Optical fiber laser three dimensional printer for preparation of nano-ceramic bone tissue engineering scaffold

A technology of bone tissue engineering and three-dimensional printing, applied in the field of equipment for preparing bone tissue engineering scaffolds, can solve the problems of high brittleness, low toughness, poor reliability and damage resistance, and achieve slow power attenuation, long service life, The effect of small focus spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0023] The present invention will be further described with reference to the accompanying drawings and specific embodiments.

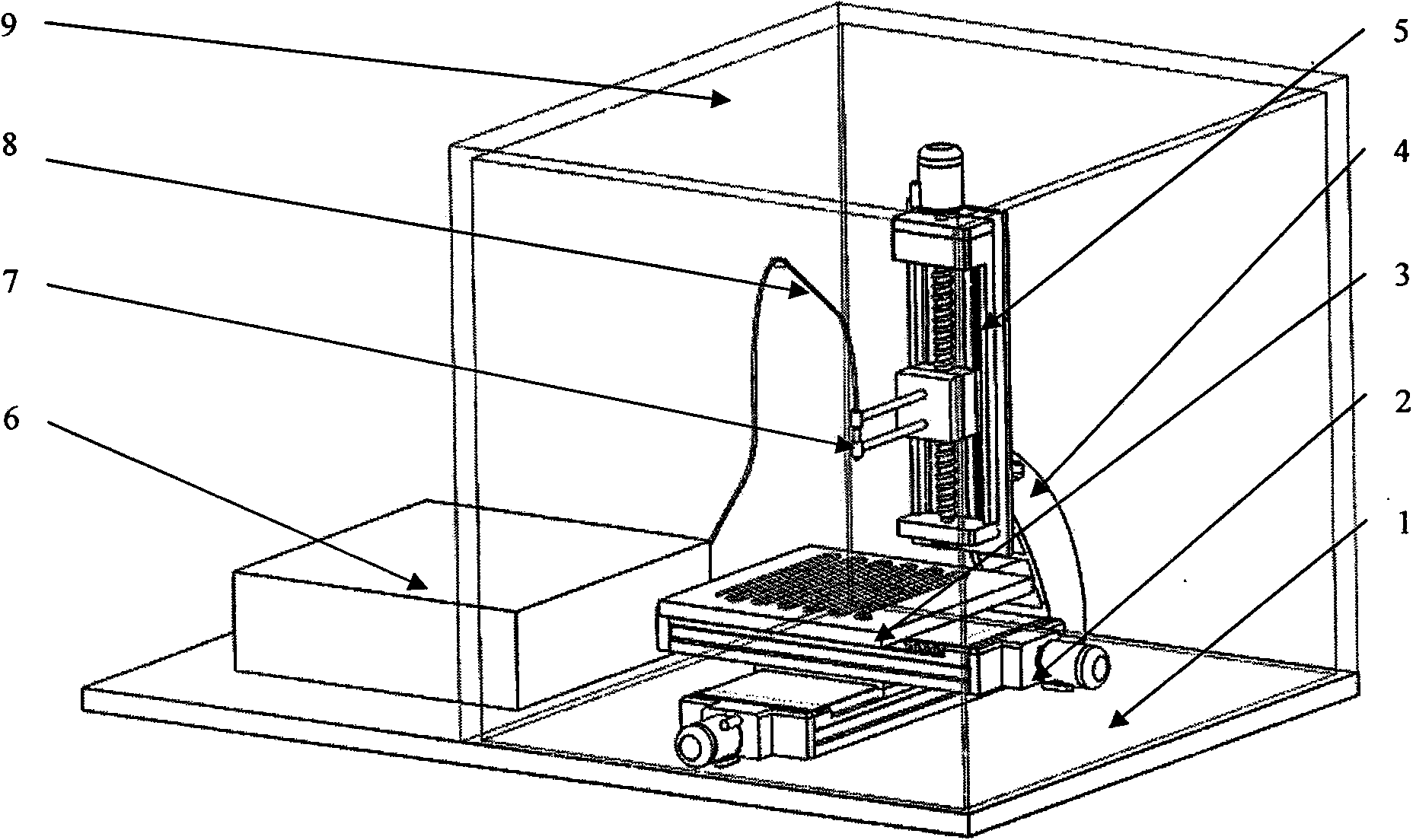

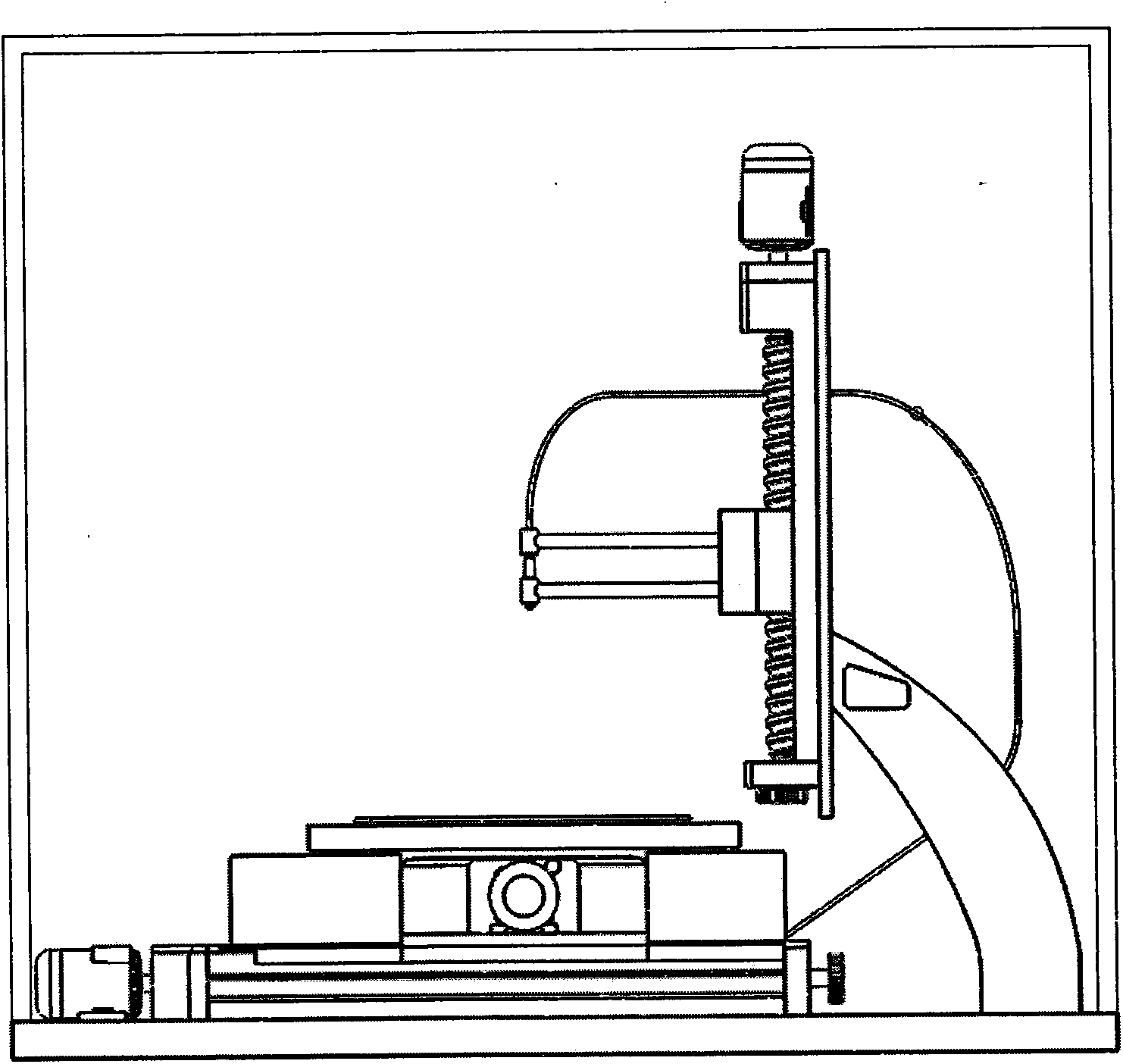

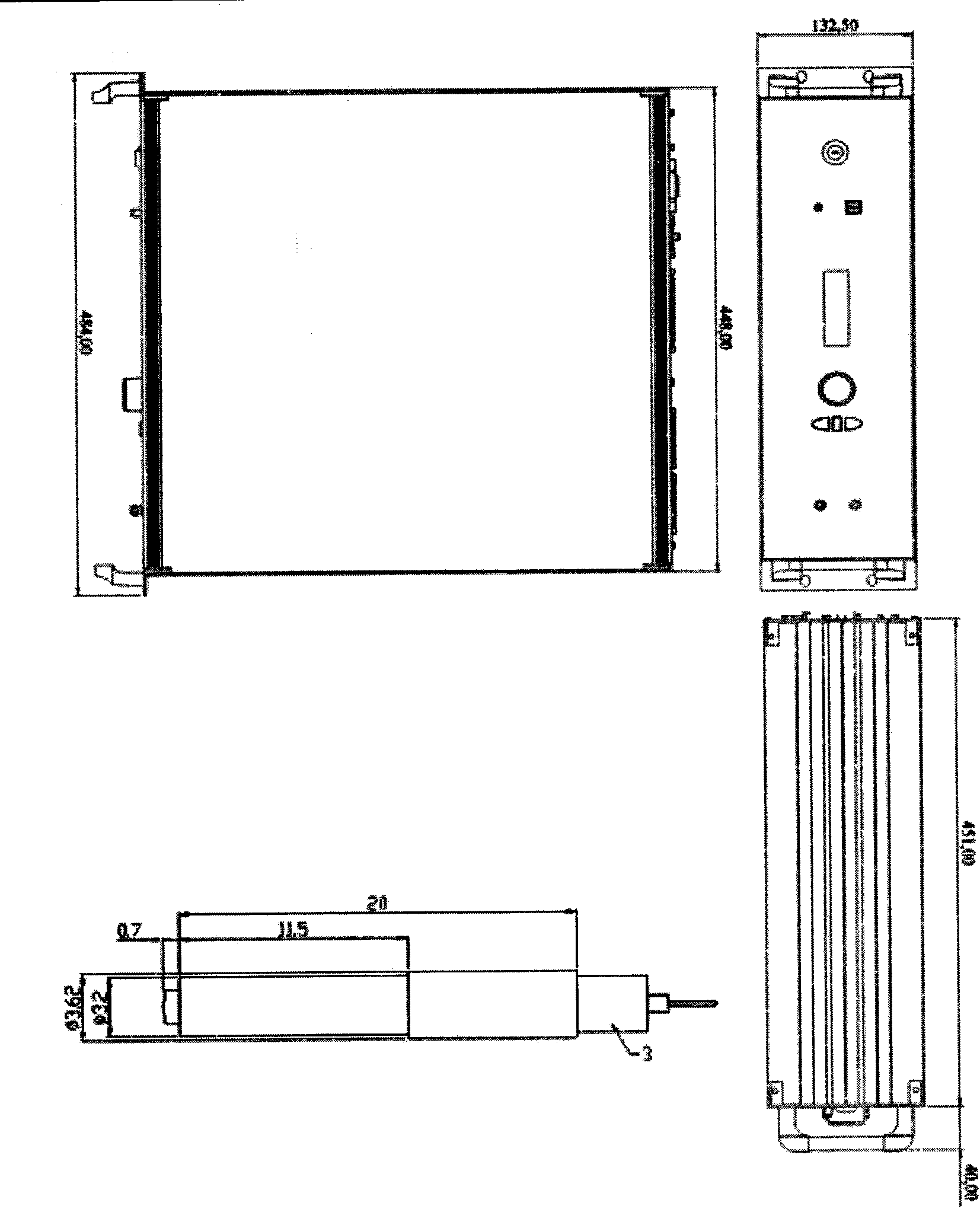

[0024] see figure 1 , figure 2 , image 3 and Figure 4 , the base (1) is provided with a horizontal movement mechanism (2) in the X-Y direction, a forming support plate (3) is installed on the horizontal movement mechanism (2) in the X-Y direction, and the base (1) is also A bracket (4) is provided, a Z-direction vertical movement mechanism (5) is arranged on the bracket (4), a laser focusing system (7) is installed on the Z-direction vertical movement mechanism (5), and a laser focusing system (7) is installed on the Z-direction vertical movement mechanism (5). The base (1) is also provided with a fiber laser (6), the fiber laser (6) and the laser focusing system (7) are connected by an optical fiber (8), and the above-mentioned components are placed in a vacuum in the extraction chamber (9).

[0025] The laser in the present invention selects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com