Laser processing method and laser processing system

A laser processing method and laser processing technology, applied in laser welding equipment, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and limited laser focal depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

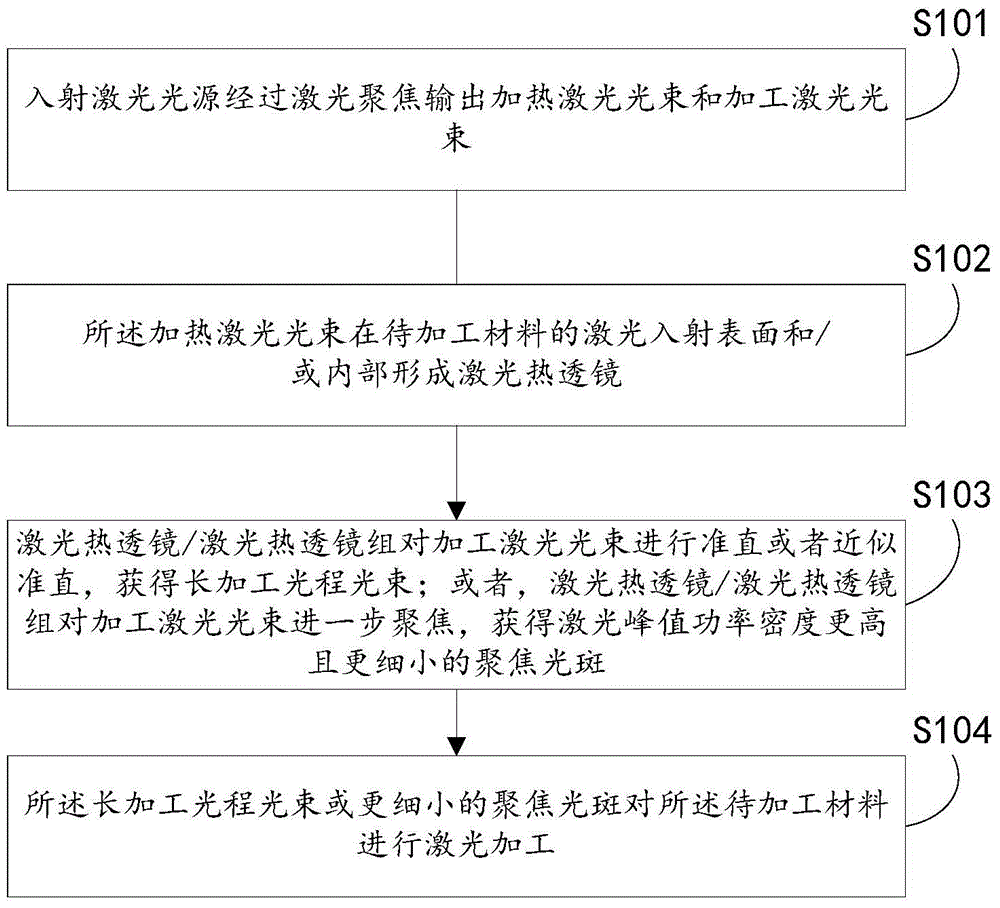

[0038] Embodiment 1, a kind of laser processing method, combine below figure 1 The method provided in this embodiment will be described in detail.

[0039] figure 1 In S101, the incident laser light source outputs a heating laser beam and a processing laser beam through laser focusing.

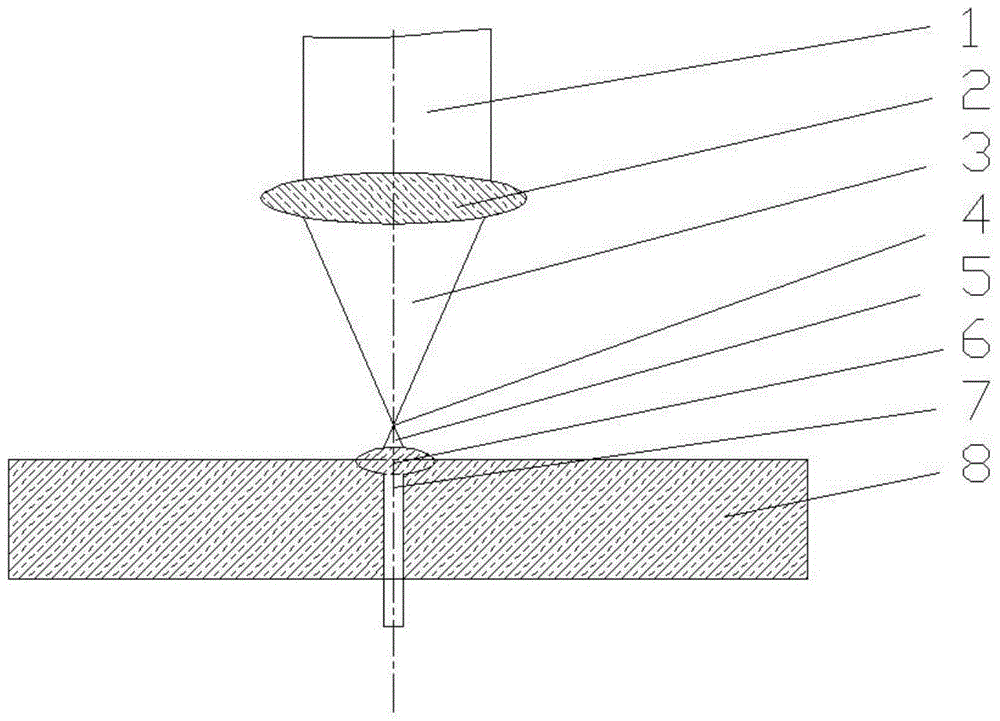

[0040] Specifically, see figure 2 and image 3 , when it is necessary to carry out laser processing on the material 8 to be processed, a laser focusing module 2 is arranged at a certain distance (along the incident direction of the laser light source) of the material 8 to be processed, for example, when the laser light source is incident from above the material 8 to be processed, then A laser focusing module 2 is set at a certain distance above the material 8 to be processed; Among them, the material 8 to be processed can be sapphire, glass, silicon wafer, quartz or transparent plastic, etc.; the laser focusing module 2 can be focused by a single lens, can also be focused by a multi-lens,...

Embodiment 2

[0048] Embodiment 2. A method for laser processing sapphire scribing. Combine below figure 2 The method provided in this embodiment will be described in detail.

[0049] see figure 2 , figure 2 The heating laser beam is not marked in , and the heating laser beam and the processing laser beam 1 can be the same or different laser light sources, for example, the transmission parameters of the beams are different, the wavelength is different, or the laser pulse width is different. The heating laser beam is also focused by the laser focusing module 2 , the cross section of the focused spot is a solid circle, and a laser focusing thermal lens 6 is formed on the laser incident surface and / or inside of the material 8 to be processed. In this embodiment, the laser focusing thermal lens 6 is formed on the laser incident surface of the material 8 to be processed, and the convex lens surface of the laser focusing thermal lens 6 is formed due to thermal stress.

[0050] The laser fo...

Embodiment 3

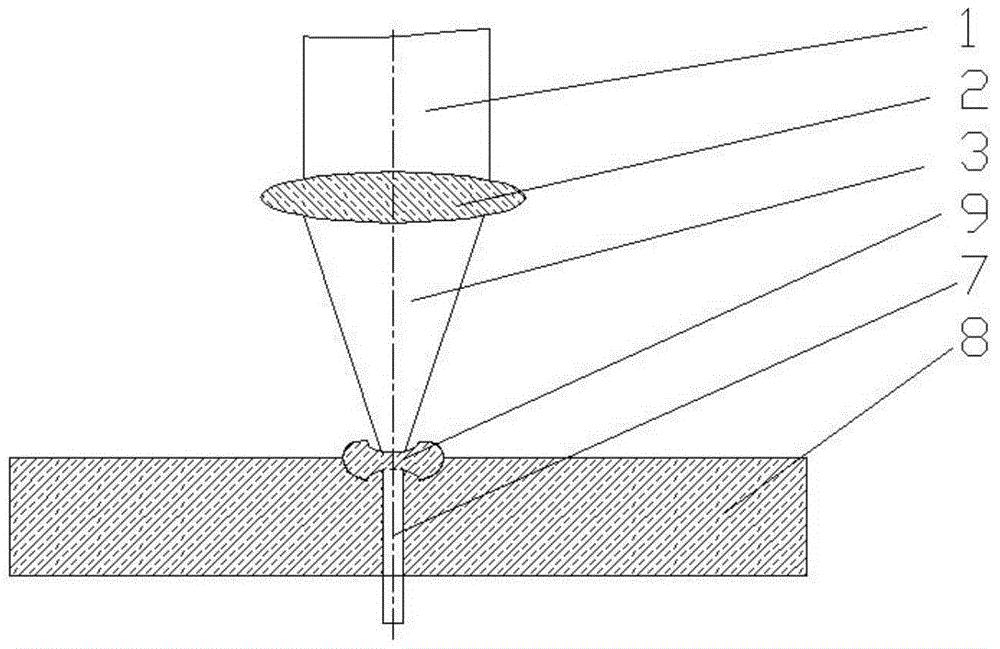

[0056] Embodiment 3. A method of laser processing the glass sheet of the touch screen. Combine below image 3 and Figure 4 The method provided in this embodiment is described in detail.

[0057] see image 3 , image 3 The heating laser beam is not marked in , and the heating laser beam can be the same or different laser light source as the processing laser beam 1, for example, the beam transmission parameters are different, the wavelength is different, or the laser pulse width is different. The heating laser beam is also focused by the laser focusing module 2, and the heating laser beam is focused into a hollow ring with a spot section, see Figure 4 , 29 is a low laser energy or no laser energy area, 28 is a high laser energy area, high laser energy and low laser energy are relative terms. The heating laser beam forms a laser radiation heat dissipation lens 9 on the laser incident surface and / or inside of the material to be processed 8. Radiation heat sink lens 9 conc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com