Non-imaging disc type condenser and design method thereof

A design method and concentrator technology, applied in the field of solar power generation, can solve the problems of reducing the working efficiency of the receiver, affecting the safety of the receiver, uneven energy flow distribution, etc., so as to avoid the formation of high temperature hot spots and improve the working life. and reliability, the effect of reducing optical loss and heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

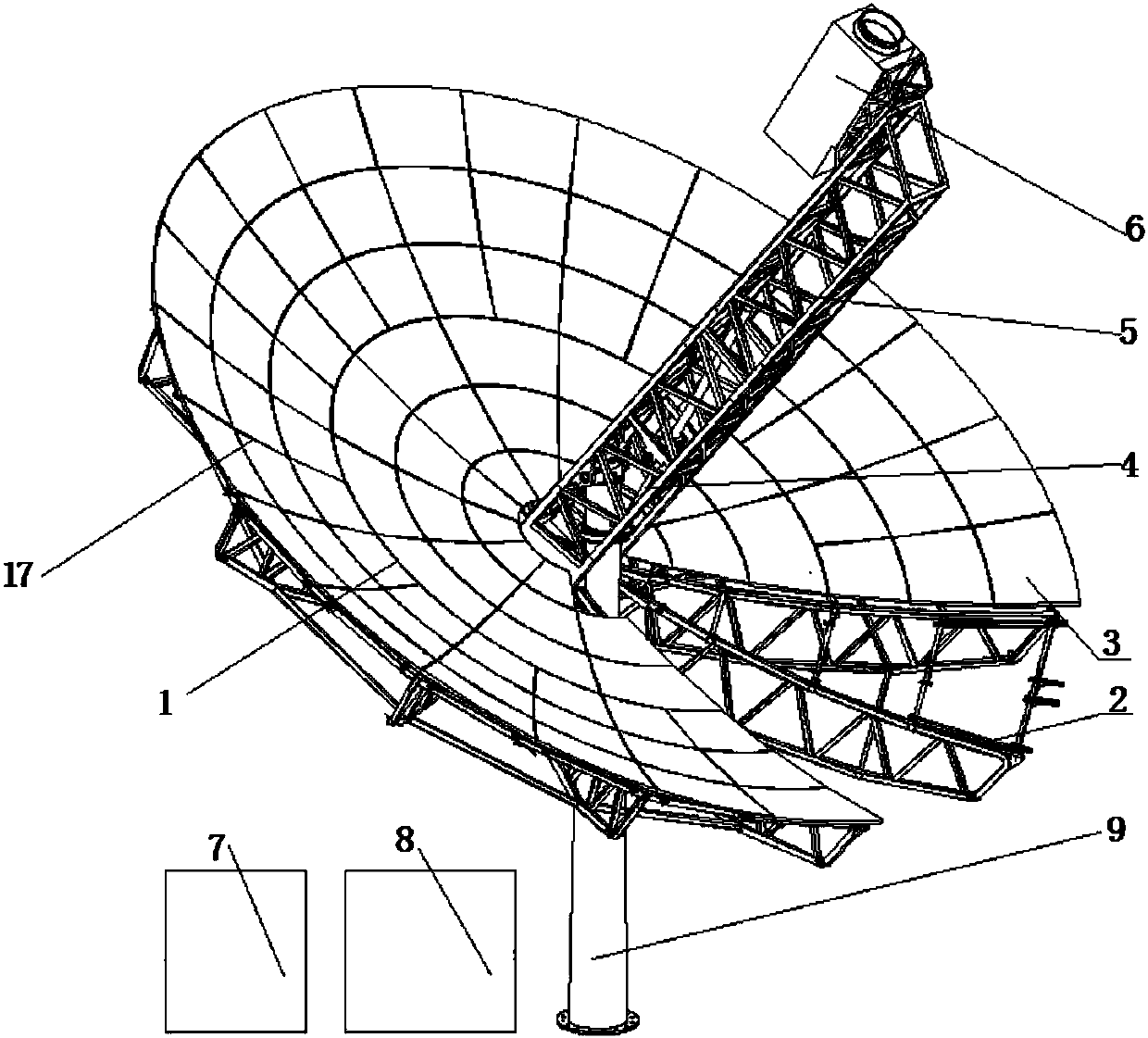

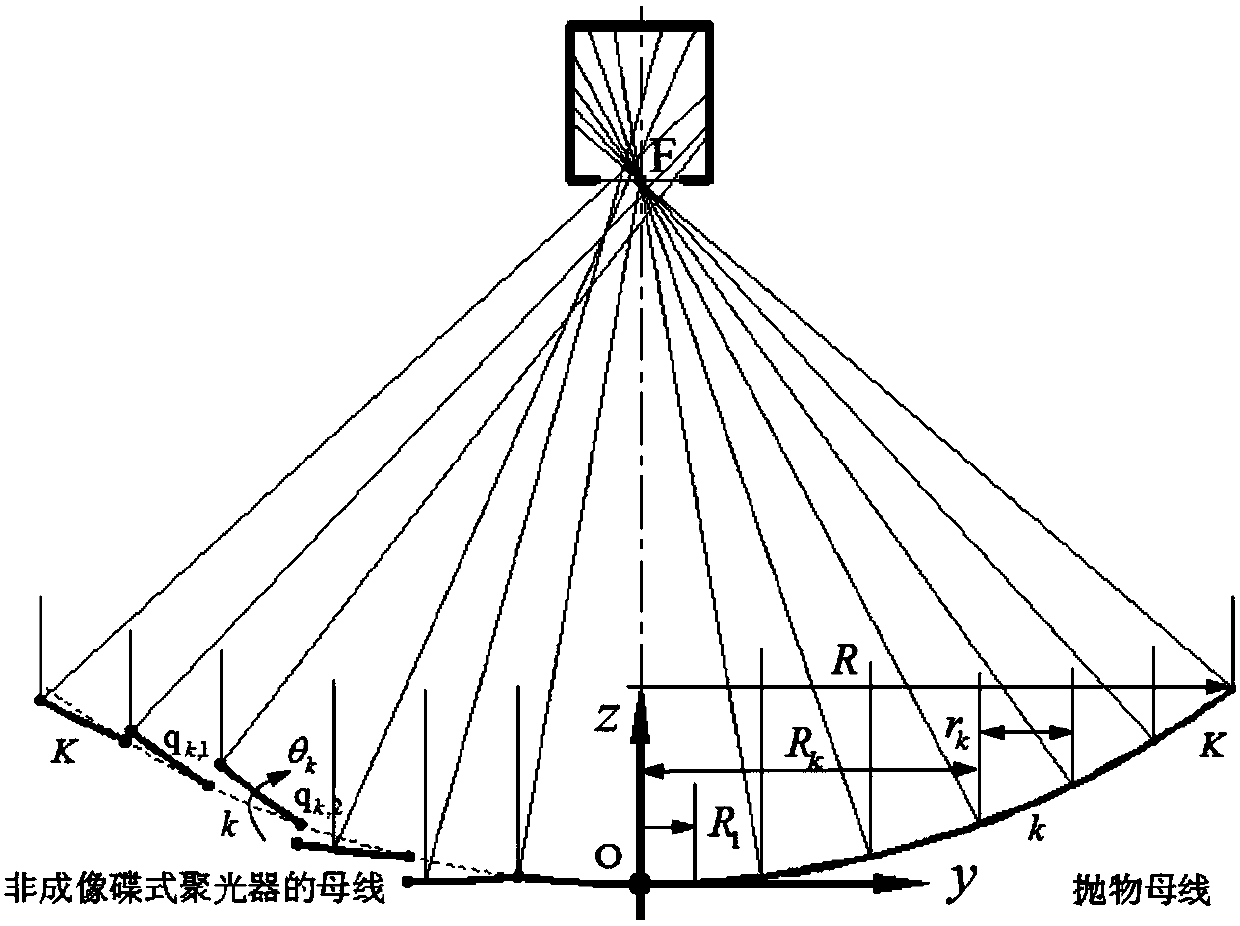

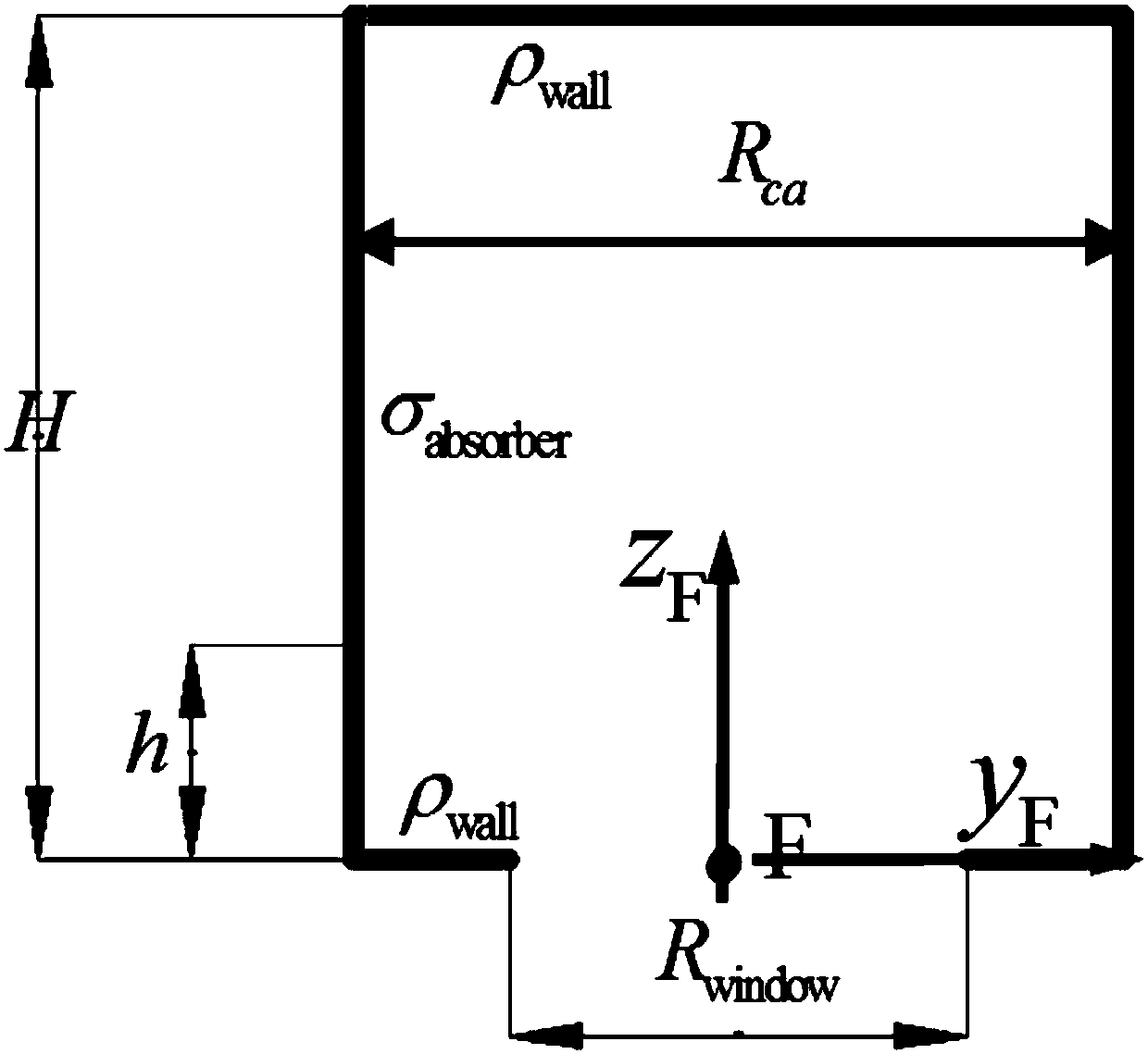

[0045] Such as Figure 1-Figure 3 As shown, a non-imaging dish concentrator 1 includes a Stirling heat engine 6, an electrical energy exporter 8, a concentrator 17, a column 9, a biaxial tracking device 4, a support truss 5 and a control device 7, the The dual-axis tracking device 4 is installed on the top of the column 9, the control device 7 is electrically connected to the dual-axis tracking device 4, the control device 7 calculates the real-time position of the sun and controls the rotation of the dual-axis tracking device 4, and realizes non-imaging dish-type focusing The device tracks the position of the sun in real time; the lower end of the support truss 5 is connected with the biaxial tracking device 4, the concentrator 17 includes a grid 2 and a reflector 3, and the U-shaped body at the center of the grid 2 is fixedly connected with the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com