Solar energy condensing electricity-generating device with summit-cutting curve condensing lens

A solar concentrating and concentrating lens technology, which is applied in the field of solar power generation, can solve problems such as high processing costs, difficult demoulding of molds and lens materials, and difficult process implementation, so as to reduce losses, improve photoelectric conversion efficiency, and reduce Effect of Accuracy Requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041]The technical solution of the present invention will be further described below in conjunction with the examples.

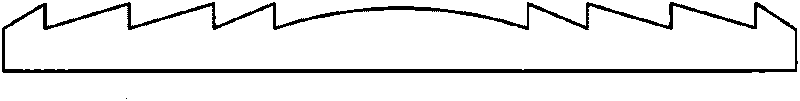

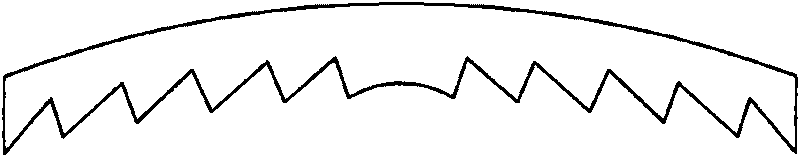

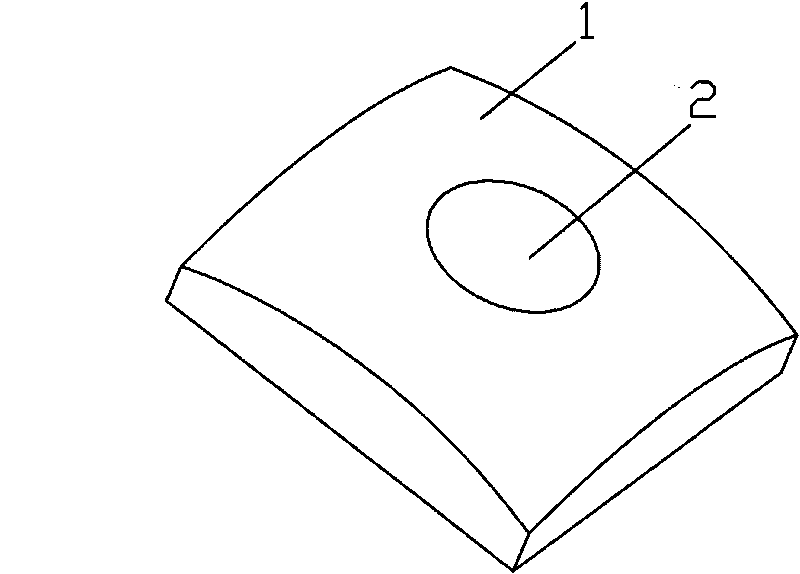

[0042] Such as Figure 7 It is a rear view structural schematic diagram of the device of the present invention, Figure 8 It is a schematic diagram of the side view structure of the device of the present invention; a solar concentrated power generation device using a truncated curved surface concentrating lens, including a plurality of solar concentrated power generation modules 7 and a solar tracking support for installing the solar concentrated power generation modules 7 System 5, concentrated solar power generation module 7 includes a plurality of concentrated solar power generation units 6 arranged in a matrix (see Figure 9 ),Such as Figure 10 It is a schematic structural view of the solar concentrating power generation unit of the present invention; the solar concentrating power generation unit 6 includes a truncated curved surface concentrating le...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com