Laser beam reshaping five-portion lens and four-portion lens

A laser beam and lens technology, applied in the field of lasers, can solve the problems of inability to strengthen by laser shock, high processing cost, loss of energy, etc., and achieve the effect of easy popularization and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

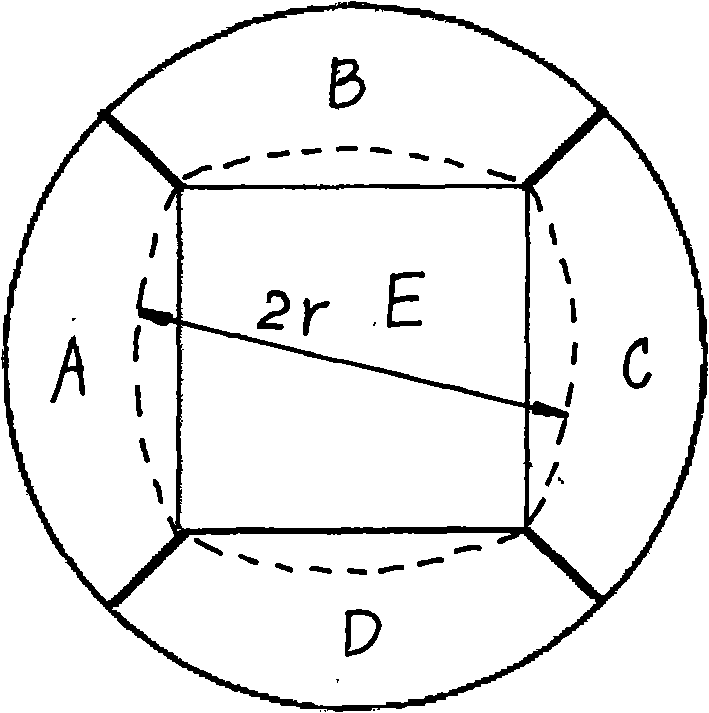

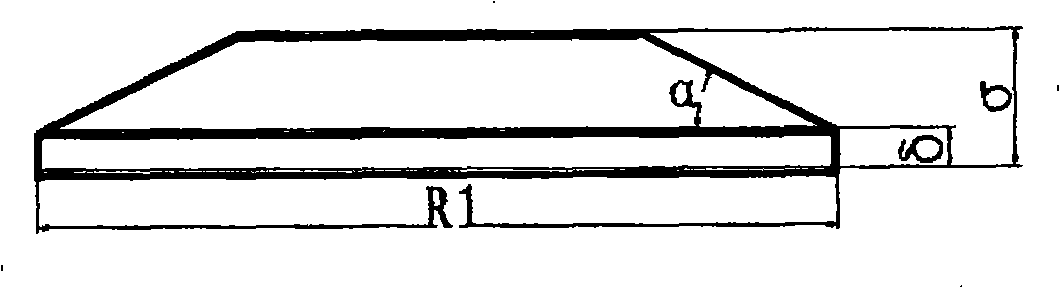

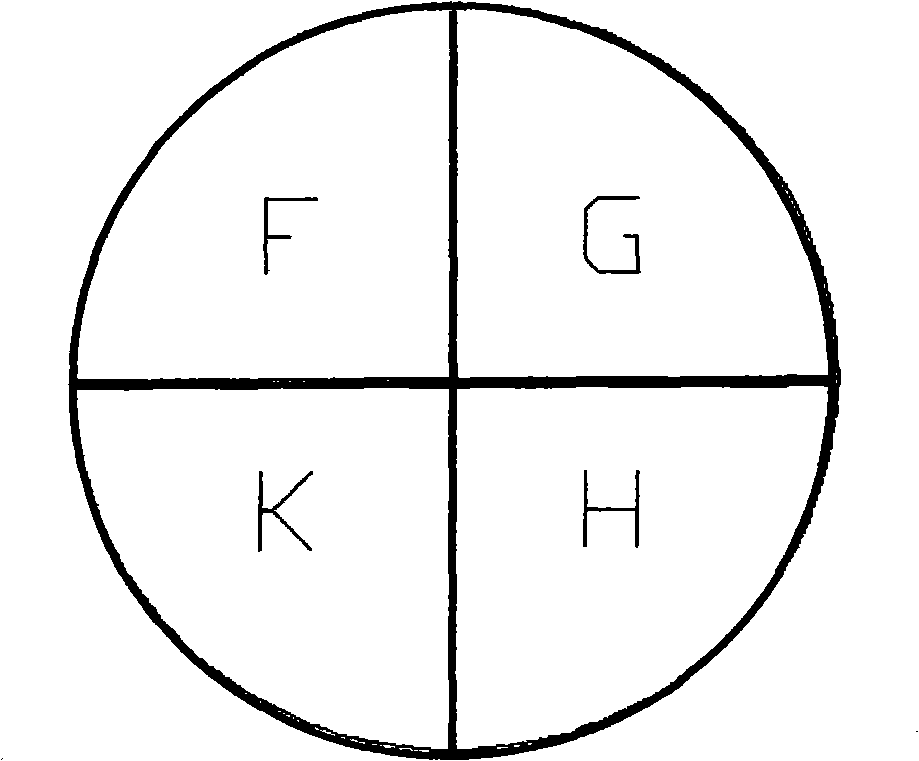

[0011] The present invention will be described in further detail below. see figure 1 , 2 , a five-point lens for laser beam shaping, having a disc-shaped substrate with a radius of R1 and a thickness of σ1, the bottom surface of which is a plane, characterized in that the upper surface of the shaping lens is composed of A, B, C, D, E A quadrangular truss composed of five planes, the plane E is parallel to the bottom surface of the shaping lens, the projection of the plane E on the bottom surface of the shaping lens is a square located in the center of the bottom plane, the radius of the circumscribed circle of the plane E is r, r=0.4~ 0.7R1; planes A, B, C, and D have the same shape. It is an isosceles trapezoid whose lower base is an arc. The upper base of the isosceles trapezoid is a side of plane E. Planes A, B, C, and D The included angles with the bottom surface of the shaping lens are all α, and α=0.01-0.4 radians.

[0012] The radius R1 of the disc-shaped substrate m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com