Light focusing structure

A focusing structure and asymmetric structure technology, applied in the field of light energy focusing, can solve the problems of inconvenient three-dimensional size, high price, and difficult structure control, etc., and achieve the effect of high feasibility and high scalability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

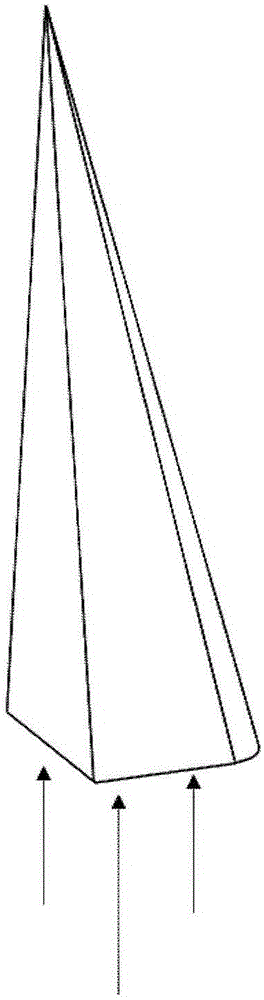

[0020] The object of the present invention is to provide a light focusing structure that can focus light energy on the tip of the three-dimensional structure under broad-spectrum lighting conditions.

[0021] The specific implementation plan is as follows:

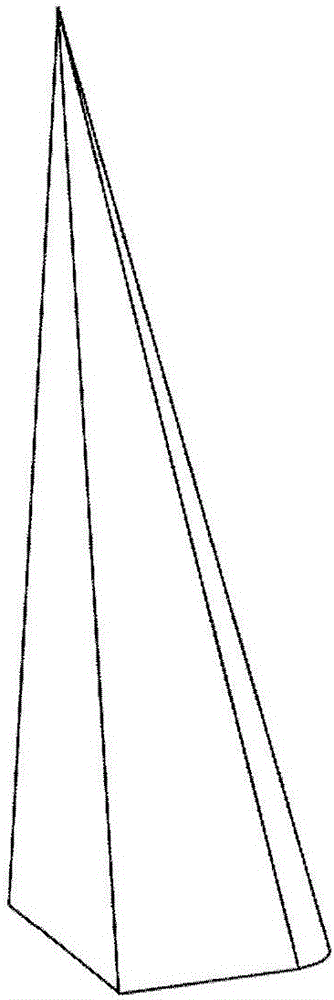

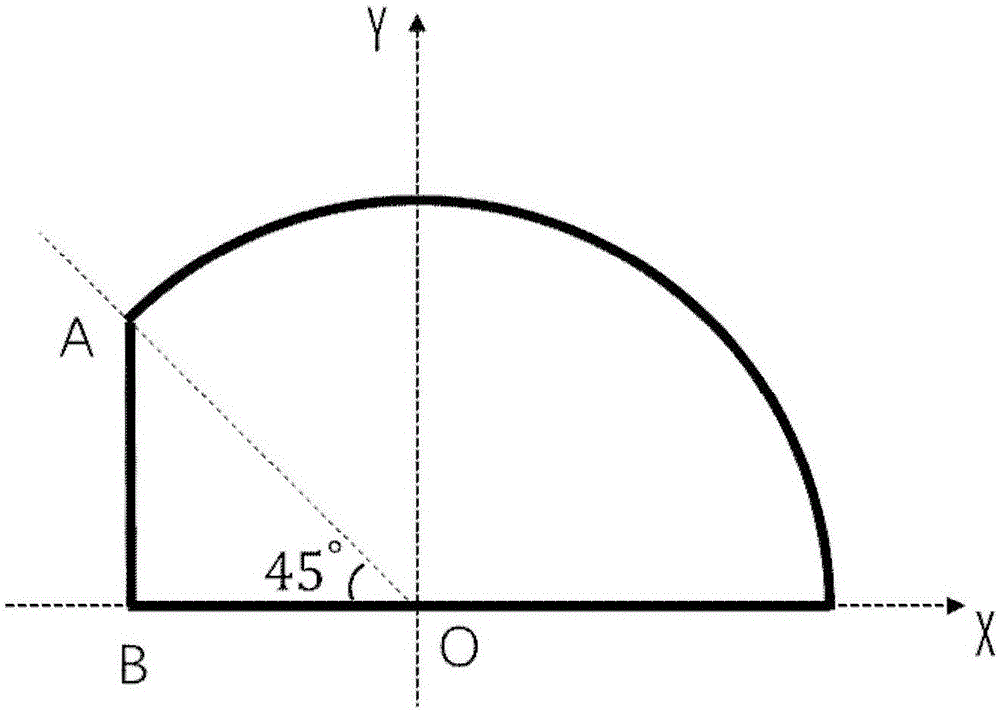

[0022] The structure is a three-dimensional tapered asymmetric structure made of photoresist. On the side of the tapered asymmetric structure, there are two tapered planes and the other tapered arc surface. The bottom surface of the conical asymmetric structure is a plane, and a metal layer is plated on the surface of the conical asymmetric structure. The arc surface of the cone is an arc on the bottom surface of the tapered asymmetric structure, and the two tapered planes are respectively the radius of the line segment AB and the line segment OB+arc on the bottom surface of the tapered asymmetric structure, so The ratio of the height of the three-dimensional conical asymmetric structure to the radius of the bottom surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com