Segmented defocusing laser polishing method for turbine guide vane of oxygenerator

A laser polishing and oxygen generator technology, which is applied in laser welding equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of high cost of polishing curved surface equipment, and achieve the effect of high efficiency, simple process, and high-efficiency polishing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

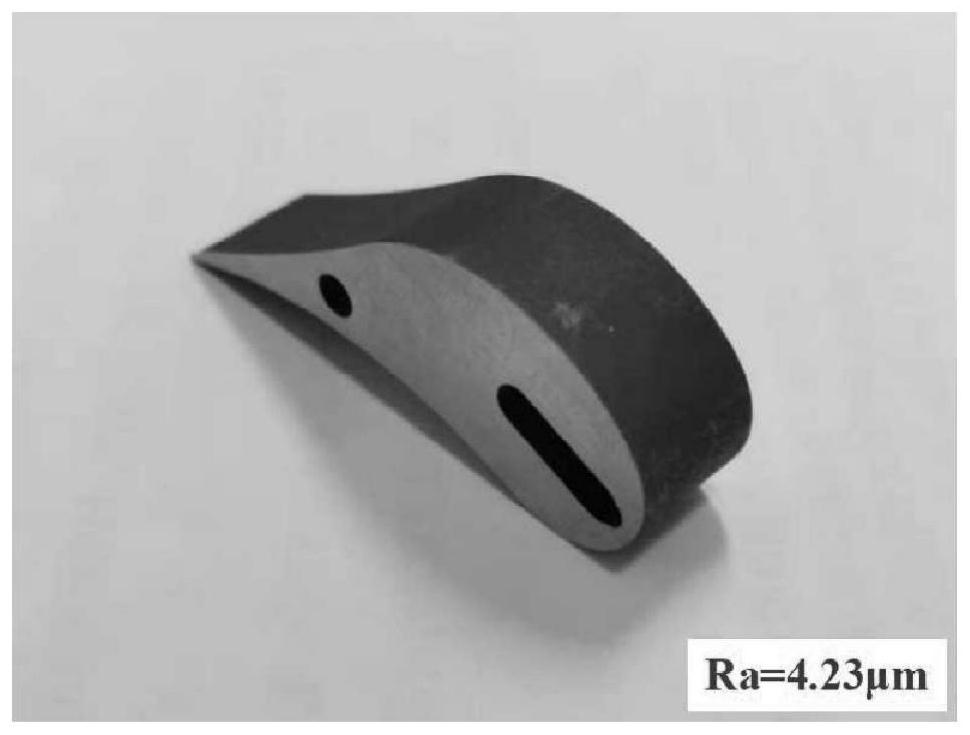

[0034] Select the stainless steel turbine guide vane in the oxygen generator, its shape is as follows figure 1 As shown, the length and width dimensions are 52mm×28mm, and the thickness is 12mm. The rough surface is pretreated by cleaning and drying.

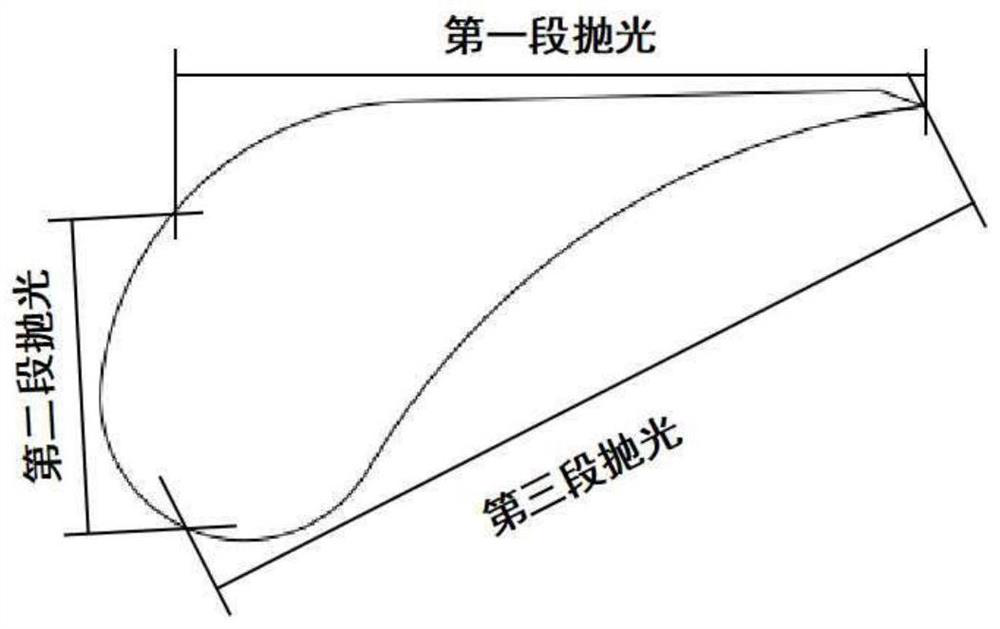

[0035] According to the defocus range of -5~+5mm for the same polishing effect of the laser, and the size and shape of the turbine guide vane, the rough surface of the guide vane is divided into 3 areas to be polished, and the scanning areas are 14×45mm and 14×25mm respectively. and 14×65mm, the length and width of the scanning area are 1mm more than the edge of the side to be polished to ensure that the side to be polished is covered, and there is an overlapping area with a width of 1mm between each divided area. The division diagram is as follows figure 2 shown. Place the guide vane with the first area to be polished facing up in the atmosphere protection box and fix it.

[0036] Set the laser power to 250W, the scanning sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com