Laser cutting system and cutting method thereof

A laser cutting and laser technology, applied in the direction of laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of battery pole sheet curling, burrs, and uneven cutting surface, etc., to achieve improved cutting speed, large cutting range, cost saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

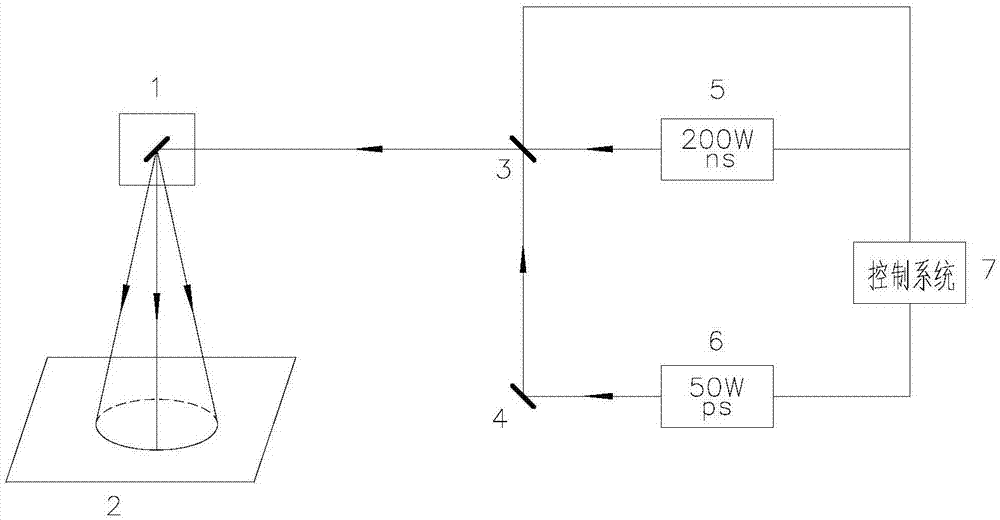

[0028] figure 1 and figure 2 Shown is a schematic structural diagram of the laser cutting system of the present invention, and the laser cutting system is used for laser cutting the workpiece 2 .

[0029] In this embodiment, the workpiece 2 is a battery pole piece, and there are three situations for the battery pole piece: both sides of the battery pole piece have a coating layer, one side of the battery pole piece has a coating layer, and only the battery pole piece has no coating layer . The cutting process and cutting parameters will be different in each case.

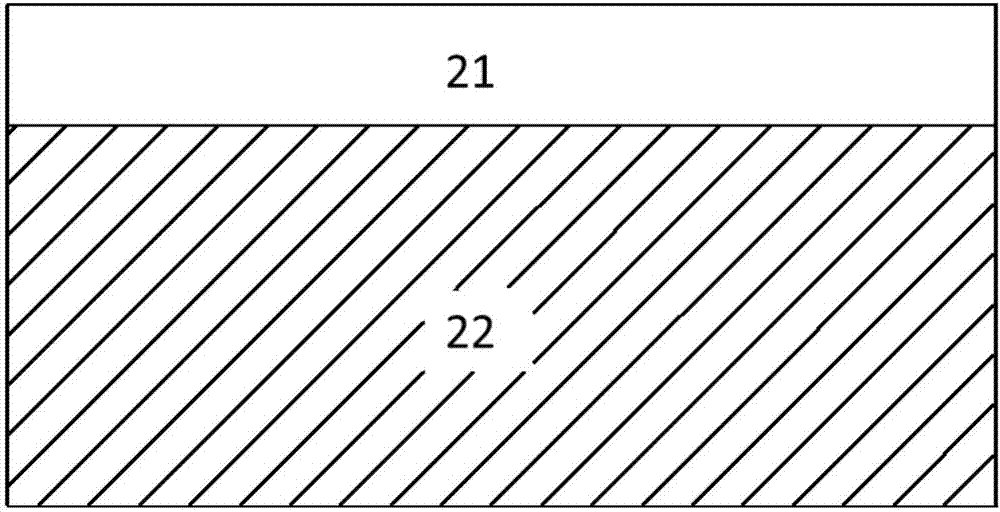

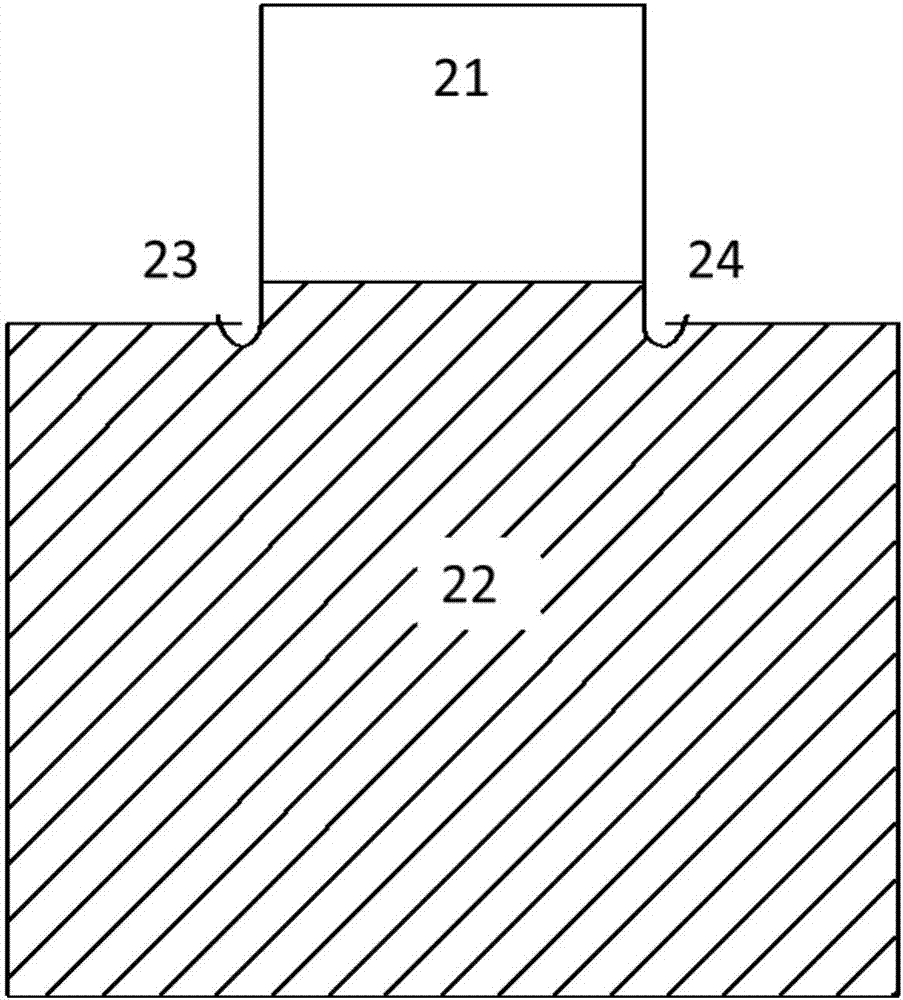

[0030] Such as figure 2 As shown, the workpiece 2 includes a bare area 21 and a coating layer 22 connected to the bare area 21 .

[0031] The bare area 21 is the tab part of the battery pole piece, which is the copper foil or aluminum foil directly exposed; the coating layer 22 is figure 2 The shaded area shown.

[0032] The laser cutting system includes: galvanometer system 1, variable reflector 3, fixed r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com