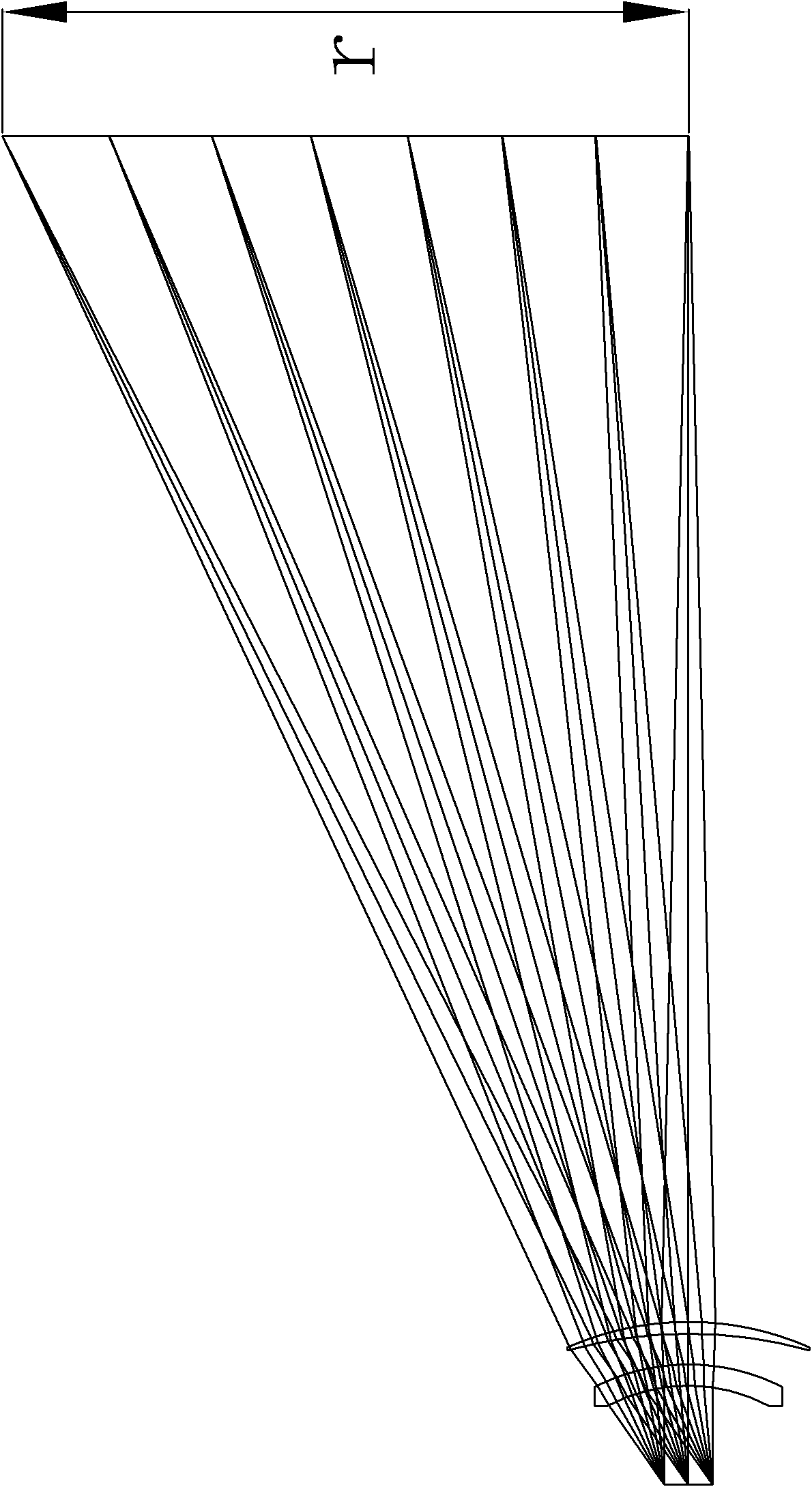

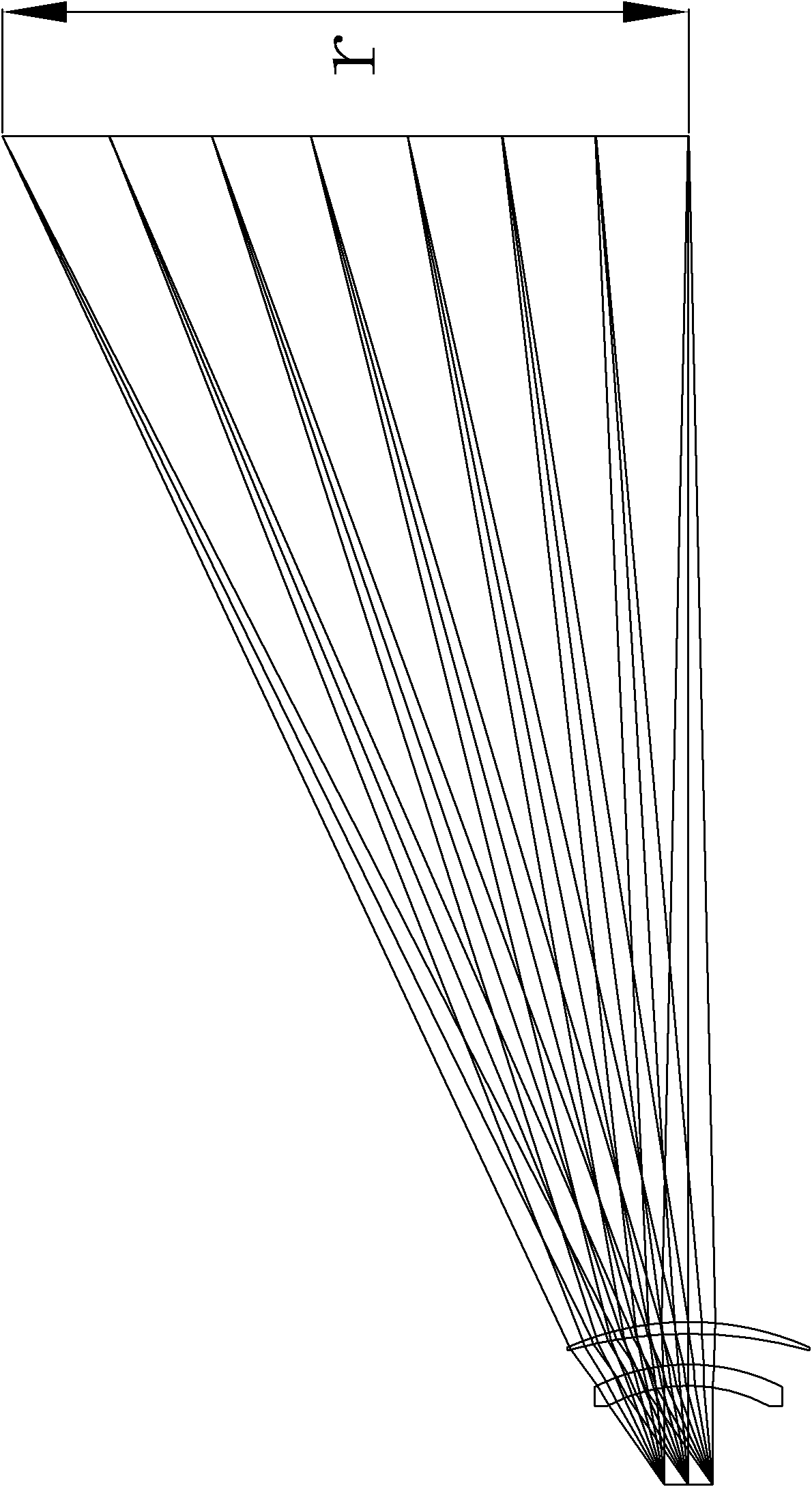

F-theta lens and optical system

ActiveCN102809804AGuaranteed energy concentrationFocus spot is smallOptical elementsLength waveOmega

The invention provides an F-theta lens and an optical system. The F-theta lens comprises a first lens and a second lens, which are arranged in a light propagation direction in sequence; the first lens is a crescent-shaped negative lens; the second lens is a crescent-shaped positive lens; and curved surfaces of the first lens and the second lens are both bent toward a light incident direction; the incident light wavelength of the lens is 10.6 microns, view field angle 2 omega of the lens is 70 degrees, light incident aperture of the lens is 30 mm, and the scanning range of the lens is 608 mm X 608 mm. The F-theta lens provided by the invention is a large-range field flattening lens, which is designed through double-plate type negative-positive focal power distribution; and on the premise that energy concentration and small focusing spots of a laser are guaranteed, a scannable range can be further enlarged, so that the F-theta lens provided by the invention is beneficial for enlarging the application range of the laser machining industry.

Owner:HANS LASER TECH IND GRP CO LTD

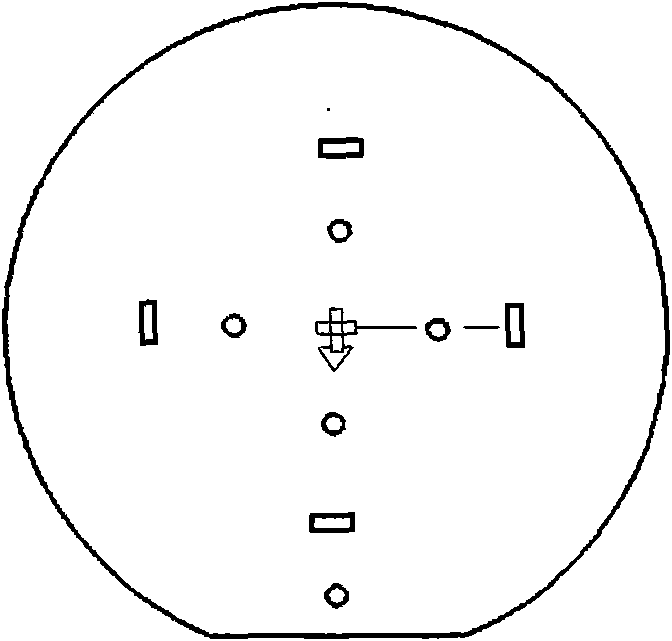

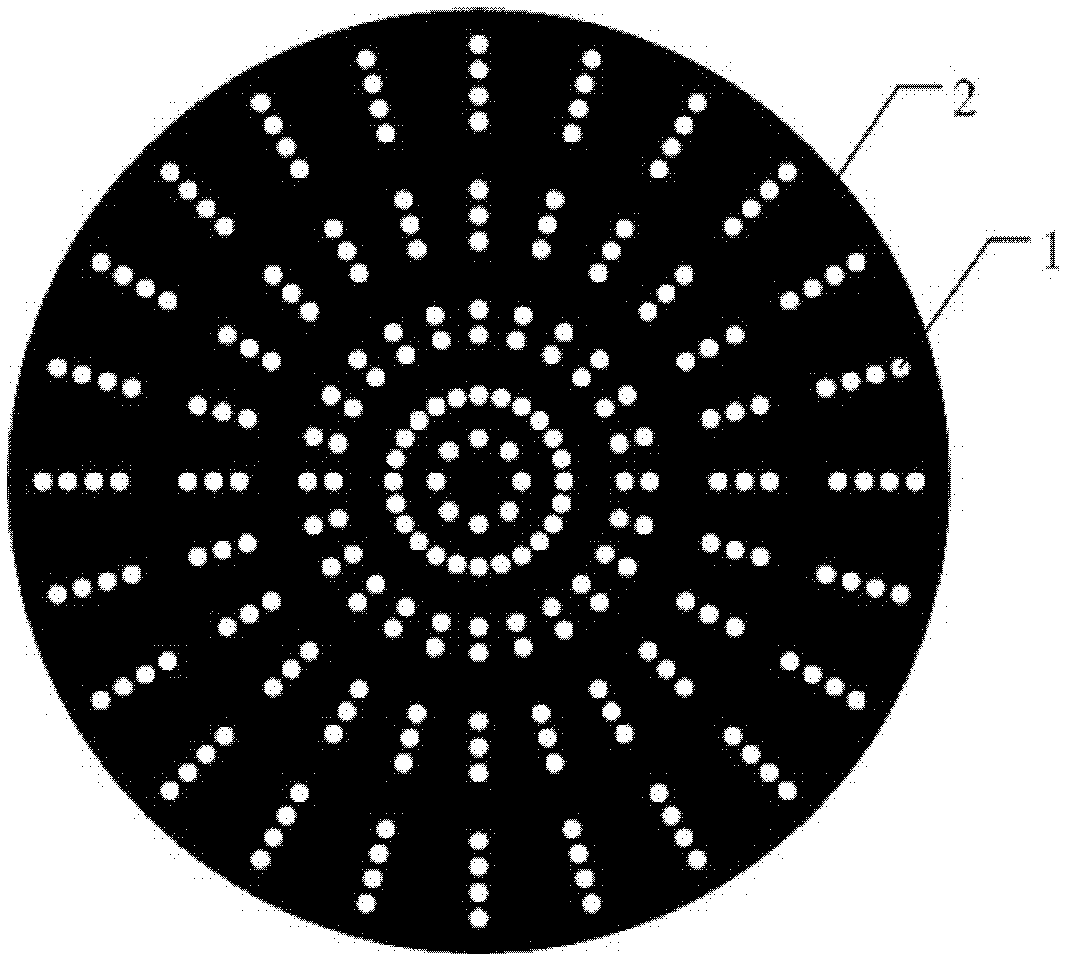

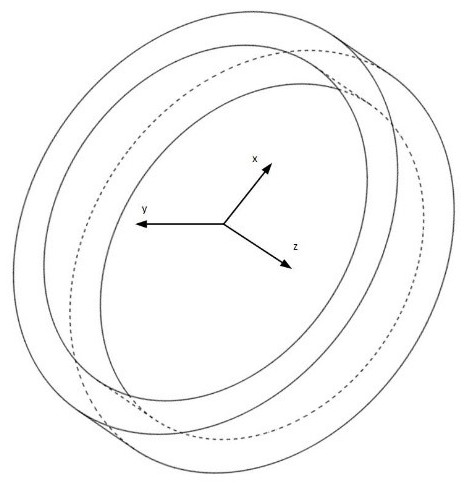

Manufacture method of high resolution super diffraction focusing structure lens

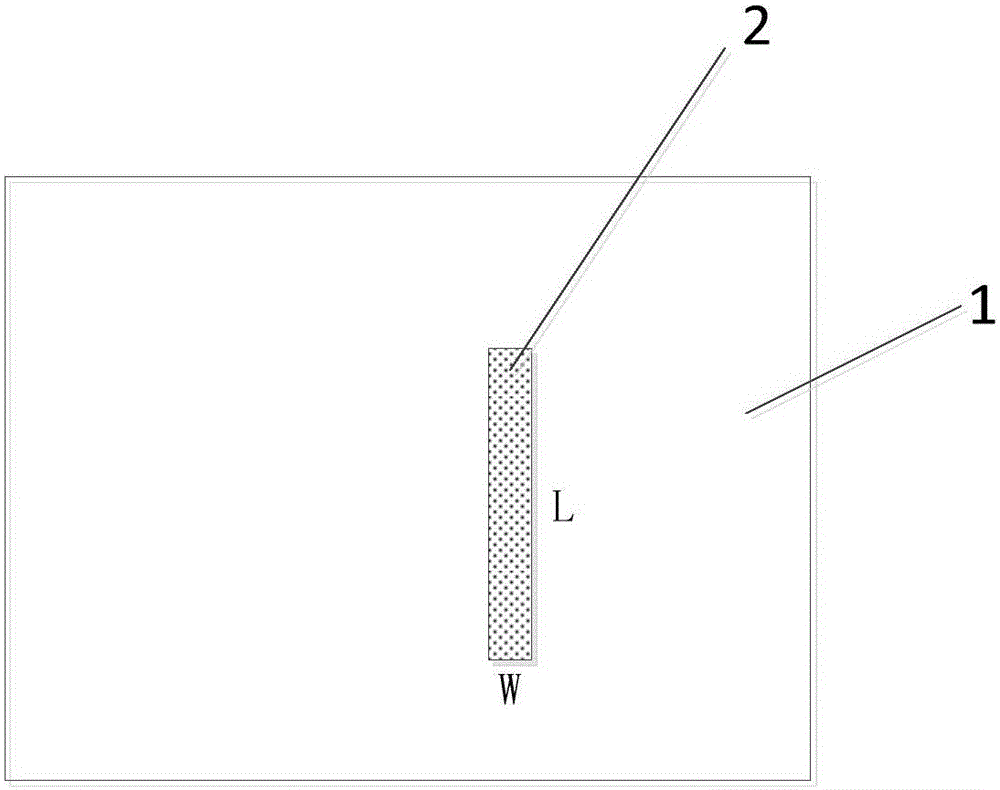

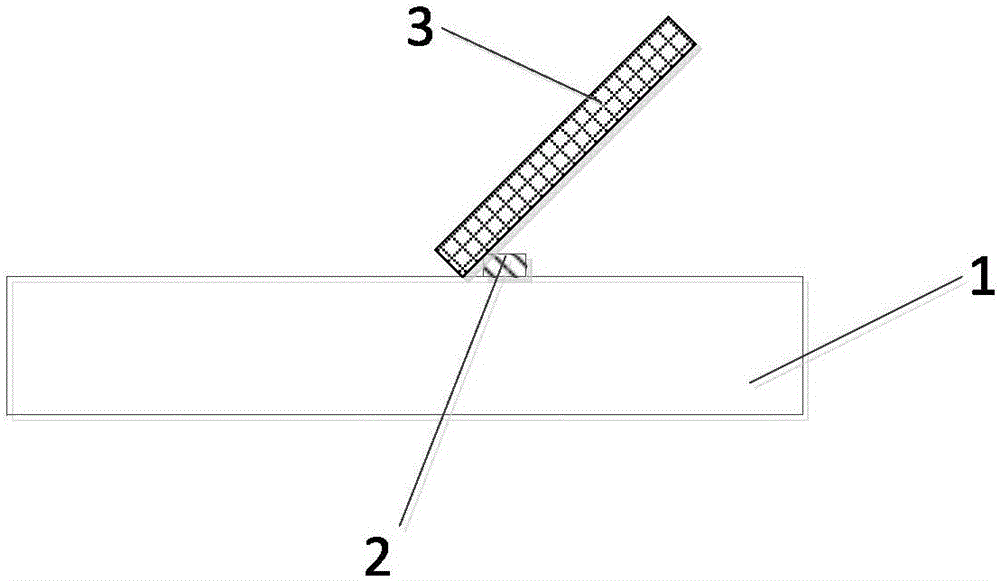

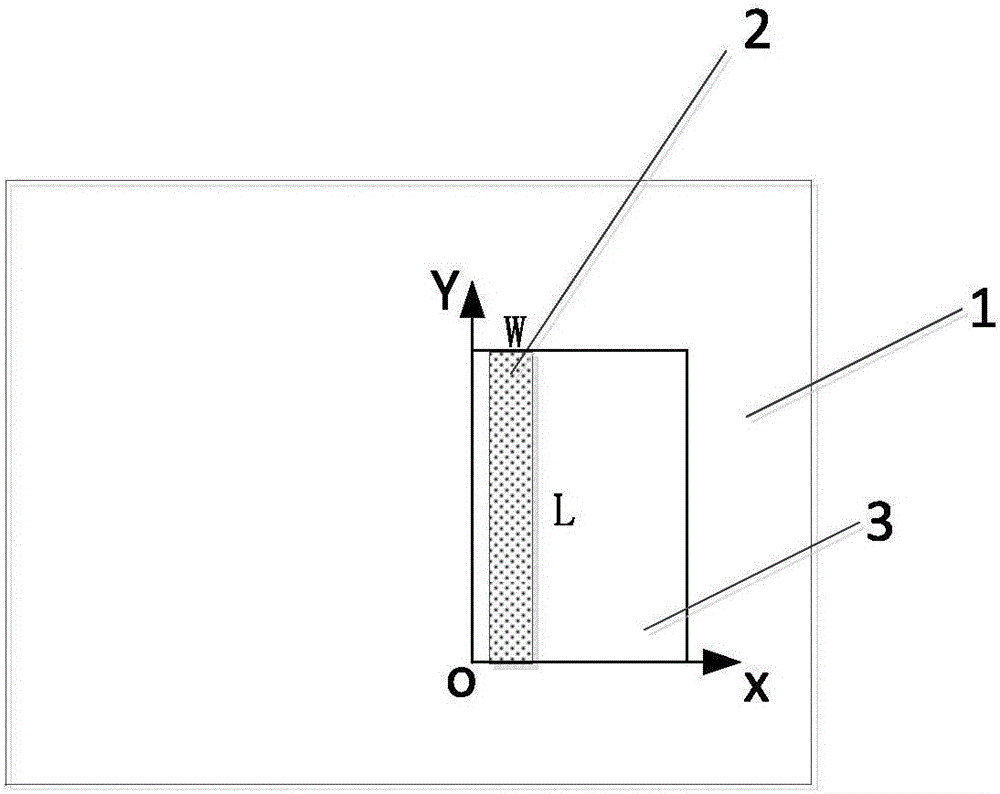

The invention provides a manufacture method of a high resolution super diffraction focusing structure lens, which includes selecting a proper substrate material, evaporating or sputtering and precipitating a metal film on a substrate, enabling monochromatic light in certain polarization state to enter in incident mode and be perpendicular to the metal film, selecting a central point on the upper surface of the metal film as the coordinate origin, enabling a coordinate axis passing through the central point to be the X axis and the Y axis and a connection line perpendicular to the metal film to be the Z axis, calculating Fresnel each-level annular belt position of the metal film according to the aplanatism principle, utilizing the prior nanometer processing art, opening nanometer small holes on each annular belt area of the metal film, determining periodic or non-periodic arrangement position of the nanometer small holes in the annular belt area through the polarization state of the incidence light, and then alternatively evaporating or sputtering and precipitating the nanometer and medium plane multi-layer film structure with nanometer thickness. The manufacture method is simple in lens structure, capable of being used in nanometer photoetching and data storage, greatly improves integration level of electronic devices and has wide development prospect.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

F-theta optical lens

The invention relates to an f-theta optical lens of UV laser application. The f-theta optical lens comprises a first lens, a second lens, a third lens and a fourth lens which are sequentially ranged in the incoming direction of light beams, wherein the first lens is a biconcave lens, the second lens is a meniscus lens with the curve surface bending towards the incoming direction of light rays, the third lens is a plane convex lens, and the fourth lens is a biconcave lens, wherein the optical lens is used for the processing region of UV laser with the lens viewing angle of 50 degrees, the focal length of 100 mm and the wavelength of 355 nm in the processing range of 60 mm*60 mm. The UV laser passing the lens of the invention has small focusing spots and concentrated energy, and can be usedfor marking or drawing on some processed special materials with superfine effects.

Owner:HANS LASER TECH IND GRP CO LTD

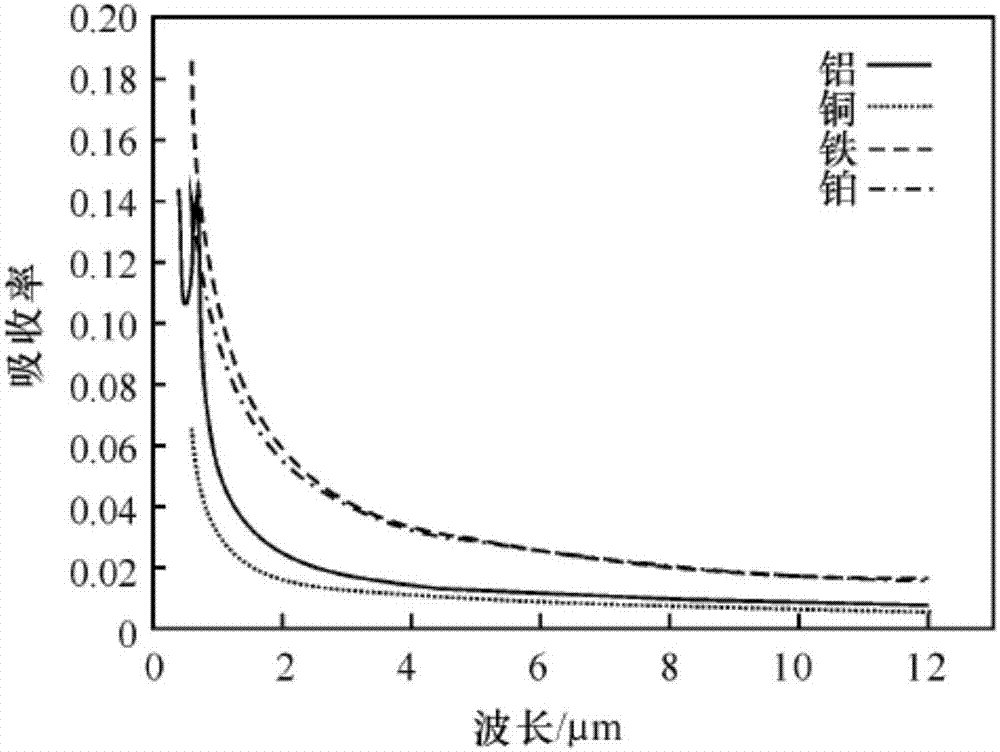

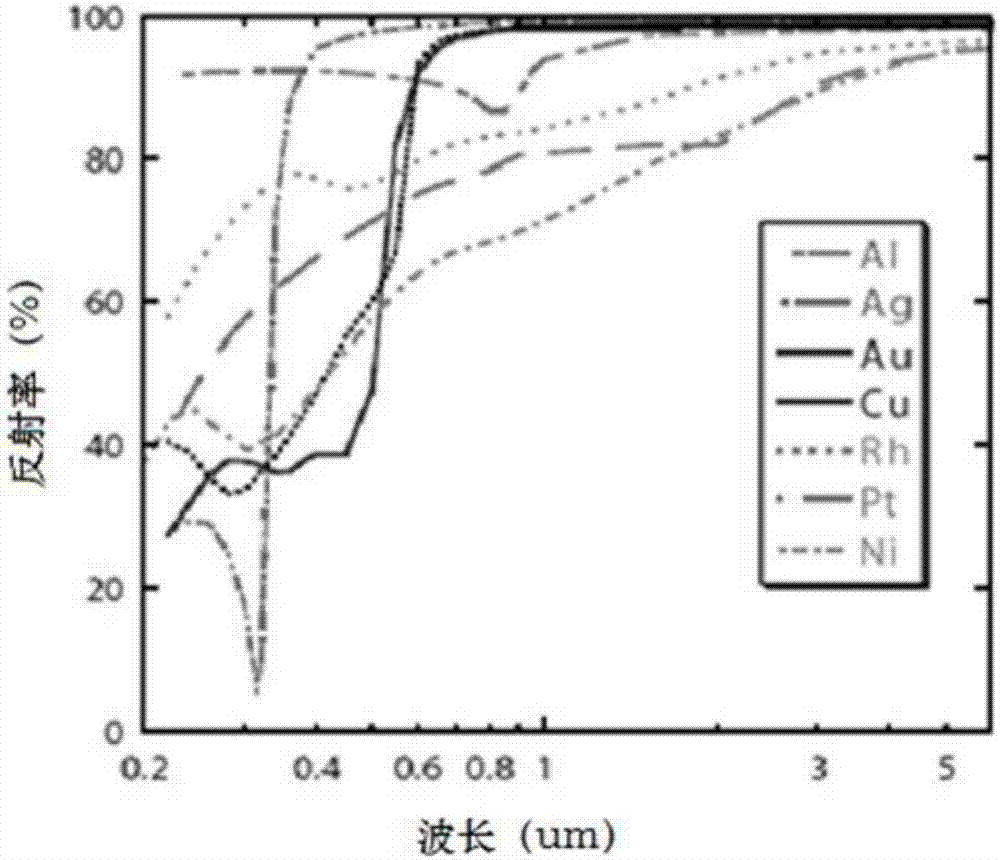

Short-wavelength efficient stable high-reflectivity metal laser welding system

PendingCN107971631AReduce lossLaser output power is stableLaser beam welding apparatusBeam splittingPrism

Owner:CHANGZHOU INNO MACHINING +1

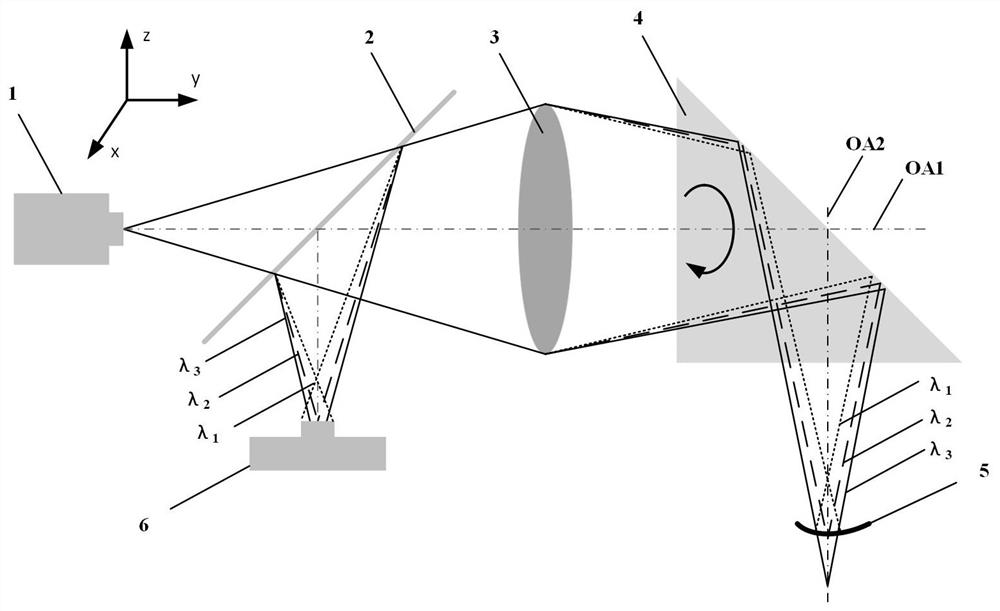

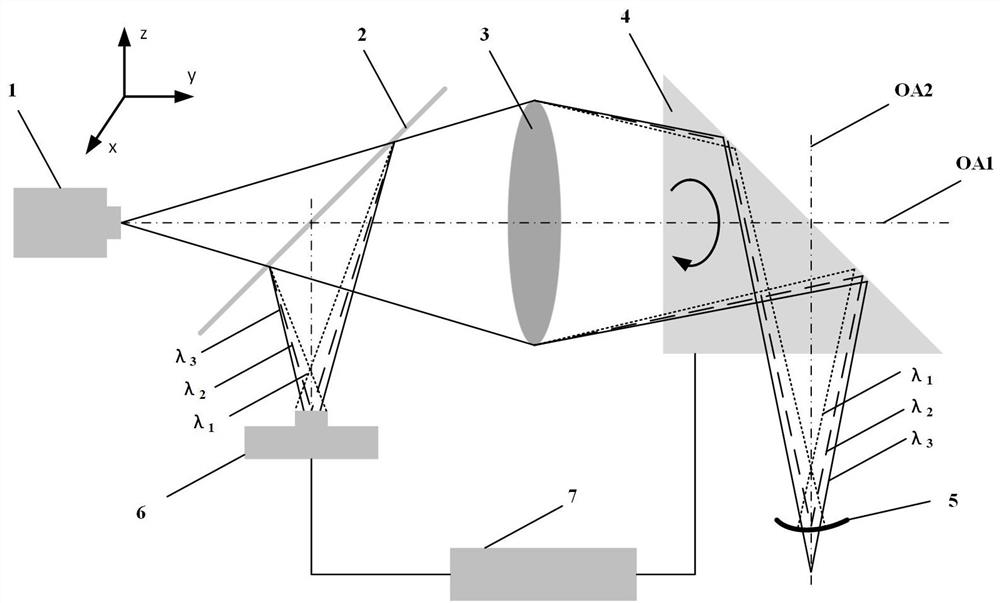

Dispersion confocal autorotation endoscopic detection method and device

PendingCN112444523ANo wearImprove measurement efficiencyOptically investigating flaws/contaminationUsing optical meansOptical axisLight beam

The invention belongs to the technical field of dispersion confocal displacement measurement, wherein the detection of the inner surface topography information of a hole sample can be rapidly achievedby using a self-rotating light beam deflection technology and combining a dispersion confocal displacement measurement technology. According to the method, a light beam deflection mechanism is used for deflecting a measurement light beam emitted by a dispersion objective lens by a certain angle and focusing the measurement light beam on the inner surface of a hole sample, a confocal spectrum detection system is used for spatially filtering the light beam reflected by the hole sample and detecting the spectral information of the light beam, the displacement information of the inner surface ofthe hole sample in the optical axis direction of the measurement light beam is obtained by processing the detected spectral information, and the optical axis of the measurement light beam rotates around the optical axis of the dispersion objective lens to be focused at different positions of the inner surface of the hole sample by rotating the light beam deflection mechanism, so that the displacement information of different positions of the inner surface of the hole sample in the optical axis direction of the measurement light beam is obtained. According to the invention, the light beam deflection technology and the dispersion confocal measurement technology are combined, so that the inner surface topography information of the hole sample can be directly measured, and a new idea is provided for detection of the inner surface size error, the shape error, the position error and the defect information of the hole sample.

Owner:绍兴钜光光电科技有限公司

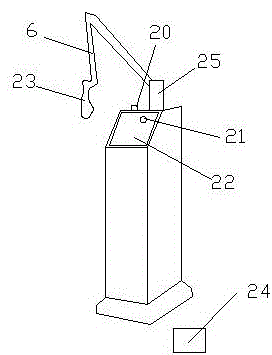

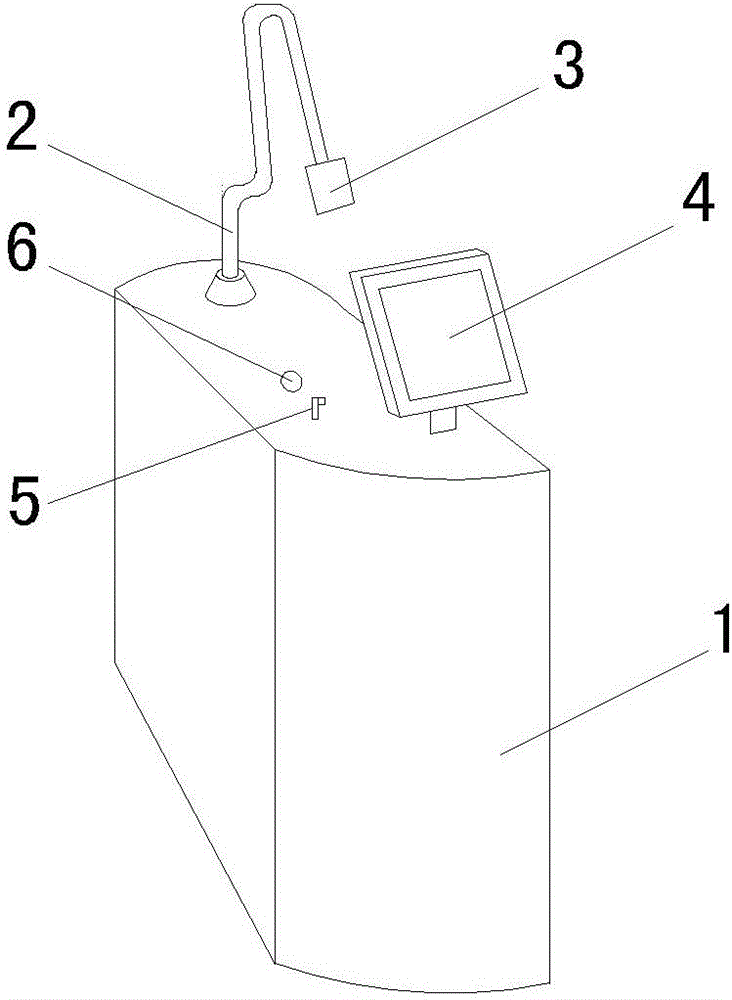

CO2 laser therapeutic instrument

InactiveCN106073893AGood laser modeFocus spot is smallDiagnosticsSurgical instrument detailsGalvanometerSelf-diagnosis

The invention discloses a CO2 laser therapeutic instrument. The instrument comprises a main body, wherein the main body comprises a laser main power supply, a main control panel (LCD touch screen), a pedal switching and an articulated arm, wherein the joint arm is fixed on an articulated arm seat; a scanning galvanometer is fixed at the other end of the articulated arm; the articulated arm is a seven-joint spring type light-guide articulated arm, and a reflector M1, a reflector M2, a reflector M3, a reflector M4, a reflector M5, a reflector M6 and a reflector M7 are arranged on joints of the seven-joint articulated arm; and a sealed-off CO2 laser and an indicating light are arranged inside the main body, and a shutter and a germanium wafer are arranged above the sealed-off CO2 laser. The CO2 laser therapeutic instrument is of a vertical structure, has the characteristics of high cutting speed, good coagulation effect, slight hemorrhage during operation, clear operative field and the like, is flexible and convenient to use and large in operating area, has high laser power stability, randomly preset volume and status self-diagnosis indication, and can be used in sickrooms, beauty salons and private clinics.

Owner:合肥安博罗医疗器械有限公司

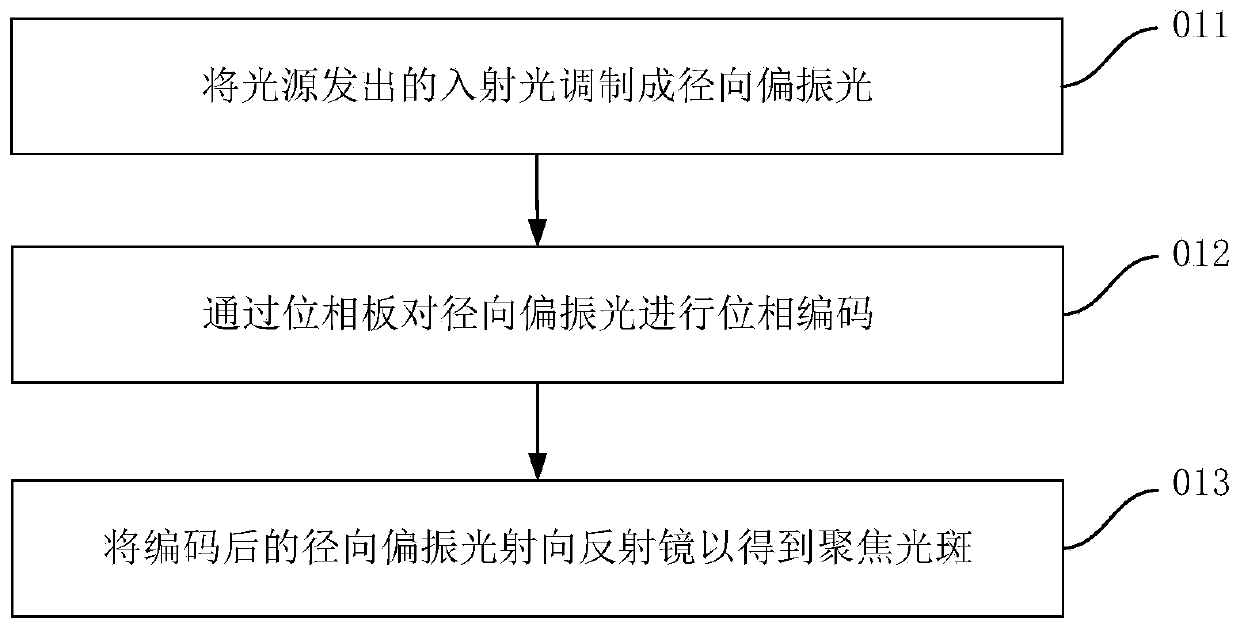

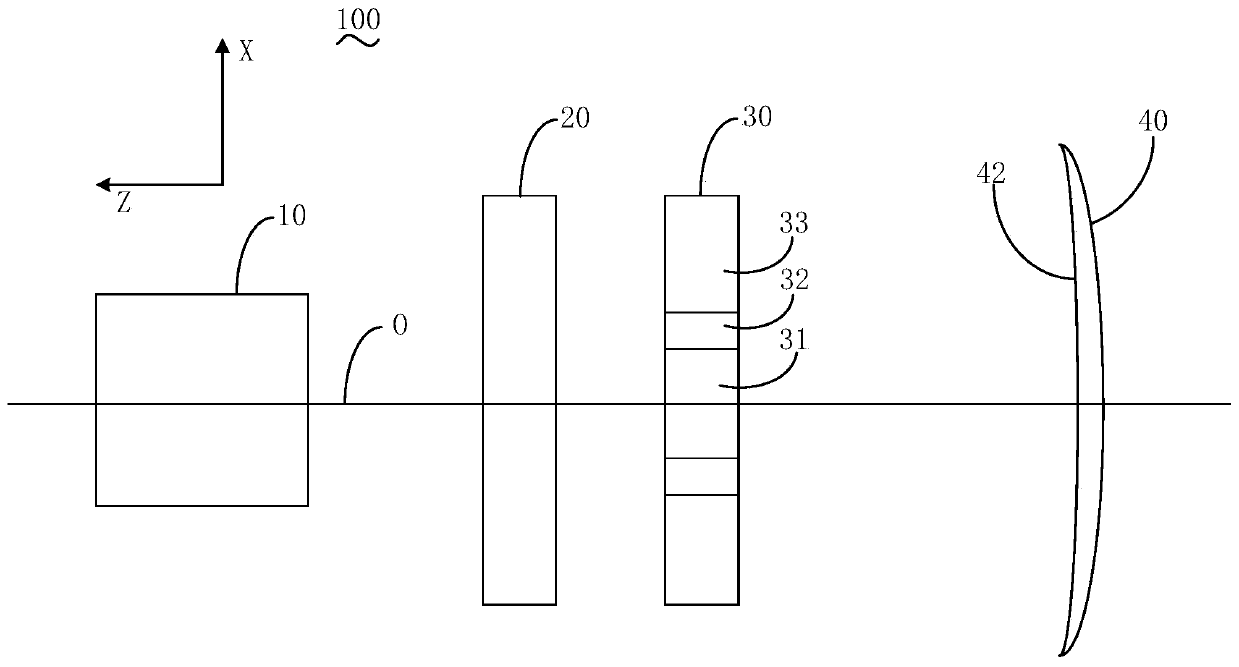

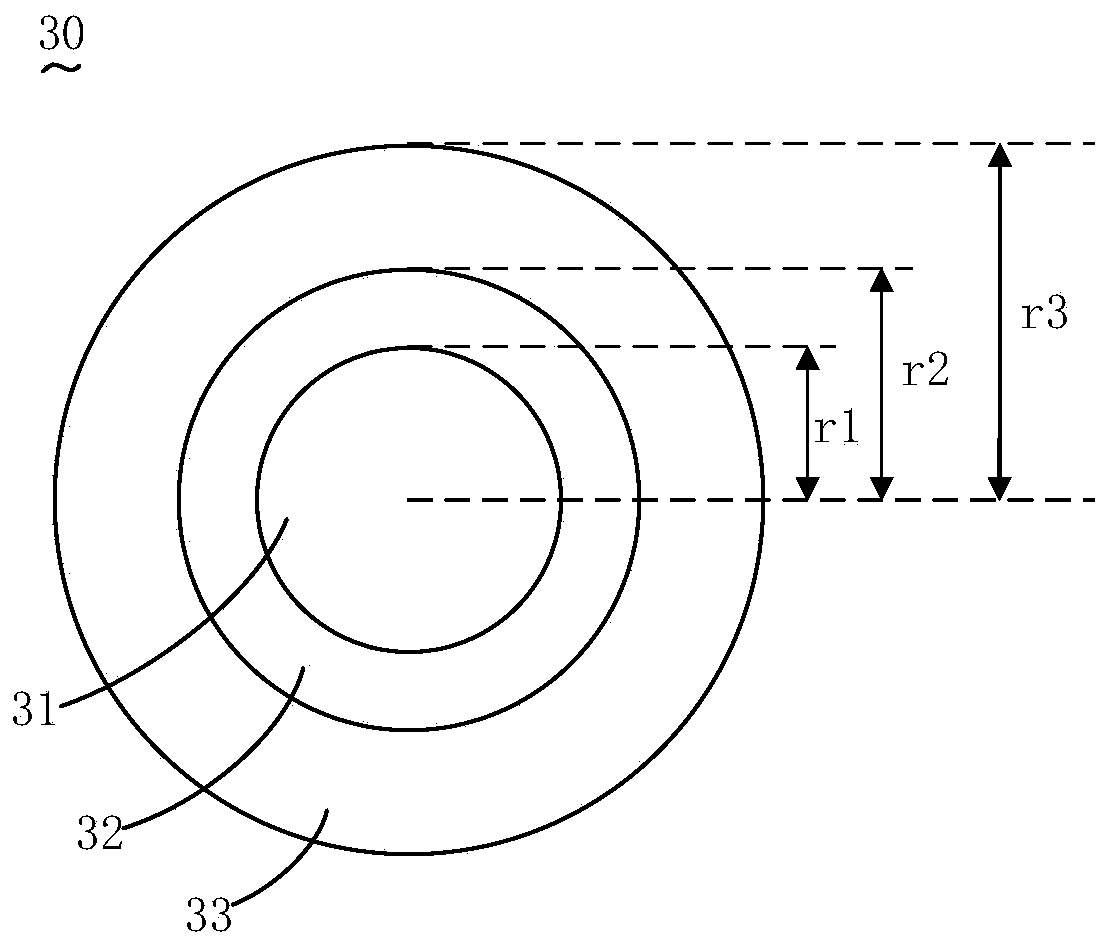

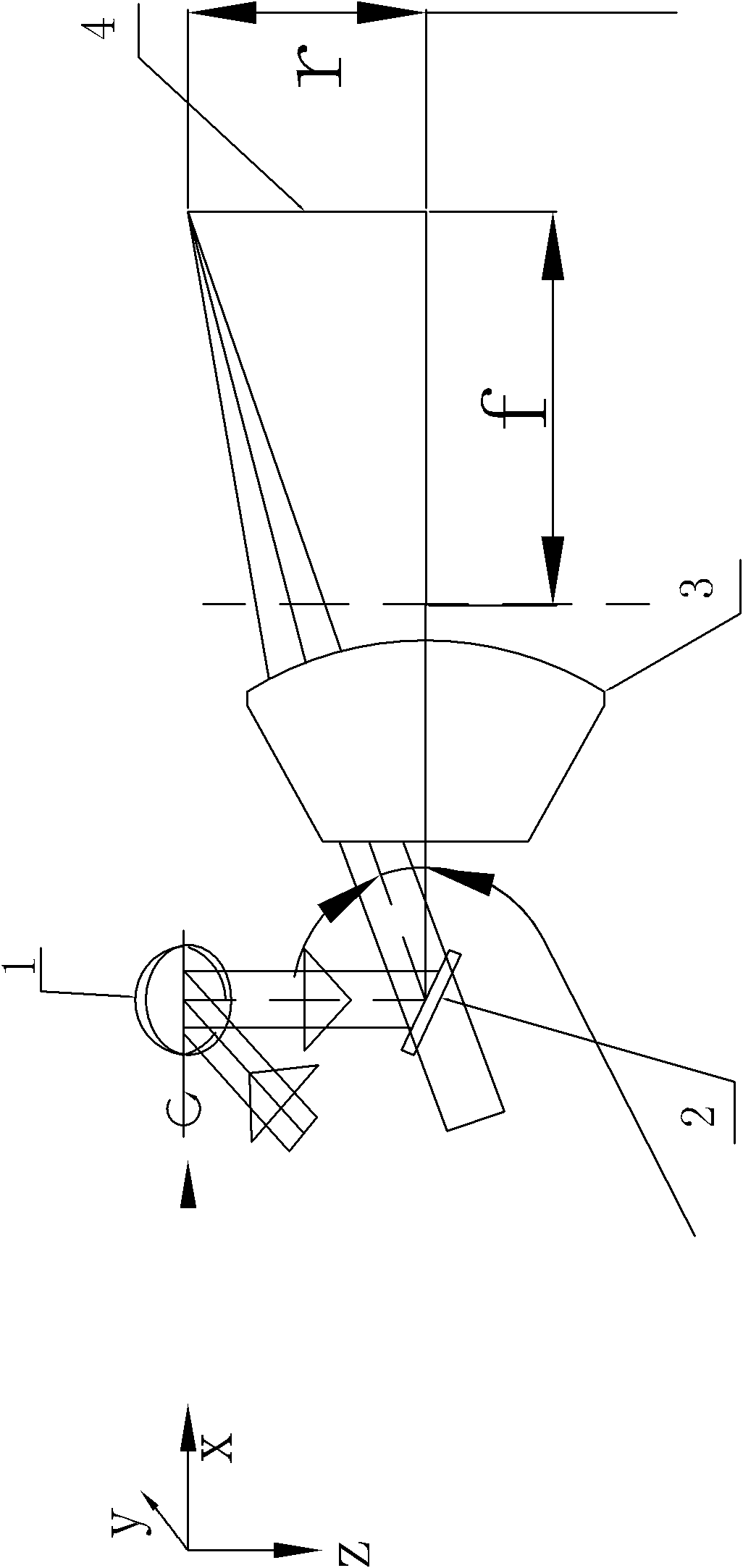

Focusing method and focusing device

ActiveCN111221139AFocus spot is smallDesign difficulty and low cost requirementsOptical elementsMechanical engineeringFacula

The invention provides a focusing method. The focusing method comprises the following steps: modulating incident light emitted by a light source into radially polarized light; performing phase encoding on the radially polarized light through a phase plate; and emitting the coded radial polarized light to a reflector to obtain a focusing light spot, wherein the reflecting surface of the reflector is a paraboloid. According to the focusing method and the focusing device, phase encoding is carried out on the modulated radial polarized light; focusing is carried out by using a reflecting mirror ofwhich the reflecting surface is a paraboloid to obtain a focusing light spot; compared with a lens, the reflector can realize larger NA (such as NA = 1), so the phase plate can perform phase encodingwith fewer light-transmitting areas, not only can obtain smaller focusing light spots, but also has lower design difficulty and cost requirements, and can meet the requirements of industrial production.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Extrusion forming laser welding brazing method

ActiveCN106077862ASpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMelting tankLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

F-theta lens and optical system

ActiveCN102809804BGuaranteed energy concentrationFocus spot is smallOptical elementsCamera lensLength wave

Owner:HANS LASER TECH IND GRP CO LTD

Dense array-type concentrating solar photovoltaic device

InactiveCN106024961ASmall focal lengthLower the altitudePhotovoltaic energy generationSemiconductor devicesFresnel lensPlanar substrate

The invention relates to a dense array-type concentrating solar photovoltaic device, and belongs to the field of photovoltaics. The dense array-type concentrating solar photovoltaic device comprises a Fresnel lens array, a planar substrate and at least two photocells, wherein the Fresnel lens array is located on a top layer; the Fresnel lens array is an overall lens, the upper surface is a plane and the lower surface is provided with at least two groups of sawteeth in a concentric ring form; each group of concentric rings form a Fresnel lens; all Fresnel lenses form an array form; the planar substrate is arranged on a bottom layer; at least two photocells are arranged on the upper surface of the planar substrate and are arranged in an photocell array form; the number of the photocells in a photocell array is the same as that of the Fresnel lenses in the Fresnel lens array; and each photocell corresponds to one Fresnel lens. The dense array-type concentrating solar photovoltaic device provided by the invention is simple in heat dissipation, short in concentrating focal length and high in solar energy utilization ratio; and an electrode does not need to be arranged in a photocell chip.

Owner:KUNSHAN KEDE NEW ENERGY TECH

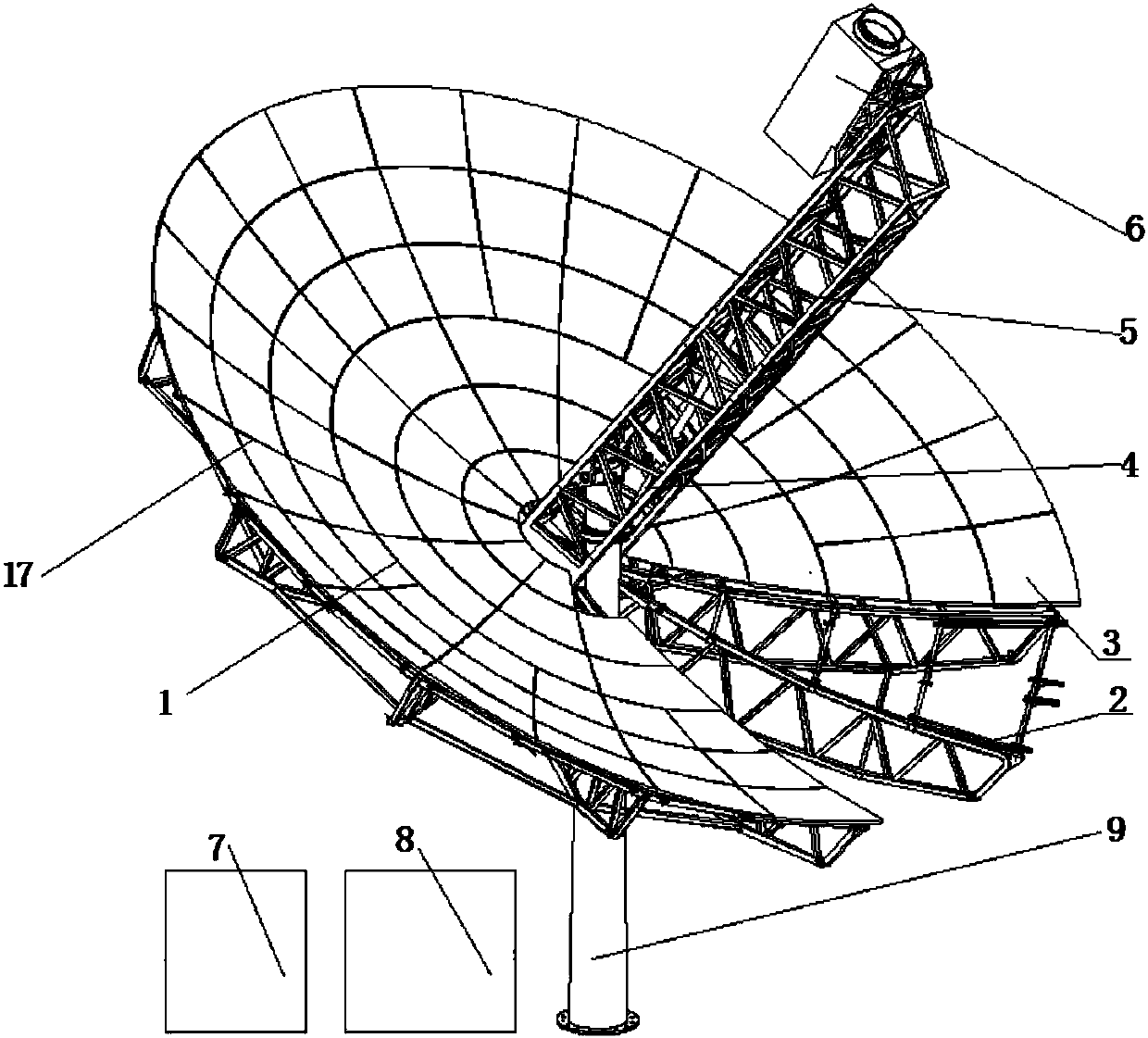

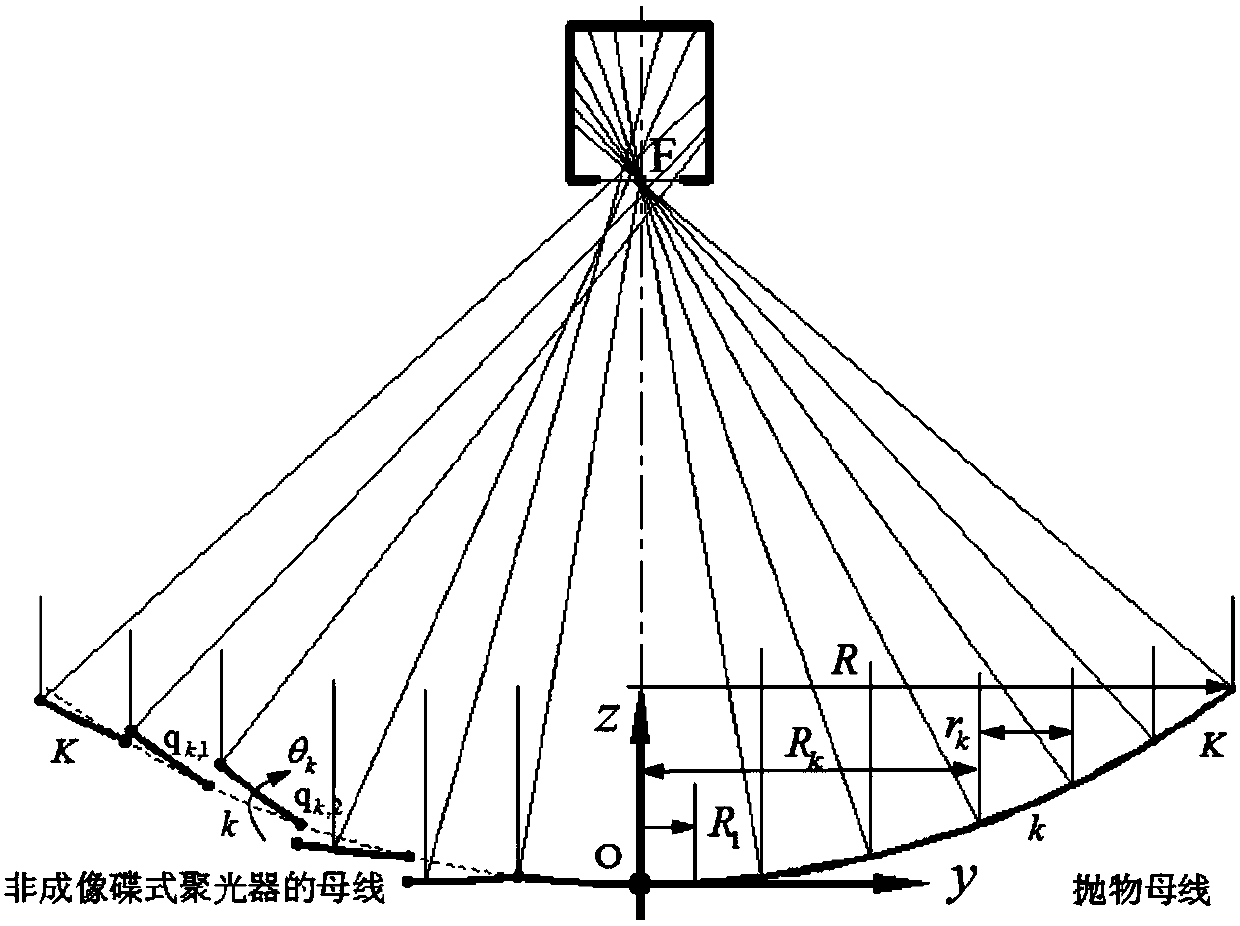

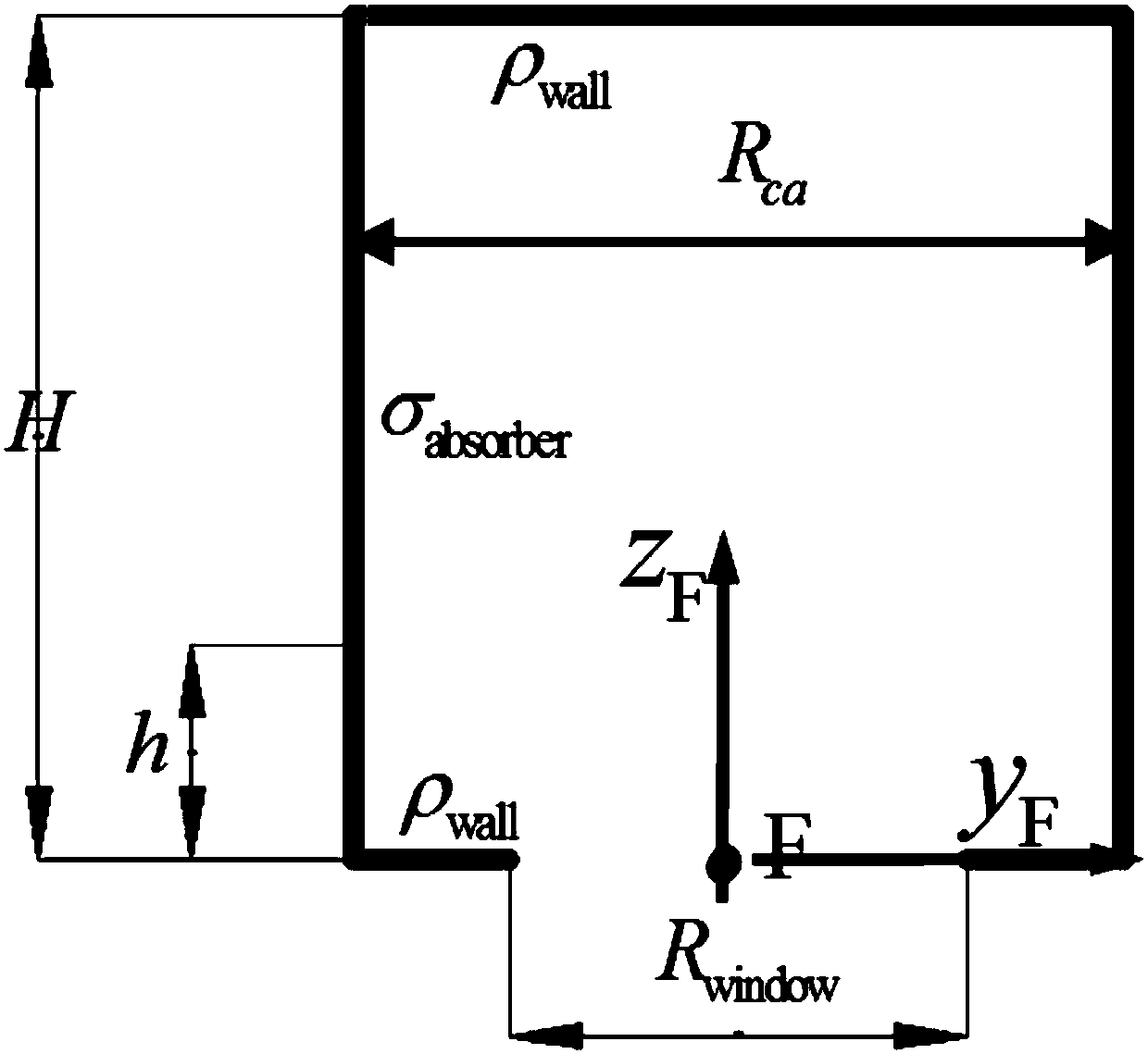

Non-imaging disc type condenser and design method thereof

The invention discloses a design method of a non-imaging disc type condenser. The design method includes the steps of establishing a global coordinate system, installing a cavity receiver on a focal point position of an ideal parabolic dish condenser, establishing a spatial equation of a curved surface of a reflector of the non-imaging disc condenser, establishing a radius model of the focused light spots of each ring of the reflector surface, establishing a mathematical model with the energy flow uniformity as a target and the rotating angle of each section of a parabolic bus as an optimization variable, optimizing the established mathematical model, finally determining the curved surface shape of the reflector of the non-imaging disc condenser matched with a cavity receiver to obtain uniform energy flow distribution. The reflector of the non-imaging disc condenser is composed of multi-ring reflector surfaces, the curved surface equation of each ring of reflector surfaces is different, so that the energy flow uniformity can be remarkably improved, and the peak value of the local condensation ratio can be reduced. The formation of high-temperature hot spots is effectively avoided,so that the service lifetime of a heat absorber is prolonged, and reliability of the heat absorber is improved.

Owner:HUNAN UNIV OF SCI & TECH

Laser multipoint focusing processing system

ActiveCN102653032BFocus spot is smallSmall Optical System RequirementsGlass severing apparatusLaser beam welding apparatusBeam expanderOptical axis

The invention discloses a laser multipoint focusing processing system, wherein the structure of the system is as follows: a laser, a beam expander, a light guide lens, a focusing lens and first and second total reflection mirrors are sequentially located on the same light path, the first total reflection mirror is a spherical mirror or non-spherical mirror processed with a minipore at the middle part, and the curvature radius of the first total reflection mirror is smaller than a half of the minimal distance between the two total reflection mirrors; at work, the concave surface of the first total reflection mirror faces to an xy two-dimensional work table, and the optical axis of the first total reflection mirror is overlapped with the optical axis of the laser; the centre of the minipore is overlapped with the optical axis of the laser; and the position of the focusing lens is adjustable up and down, and the distance between the two total reflection mirrors is adjustable. The system can convert a single focusing point introduced by the laser to a transparent material into a plurality of focusing points with the same optical axis, thereby improving the laser energy absorption uniformity of the cut and separated transparent brittle material along the thickness direction so as to reinforce the heating uniformity of the transparent material along the thickness direction and sharply reduce the stress difference along the thickness direction to cut and separate the transparent brittle material in high quality, high efficiency and high success rate.

Owner:武汉飞能达激光技术有限公司

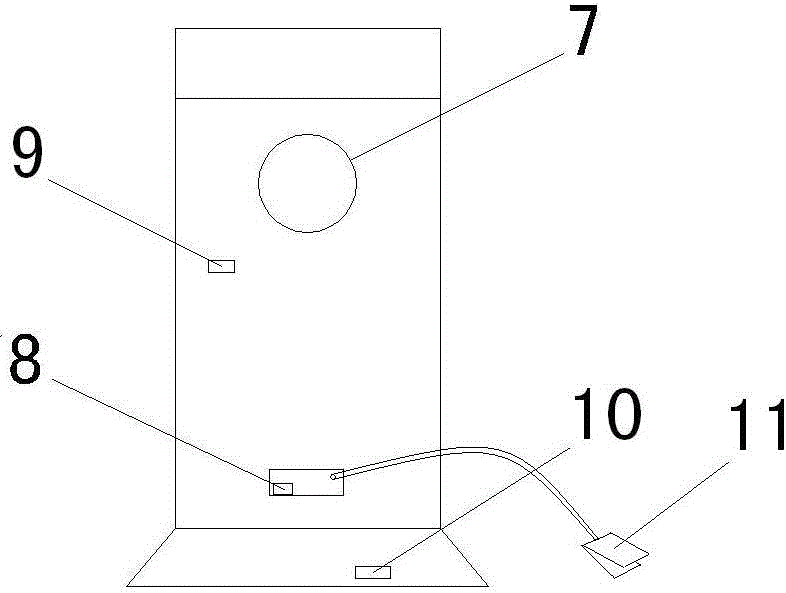

Photoelectric sensor and infrared thermometer

PendingCN106969842ARealize non-contactRealize remote temperature measurementPyrometry using electric radation detectorsLight sensingLight spot

The invention relates to a photoelectric sensor and an infrared thermometer. Multiple visible light sources are symmetrically arranged by taking an infrared light sensing chip as the center. The light sensing face of the infrared light sensing chip and the light emitting faces of the variable light sources share one plane. The photoelectric sensor cooperates with a focusing lens and a detection circuit to form the infrared thermometer. Thus, it is achieved that, when non-contact long-distance temperature measurement is performed on a to-be-measured object, and when light spots of the visible light sources are focused on the surface of the to-be-measured object, according to the reversibility of the light, infrared light irradiated out, at the central positions of the light spots, where the surface of the to-be-measured object is arranged is rightly transmitted to the light sensing face of the infrared light sensing chip. The infrared light sensing chip converts light signals into electric signals, and the electric signals are converted into temperature signals to be output through a detection circuit electrically connected with the photoelectric sensor. Thus, the non-contact long-distance temperature measurement of the to-be-measure object is achieved; the position of temperature measurement points is precise; and temperature measurement of tiny targets within the range being less than 0.1mm can be achieved.

Owner:李军

Pedal laser skin treatment instrument

InactiveCN106075744AGood laser modeGood wavelength biological effectLight therapyLaser power scalingEngineering

The invention discloses a pedal laser skin treatment instrument, which comprises a host. The top of the host is provided with a spring-type light guide joint arm, a touch-type operation liquid crystal screen, a power key and an emergency stop switch; the tail end of the spring-type light guide joint arm is connected with a scanning mirror; the scanning mirror is connected with a laser generator in the host; the back surface of the host is provided with a cooling fan, a power socket, a water adding port and a water outlet; the water adding port and the water outlet are both connected with a heat exchanger arranged in the host; the heat exchanger coats the laser generator; and the back surface of the host is also connected with a pedal switch via a socket. The pedal laser skin treatment instrument has the advantages that the laser mode is good; the focusing spot is small; the power density is high; wavelength biological effects are good; the blasting speed is quick; pigment clearing effects are good; bleeding during operation is little; the operative view field is clear; the use is flexible and convenient; the operation face is large; the laser power stability is high; and the service life of products is greatly enhanced.

Owner:合肥安博罗医疗器械有限公司

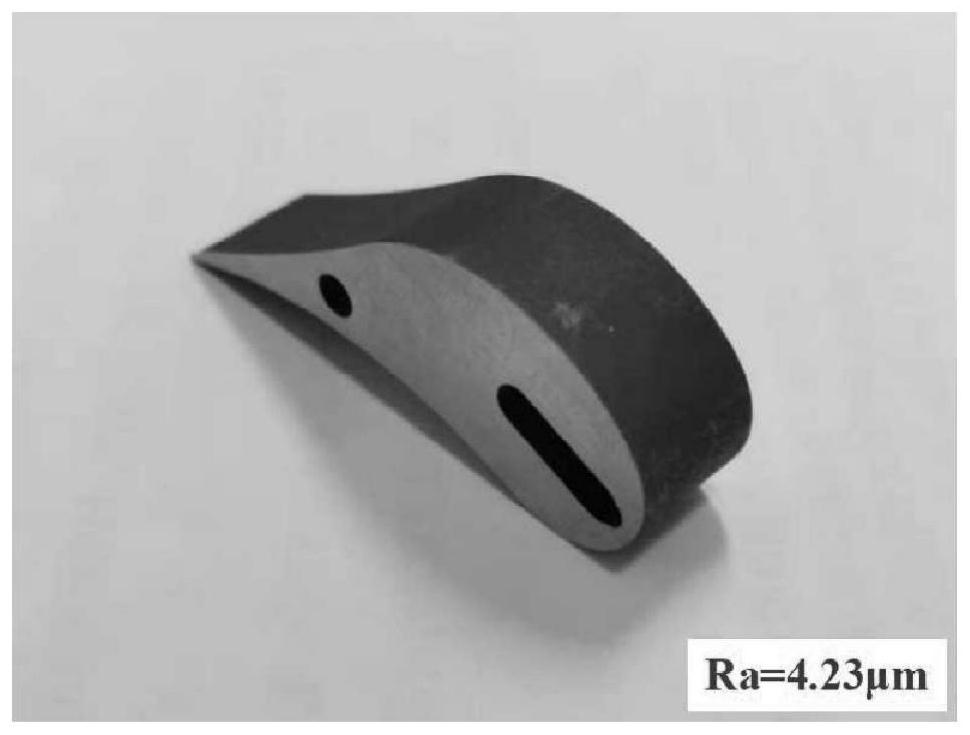

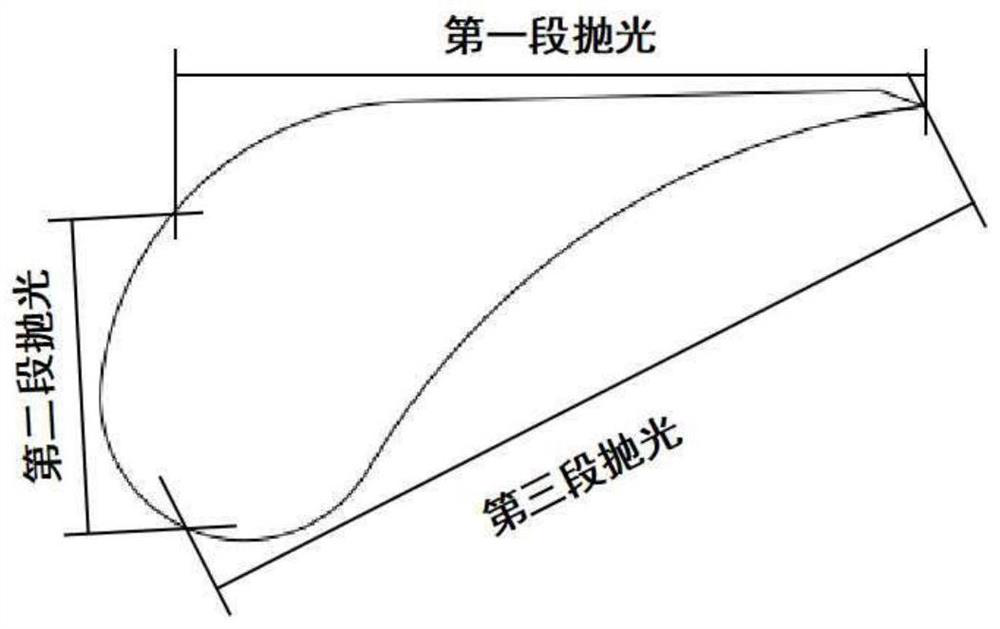

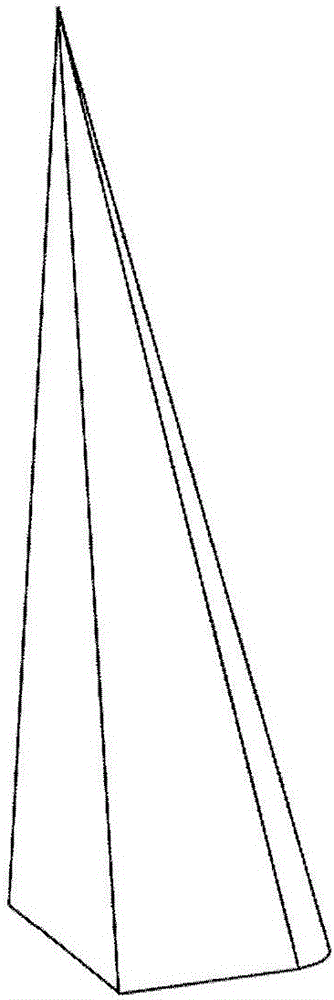

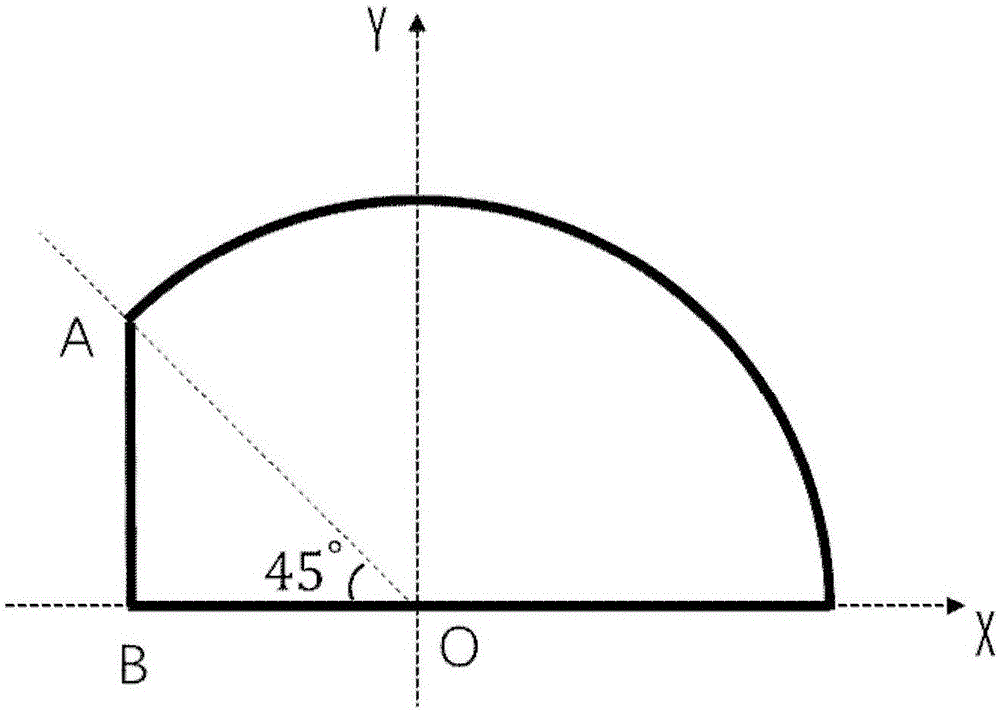

Segmented defocusing laser polishing method for turbine guide vane of oxygenerator

ActiveCN112589264AImprove efficiencyFocus spot is smallLaser beam welding apparatusGalvanometerManipulator

The invention provides a segmented defocusing laser polishing method for a turbine guide vane of an oxygenator. The rough surface of the turbine guide vane is efficiently polished in a laser polishingmode, and segmented defocusing polishing is conducted on the irregular rough surface of the turbine guide vane by means of the characteristic that laser polishing equipment has the same polishing effect under different defocusing amounts; according to the method, according to the defocusing amount range of the laser polishing equipment and the size and shape of the turbine guide vane, the to-be-polished side surface of the turbine guide vane is segmented, and in the defocusing amount range with the same polishing effect, laser polishing is conducted on different segments, so that full-coverage polishing of the irregular surface of the guide vane can be achieved; with adoption of the method, the problems of ultrahigh cost and complex control system caused by introduction of a manipulator and a three-dimensional galvanometer for polishing of irregular curved surfaces are avoided, and the method has the characteristics of high machining precision, simple technological process and small influence on a base material.

Owner:ZHEJIANG UNIV OF TECH

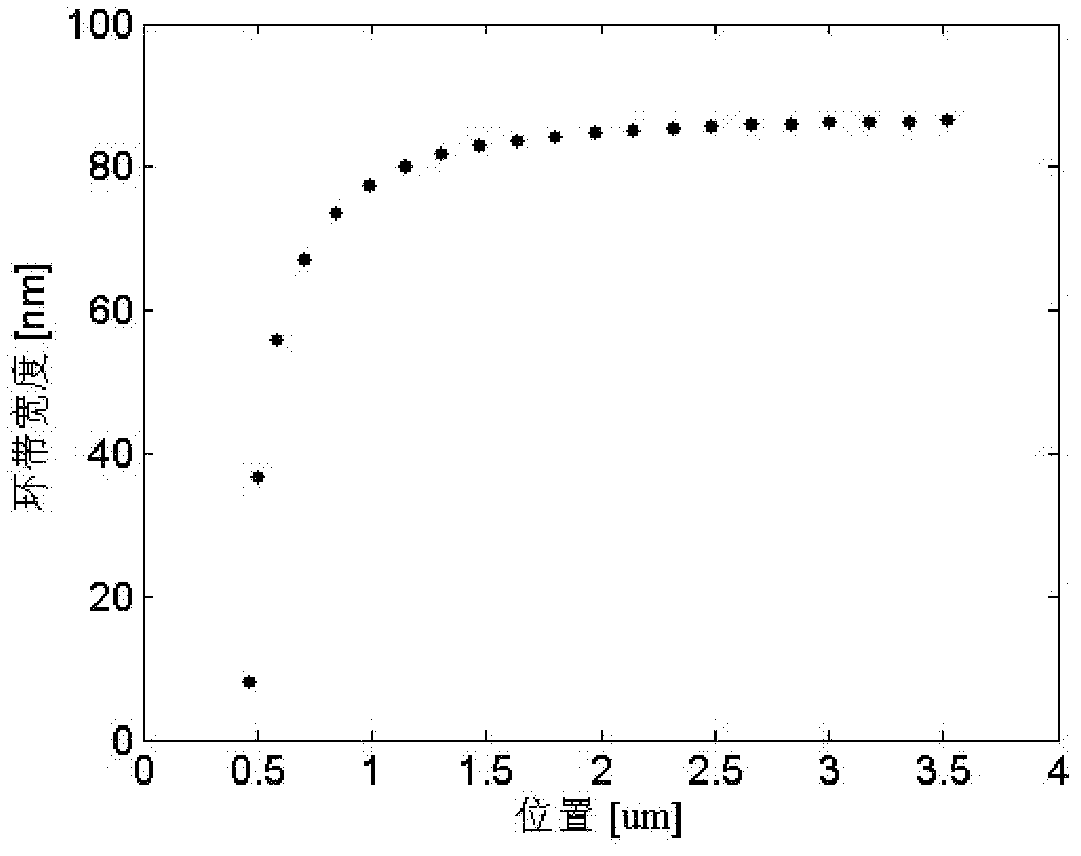

Light focusing structure

The invention discloses a light focusing structure. The light focusing structure is a three-dimensional taper asymmetric structure made of photoresist; two faces of the sides of the tapered asymmetric structure are tapered planes, and the other face is a tapered arc surfacer; the bottom surface of the tapered asymmetric structure is a plane; and the surface of the tapered non-asymmetric structure is plated with a metal layer. Incident light is coupled as plasma wave on the metal surface to focus on a structure tip, which can break through a diffraction limit and makes the diameter of a focusing facula smaller than 100 nanometers. Besides, the light focusing structure has no a symmetric axis in any direction, so that the light focusing structure can effectively utilize polarized light energy of any polarization direction under radiation of a wide light spectrum light source without polarization processing and can maximally utilize the incident light energy. The light focusing structure is high in feasibility, can be used for manufacturing the optical fiber probe to be used for near field optical detection, can be applied in the optical cutting edge field like the single molecule fluorescence imaging and has a high scientific research value and a wide market application prospect.

Owner:SOUTHEAST UNIV

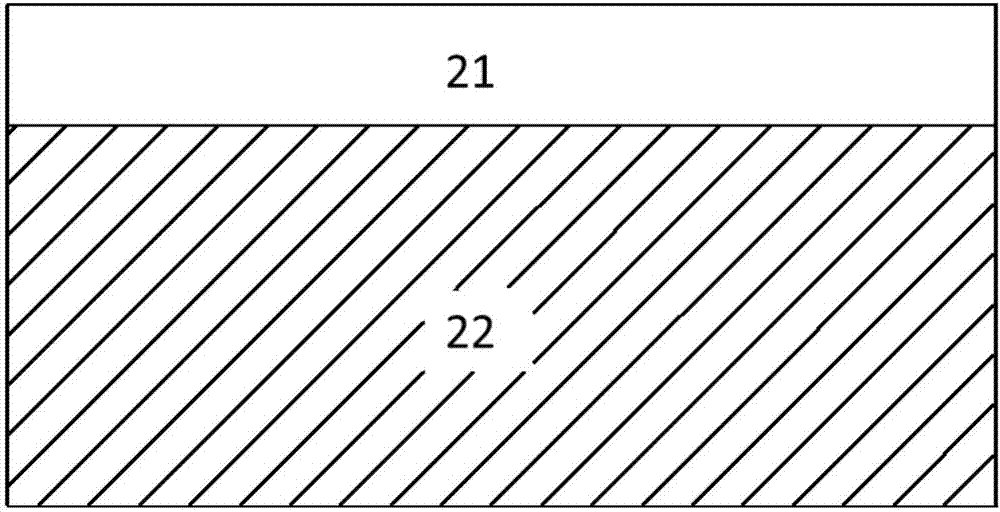

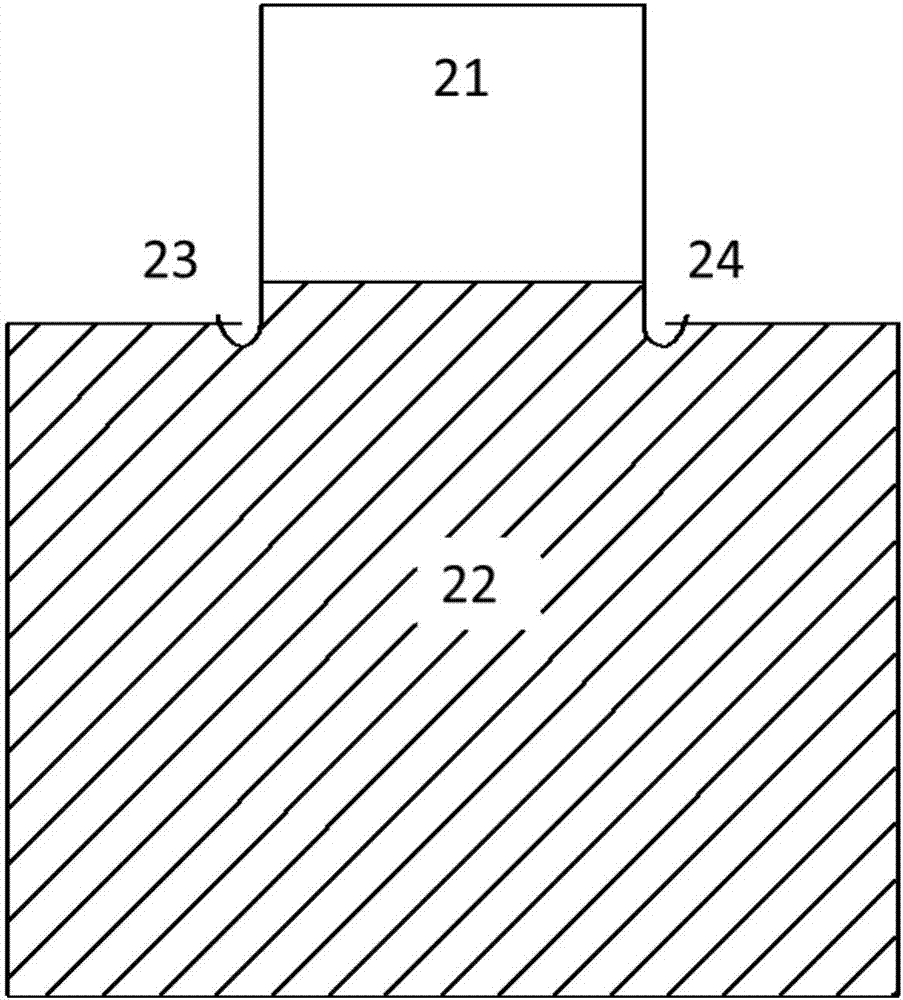

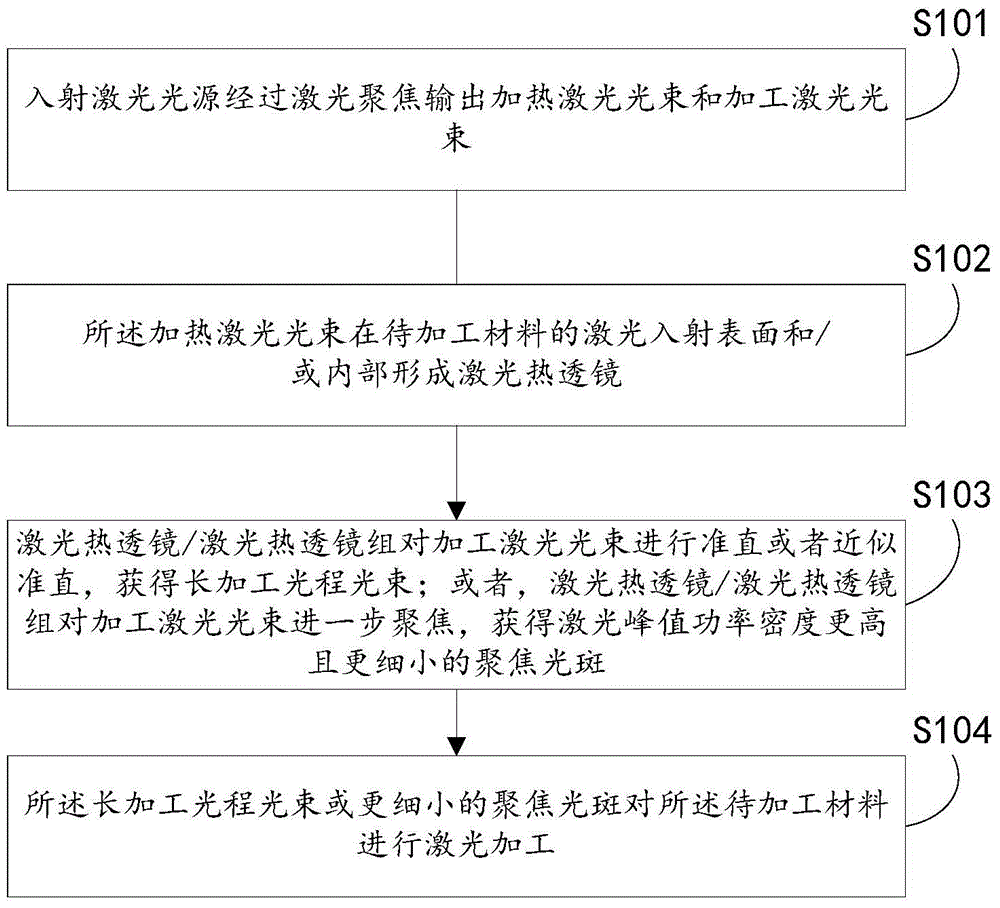

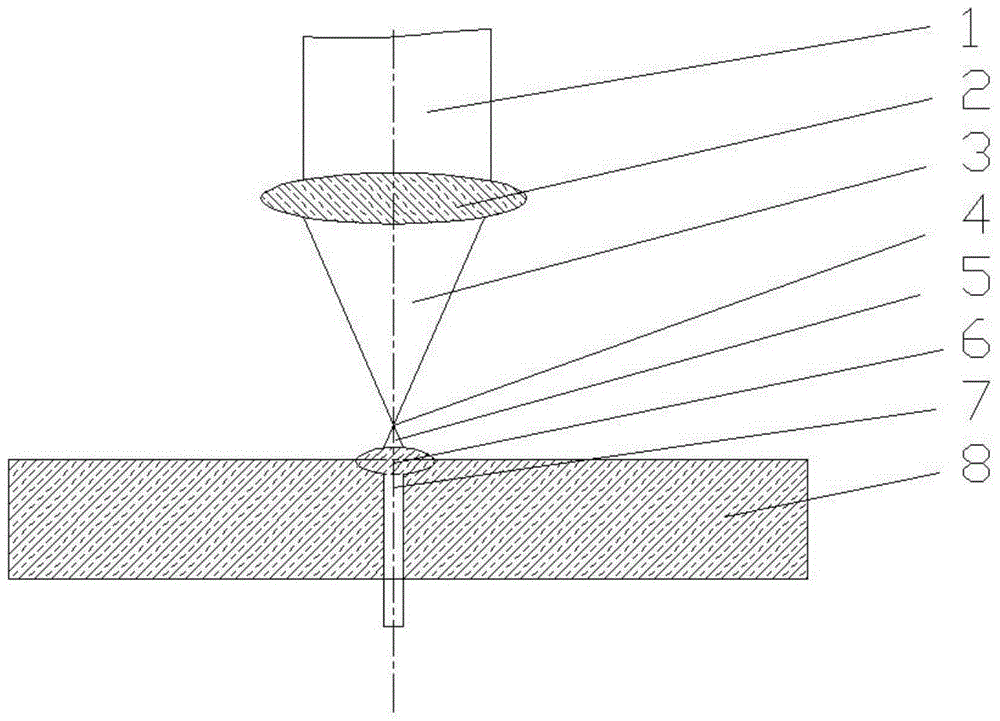

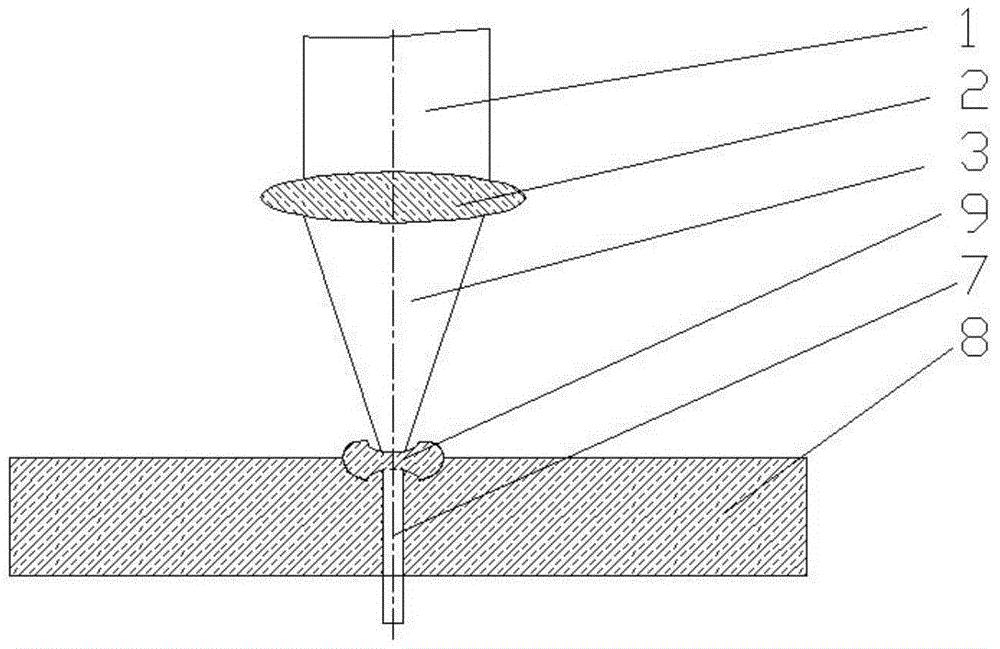

Laser processing method and laser processing system

ActiveCN104526160BHigh peak laser power densityFocus spot is smallLaser beam welding apparatusLaser processingLight beam

The invention discloses a laser machining method and system. The laser machining method comprises outputting heating laser beams and machining laser beams from an incident laser light source through laser focusing; forming a laser thermal lens or a laser thermal lens group on the laser incident surface of materials to be machined and or inside the materials to be machined through the heating laser beams; performing collimation or similar collimation on the machining laser beams through the laser thermal lens or the laser thermal lens group to obtain the long machining optical path length beams or performing further focusing on the machining laser beams through the laser thermal lens or the laser thermal lens group to obtain high laser peak power density of small focusing light spots; performing laser machining on the materials to be machined through the long machining optical path length beams or the focusing light spots. According to the laser machining method, the long machining optical path length beams in comparison with the traditional laser focal depth or the high laser peak power density of small focusing light spots can be obtained through the thermal lens effect and the laser machining method is suitable for machining of thick transparent or partially-transparent hard brittle materials.

Owner:张立国

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com