Patents

Literature

94 results about "Photon sieve" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

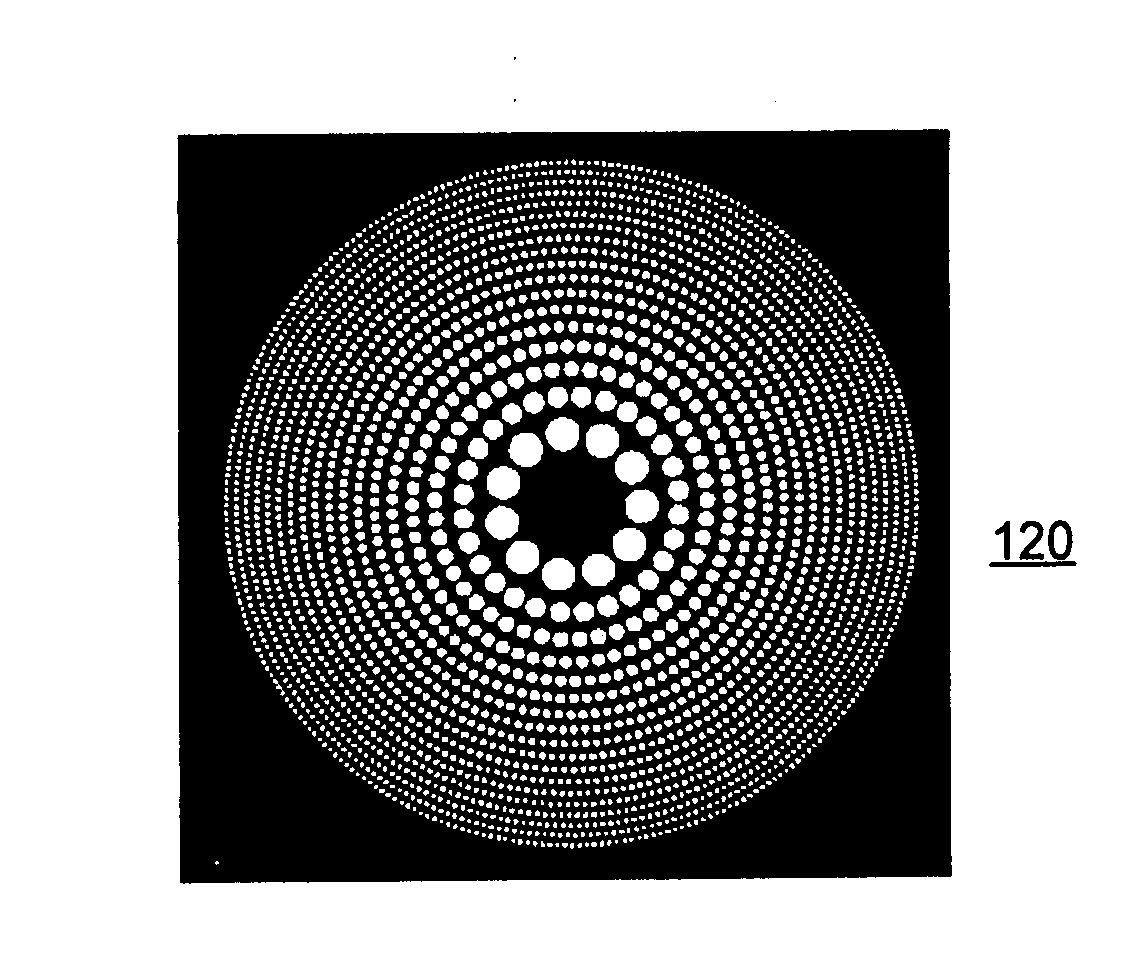

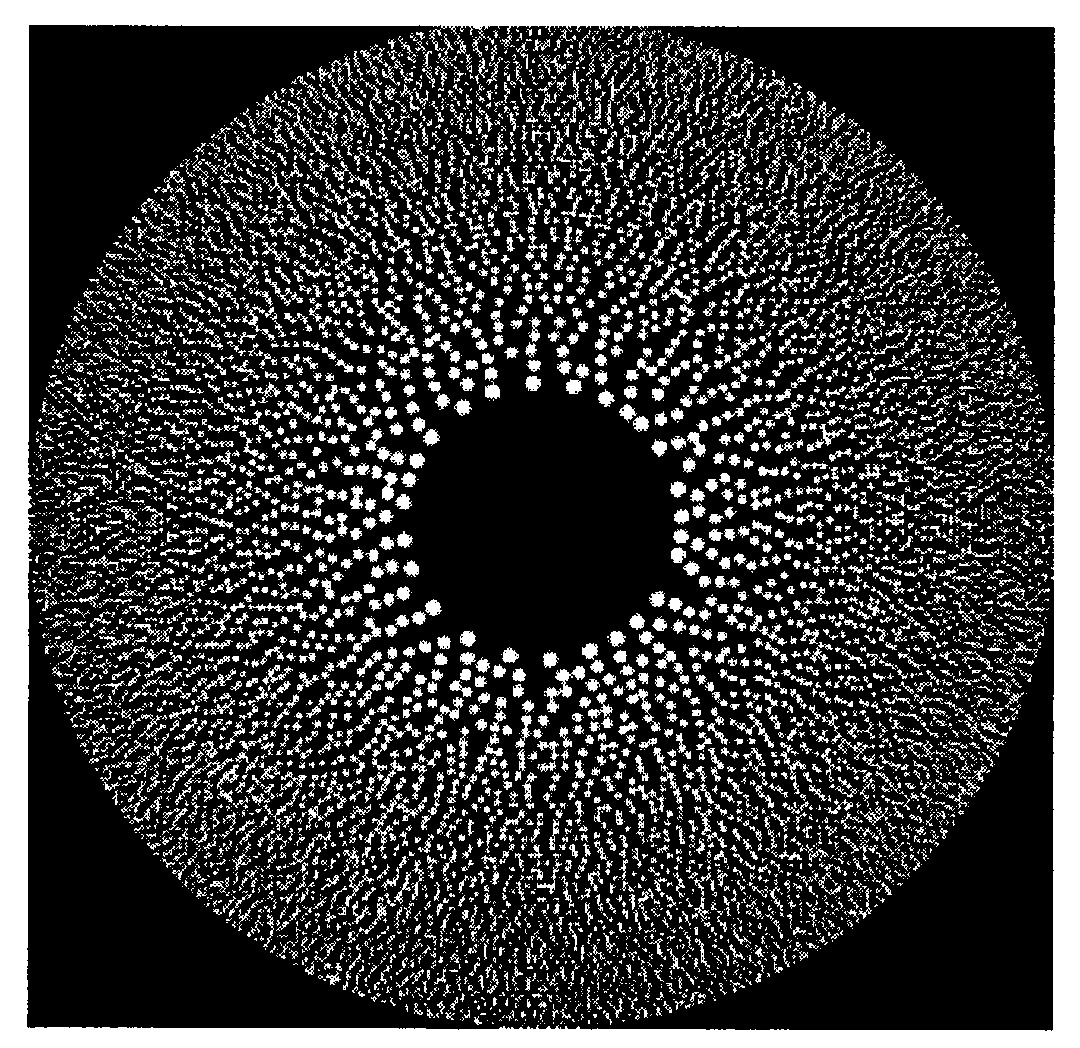

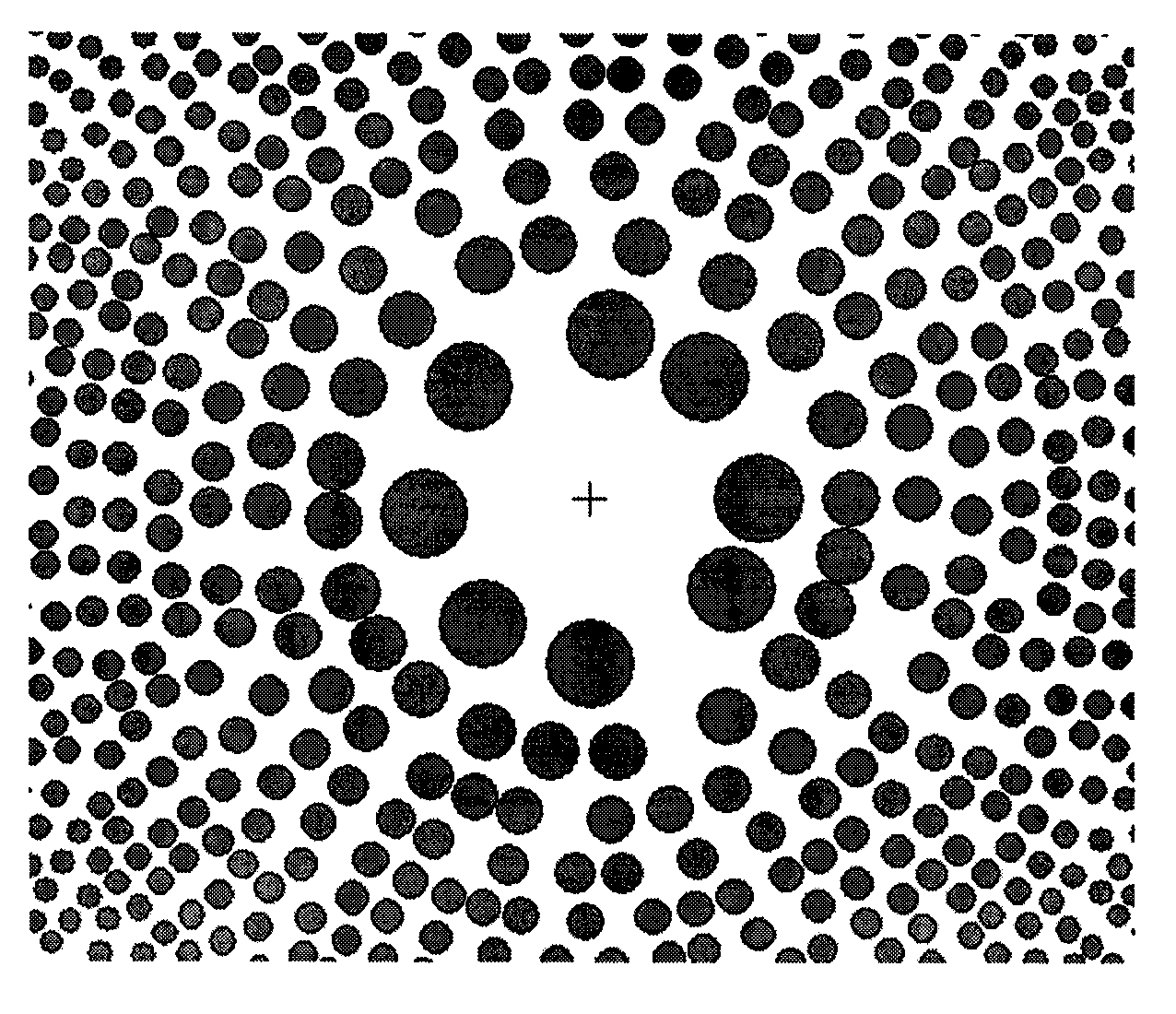

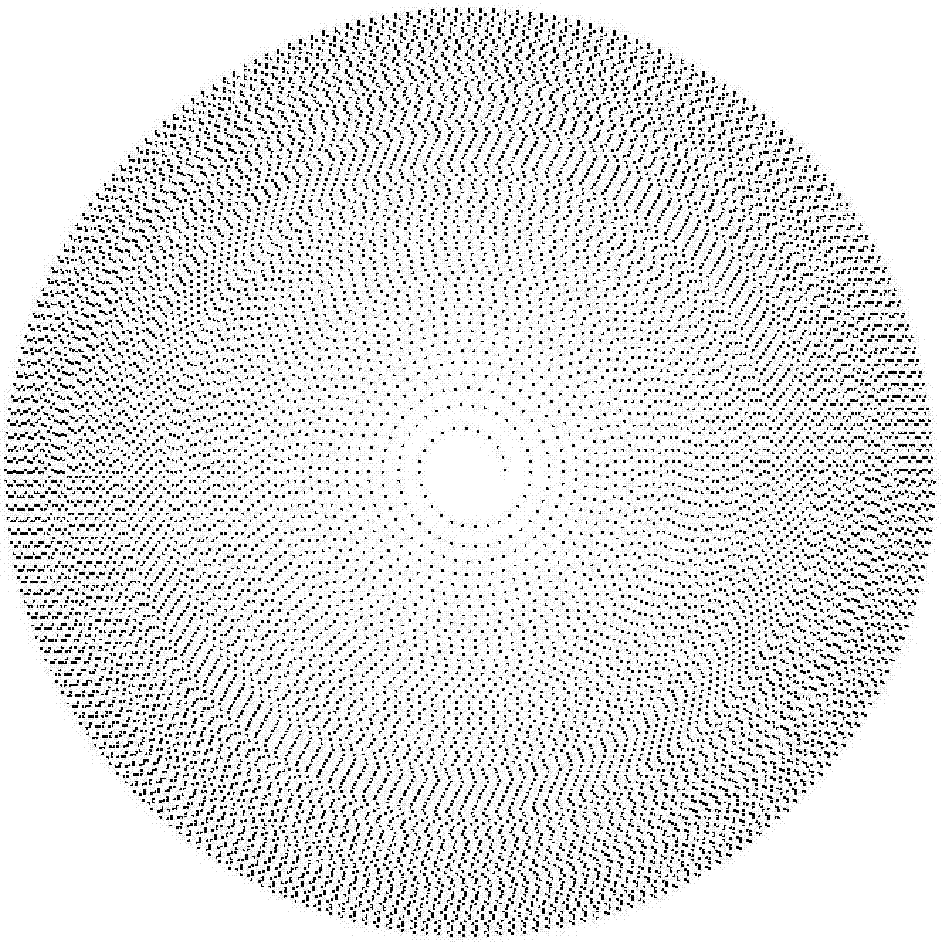

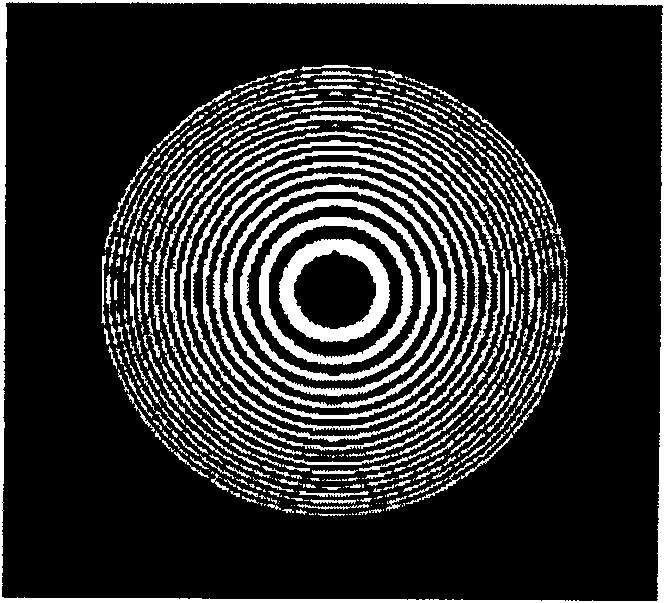

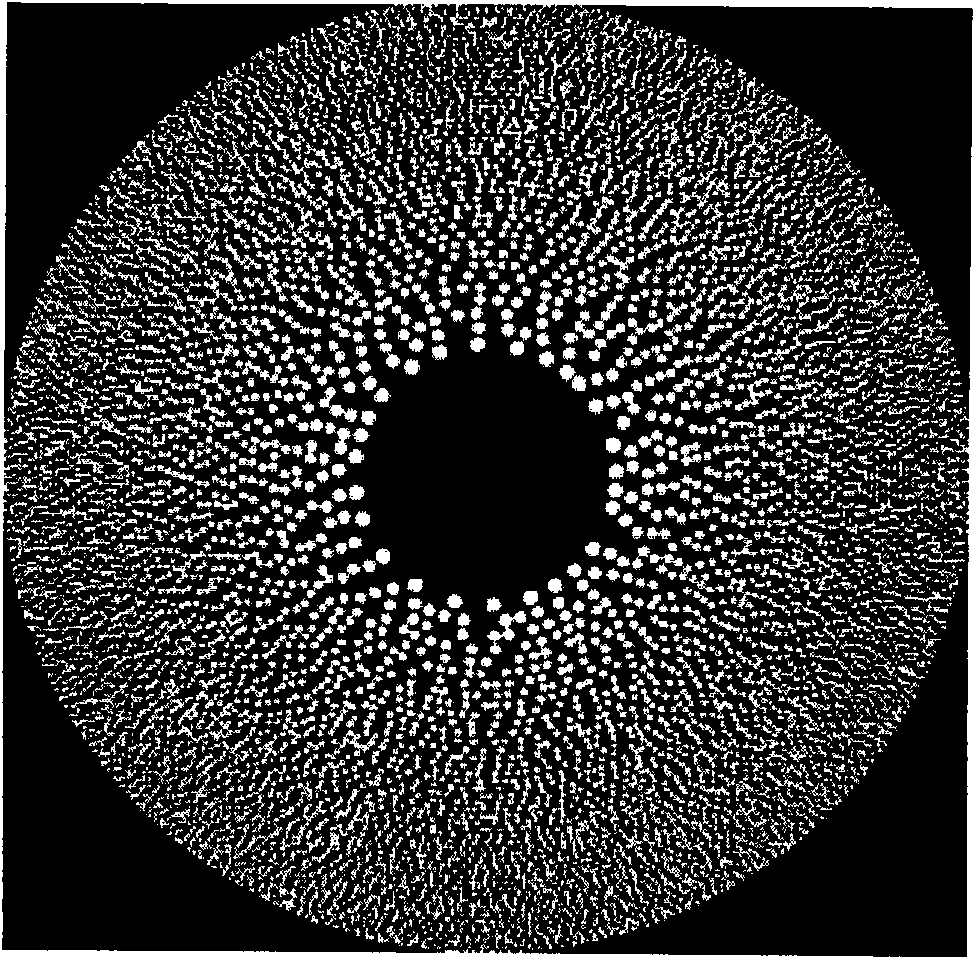

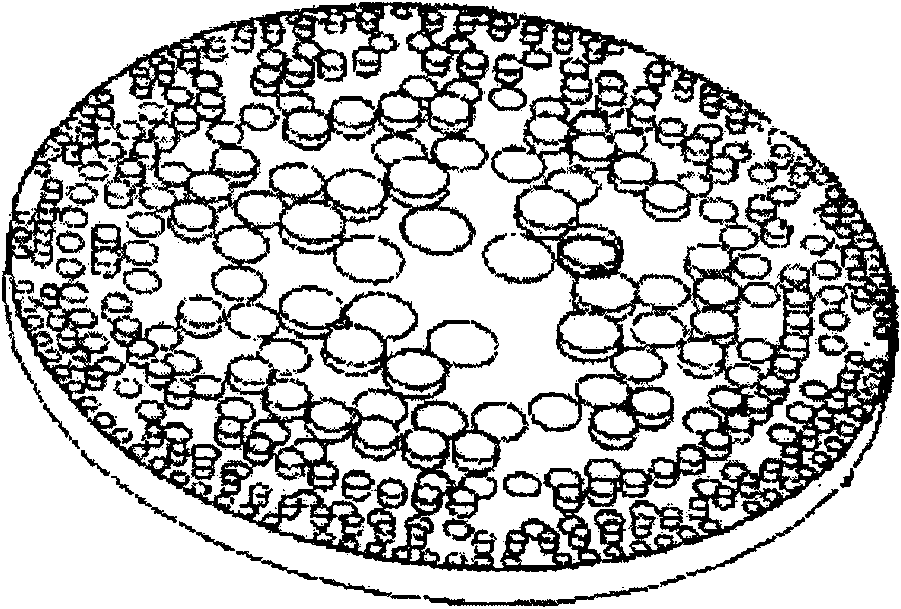

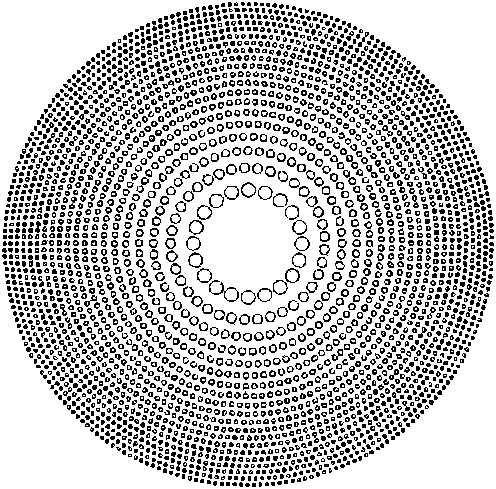

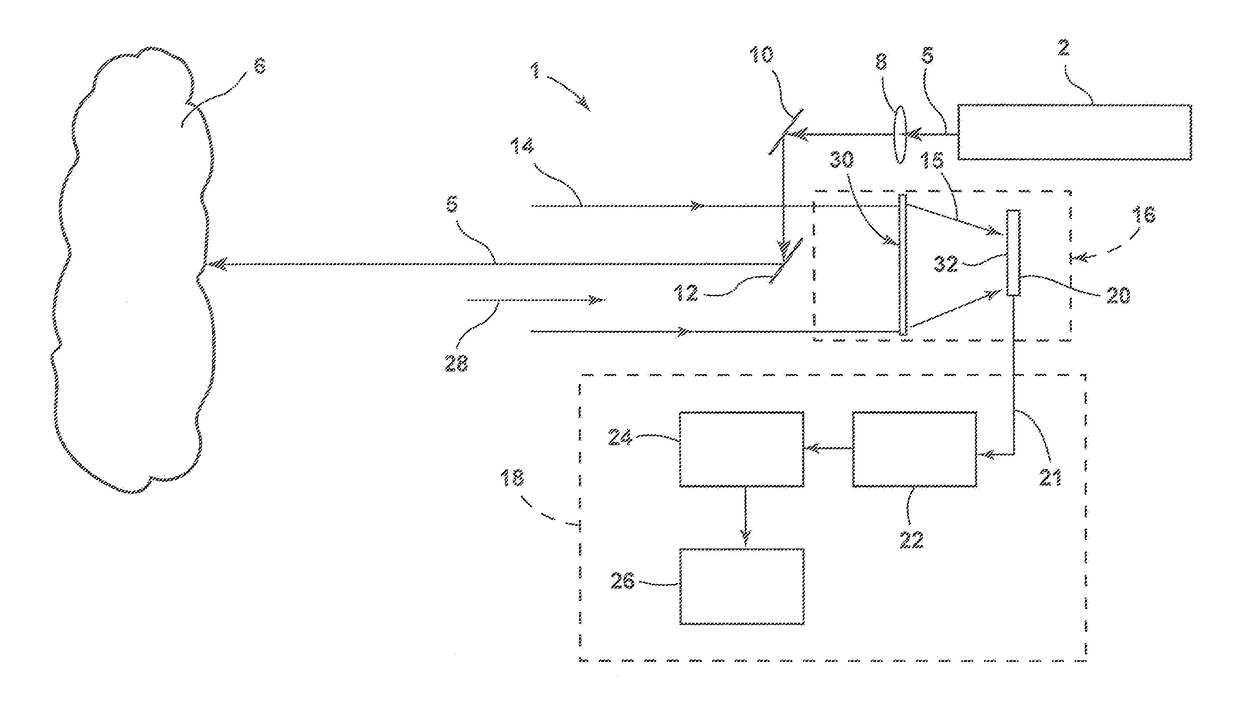

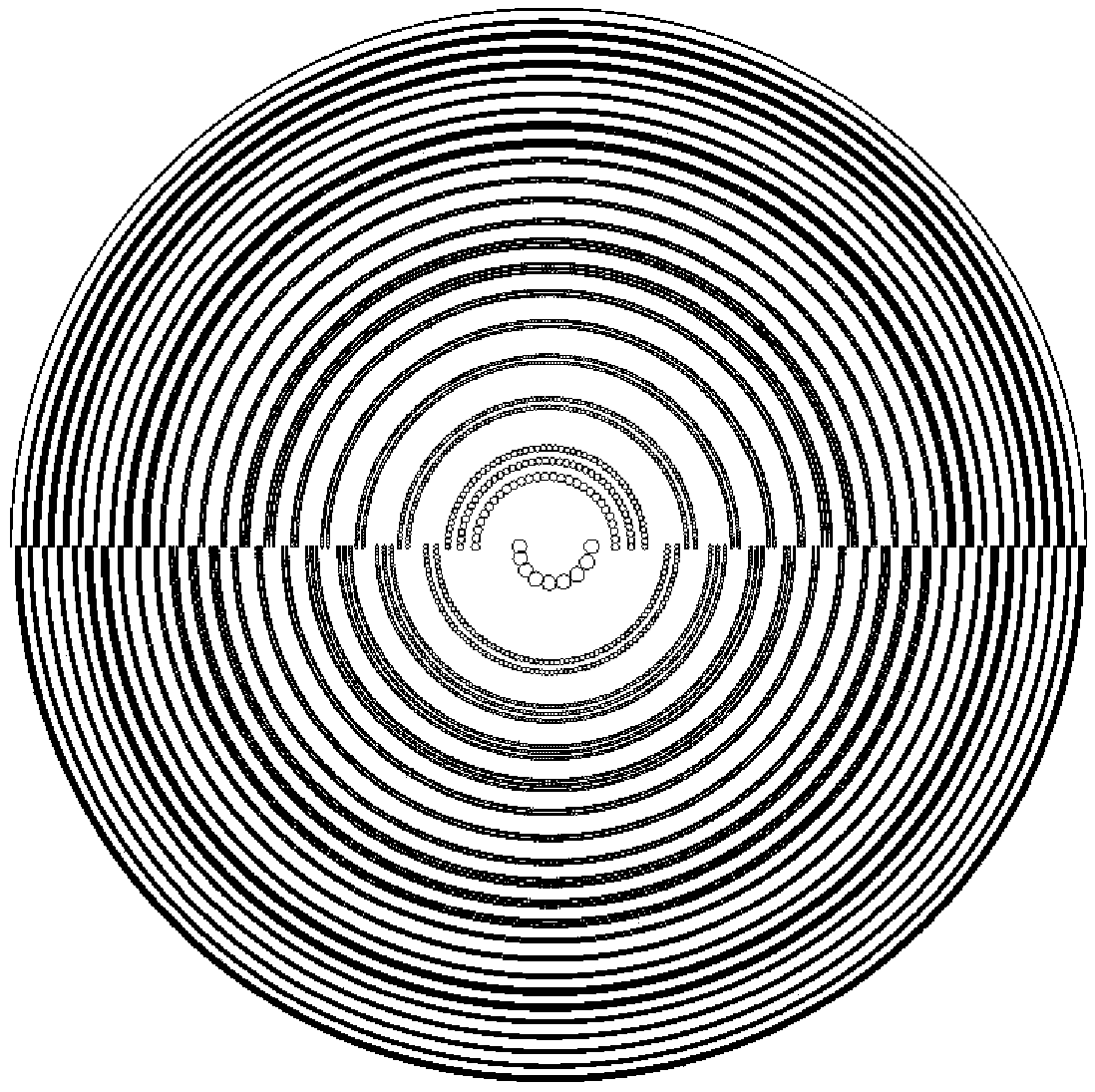

The photon sieve is a thin film of titanium filled with randomly oriented pinholes. By placing the photon sieve close to a transmissive LCD panel, the diffraction angle of the light field can be considerably enhanced. The actual 3D holographic display, and an electron microscope image of the nonperiodic pinholes. Courtesy of KAIST.

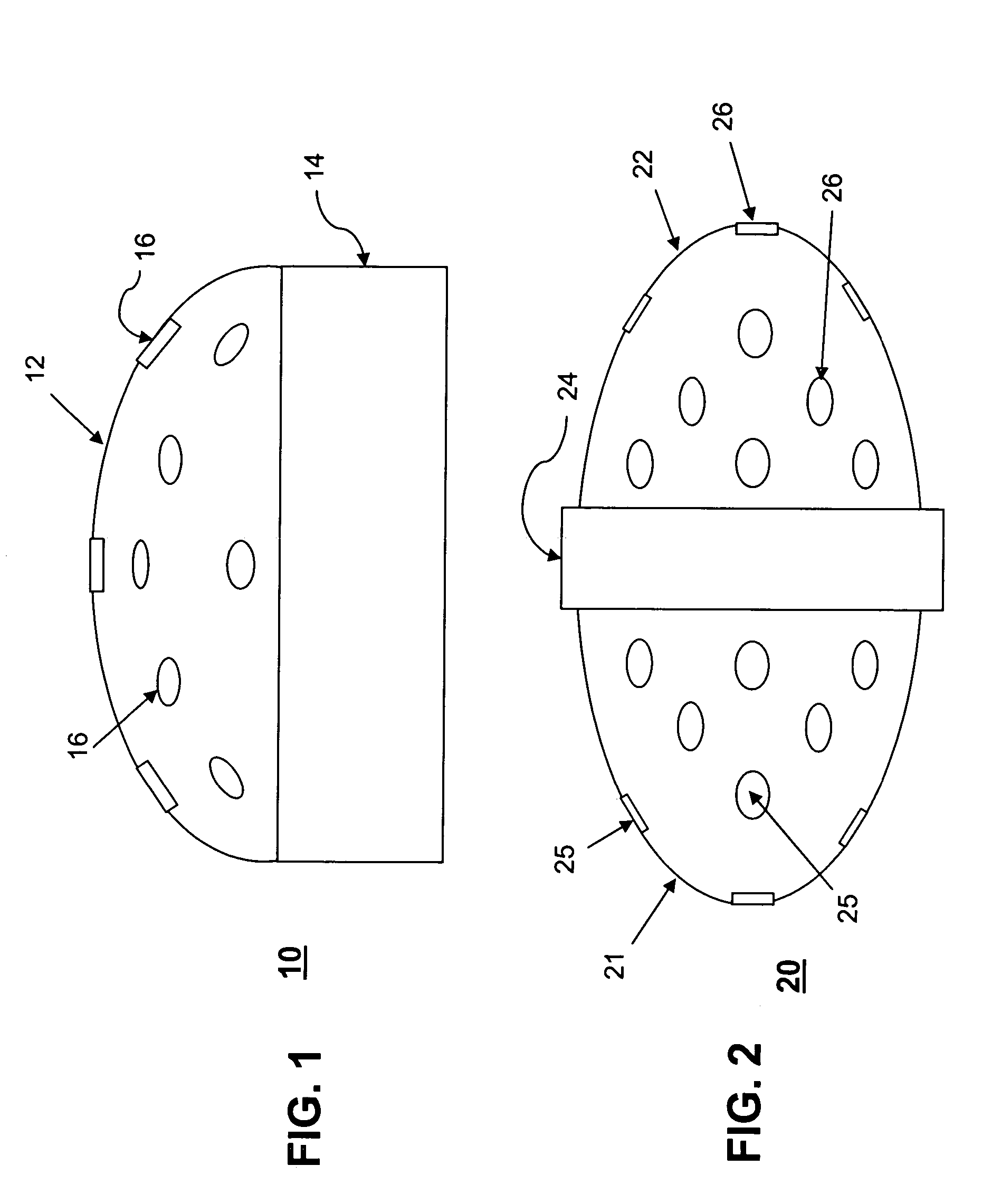

Imaging devices and methods

Owner:INT TECH CENT

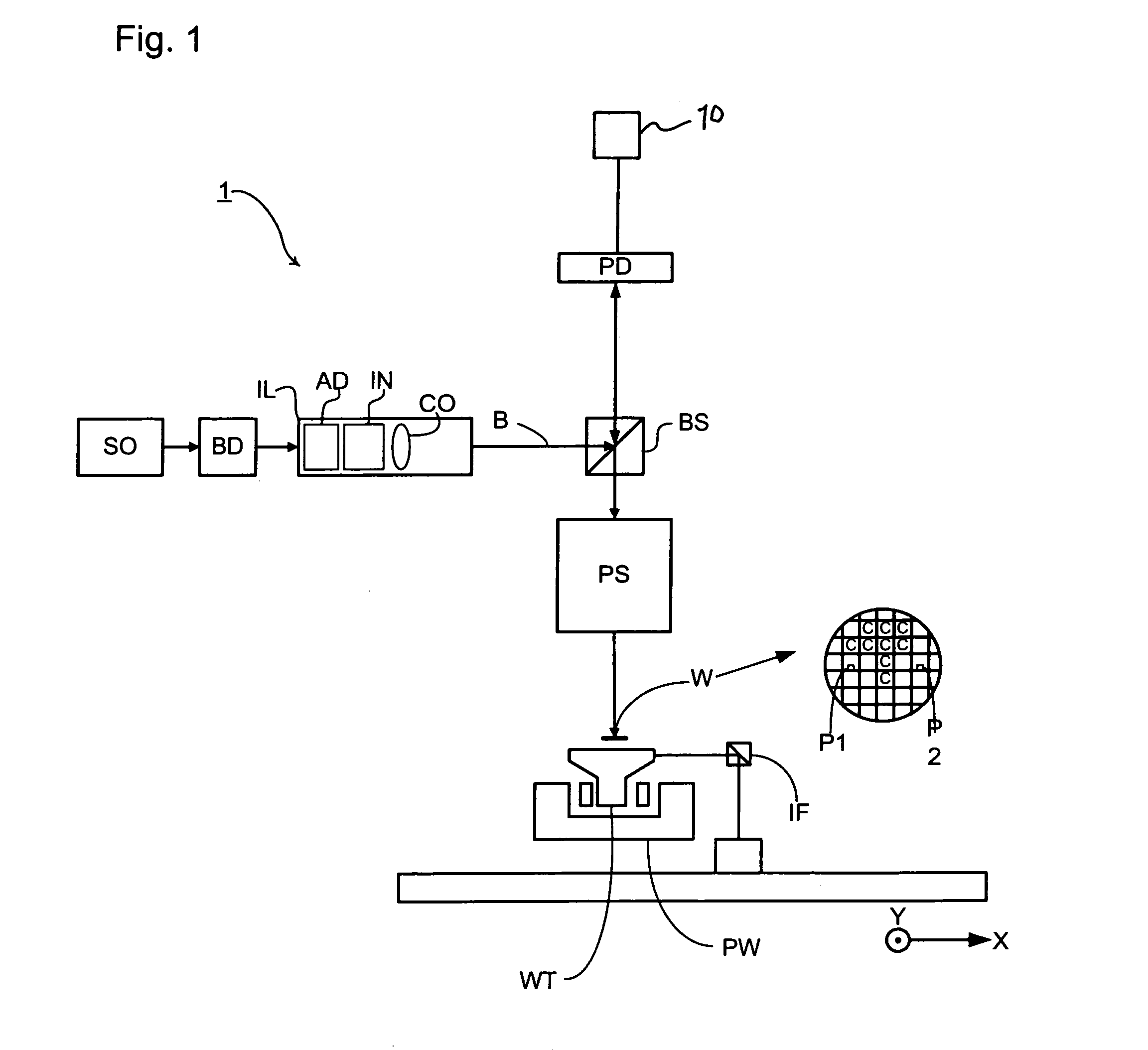

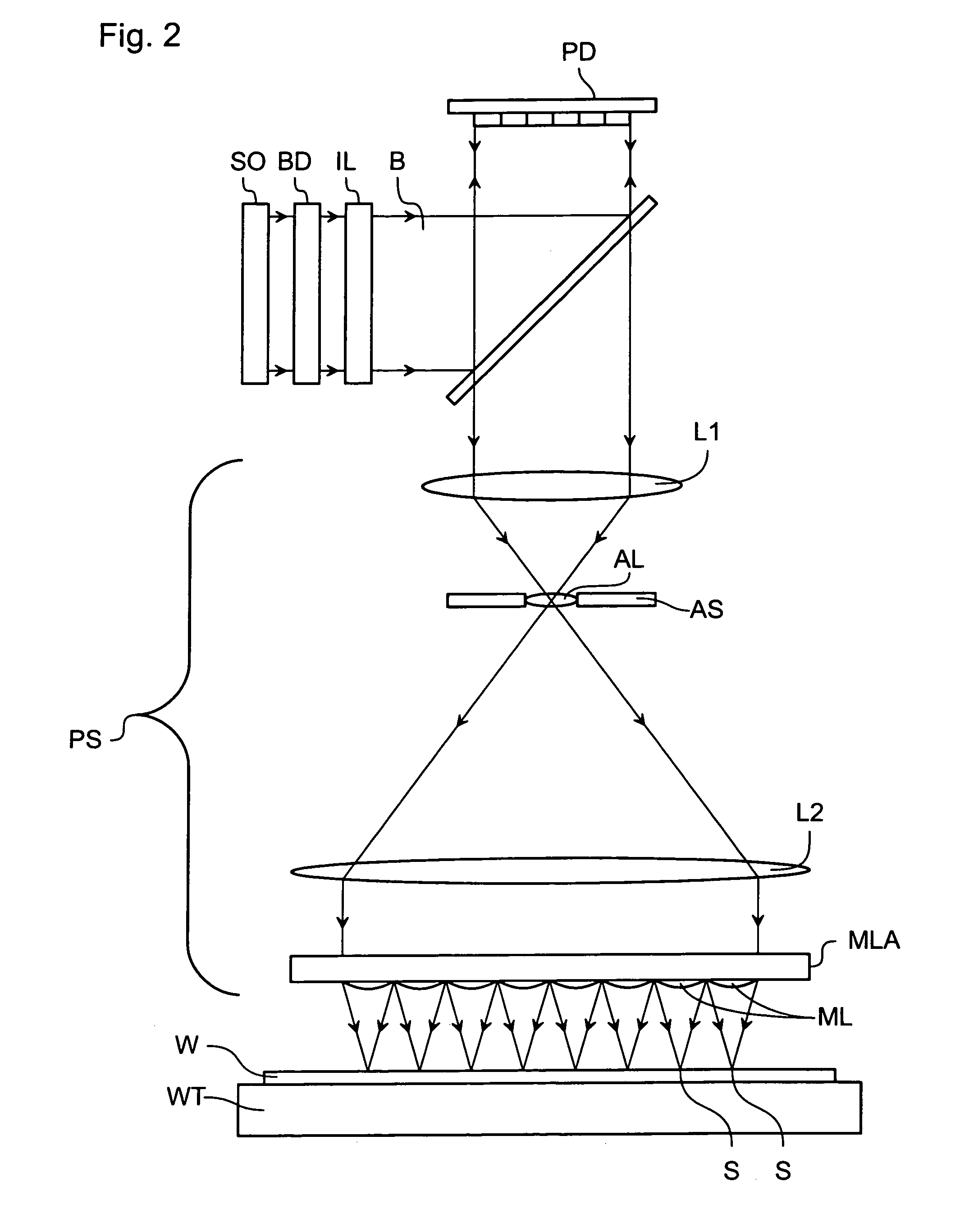

High resolution multi-lens imaging device

InactiveUS6954310B2FocusTelevision system detailsColor television detailsCamera lensMulti dimensional

Owner:UNIV OF FLORIDA RES FOUNDATION INC +2

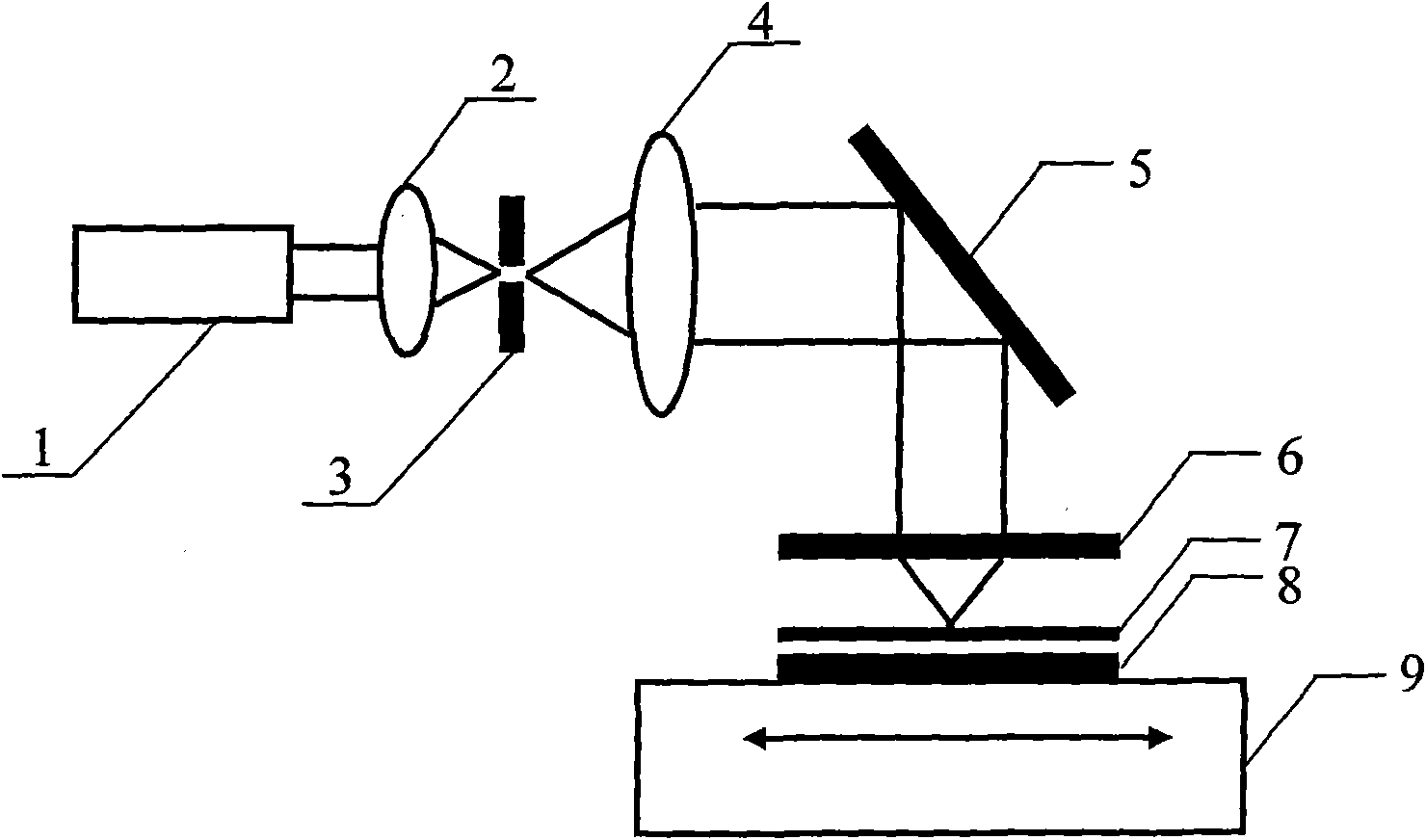

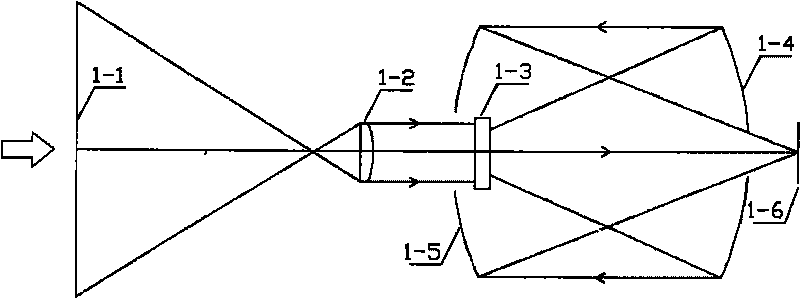

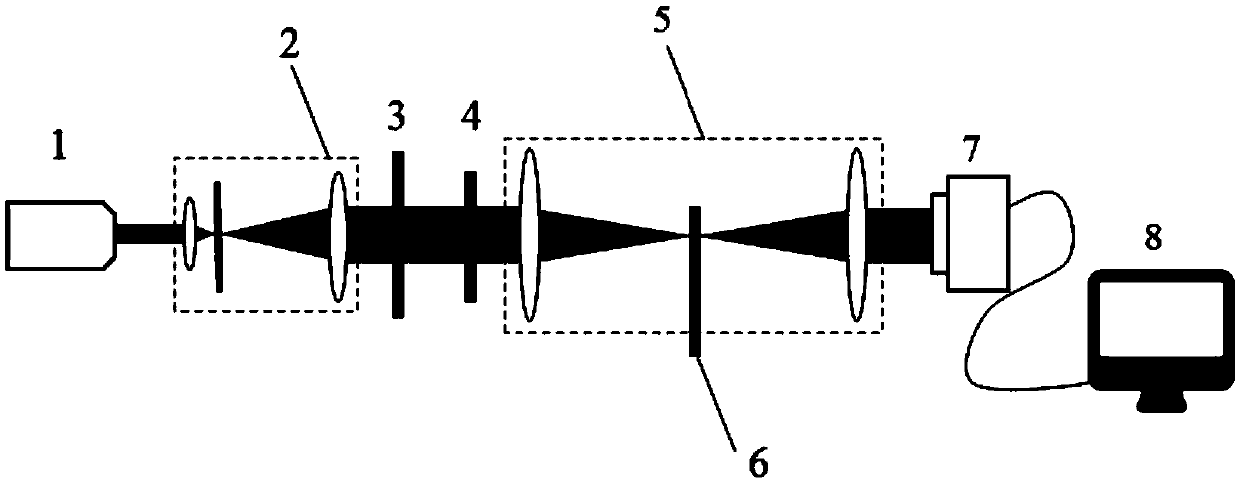

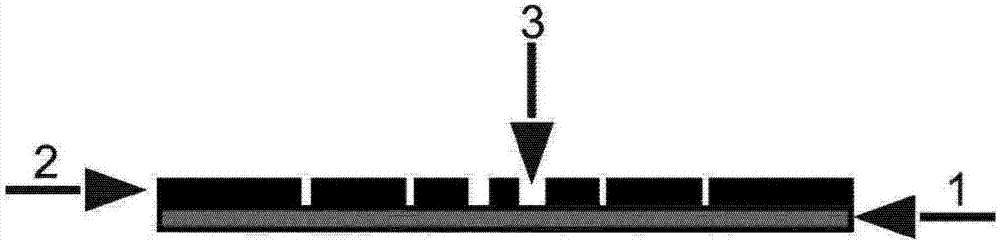

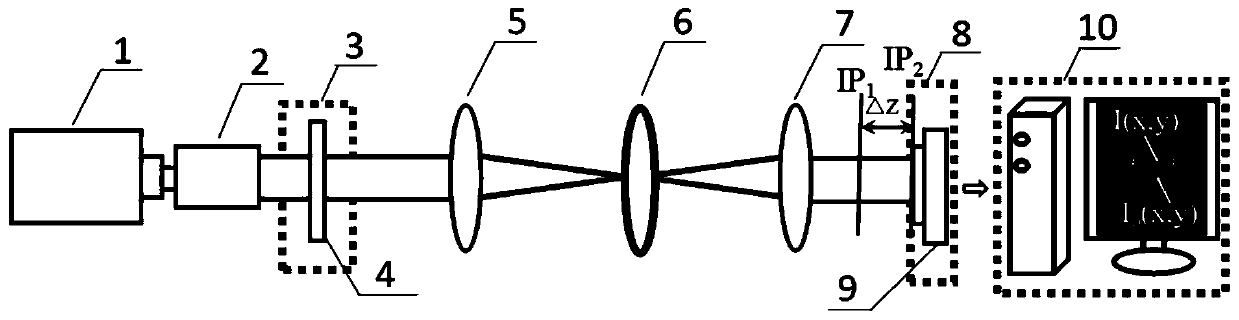

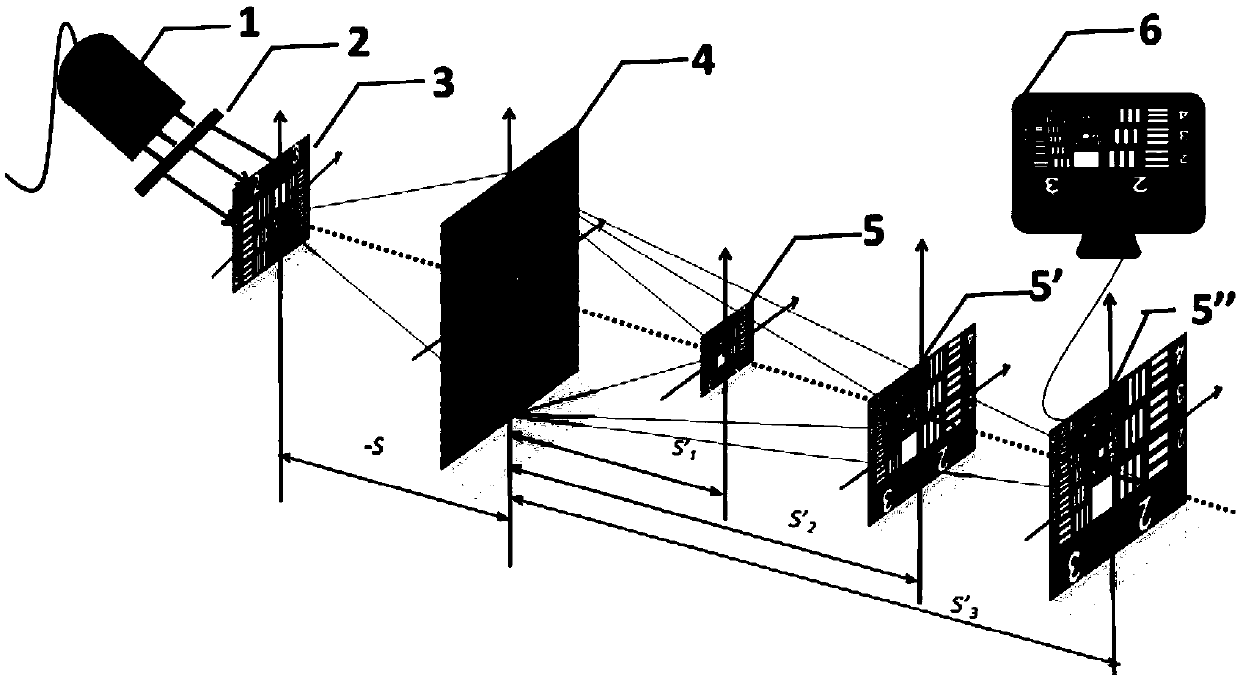

Laser direct-write photoetching system based on photon sieve

InactiveCN101561637ASmall attenuationLow costPhotomechanical exposure apparatusMicrolithography exposure apparatusLaser lightRelative motion

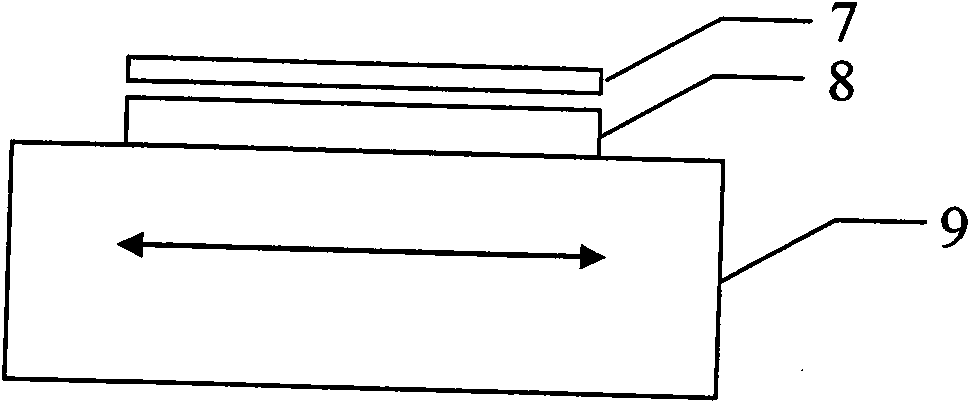

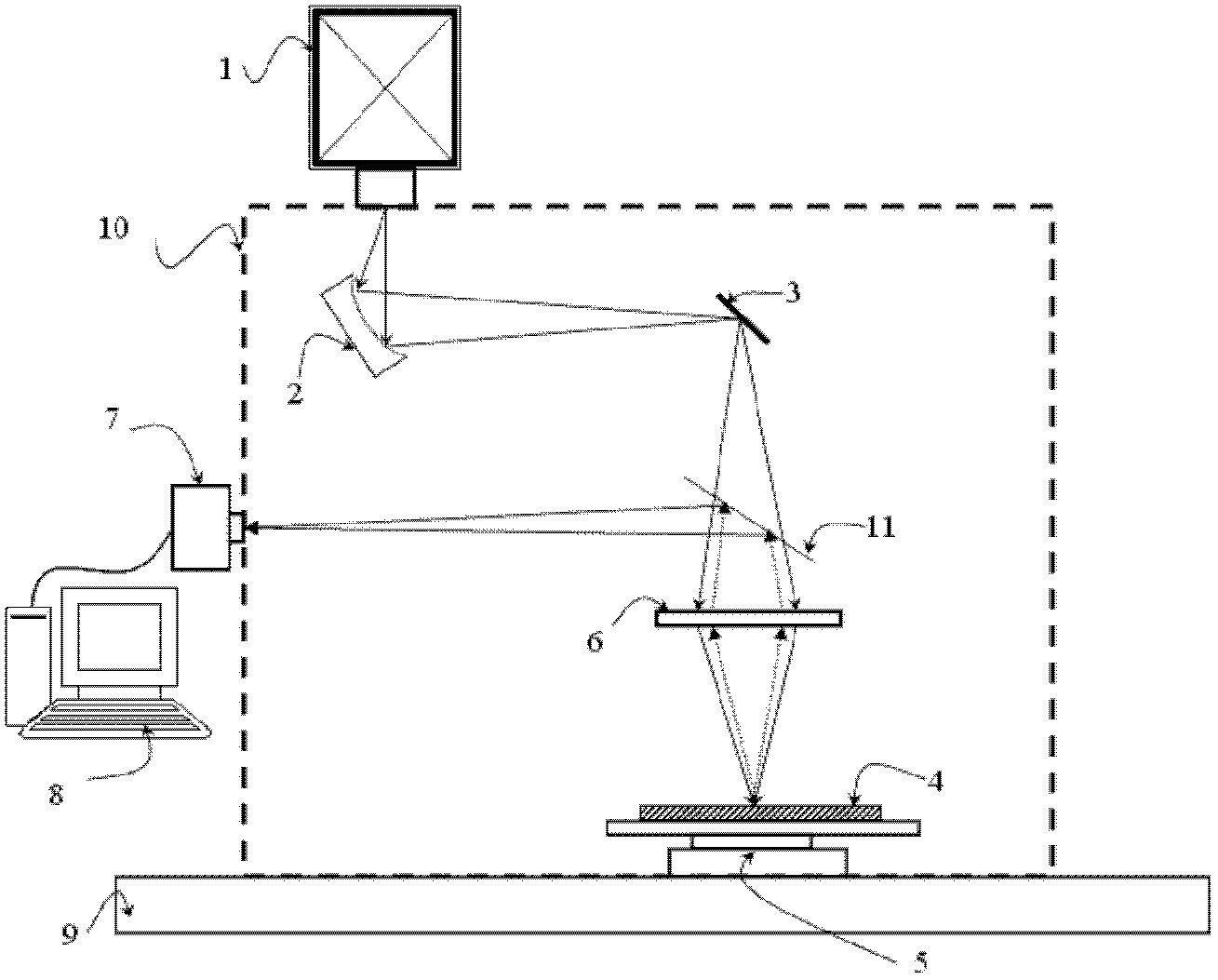

The invention relates to a laser direct-write photoetching system based on a photon sieve, which consists of an exposure light source (1), a lens (2), a spatial filtering device (3), a uniform collimating lens group (4), a reflector (5), the photon sieve (6), a photoresist (7), a substrate (8) and precise workpiece platforms (9). The laser light source becomes uniform and collimating parallel light after passing through the lens, the spatial filtering device and the uniform collimating lens group, the collimating parallel light irradiates the photon sieve, and the photon sieve has excellent focusing capability and focalizes on the substrate coated with the photoresist. The substrate is placed on X and Y precise workpiece platforms to achieve the required photoetching patterns by using the relative motion between the photon sieve and the substrate. The laser direct-write photoetching system has good process compatibility, the structure of the whole system is not needed to be changed; and only by changing a focusing element into a photon sieve device, the nano-scale resolving power can be achieved by using the conventional i ling and g line laser direct-write photoetching system. If the wavelength of the exposure light source is further shortened on the basis, higher resolving power can be achieved, and the nano-scale patterns can be made with ultra-low cost.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

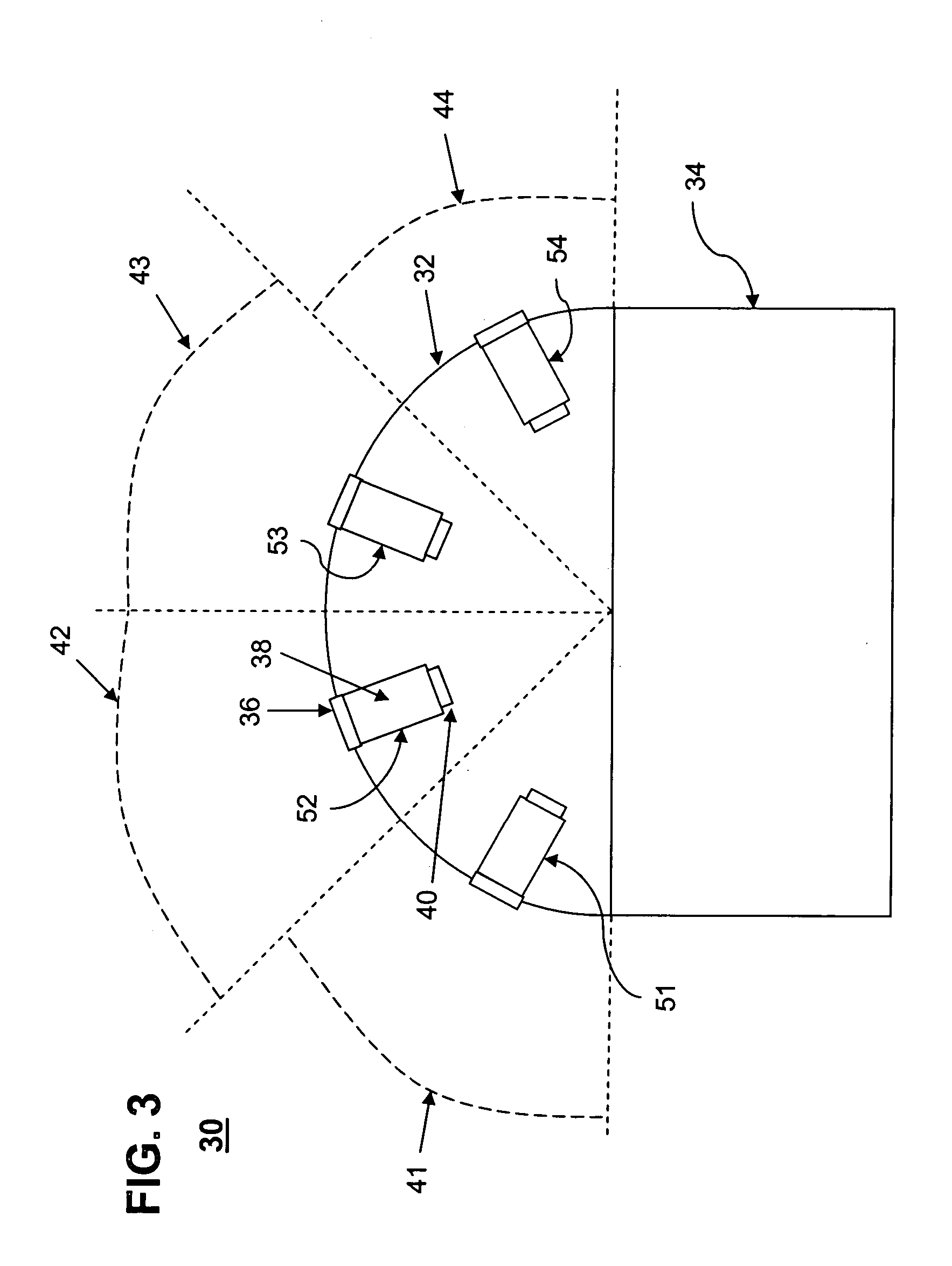

High resolution multi-lens imaging device

InactiveUS20050068632A1FocusTelevision system detailsColor television detailsWavelengthMulti dimensional

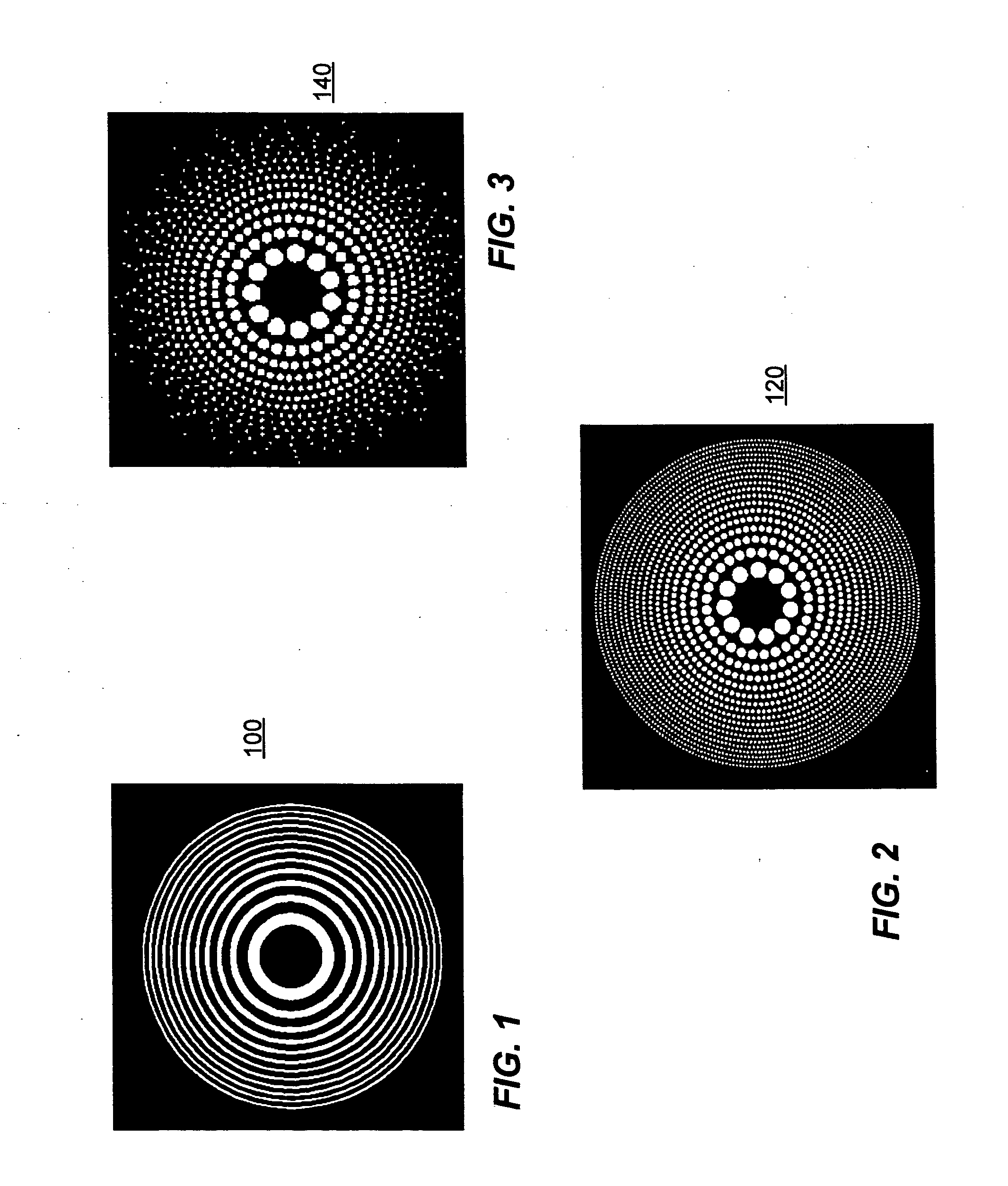

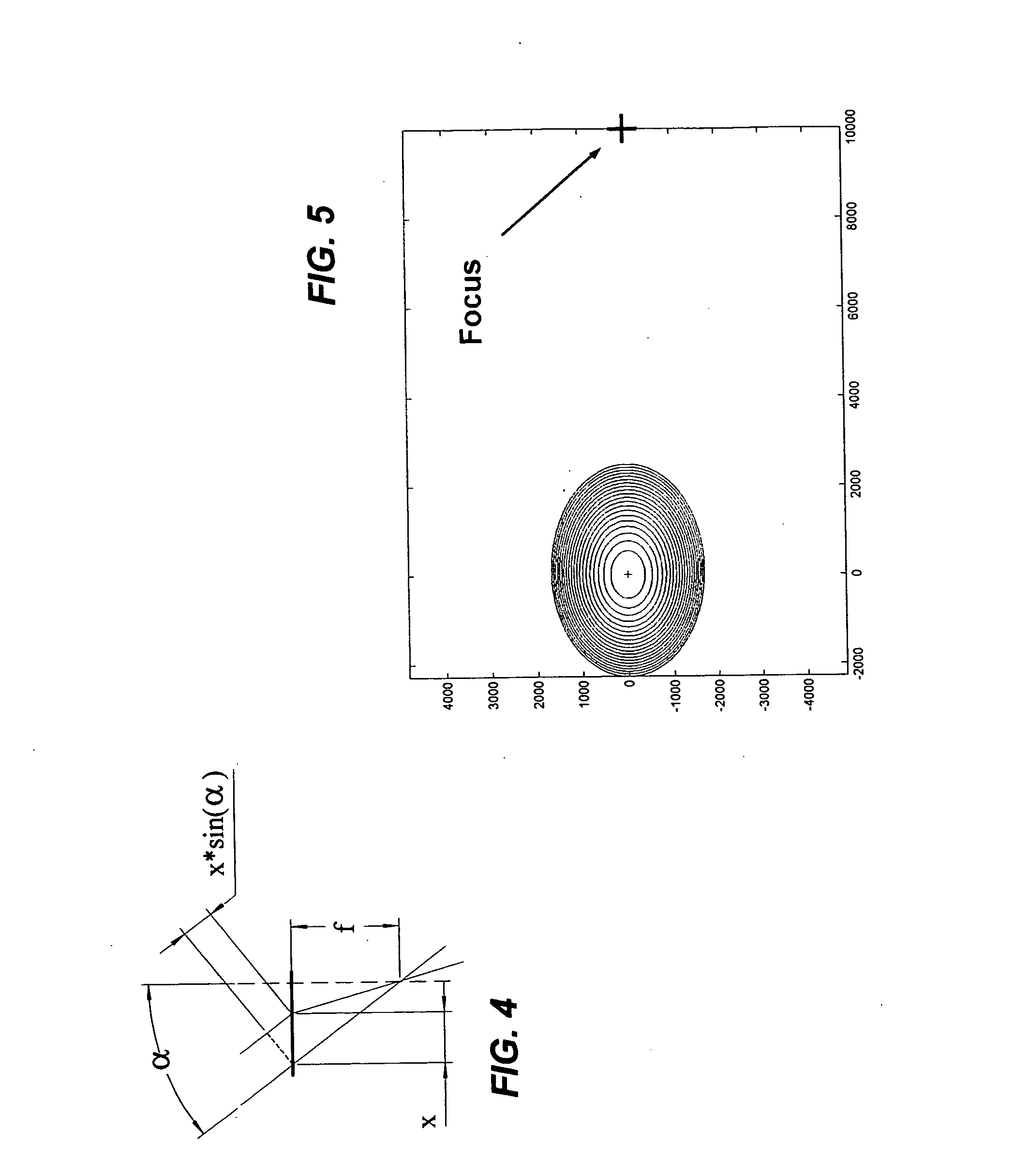

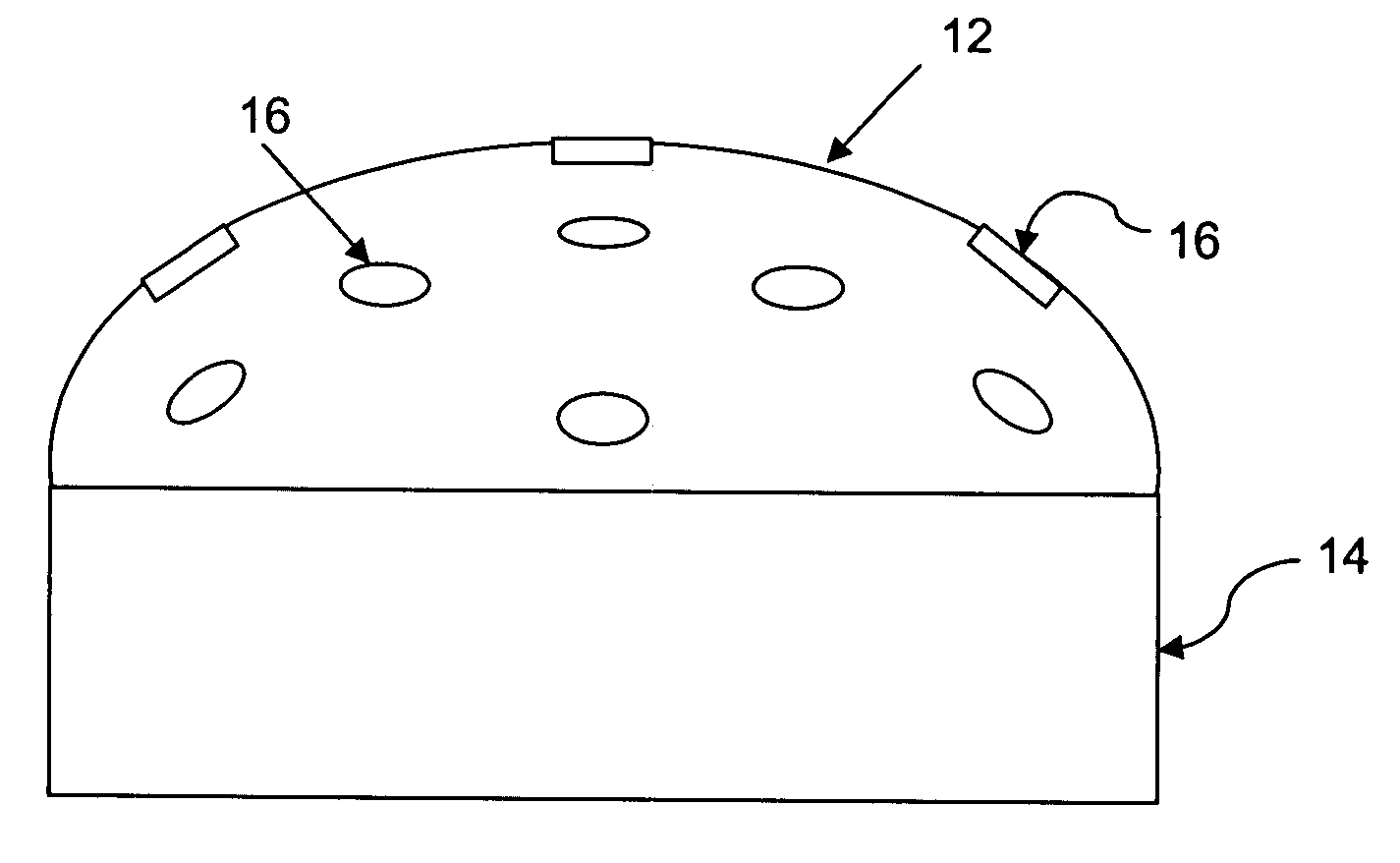

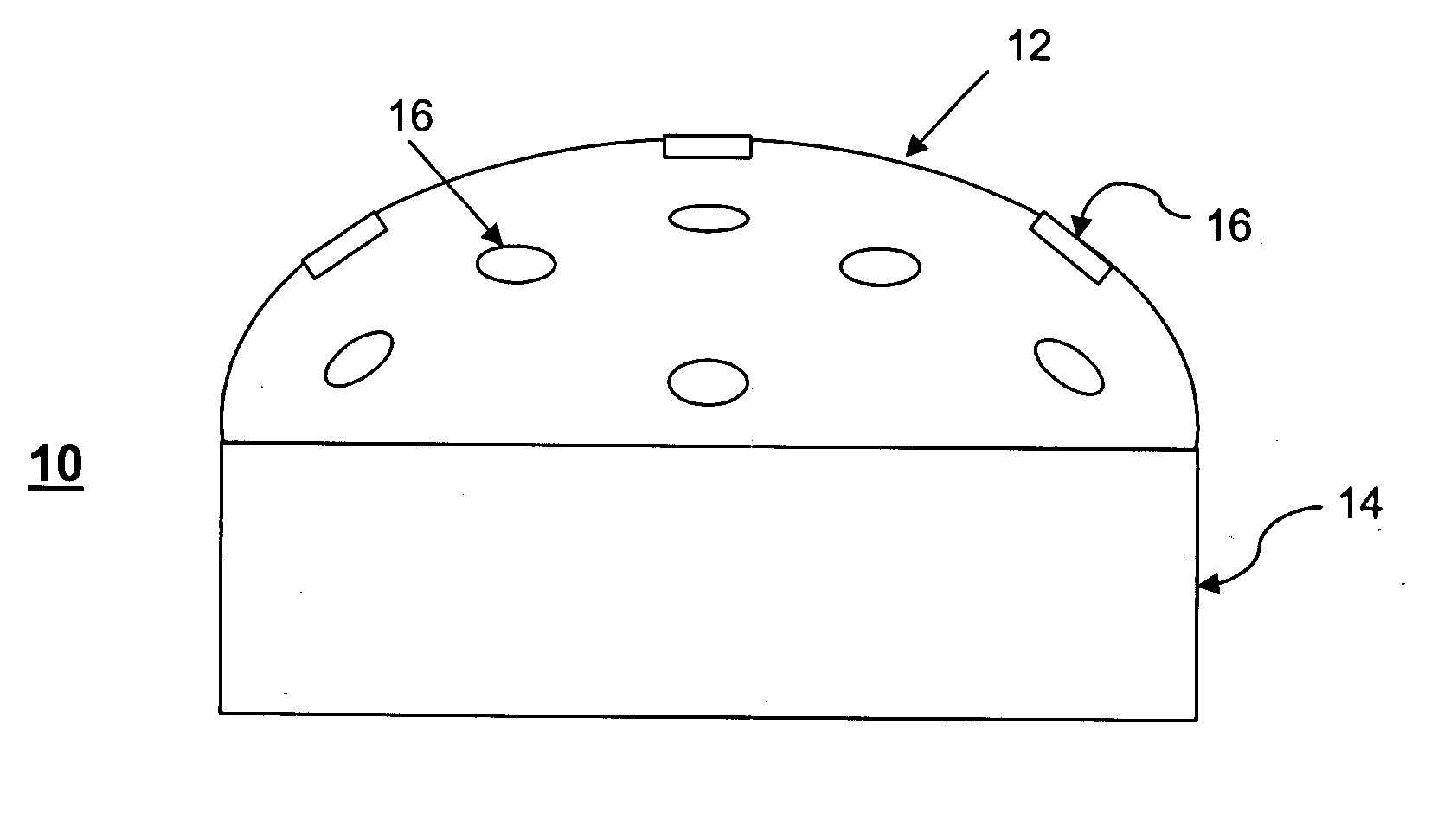

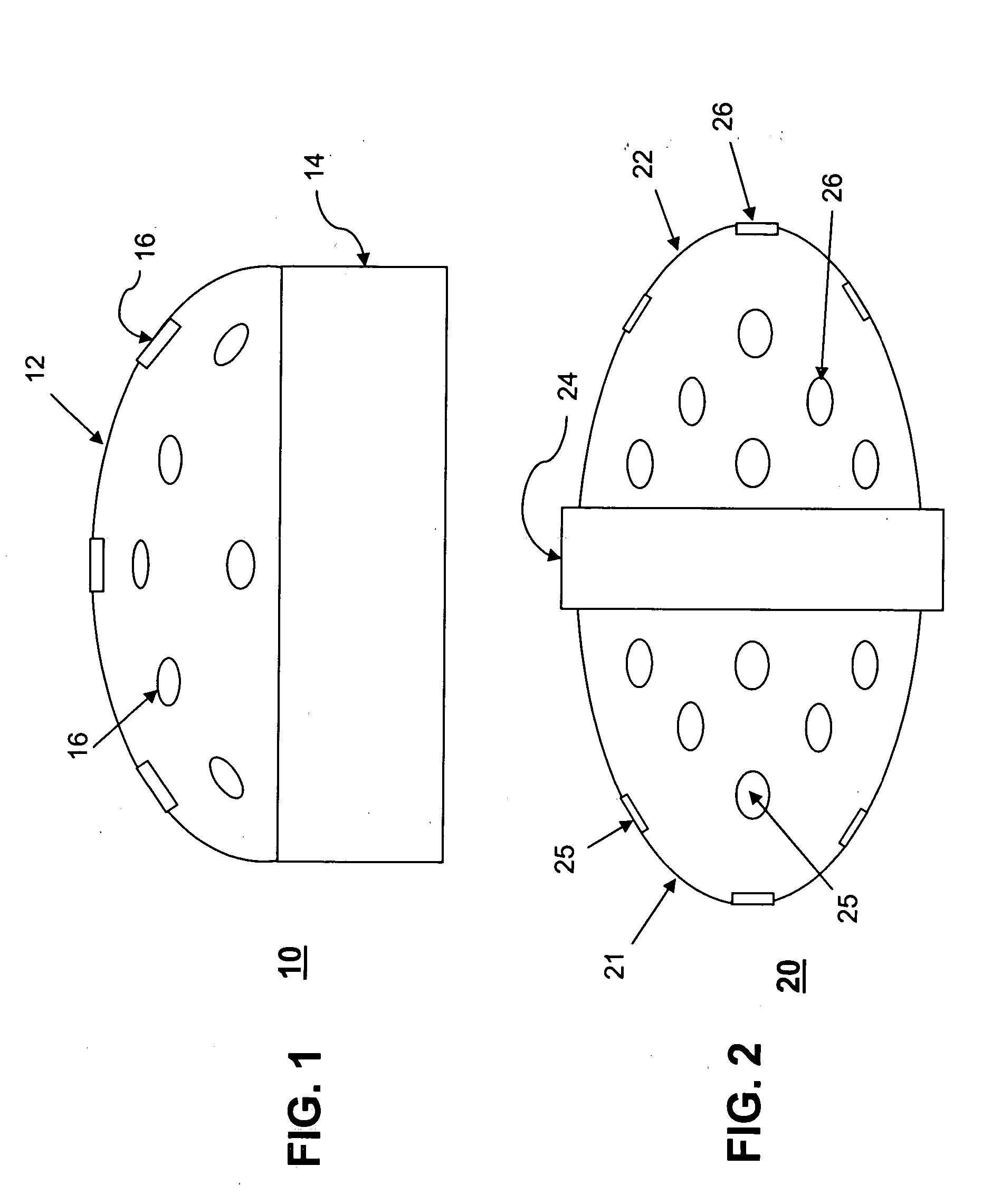

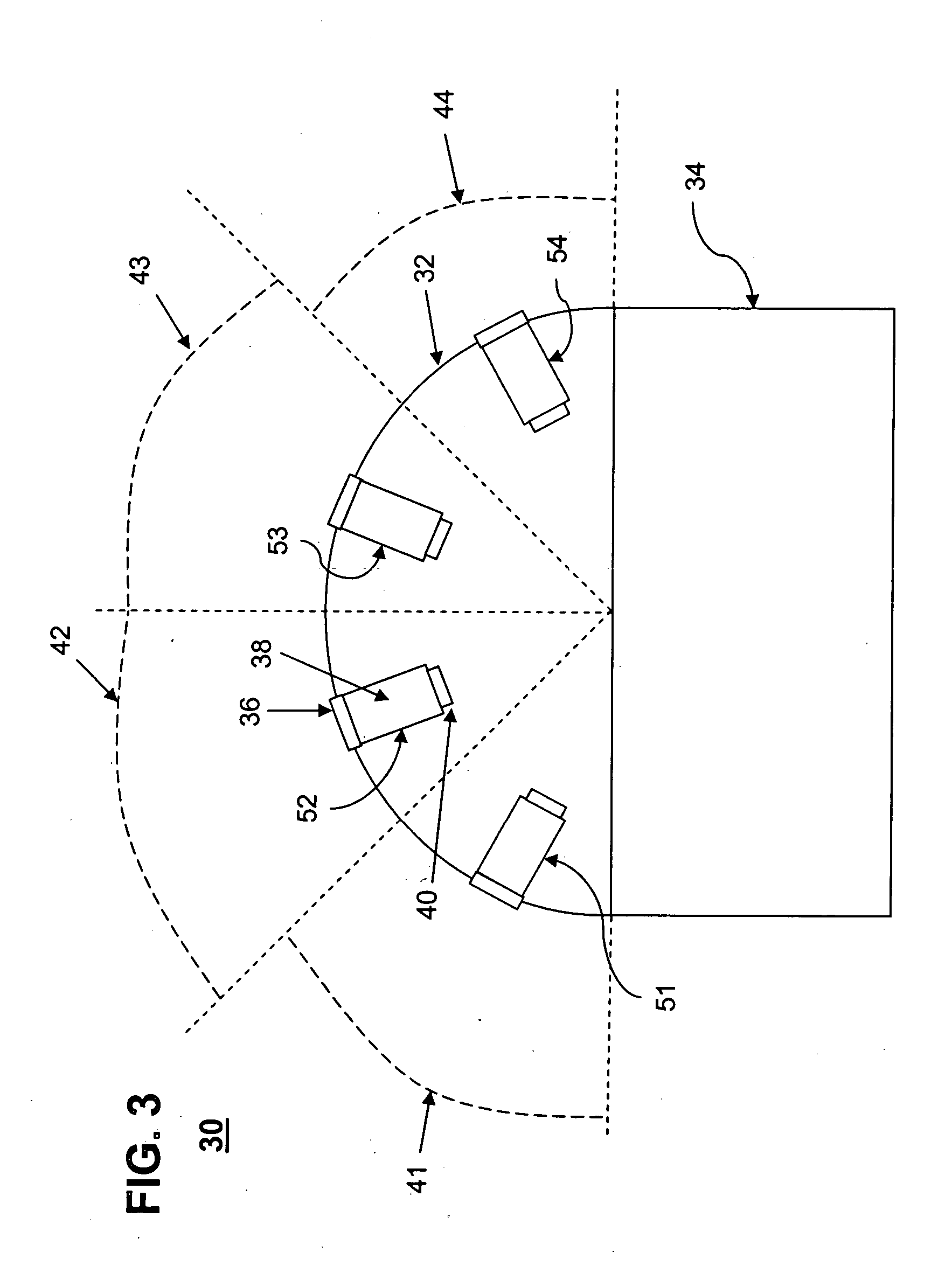

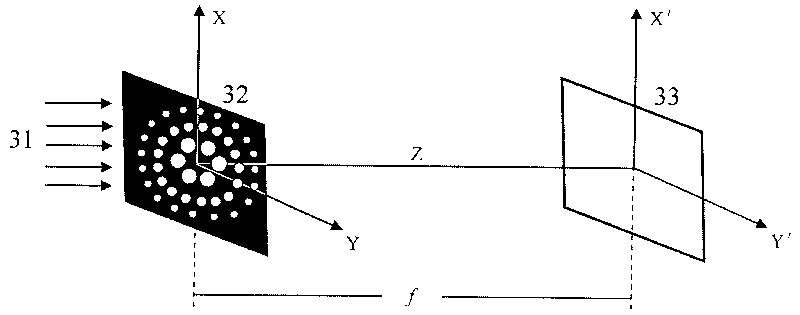

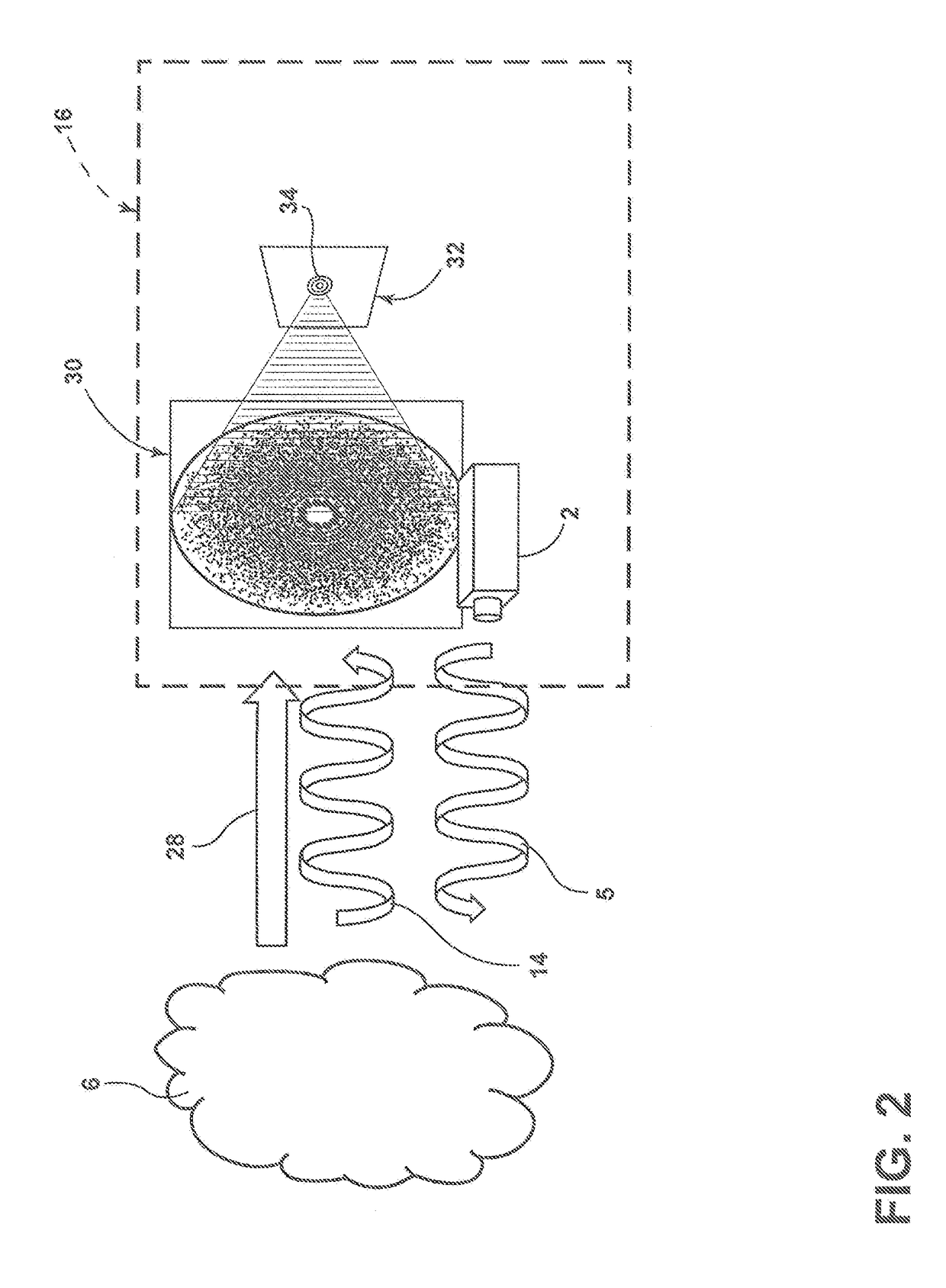

An imaging device (30) can include a plurality of lenses (51, 52, 53, 54) mounted on a multi-dimensional support structure (32), a plurality of optical detectors (40) corresponding to the plurality of lenses for capturing an optical signal from at least two lenses among the plurality of lenses, and a processor (34) for combining the optical signal from at least two lenses to form an image and electronically controlling the field of view and a resolution of the image. The plurality of lenses each can include an array of sub-wavelength apertures or a plurality of photon sieve lenses (36).

Owner:UNIV OF FLORIDA RES FOUNDATION INC +2

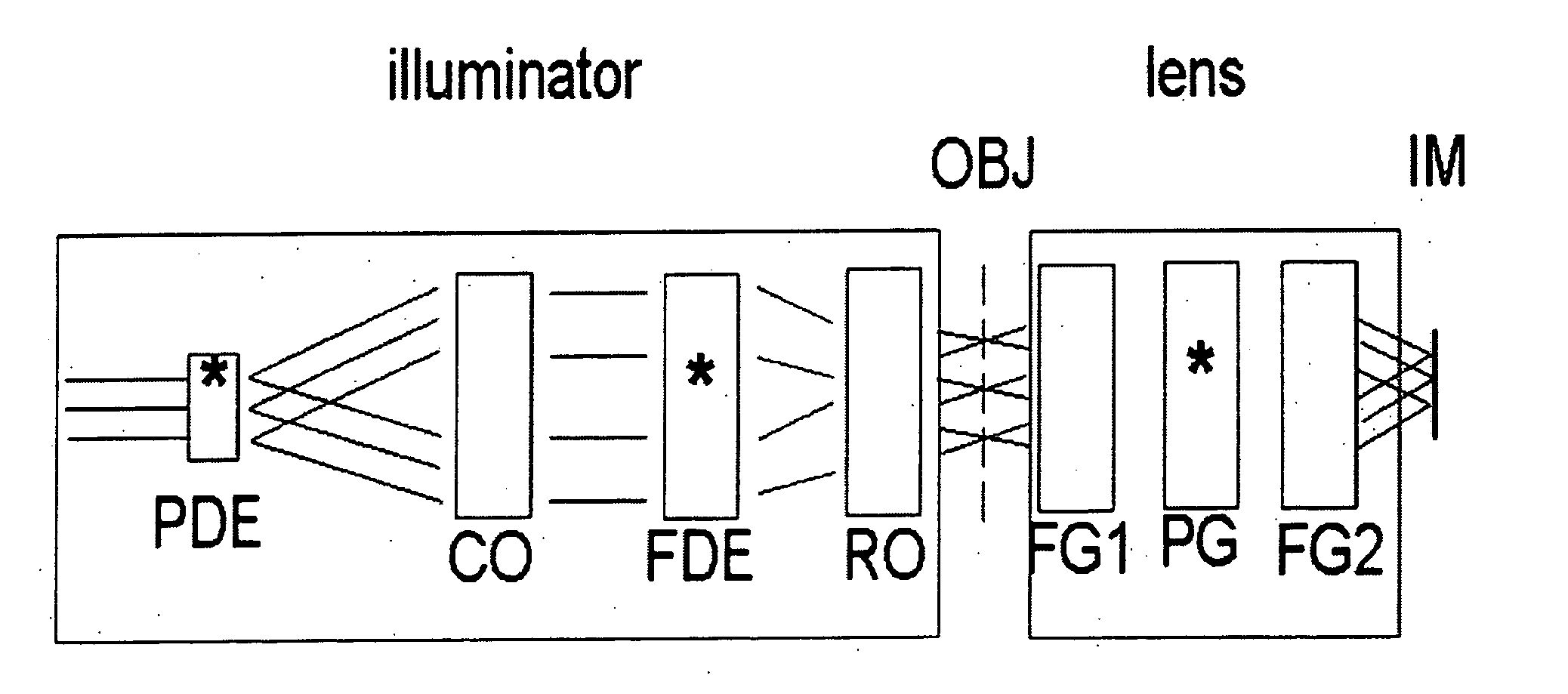

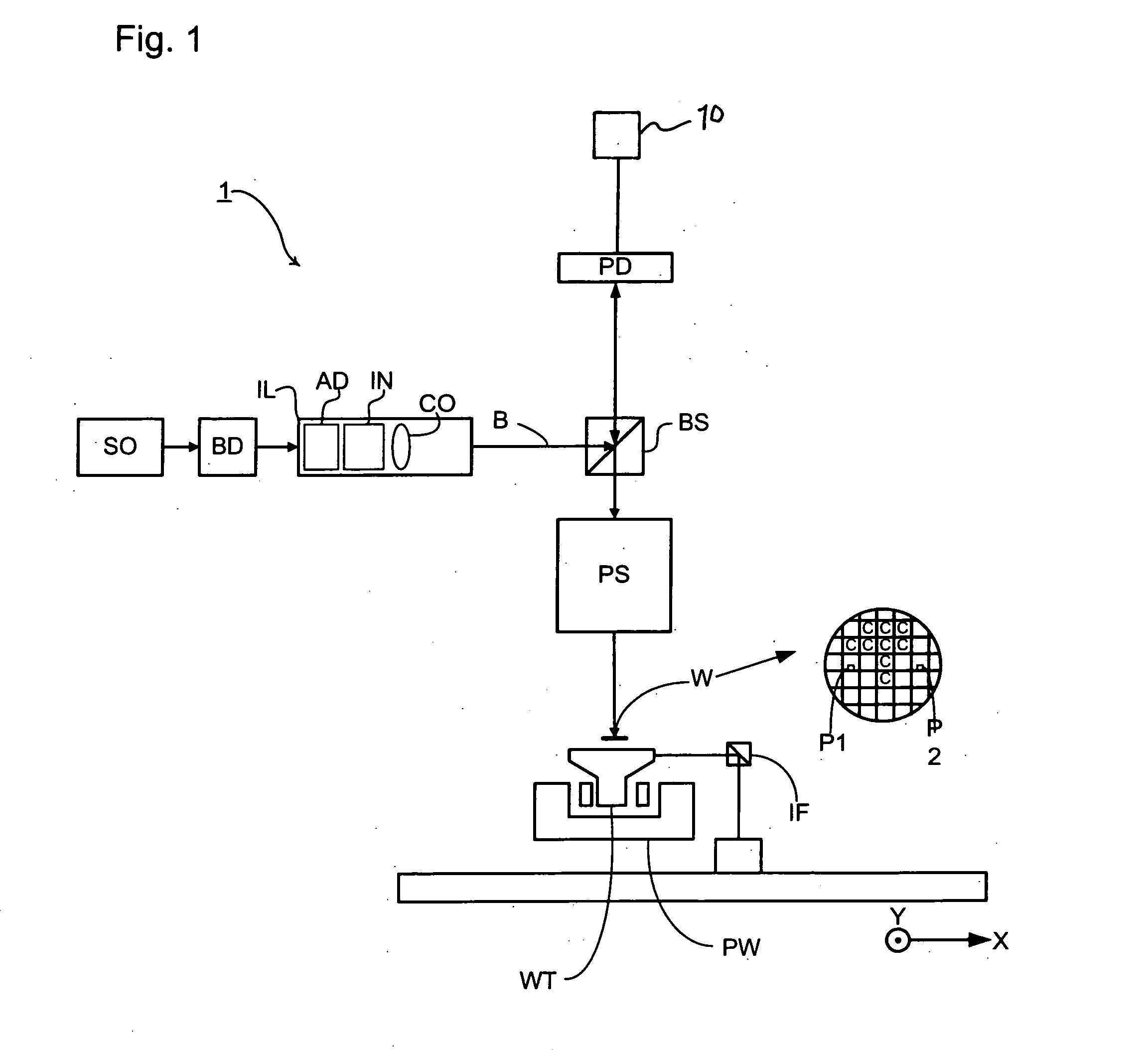

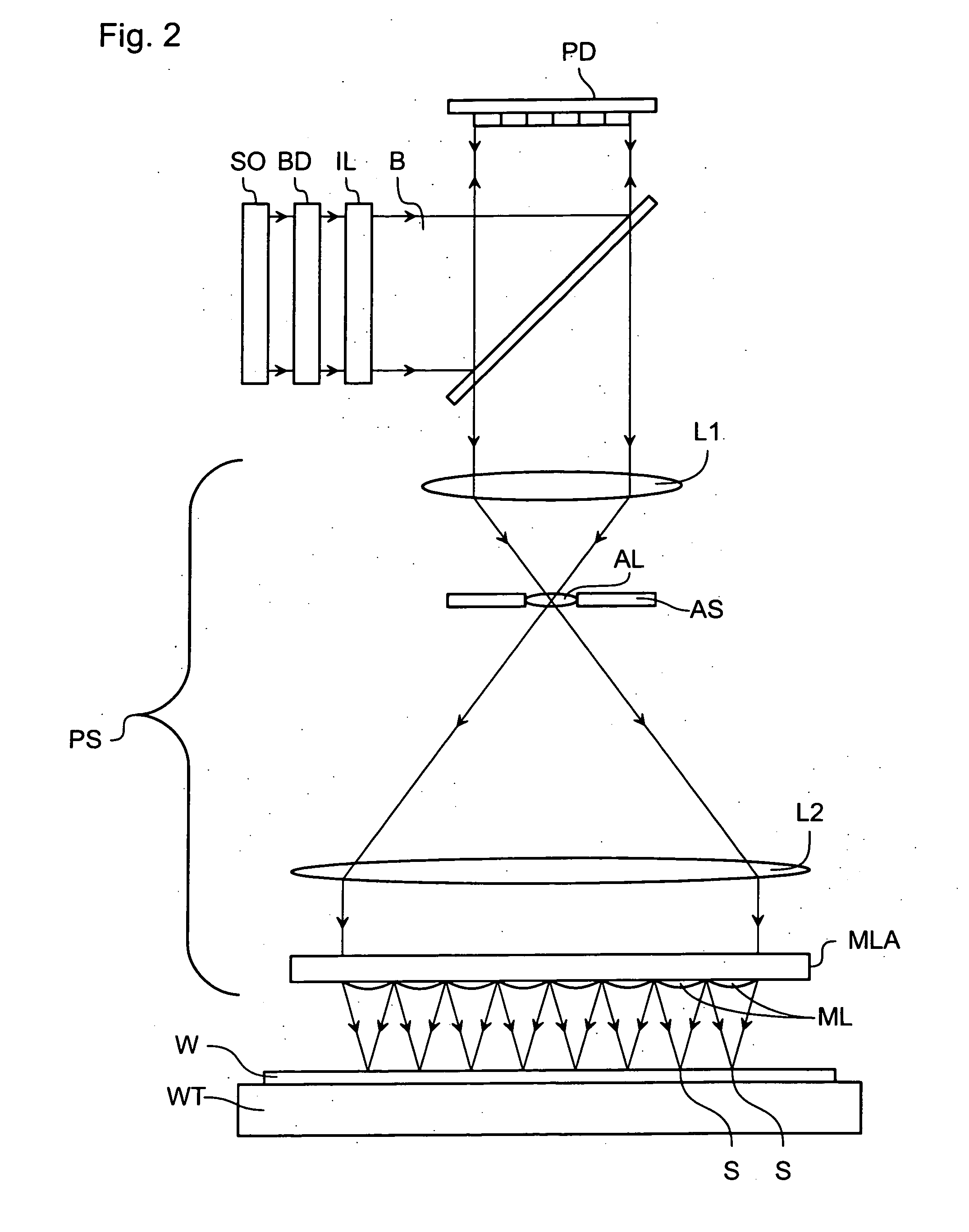

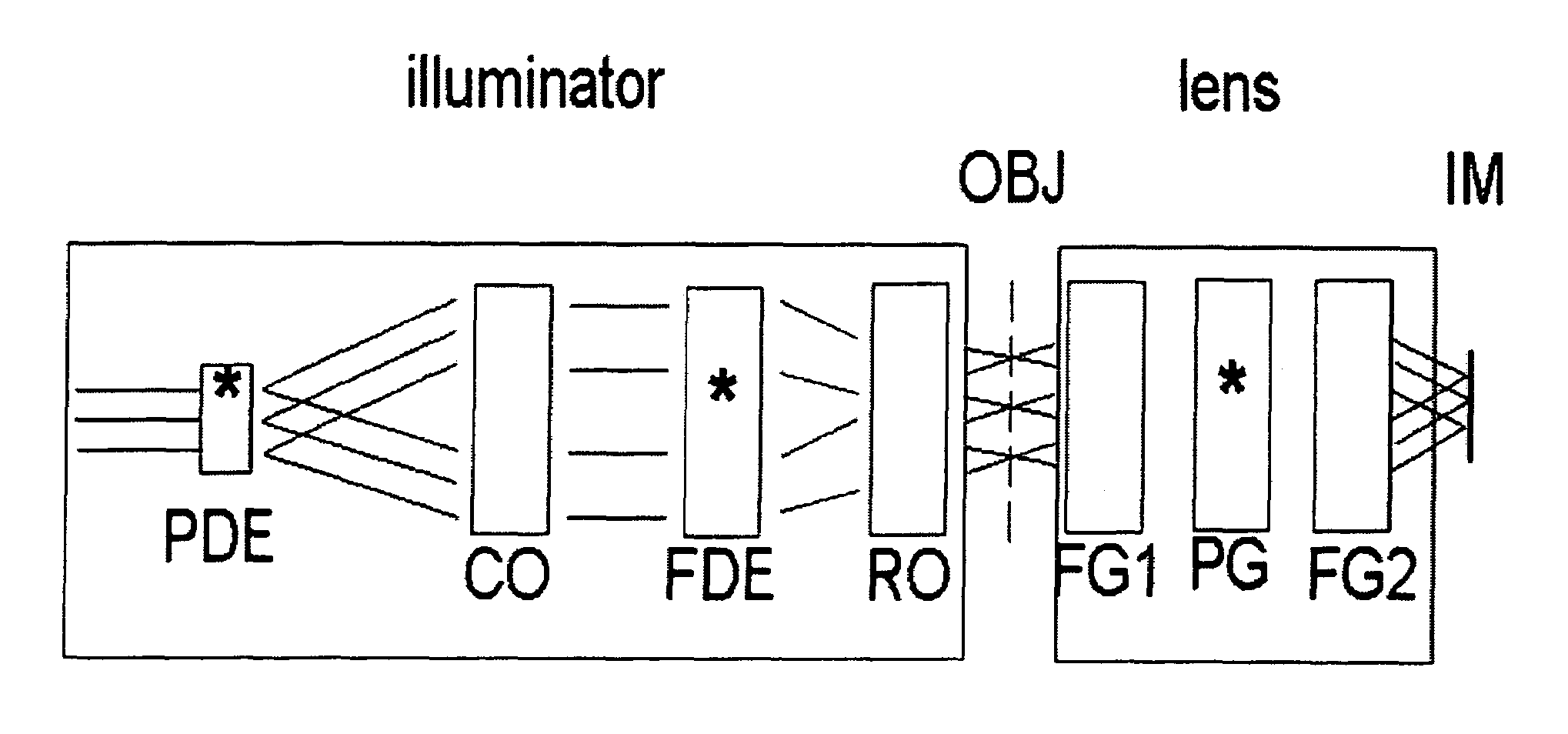

Photon sieve for optical systems in micro-lithography

InactiveUS20070194254A1Efficiently and effectively focusingRadiation pyrometryPhotomechanical apparatusLithographic artistColor correction

The use of photon sieves may be as a pupil defining element in an illumination system; a field of defining elements in an illumination system; a pupil lens element in a projection lens; a color correction system in the projection system; or as a transmitting diffractive element for EUV.

Owner:ASML NETHERLANDS BV

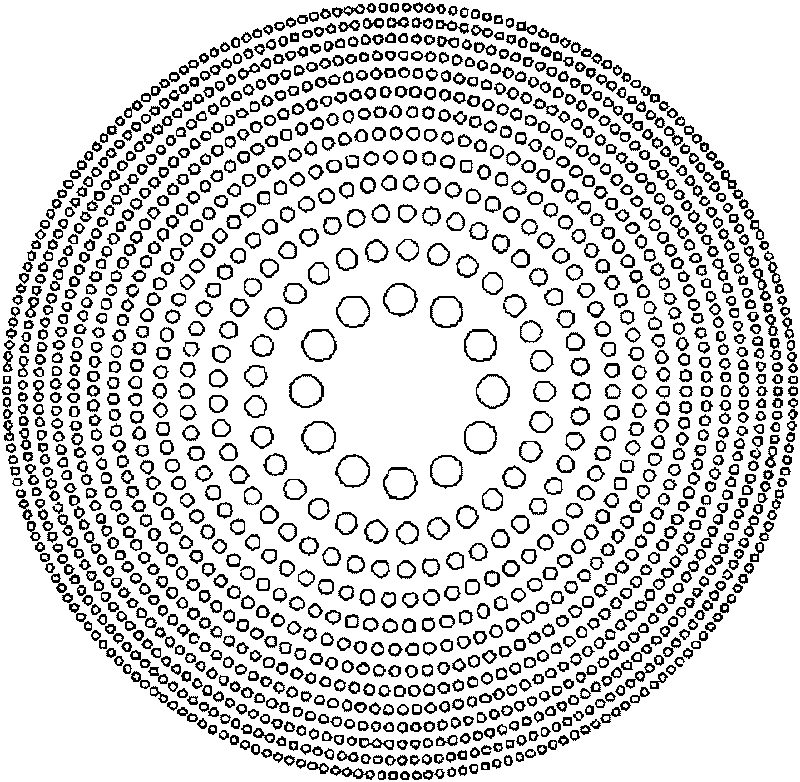

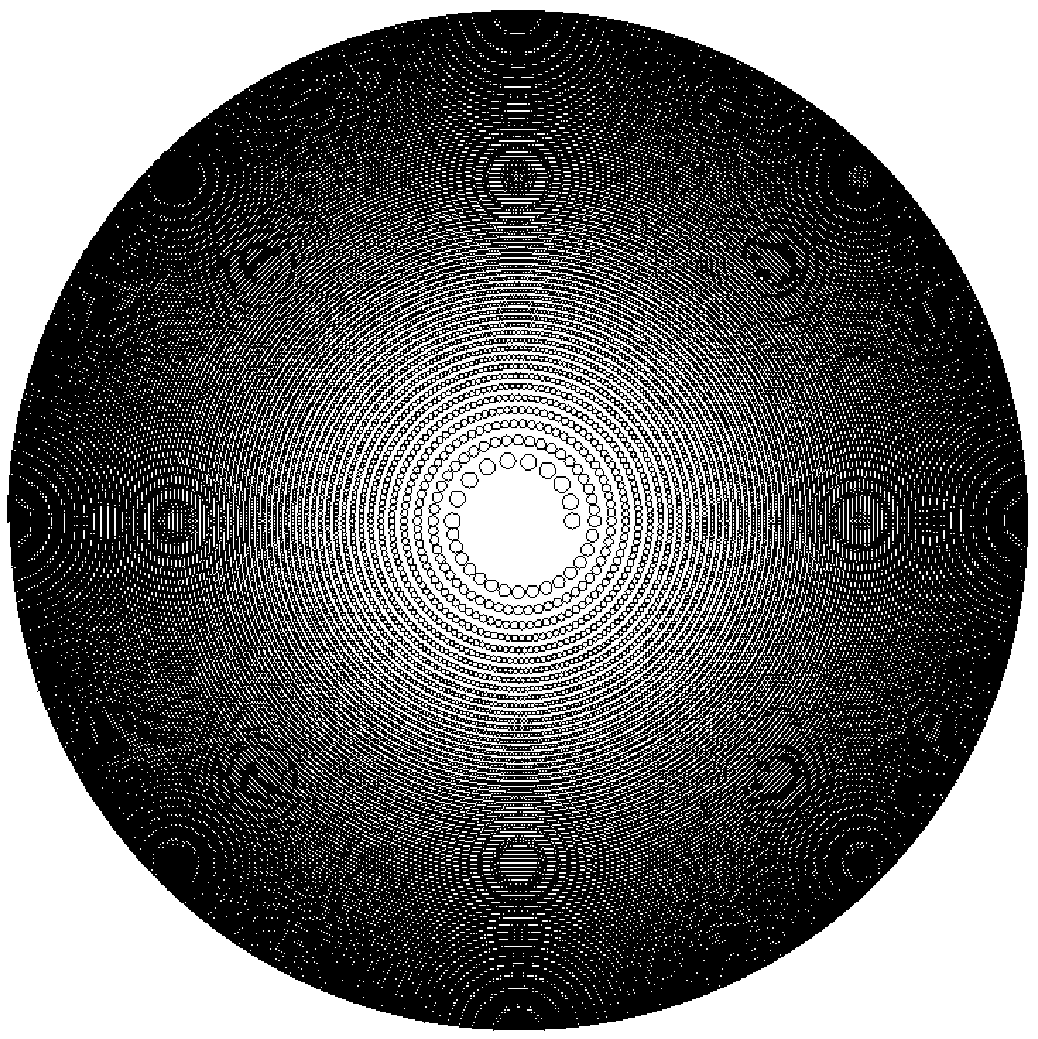

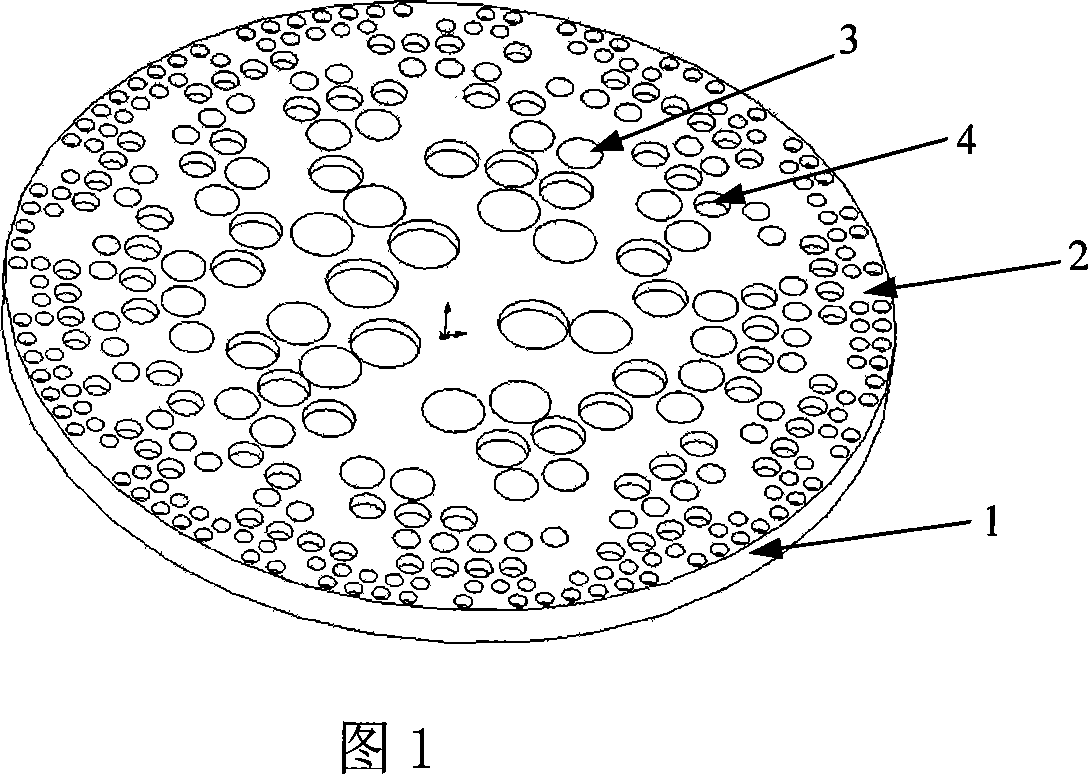

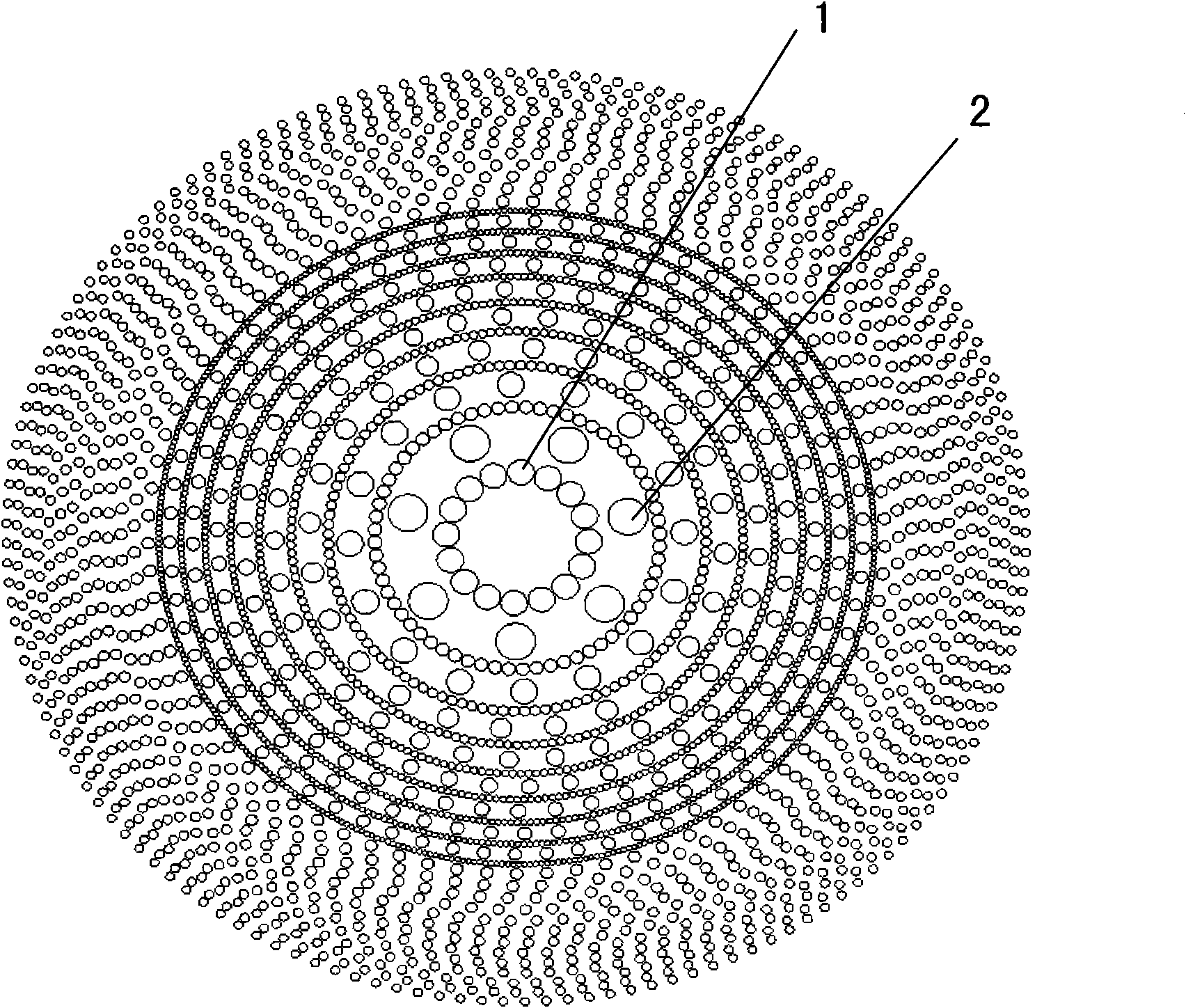

Large-aperture imaging photon sieve and production method thereof

InactiveCN101630027AHigh-resolutionSharp focal spotDiffraction gratingsImage resolutionOptoelectronics

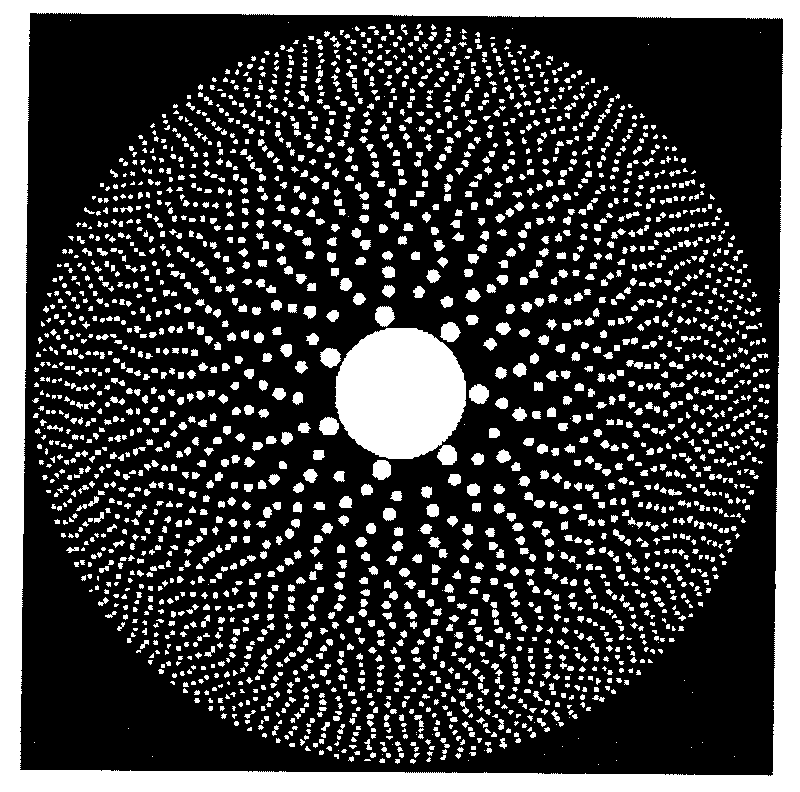

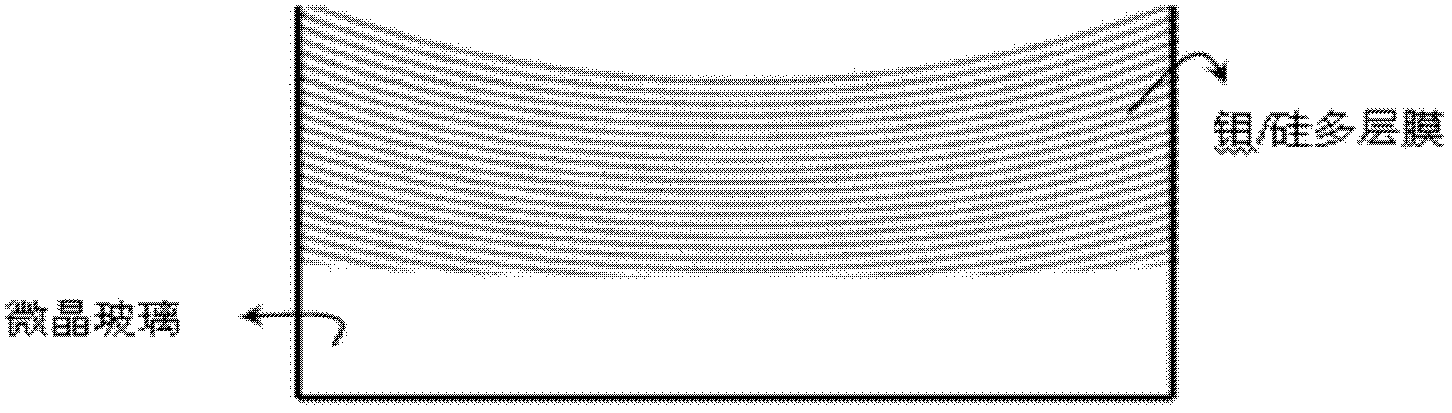

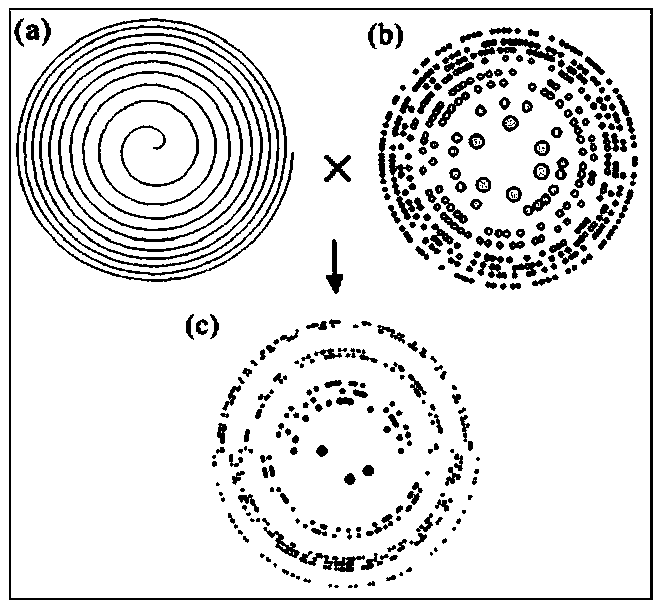

The invention discloses a large-aperture imaging photon sieve and a production method thereof, which belong to the technical field of diffractive optical elements. The large-aperture imaging photon sieve comprises a transparent substrate and an opaque metal thin film plated on the transparent substrate, wherein, a plurality of transparent small holes are randomly distributed on the opaque metal thin film, and the transparent small holes which are randomly distributed lead diffraction light to generate mutual interference, thereby effectively suppressing sidelobe effect and high-level diffraction, improving resolution and obtaining more sharp focal spots. The production method adopts a Connes shaping function for shaping the small holes which are randomly distributed, thereby reducing the number of the holes, reducing the data amount of a layout, optimizing the overall distribution of the small holes, leading the imaging focal spots to be more sharp and leading the level of the existing processing technology to be capable of meeting the manufacturing needs of the large-aperture photon sieve.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

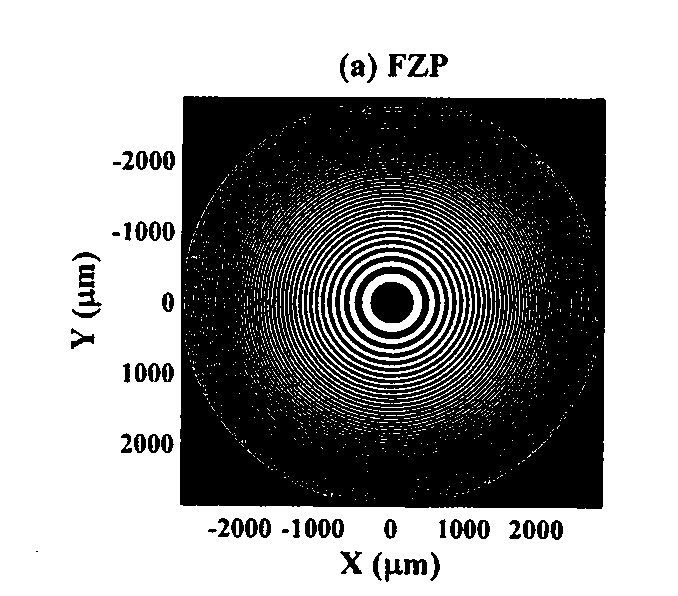

Phase type photon sieve

A phase type photon sieve is improved from a conventional Fresnel zone plate structure and consists of orifices distributed on transparent and non-transparent annulus of the Fresnel zone plate randomly, wherein Pi-phase shift is existed between the orifices on the transparent annulus and the orifices on the non-transparent annuls, and phase difference is achieved by accurately controlling etching depth of each annulus. Manufacturing process of the phase type photon sieve is completed by an electro beam machining process. Compared with the Fresnel zone plate, the phase type photon sieve can keep high diffraction efficiency and simultaneously has more excellent resolution capacity. Compared with an amplitude photon sieve, the phase type photo sieve can keep high resolution capacity and simultaneously has more excellent diffraction efficiency. As an excellent nano-level diffraction imaging device, the phase type photon sieve can be widely applied to fields of photo-etching, astronomical observation, air shot, weapon vision and the like.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

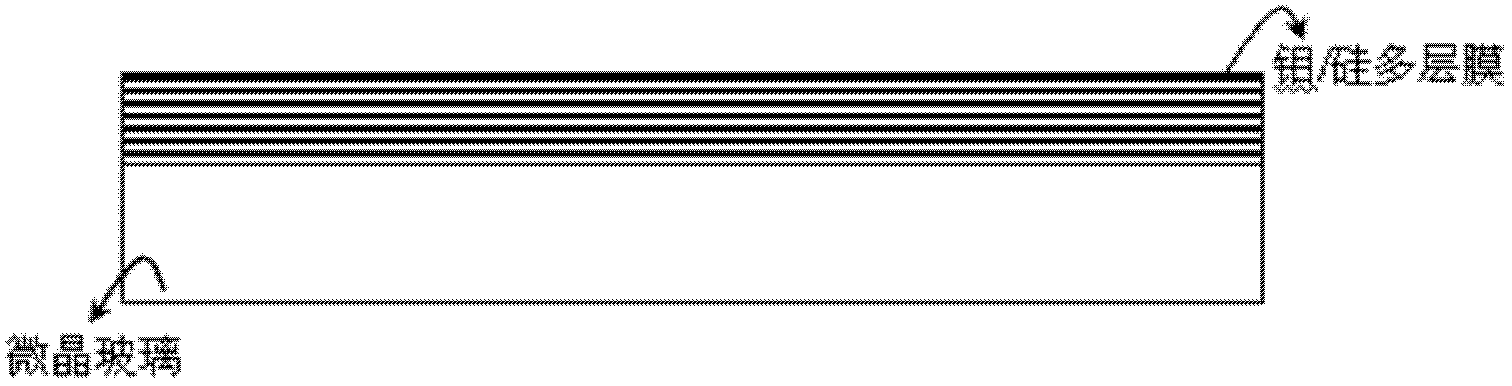

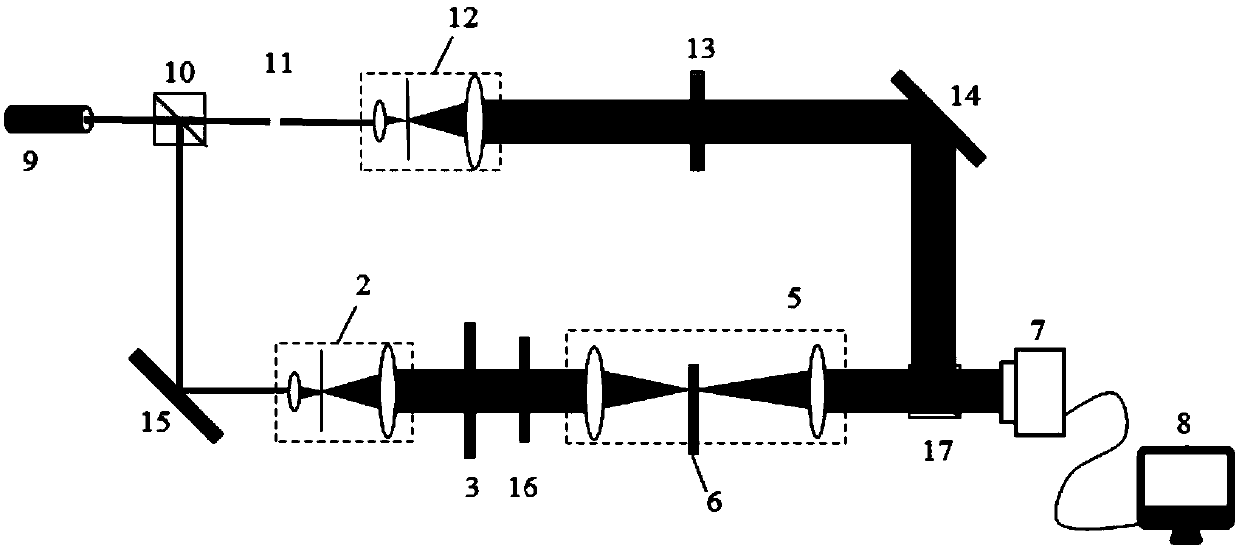

Defect detection system for extreme ultraviolet lithography mask

InactiveCN103424985AReduce volumeEasy to processOriginals for photomechanical treatmentTransport systemPlane mirror

The invention discloses a defect detection system for an extreme ultraviolet lithography mask. The defect detection system for the extreme ultraviolet lithography mask comprises an extreme ultraviolet light source, an extreme ultraviolet light transmission system (comprising a multilayer plane mirror and a multilayer concave condenser), an extreme ultraviolet lithography mask, a sample scan stage, a photon sieve, a CCD camera, a PC, an vibration isolation platform, a vacuum chamber and a multilayer half-transparent half-reflecting mirror. In the defect detection system for the extreme ultraviolet lithography mask, a conventional Schwarzchild lens is replaced by the photon sieve, so that imaging of the mask by an extreme ultraviolet band is realized, and thus defects on the mask are detected. Due to the fact of replacement of the conventional Schwarzchild lens which is difficult to process, high in cost and large in volume by the photon sieve which has the characteristics of small volume, good workability, low cost and high resolution ratio, the defect detection system for the extreme ultraviolet lithography mask is realized in lower cost, smaller volume and high resolution ratio.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

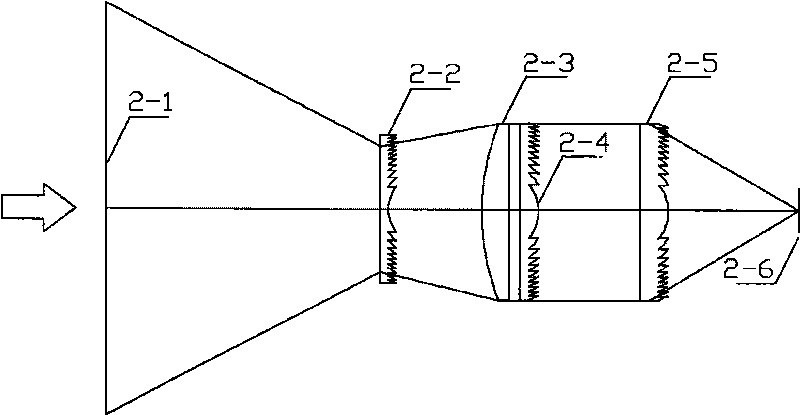

Broad spectrum optical imaging system of large-diameter photon sieve space telescope

InactiveCN101726838ABroaden the spectral widthLarge caliberTelescopesLight equipmentPhotovoltaic detectors

The invention relates to a broad spectrum optical imaging system of a large-diameter photon sieve space telescope. The broad spectrum optical imaging system comprises a large-diameter photon sieve. A negative diffraction lens, a positive lens, a first harmonic diffractive and a second harmonic diffractive of lens zero focal power, and a photoelectric detector are arranged in sequence after the photon sieve along the incident direction of light. The system has the advantages of large diameter, light equipment, broad spectrum and high resolution.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

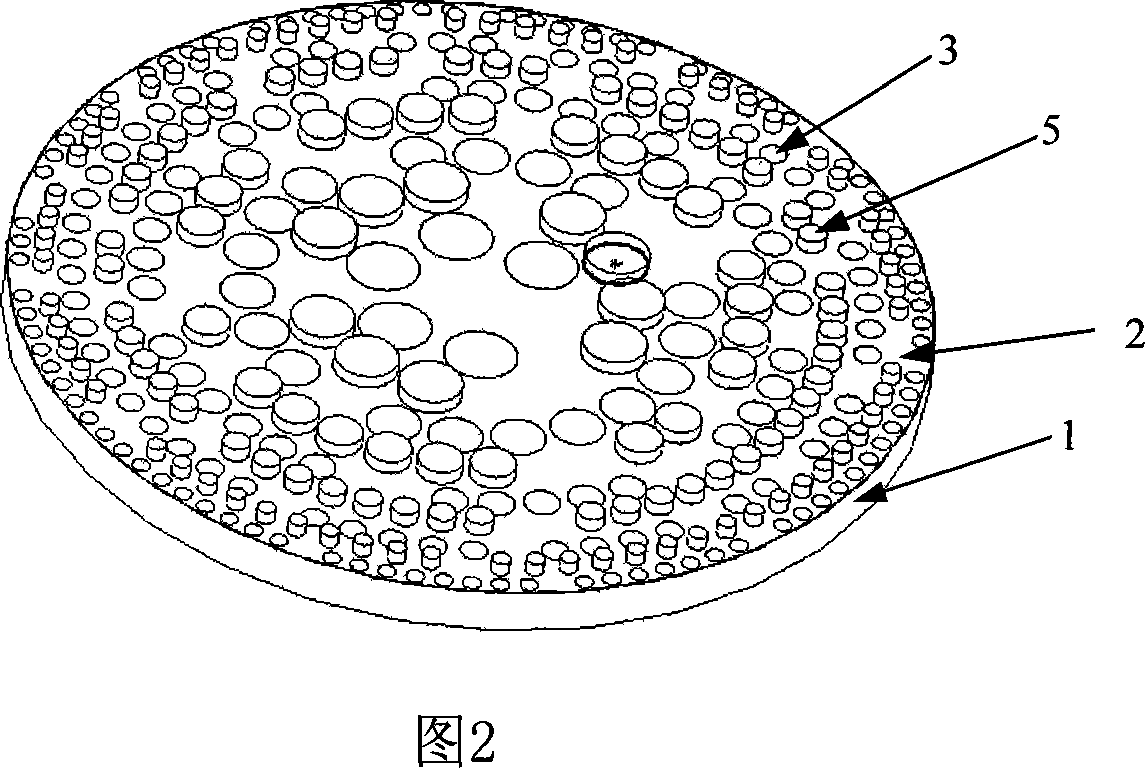

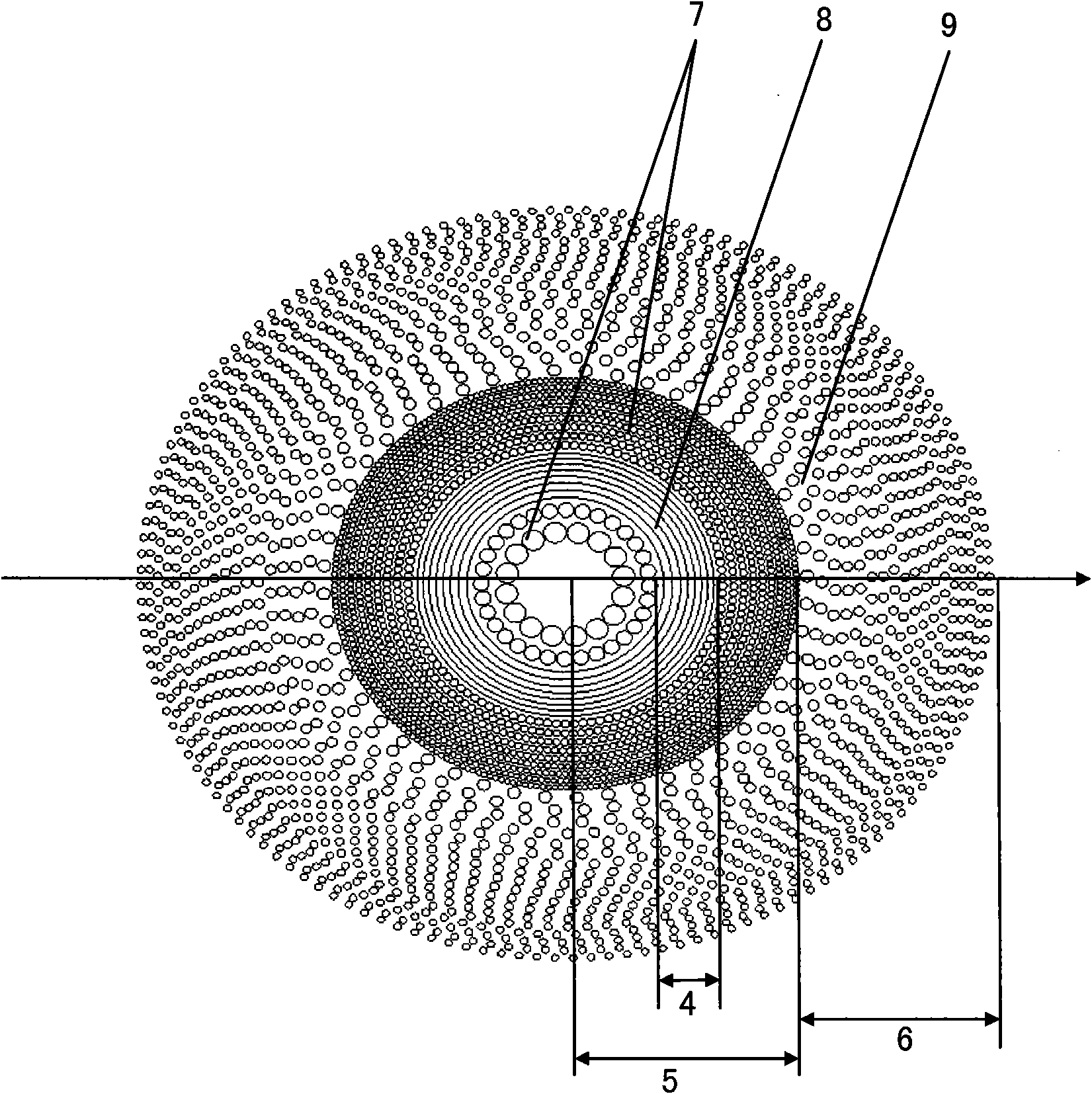

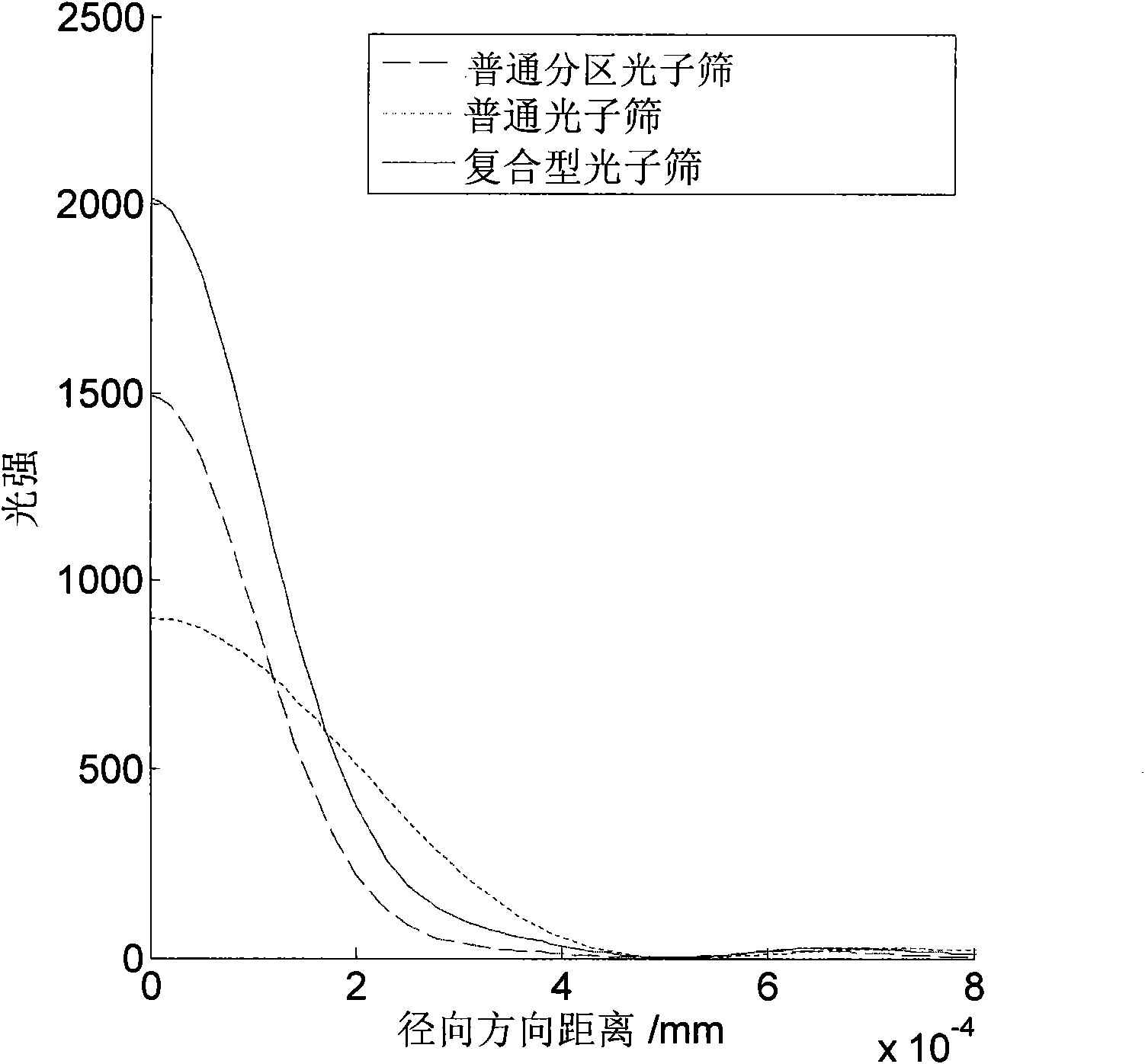

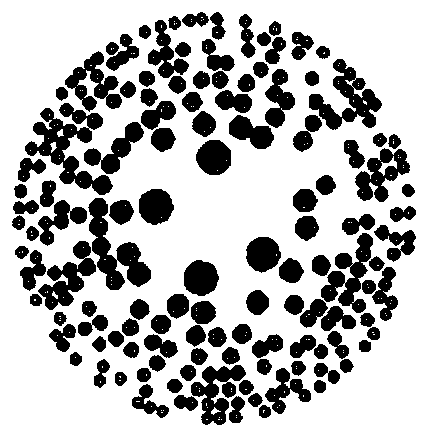

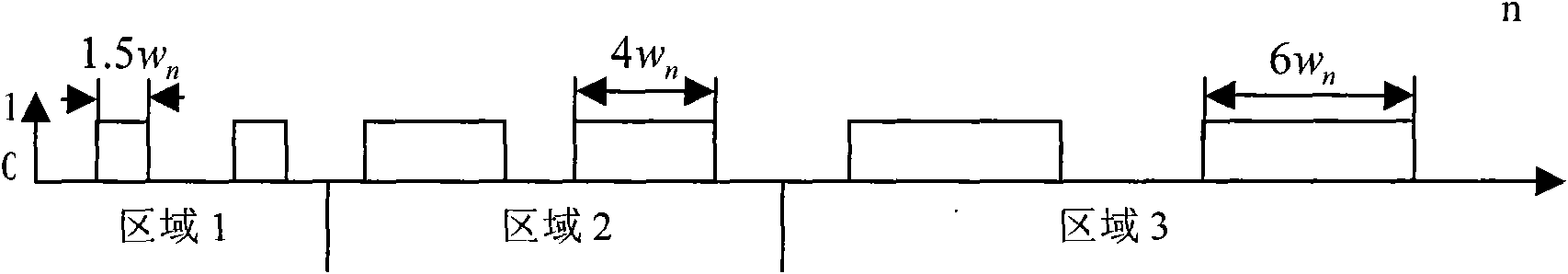

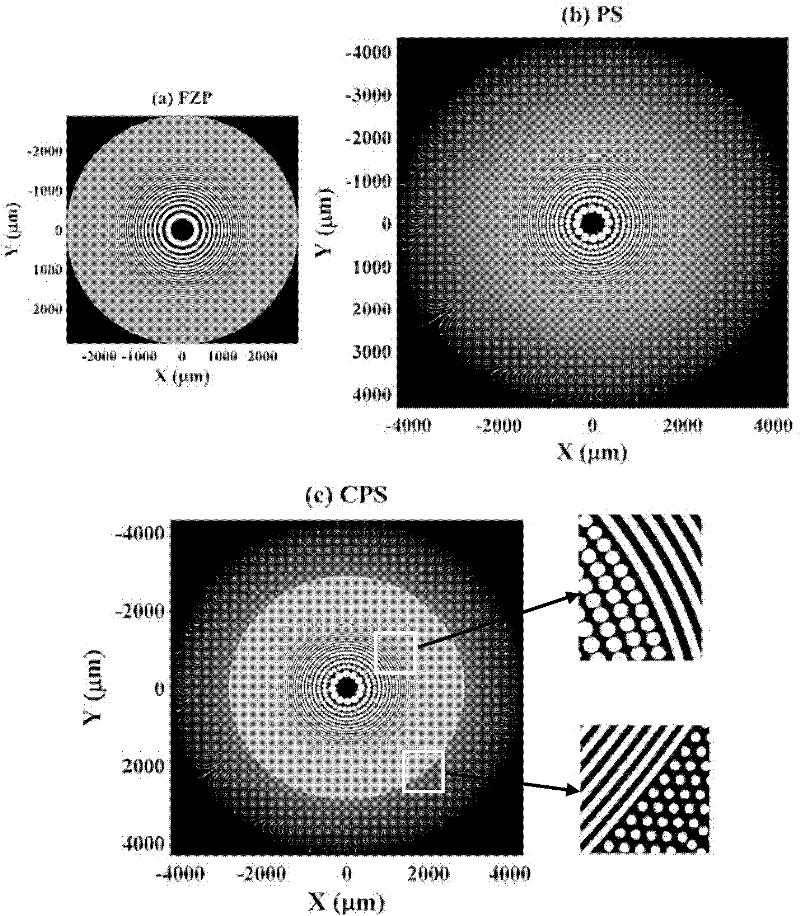

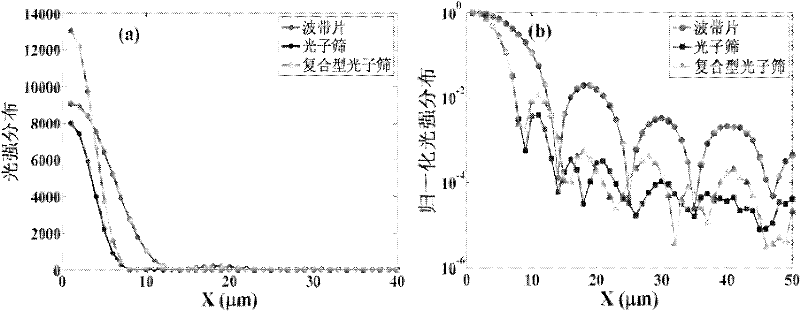

Compound photon sieve for large-caliber imaging and manufacturing method thereof

ActiveCN102043178AHigh-resolutionSharp focal spotPhotomechanical apparatusDiffraction gratingsOrganic glassBlocking layer

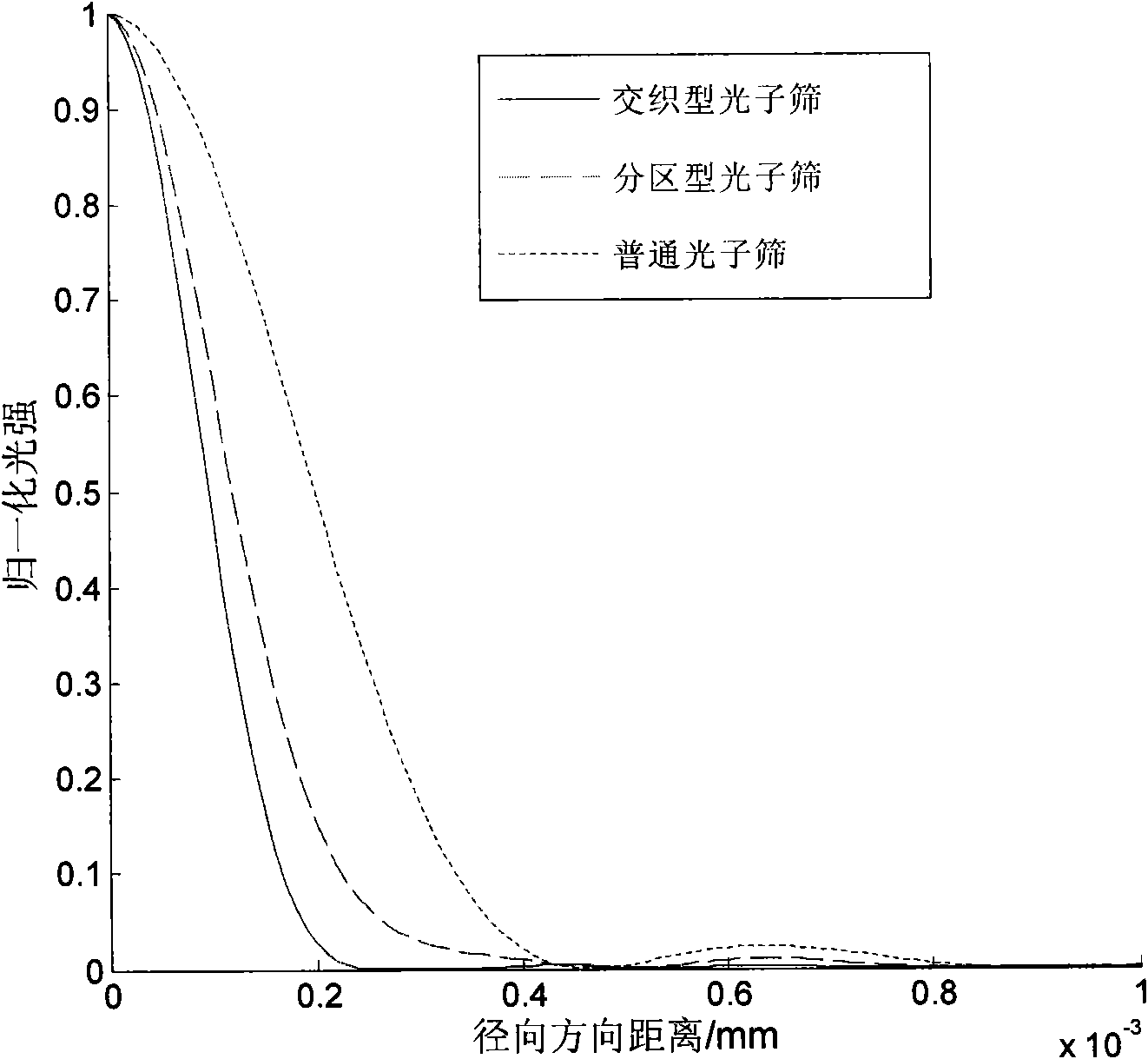

The invention discloses a compound photon sieve for large-caliber imaging and a manufacturing method thereof and belongs to the technical field of diffractive optical elements. The compound photon sieve comprises a transparent substrate and a lightproof metal film plated on the pervious substrate; a series of transparent girdles and pervious apertures which are randomly distributed are designed on the lightproof film; a pervious plane can be made of transparent materials such as fused quartz, common glass, organic glass and the like; the lightproof film is a metal light-blocking layer of chromium, gold, aluminum, copper and the like prepared on the transparent substrate; and the transparent girdles and the transparent apertures are not provided with the metal light-blocking layer. Compared with Fresnel wave zone plates, the compound photon sieve provided by the invention can improve numerical aperture and imaging resolution and can effectively restrain side-lobe effect and high-order diffraction in the direction of an optical axis; and compared with a common photon sieve, the compound photon sieve can improve imaging contrast, effectively reduces data volume of geometry data standard II (GDSII) map files, and reduces the difficulty in processing large-caliber imaging photon sieves.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

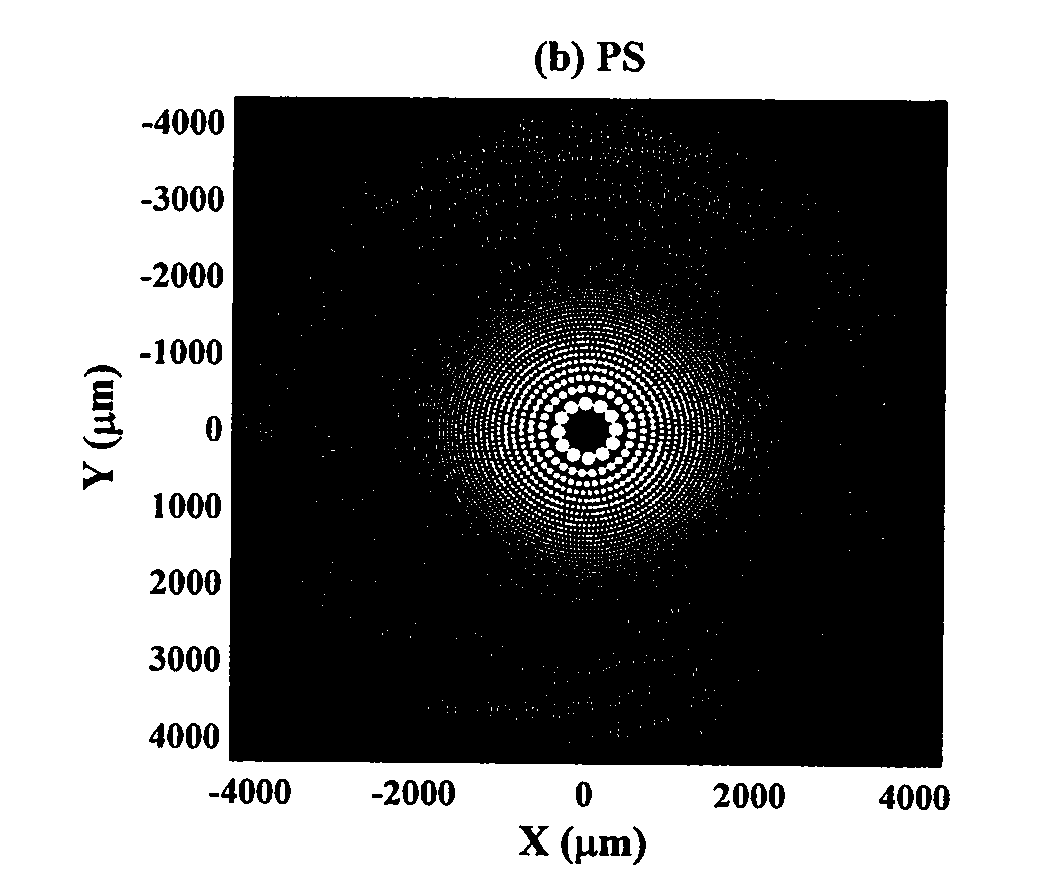

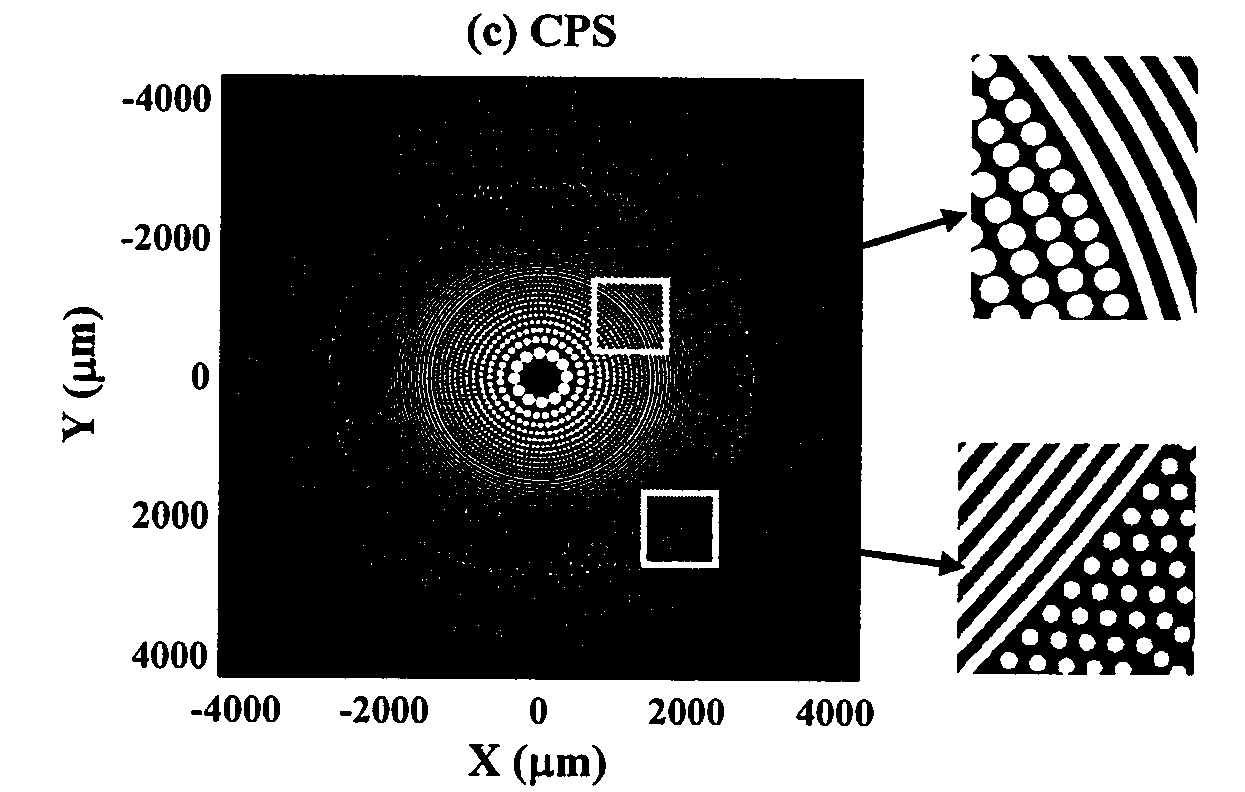

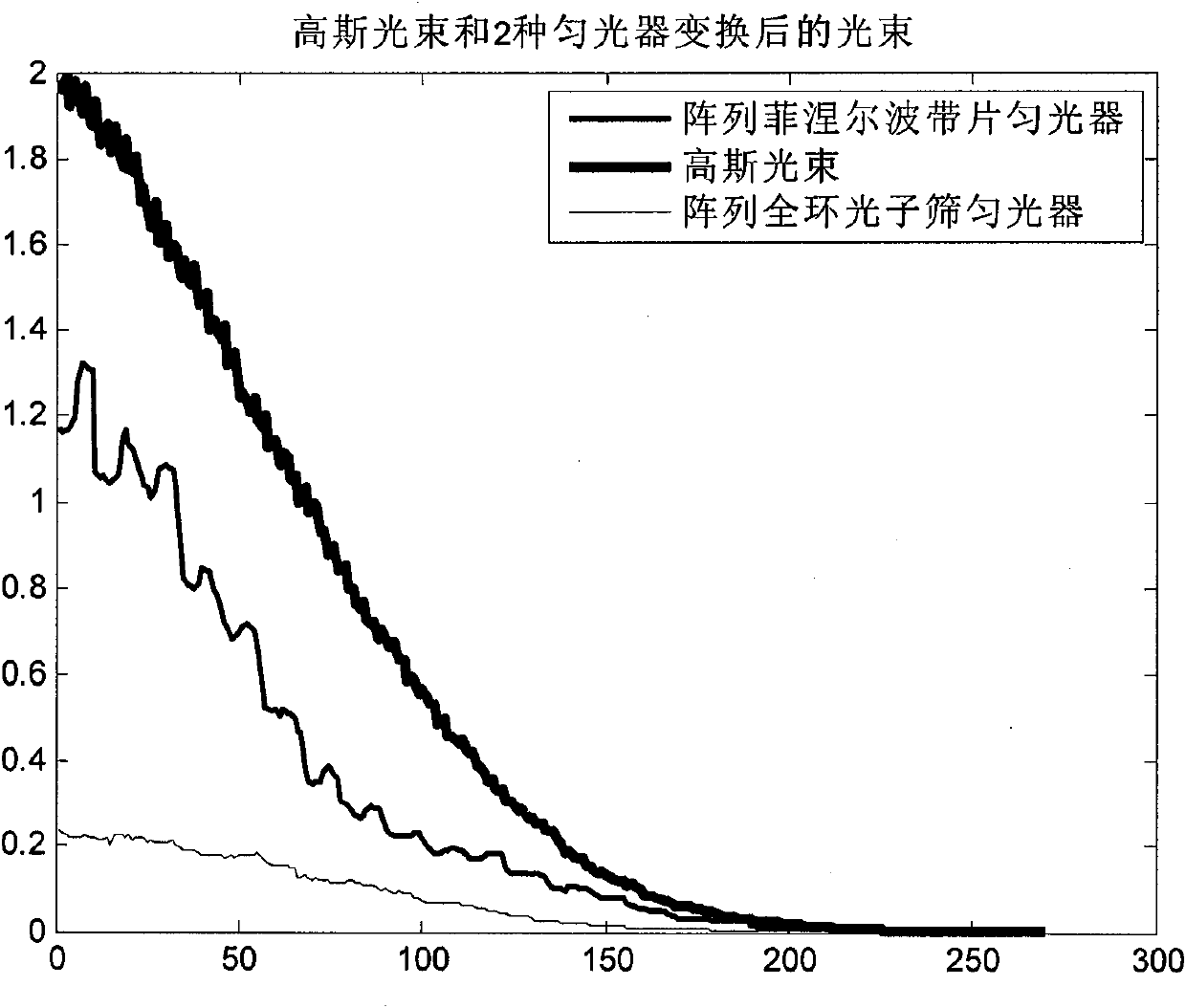

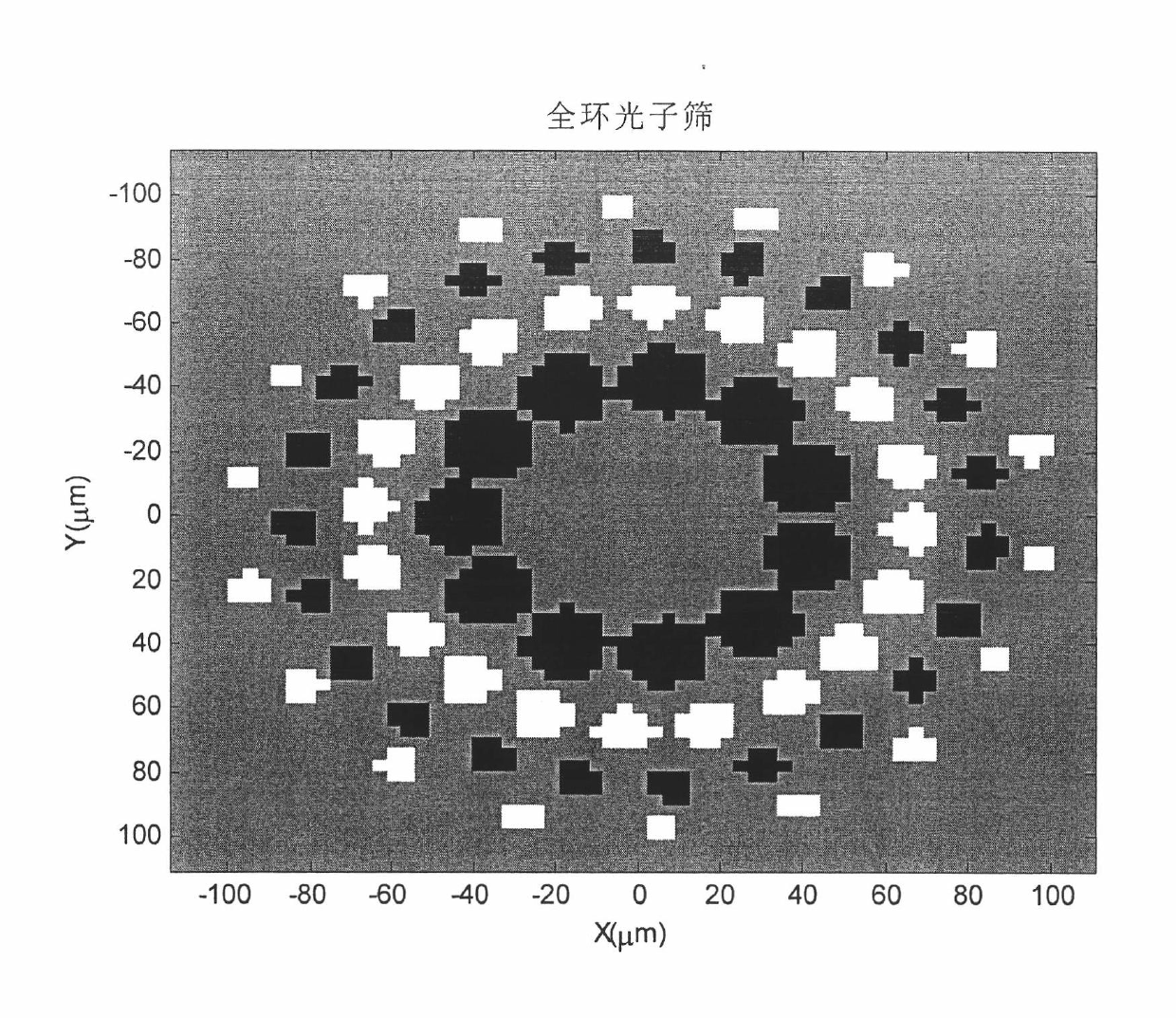

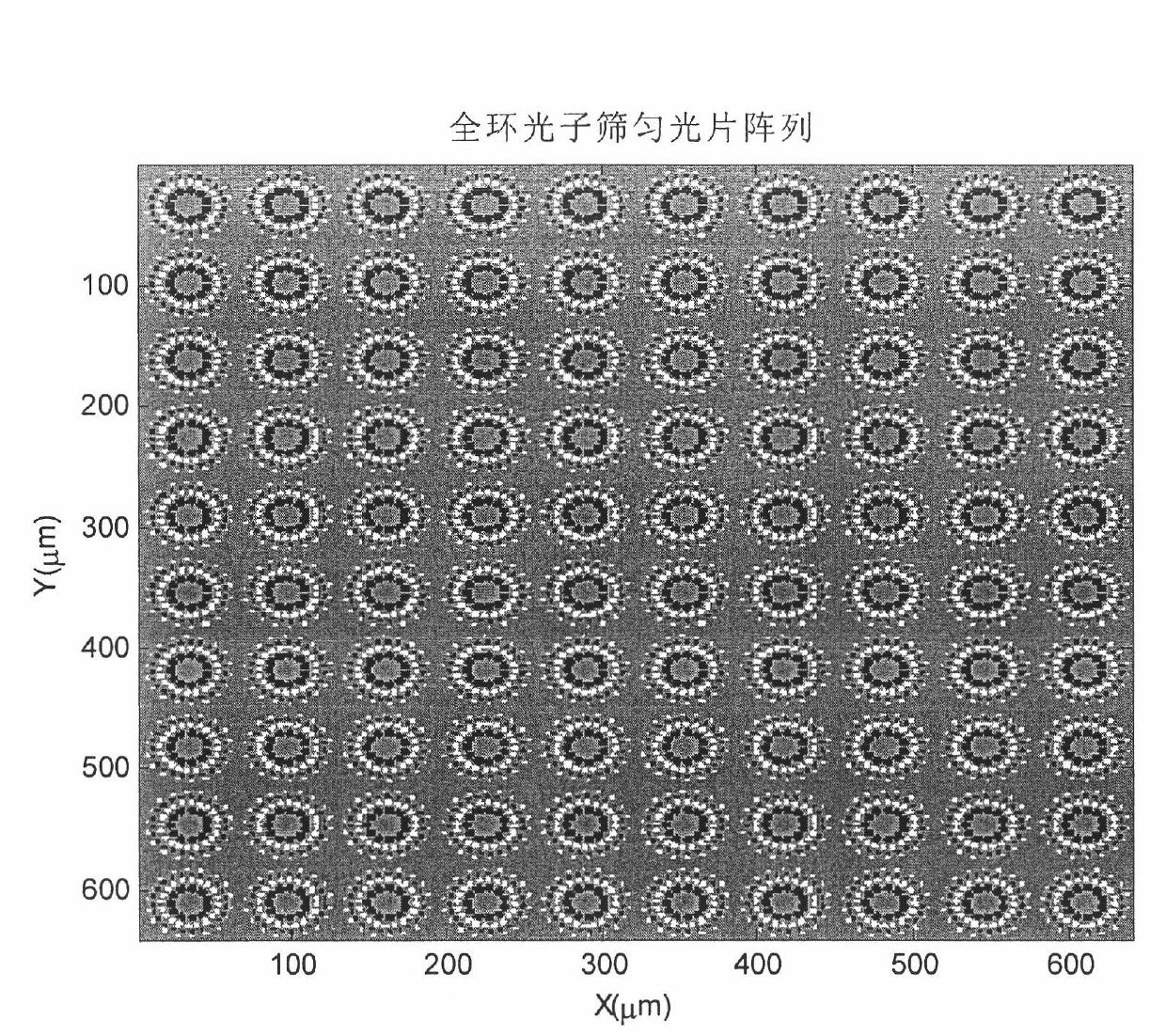

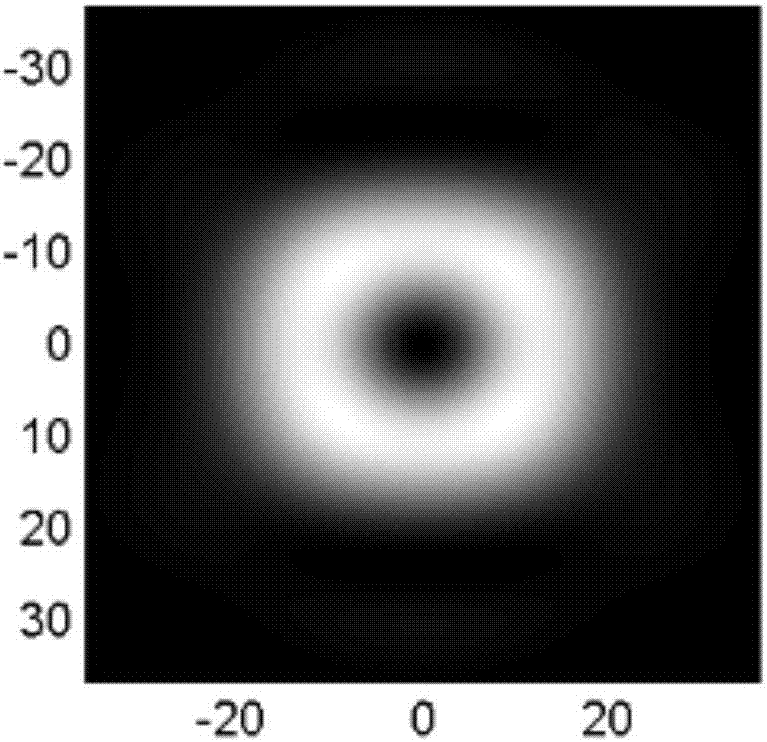

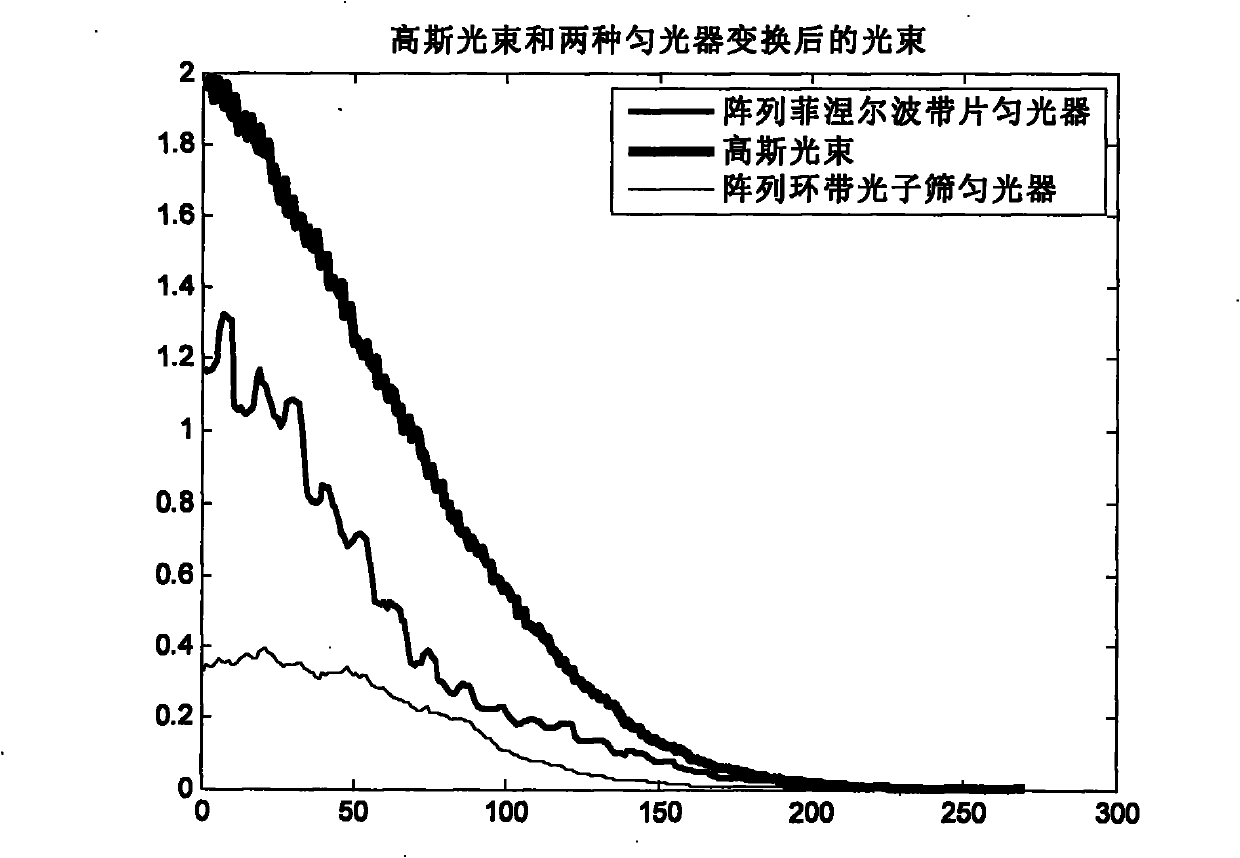

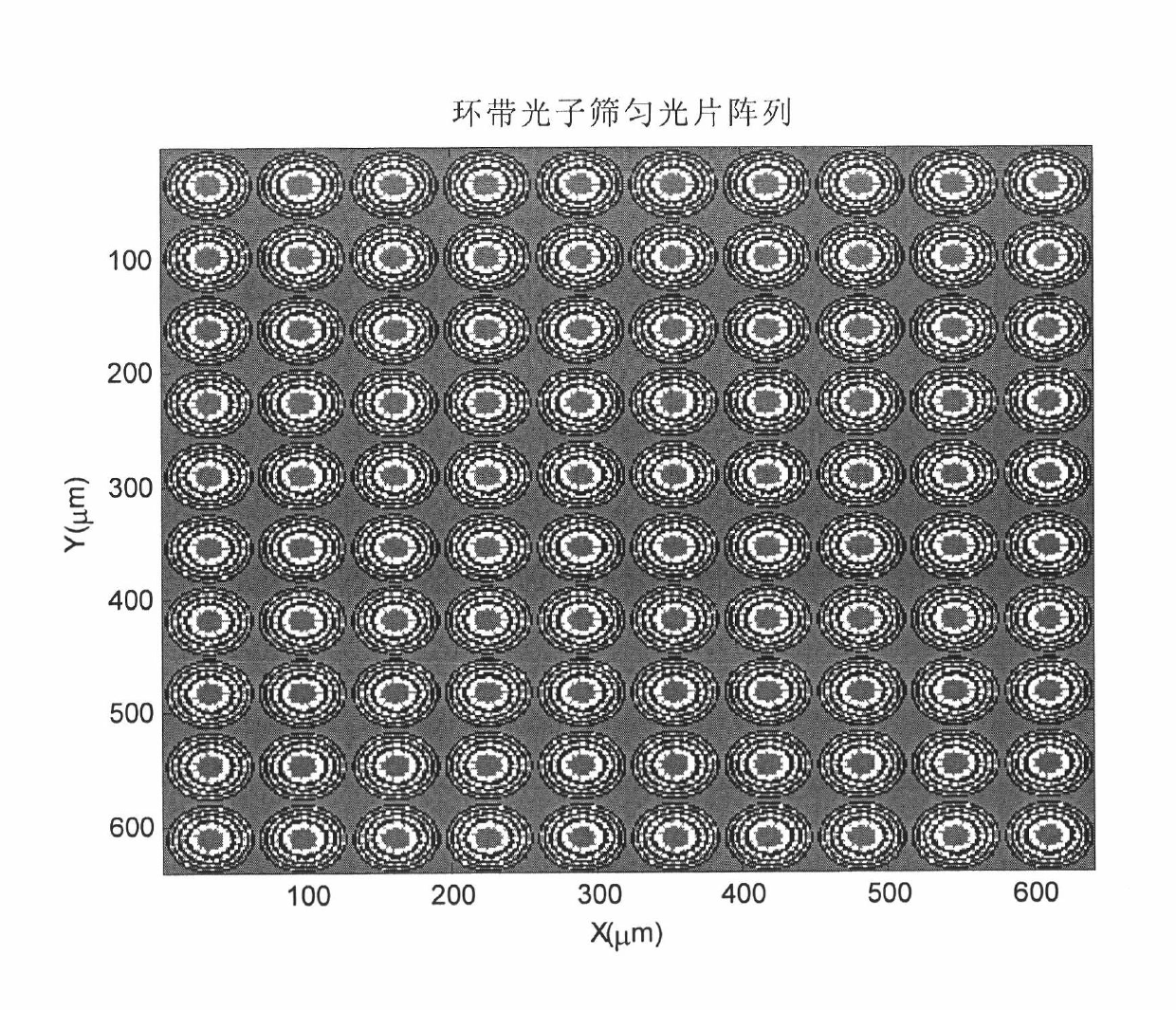

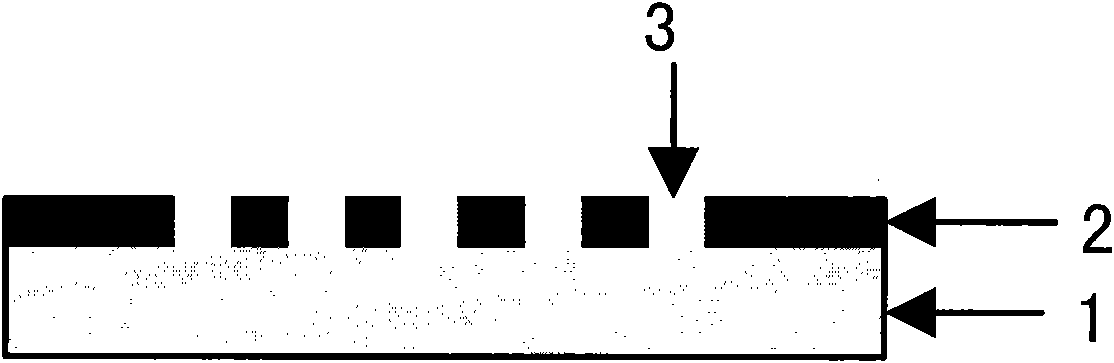

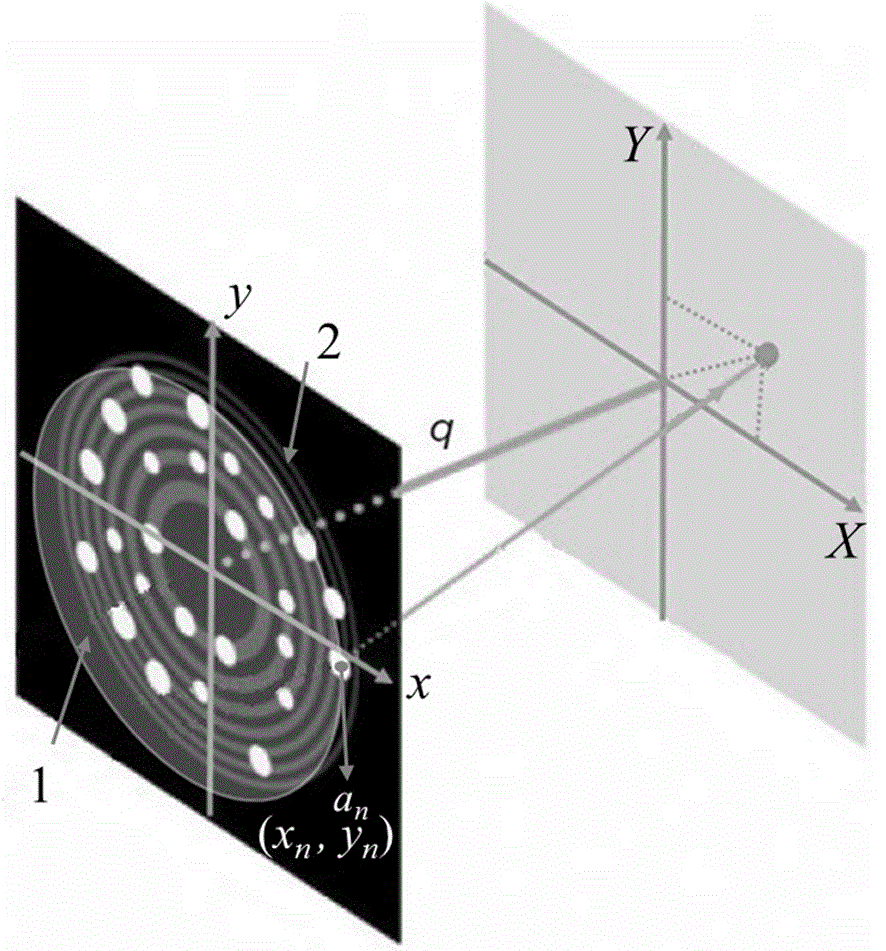

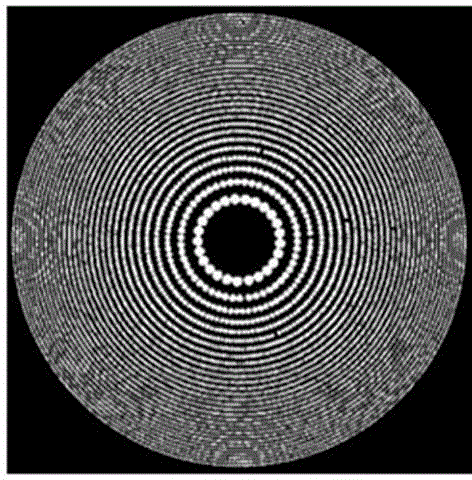

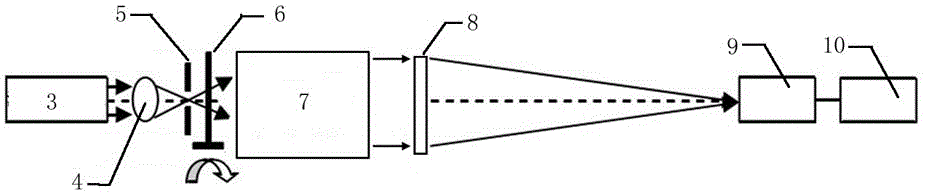

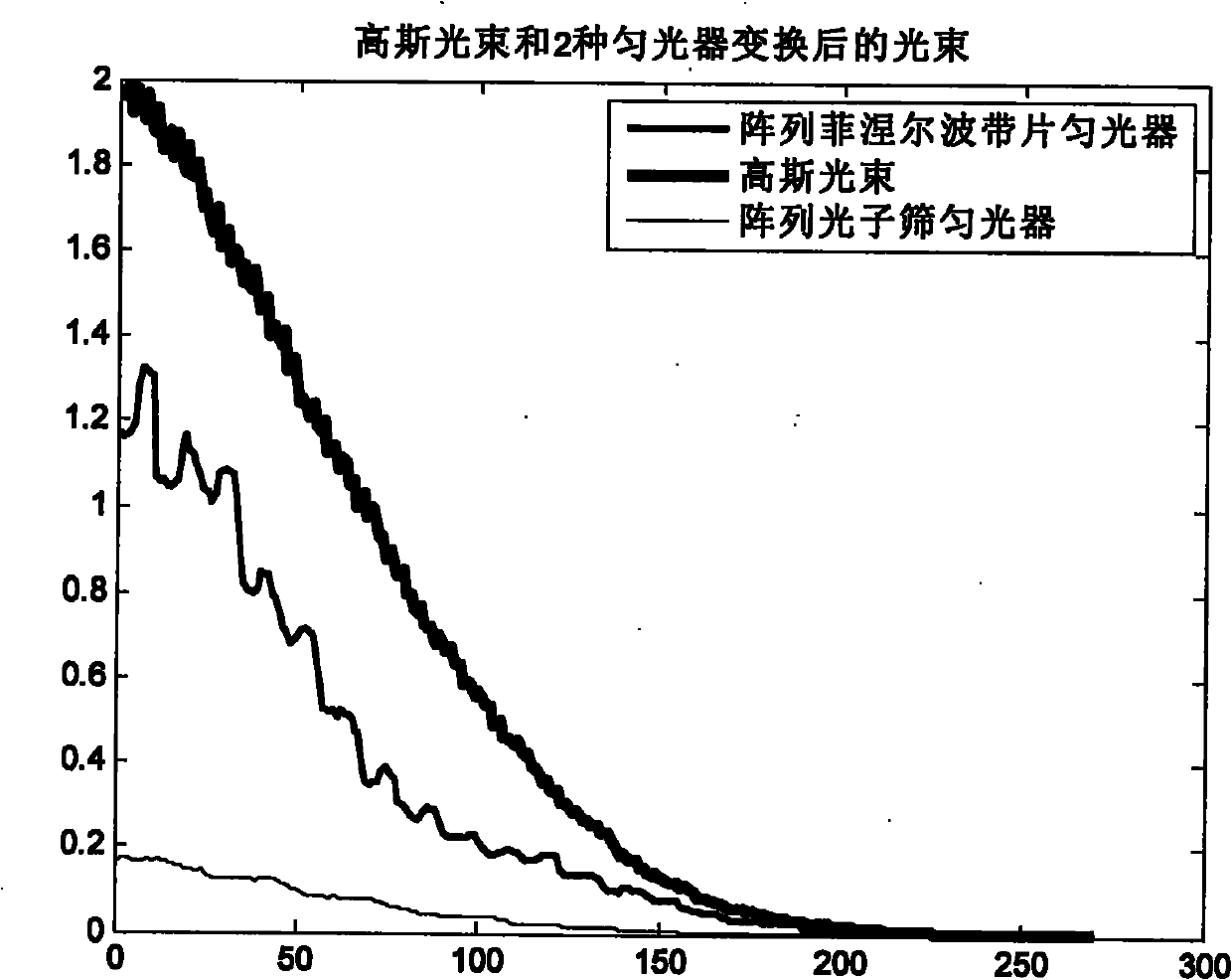

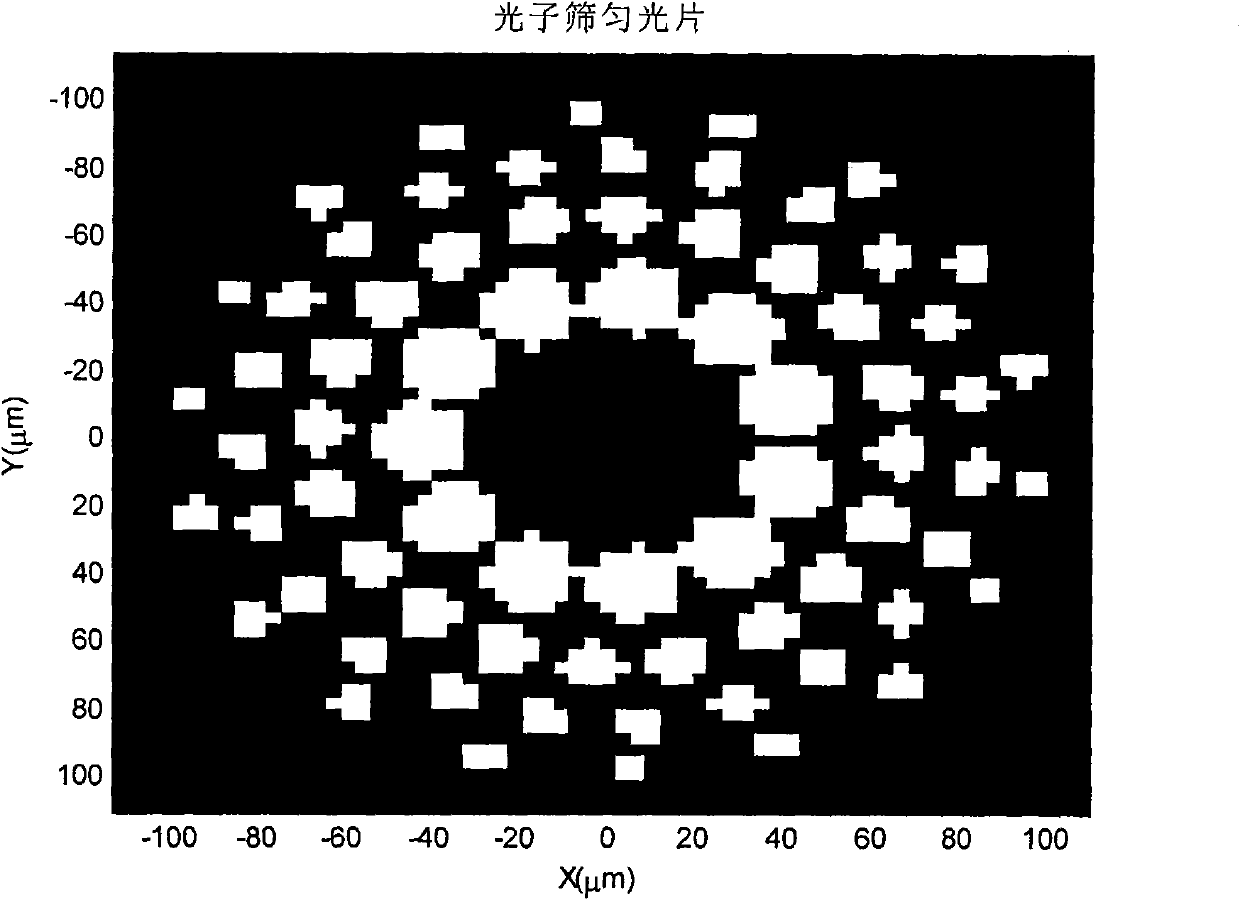

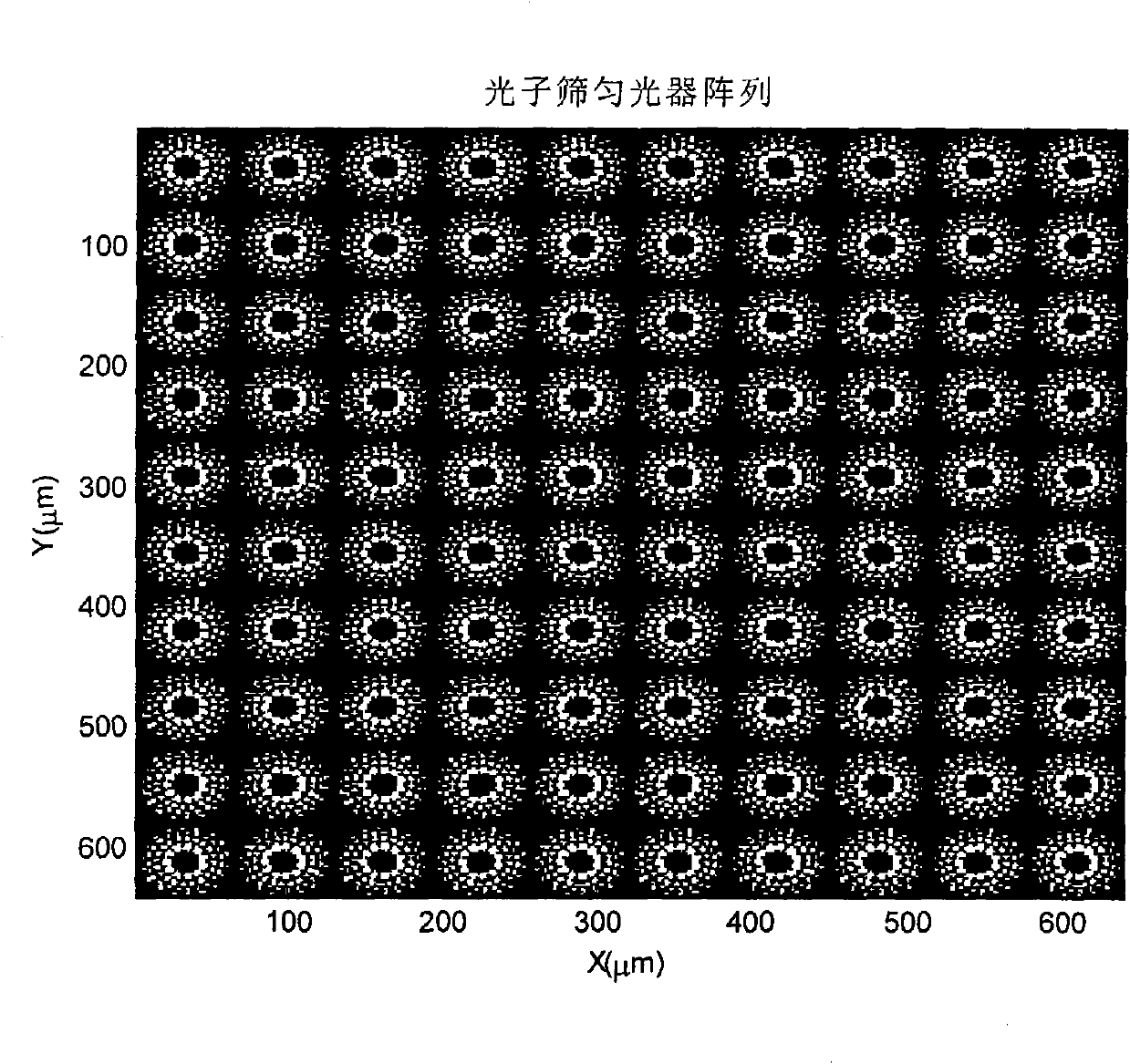

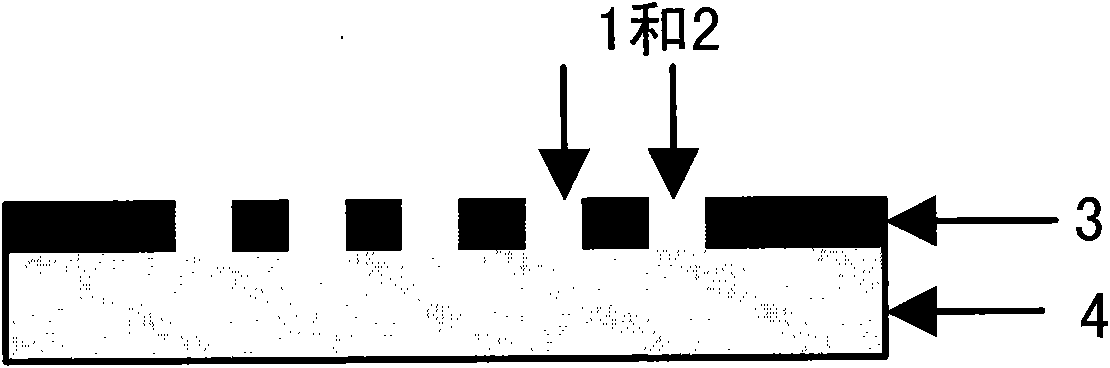

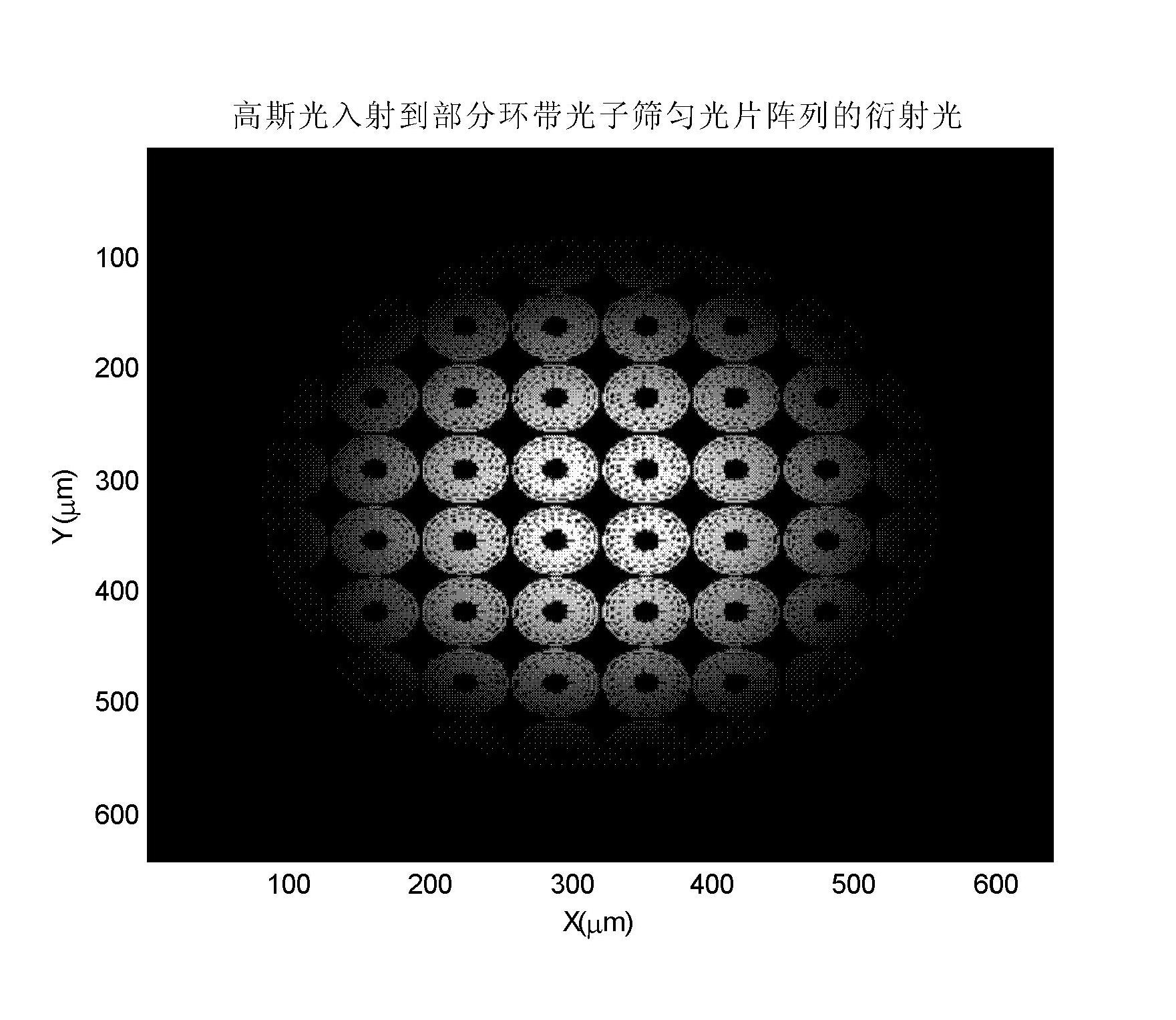

Array full-ring photon sieve light evener and manufacturing method thereof

InactiveCN102023386AAchieve refocusUniformity achievedDiffraction gratingsPhotomechanical exposure apparatusWavefrontGaussian beam

The invention discloses an array full-ring photon sieve light evener and a manufacturing method thereof. The array full-ring photon sieve light evener is a full-ring photon sieve array manufactured on a transparent medium, full-ring photon sieves are used as basic units and are a plurality of circular holes manufactured on a transparent substrate based on a Fresnel wave band sheet by the following steps of: firstly manufacturing photon sieves with the diffraction apertures one time of the corresponding Fresnel ring on the transparent medium, then still etching circular holes on the other Fresnel ring bands to form transparent etching circular holes on the odd and even ring bands of the wave band sheet, which are respectively the light-transmitting holes of the odd rings and the etching-phase light-transmitting holes of the even rings, wherein the phase of the etching-phase light-transmitting holes is pi, the size of each etching circular hole is the same as the width of the corresponding ring bands, and then forming the full-ring photon sieve by using the etching circular holes and the original diffraction holes. The invention realizes converting gauss light beams and other wavefront uneven laser beams into wavefront diffraction light beams approaching to a plane.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

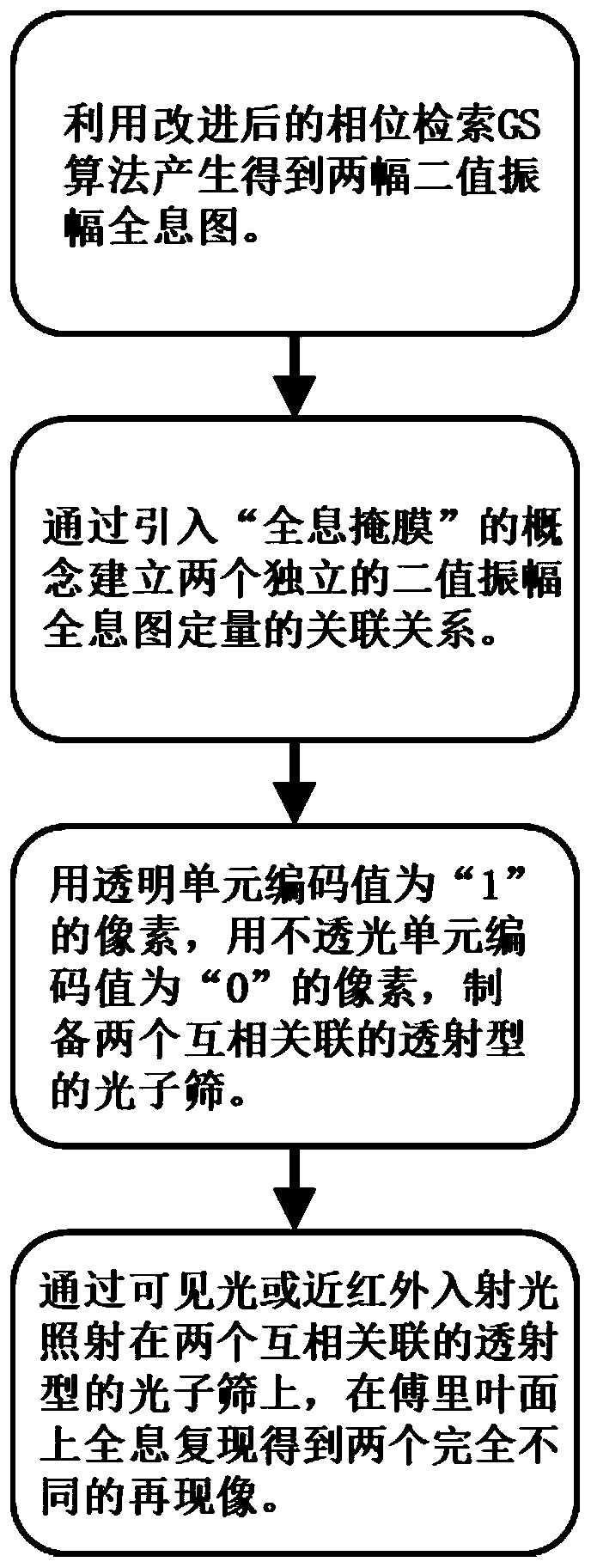

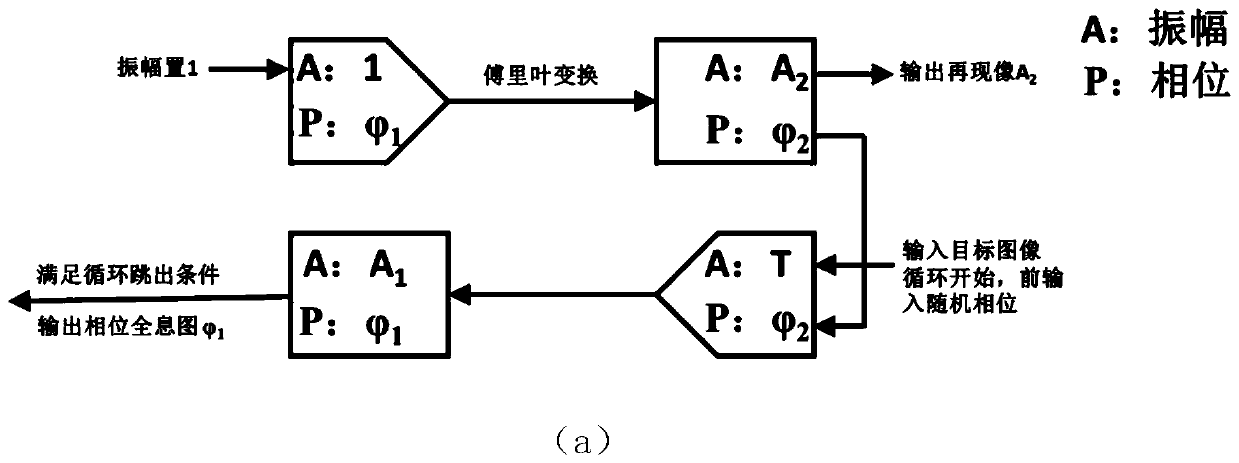

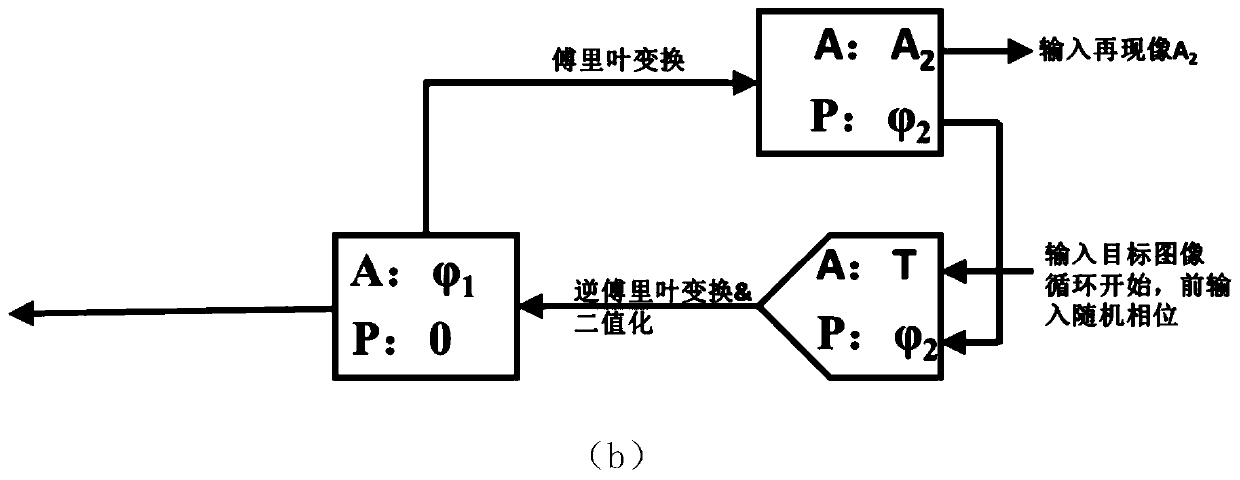

Quantitative correlation amplitude holographic method based on photon sieve

The invention discloses a quantitative correlation amplitude holographic method based on a photon sieve and belongs to the field of micro-nano holography. The implementation method comprises the following steps: obtaining two binary amplitude holograms according to a holographic reproduction image, and representing phase information in an amplitude form to improve a traditional phase retrieval GSalgorithm to generate two independent binary amplitude holograms; establishing a quantitative association relationship between the two independent binary amplitude holograms by introducing a concept of 'holographic mask' to realize the quantitative association of the binary amplitude holograms, performing evaluation and cyclic optimization by measuring a peak signal to noise ratio (SNR) to obtaina group of quantitative associated amplitude holograms corresponding to the holographic reproduction image, and generating a processing file. Two mutually associated transmission type photon sieves are prepared by using a pixel with a transparent unit coding value of 1 and a pixel with a lightproof unit coding value of 0. Visible light or near-infrared incident light irradiates on two mutually associated transmission type photon sieves, and the holographic reproduction is carried out on a Fourier surface to obtain two completely different reproduction images.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Multilayer imaging device and imaging method based on vortex photon sieve telescope system

InactiveCN109521580AImprove anti-interference abilitySimple structureDiffraction gratingsTelescopesDiffraction opticsTelescope

The invention provides a multilayer imaging device and imaging method based on a vortex photon sieve telescope system. The main component of multi-layer imaging is a combination of a vortex photon sieve and a telescope system, and the vortex photon sieve is a diffractive optical element capable of achieving a vortex light field. According to the invention, the fixed system discrete multi-layer imaging of a coherent light field can be achieved, the off-axis imaging of different magnifications can be simultaneously achieved by moving the photon screen, the degree of freedom of the optical path design is increased, the operation is simple, and the structure is stable. The device is likely used in the field of a multi-layer imaging system, an endoscopic system, wavefront measurement, medical imaging, tomography, three-dimensional information storage and optical capture.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

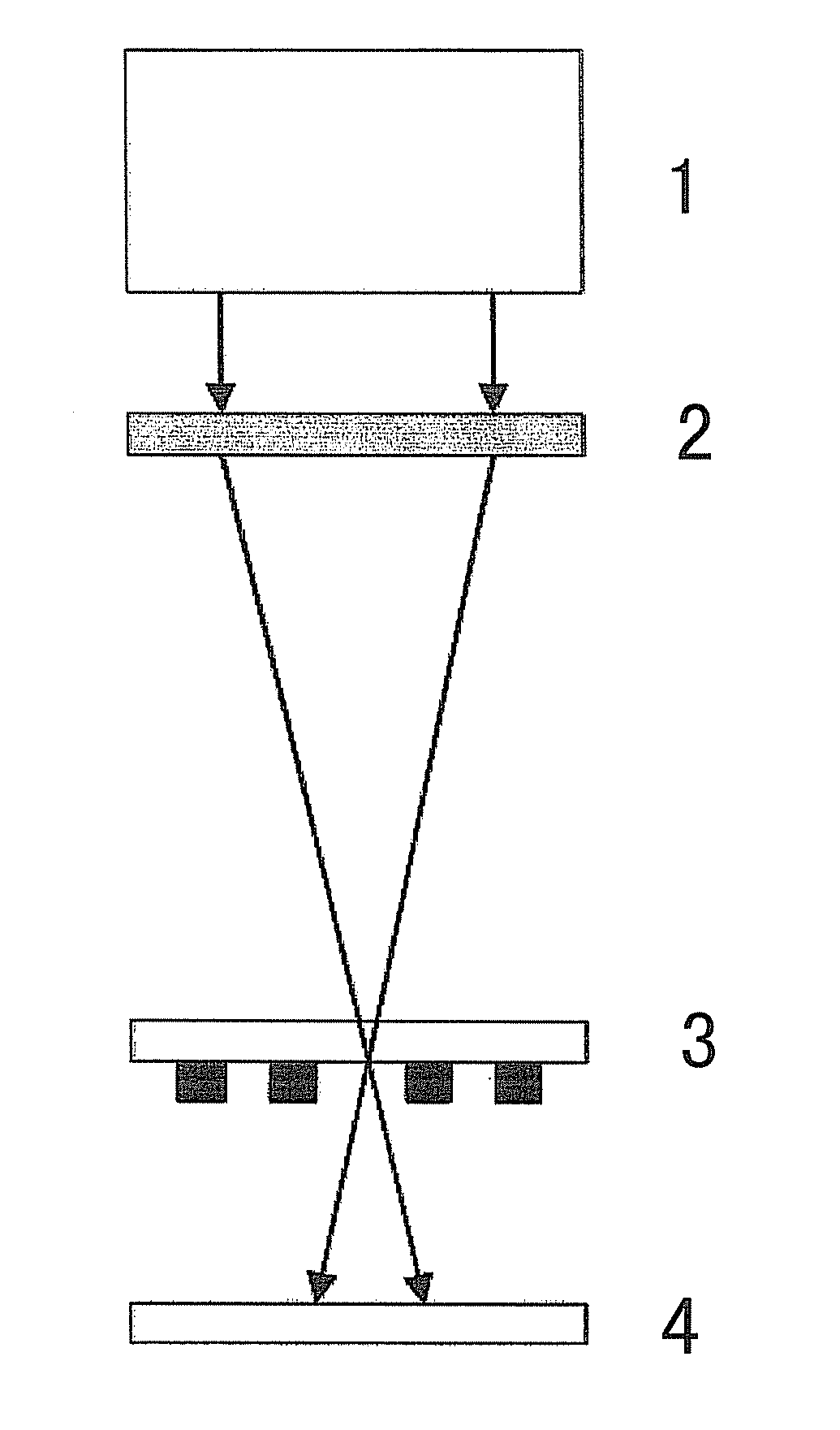

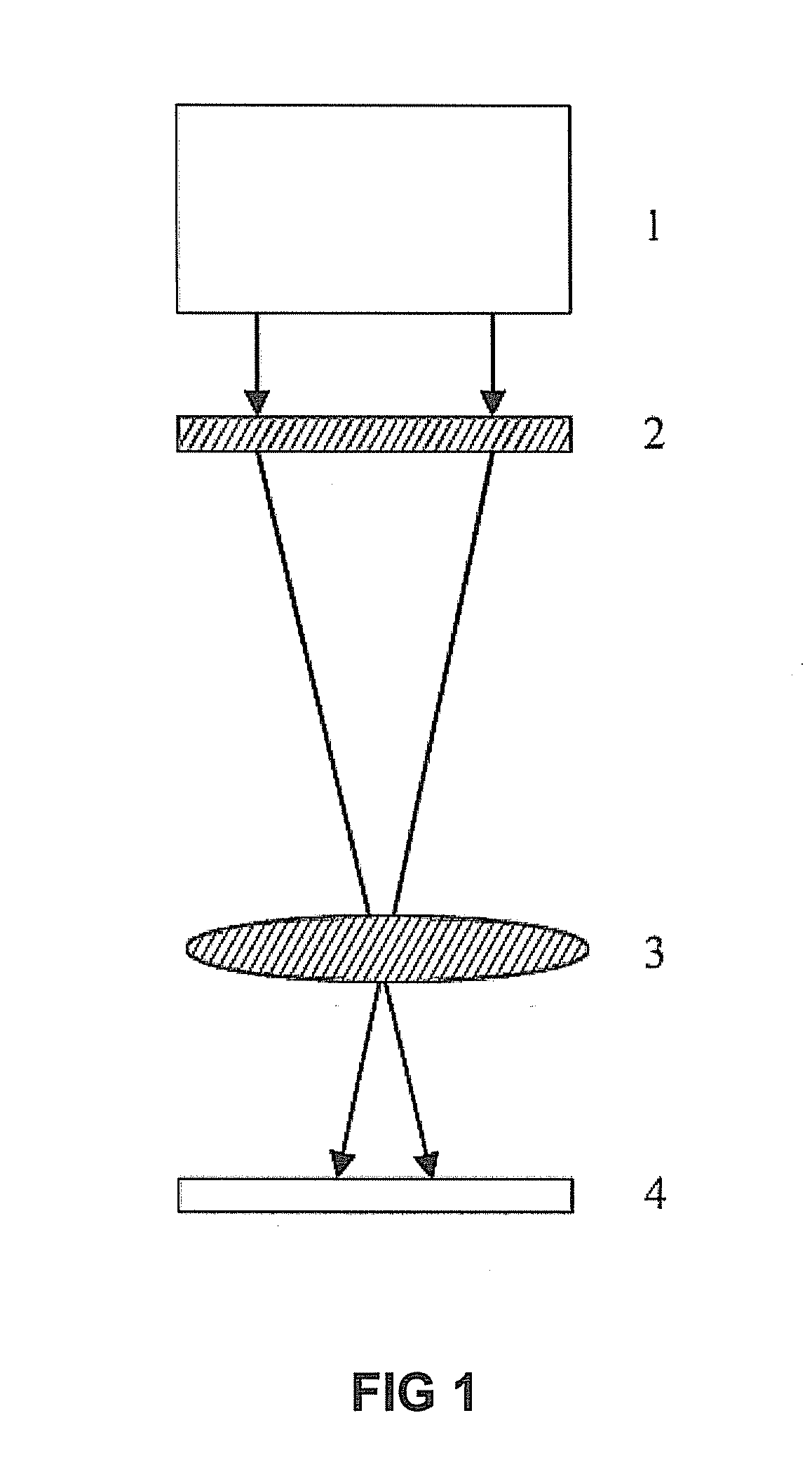

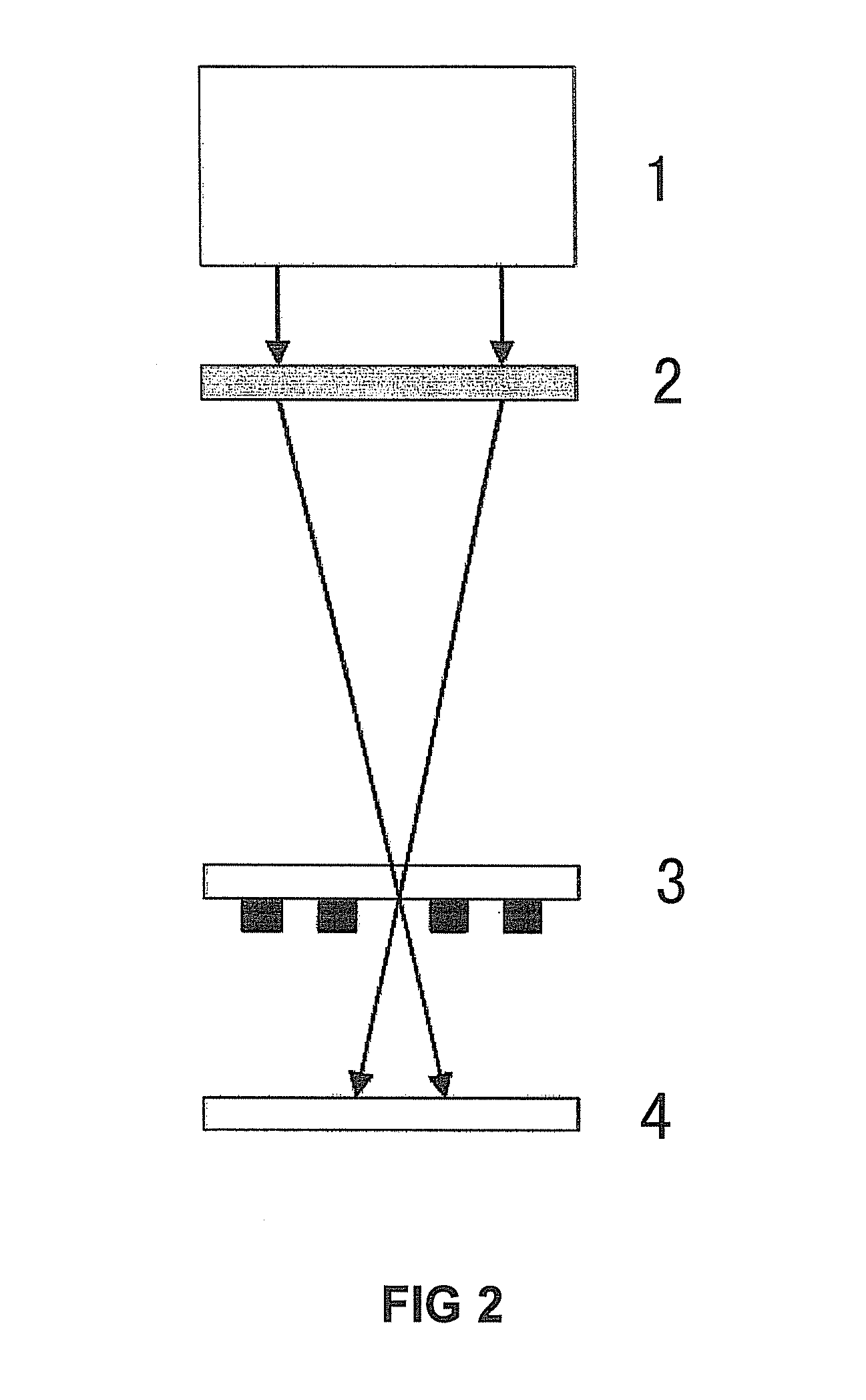

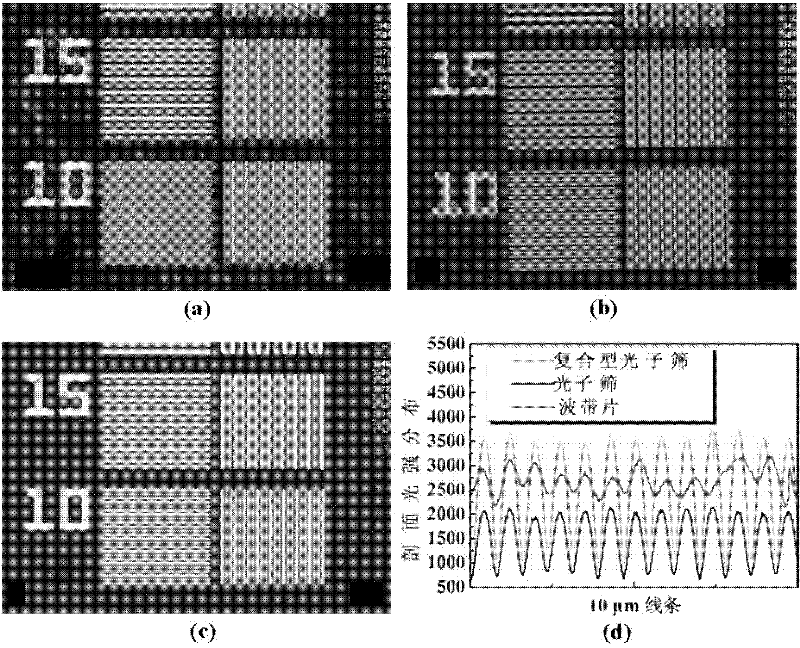

Projection-type photolithography system using composite photon sieve

ActiveUS20130044299A1Improve efficiencyLow costPhotomechanical apparatusPhotographic printingMicro nanoLighting system

The present disclosure relates to the field of micro-nano fabrication, and provides a projection-type photolithography system using a composite photon sieve. The system comprises: a lighting system, a mask plate, a composite photon sieve and a substrate, which are arranged in order. The lighting system is adapted to generate incident light and irradiate the mask plate with the incident light. The mask plate is adapted to provide an object to be imaged by the composite photon sieve, and the incident light reaches the composite photon sieve after passing through the mask plate. The composite photon sieve is adapted to perform imaging, by which a pattern on the mask plate is imaged on the substrate. The substrate is adapted to receive an image of the pattern on the mask plate imaged by the composite photon sieve. According to the present disclosure, because the composite photon sieve is used instead of a projection objective lens in a conventional projection-type photolithography system, the advantage of high efficiency in the conventional projection-type photolithography system can be reserved, and also photolithography can be performed in batches rapidly, so that photolithography efficiency can be improved. Meanwhile, costs can be effectively cut down and the system can be reduced in size.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Binary photon sieve

InactiveCN101059576AImprove image contrastHigh diffraction efficiencyOptical elementsImage contrastOptical axis

The invention discloses a binary photon screen, comprising a transparent plate base with a light-tight film provided with transparent holes, wherein the transparent holes are plane type and concave type, or plane type and cam type. The invention has the advantages that (1), relative to the Fenier zone plate, the holes on the photon screen are randomly distributed in a relative Fenier transparent annular area, to effectively restrain the high-order diffraction along optical axis and horizontal side lobe effect, to improve image contrast, to obtain cute focus, (2), relative to the Fenier zone plate and the vibration photon screen, the binary photon screen has high diffraction efficiency.

Owner:ZHEJIANG UNIV

Photon sieve for optical systems in micro-lithography

InactiveUS7368744B2Efficiently and effectively focusingRadiation pyrometryPhotomechanical apparatusCamera lensLithographic artist

The use of photon sieves may be as a pupil defining element in an illumination system; a field of defining elements in an illumination system; a pupil lens element in a projection lens; a color correction system in the projection system; or as a transmitting diffractive element for EUV.

Owner:ASML NETHERLANDS BV

Method for producing oval vortex light of amplitude modulator

The invention relates to a method for producing oval vortex light of an amplitude modulator. The method is characterized in that a novel amplitude-type photon screen is generated through imitated spiral lines and is used for appointing production of oval vortex light on a plane. The novel amplitude-type photon screen comprises a transparent medium substrate, a light-proof metal film and a spiral screen hole structure and is characterized in that the imitated spiral lines are introduced to a traditional wave zone plate structure, small holes are arranged along the spiral lines to form the amplitude-type spiral photon screen, additional optical elements are not needed, and vortex light beams can be produced. The amplitude-type photon screen related in the method is easy to process and copy and can be applied to the fields of light communication, super-resolution imaging, laser precision machining, particle control, data storage, remote sensing and the like and is applicable in wave bands ranging from X rays to terahertz.

Owner:上海霖迈实业有限公司

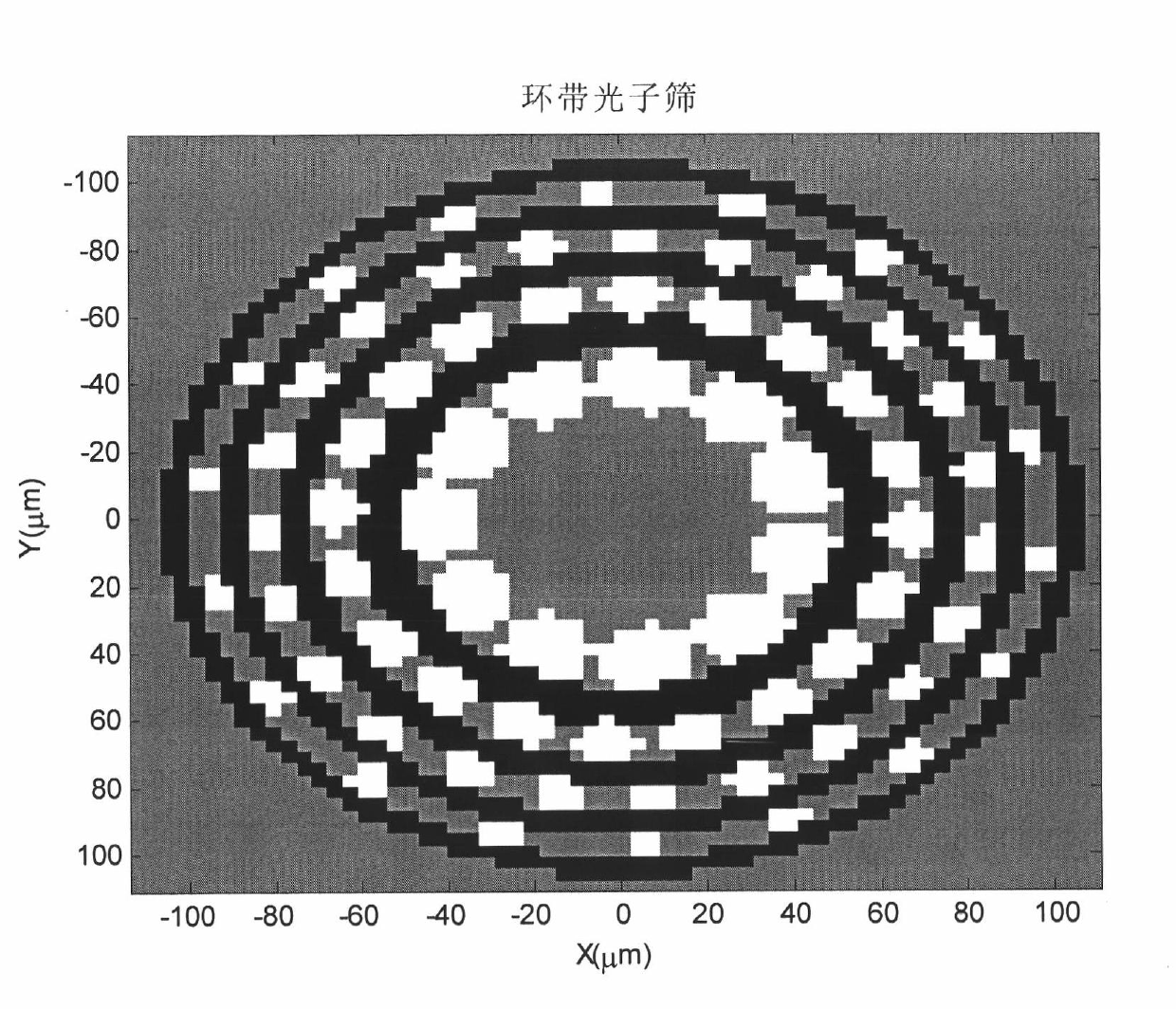

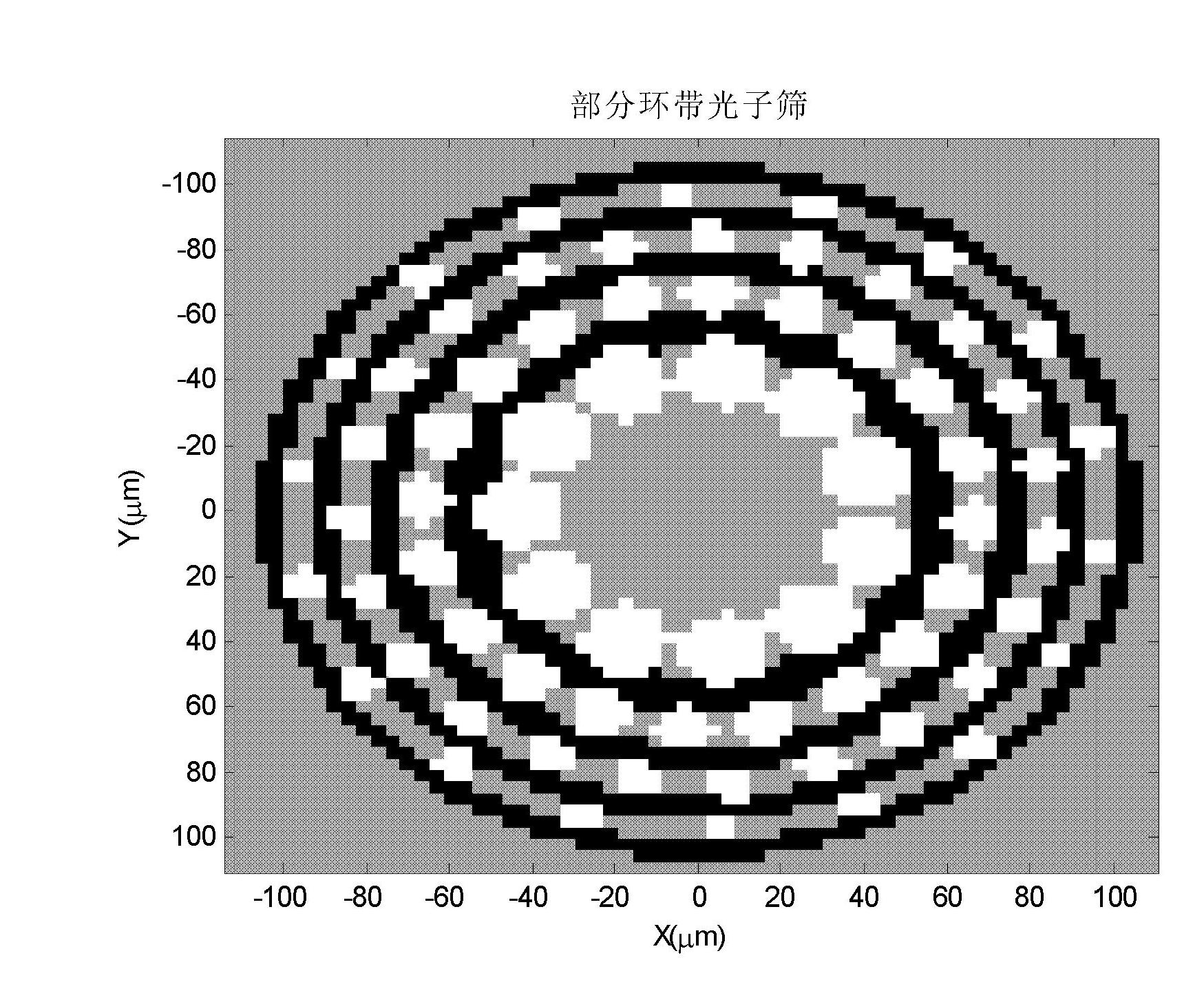

Array type light evening device with annulus photon screen and manufacturing method thereof

InactiveCN102023387AAchieve refocusUniformity achievedDiffraction gratingsPhotomechanical exposure apparatusGaussian beamWavefront

The invention discloses an array type light evening device with an annulus photon screen and a manufacturing method thereof. The array type light evening device with the annulus photon screen is an annulus photon screen array which is manufactured on a transparent medium, and the annulus photon screen is used as a basic unit of the array. The annulus photon screen is formed by a plurality of homocentric diffractive hole annuluses and a plurality of homocentric etching ring annuluses, which are alternately nested, and the diffractive hole annulus is the closest to the center of the annulus photon screen; the width of the diffractive hole annulus and the width of the etching ring annulus are gradually decreased respectively from the center of the annulus photon screen to outside, the width of the diffractive hole annulus is equal to the width of the etching ring annulus which is adjacent to the diffractive hole annulus far from the central direction of the annulus photon screen, and the size of each light penetrating hole is the same as the width of the corresponding etching phase annulus. By using the invention, gauss beams and other wavefront uneven laser beams are transformed into wavefront diffractive beams which are approximate planes.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Compound type photon sieve

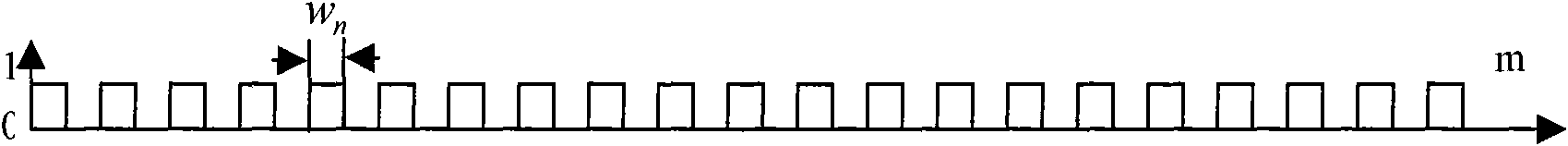

The invention discloses a compound type photon sieve which comprises a transparent medium, a metallic layer and a superfine structure, wherein the metallic layer is plated on the transparent medium; the required superfine structure is formed on the metallic layer in an etching manner; based on the smallest line width for superfine processing along the radius of the transparent medium from inner to outer, the transparent medium is divided into different areas which comprise a waveband area, a first area and a second area; the first area and the second area are both provided with a multiple groups of superfine structures; the waveband area is arranged between two groups of superfine structures in the first area; each superfine structure comprises a plurality of small holes which are different in radius and are distributed as annular strips with different radiuses; a ratio K of an aperture of the small hole arranged in each area to the width of the annular strip exists; the width of the outermost annular strip in the waveband area is equal to the smallest line width for superfine processing; and the radius of the innermost annular strip in the waveband area is 0.3 to 0.5 times of the that of the outermost annular strip.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

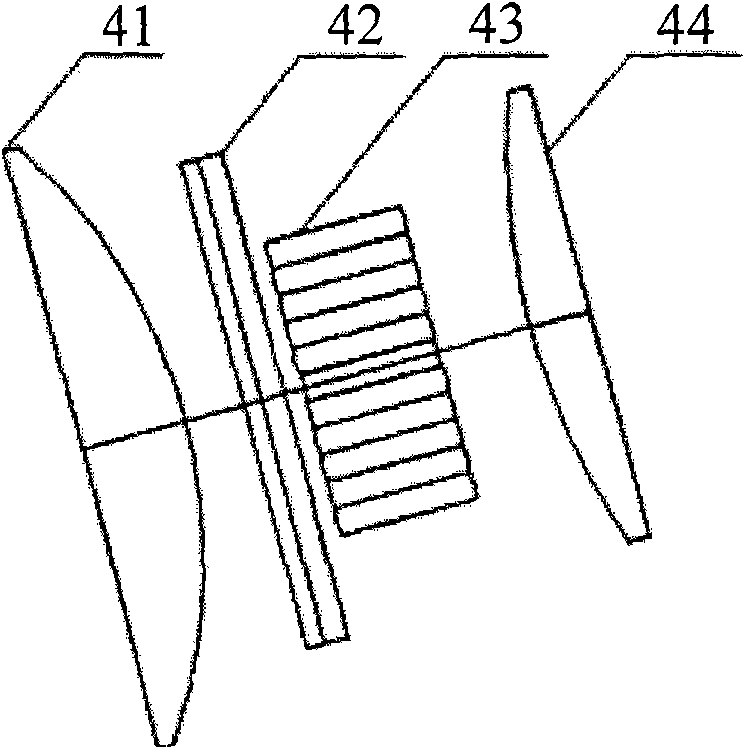

Broadband photon sieve based on wavefront coding technology

The invention discloses a broadband photon sieve based on wavefront coding technology. The photon sieve is characterized in that a phase coding plate is included, one surface of the phase coding plate is a phase coding surface, the other surface is a planar surface, a photon sieve clings to the planar surface, the phase coding surface is one selected from a triple coding surface, a logarithm coding surface and a sine coding surface, and the photon sieve carries out diffractive imaging via light of the phase coding surface. The wavefront coding technology is introduced into the photon sieve field innovatively, the phase coding plate is arranged in front of the photon sieve, wavefront coding is carried out on light entering the photon sieve, the sensitivity of the photon sieve to the wavelength is reduced, and the broadband is expanded.

Owner:SUZHOU UNIV

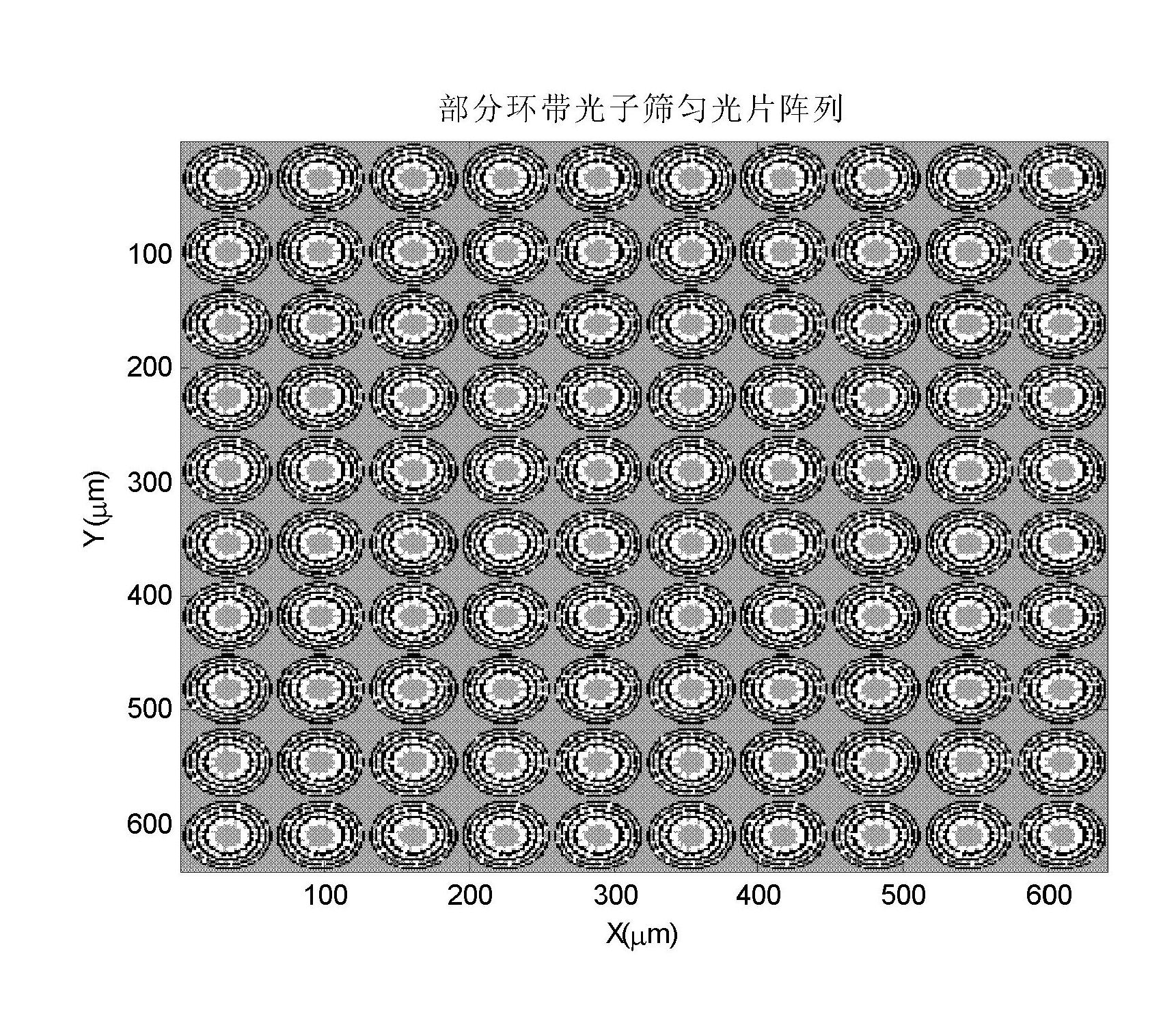

Array photon sieve light evener and manufacturing method thereof

InactiveCN102023388AAchieve refocusUniformity achievedDiffraction gratingsPhotomechanical exposure apparatusWavefrontGaussian beam

The invention discloses an array photon sieve light evener which is an array of photon sieves, wherein the array is manufactured on a transparent medium according to the actual needs, and the size of the array is given out according to the actual needs. The photon sieves are a large number of diffractive optical elements with light-transmitting micropores different in radius, wherein the diffractive optical elements are manufactured on a Fresnel wave band ring, and the photon sieves are basic units of the array photon sieve light evener; and other parts are light-proof. The array is in the structure with repeated photon sieves. The invention simultaneously discloses a method for manufacturing the array photon sieve light evener. The array photon sieve light evener realizes wavefront flattening for gauss light beams and other uneven non-planar wavefront light beams, the light evening of the light beams, and wavefront light beams approaching to the plane. The light beams are widely applied to light path systems.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

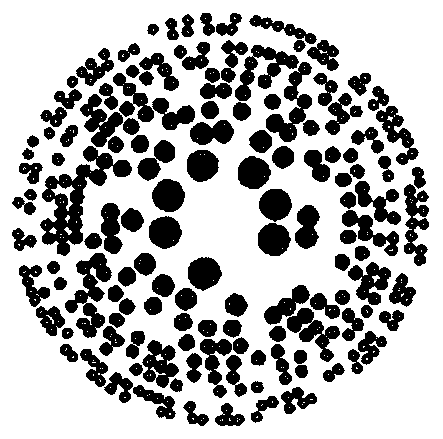

Interlaced type photon sieve

The invention discloses an interlaced type photon sieve, which comprises a transparent medium, a metallic layer and a superfine structure, wherein the metallic layer is prepared on the transparent medium; the required superfine structure is formed on the metallic layer by etching; the superfine structure comprises a plurality of small holes with different radiuses which are annularly distributed on a plurality of odd annular bands and a plurality of even annular bands; the ratios of the diameters of the small holes on the even and odd annular bands to the width of the located annular band aredifferent; amplitude signs of diffraction optical waves of the small holes on the even and odd annular bands at a focal point are reverse; the small holes on the even and odd annular bands have constructive interference at the focal point; smaller light spots are acquired; and the photon sieve size is increased under the same condition of minimum processing size. Through the interlaced type photon sieve provided by the invention, the size of the main spot formed by the focusing diffraction of the photon sieve can be efficiently compressed and the resolution ratio of an optical system can be increased.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Light intensity transmission equation based X-ray single-exposure imaging device and method

ActiveCN110455834ALow coherence requirementsSimple structureMaterial analysis by transmitting radiationBeam expanderX-ray

The invention discloses a light intensity transmission equation based X-ray single-exposure imaging device and method. The device comprises an X-ray source, a beam expander, a first three-dimensionaltranslation table, a measured object, a first single-focus photon sieve focusing lens, a double-focus photon sieve focusing lens, a second single-focus photon sieve focusing lens, a second three-dimensional translation table, an X-ray detector and a computer. The X-ray single-exposure imaging device can be used for imaging from X-rays to terahertz wave bands; the imaging method is simple in singlelight path operation, only needs to record a single intensity map, can quickly realize accurate reproduction of a phase image of the measured object online in real time, and is especially suitable for imaging and observation of a dynamic object; the imaging method has low coherence requirement on an X-ray source, and the X-ray source can be a coherent X-ray source and a partially coherent X-ray source; and the phase image of the object can be rapidly and accurately recovered by utilizing the recorded intensity map, and the robustness of the imaging device can be improved by avoiding multipleoperations.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method for producing phase type photon sieve based on HSQ (Hexadecimal Sequential) process

InactiveCN101923182AHigh diffraction efficiencyAchieve preparationPhotomechanical exposure apparatusMicrolithography exposure apparatusEtchingImage resolution

The invention discloses a method for producing a phase type photon sieve based on an HSQ (Hexadecimal Sequential) process, comprising the following steps of: A. manufacturing a first photon sieve photomask A and a second photon sieve photomask B; B. coating HSQ glue on a substrate, phtoetching and drying the HSQ glue by using the first photon sieve photomask and evaporating a layer of metal film; C. removing the metal membrane on the HSQ by using an electrochemical corrosion method; D. coating 5241 positive photoresist on the substrate, photoetching the substrate by using the second photon sieve photomask B and removing the metal member of the exposed part; and E. obtaining the phase type photon sieve after the photoresist is removed. Compared with the traditional etching method, the invention has the characteristics of simple manufacturing process, low cost, favorable stability, capability of reaching higher resolution and the like and is beneficial to being widely popularized and applied.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Large area photon sieve

InactiveCN101587198ASolve the problem that is difficult to make a large diameterHigh-resolutionDiffraction gratingsPhotomechanical exposure apparatusPhysicsPhoton sieve

The invention discloses a large area photon sieve composed of sheets with girdle band holes and characterized in that the girdle band is divided into G regions from the inner portion to the outer portion along the radius direction of the photon sieve. The regions are combined relative to the girdle band of the Phase Fresnel zone plate so as to correspondingly enhance the correspondent hole radius. The hole distribution number on each girdle band is optimized. The large area photon sieve is divided into a plurality of regions by knowing the imaging mechanism. The hole diameter in each region is amplified to a scale. Furthermore, the hole diameter of the photon sieve, especially the peripheral hole dimension is amplified by combining the girdle bands so as to basically improve the resolution of the optical system.

Owner:SUZHOU UNIV

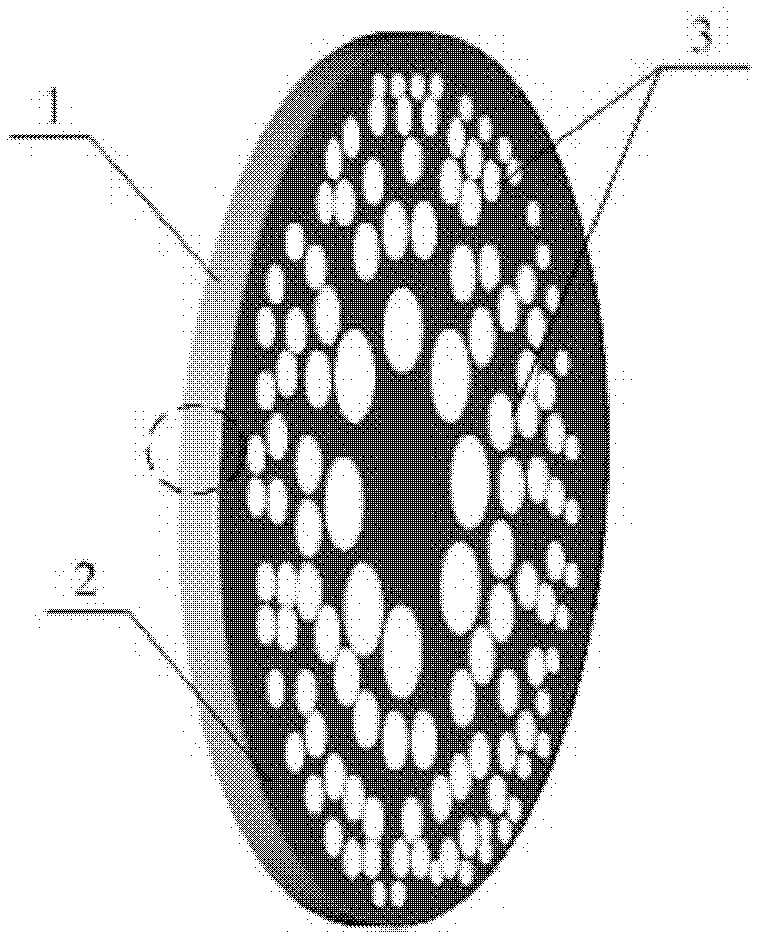

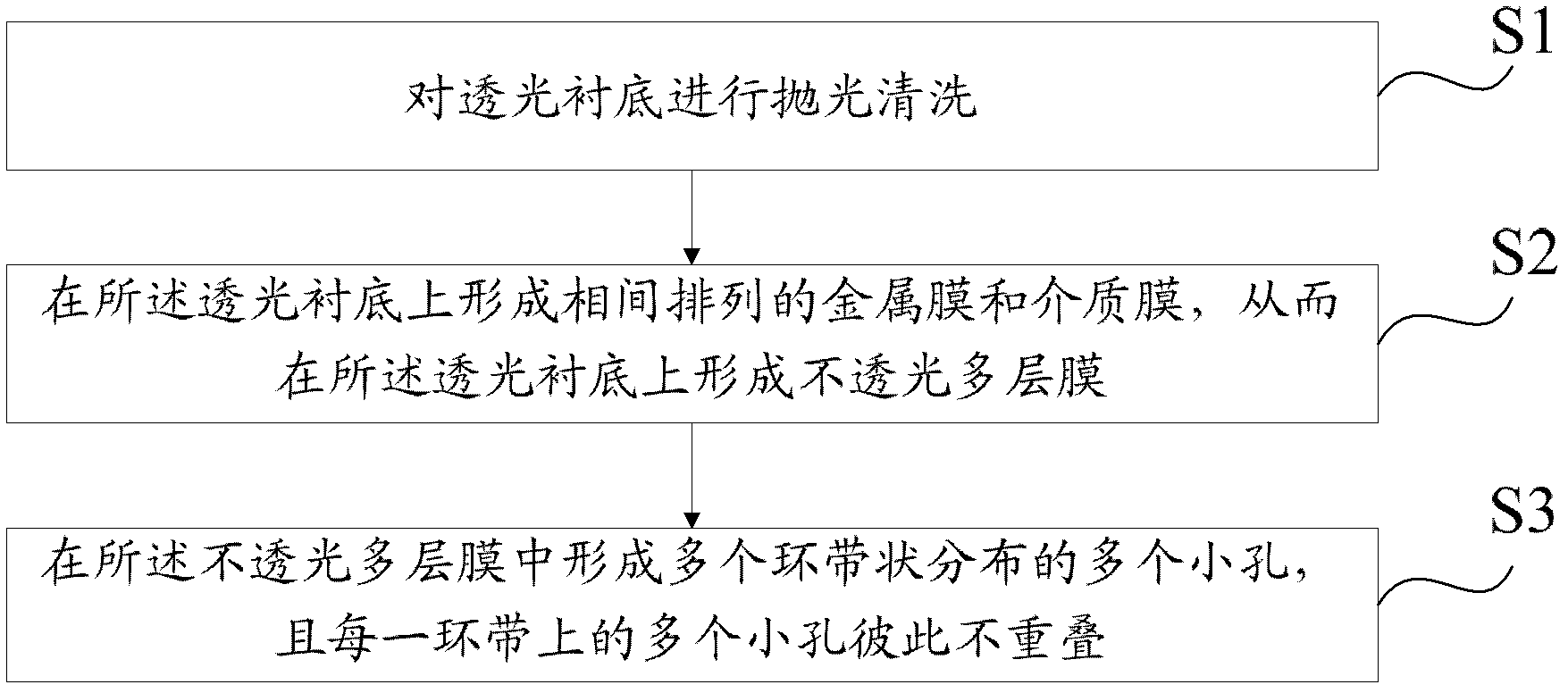

Photon sieve and manufacturing method thereof

ActiveCN103018808AHigh diffraction efficiencyImprove transmittancePhotomechanical apparatusDiffraction gratingsCouplingBand shape

The embodiment of the invention discloses a photon sieve and a manufacturing method thereof. The photon sieve comprises a light-transmitting substrate, a plurality of light-tight films and a plurality of small holes, wherein the plurality of light-tight films are located on the light-transmitting substrate and consist of a plurality of metal films and dielectric films at intervals; and the plurality of small holes are formed in the light-tight films and are distributed in a zonal shape, and a plurality of small holes in each girdle are randomly distributed and are not overlapped with one other. Because the plurality of metal films and dielectric films at intervals are arranged on the light-transmitting substrate, and the plurality of small holes distributed in the zonal shape are formed in the plurality of metal films and dielectric films at intervals, when light irradiates the a photon sieve, the surface plasma polarization and the surface plasma coupling of the metal films and the dielectric films are enhanced, the light transmittance is effectively improved, and further the diffraction efficiency of the photon sieve is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Compound type zone plate photon sieve

InactiveCN102681060AHigh-resolutionImprove transmittanceDiffraction gratingsImage resolutionTransmittance

The invention discloses a compound type zone plate photon sieve which comprises a light-transmitting substrate and a lighttight metal film coated on the light-transmitting substrate. A series of light-transmitting ring strips and a plurality of light-transmitting small holes are distributed on the lighttight metal film. The diameter of each light-transmitting small hole is 1.5 times the width of the corresponding zone plate ring strip. Relative to zone plates, the light-transmitting small holes which are distributed randomly enable diffraction light to mutually interfere so that the side lobe effect and high-order diffraction can be effectively inhibited, the resolution is improved, and a sharp focal spot is obtained. The zone plates are embedded on 2 / 3 of middle portion of the compound type zone plate photon sieve on the basis of an ordinary photon sieve so that the transmittance is improved, the diffraction efficiency is improved, and the imaging contrast is improved.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

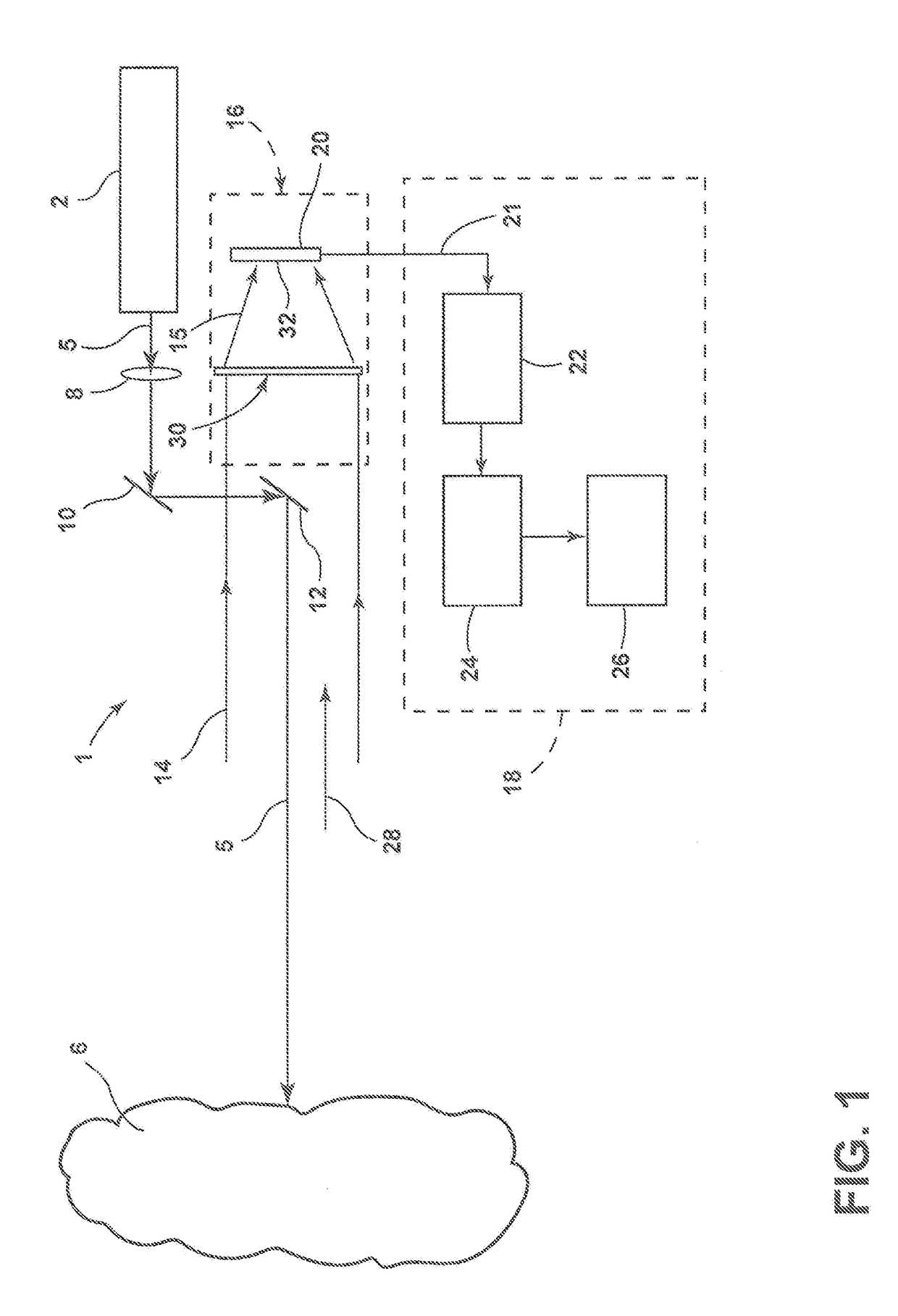

Lidar System Noise Reduction Combining Circular Polarization Laser Output with Photon Sieve Optics in the Receiver

A lidar system includes an optical transmitter having a laser light source that is configured to generate a beam of light that is azimuthally polarized or has Orbital Angular Momentum (OAM). The lidar system further includes an optical receiver having an optical sensor defining a focal plane. A photon sieve is configured to produce a ring pattern on the focal plane corresponding to a laser return signal. The ring pattern comprises azimuthally polarized or Orbital Angular Momentum (OAM) light that is transmitted by the transmitter and reflected towards the receiver. The photon sieve is also configured to cause stray light that is not polarized to produce a central region at the center of the ring pattern that is distinct from the ring pattern.

Owner:NAT INST AEROSPACE ASSOC +1

Design method of Fermat spiral Greek ladder photon sieve and imaging light path thereof

ActiveCN111290062AImprove image contrastImprove image qualityDiffraction gratingsPhoton sieveWave band

A point spread function determines an imaging property of an optical system, and different imaging results can be realized by different point spread functions. A Fermat spiral line is introduced intothe Greek ladder photon sieve, and the Fermat spiral line modulates distribution positions of sieve holes in the Greek ladder photon sieve to obtain the Fermat spiral Greek ladder photon sieve. A plurality of axial focuses are generated through the imaging light path based on the Fermat spiral Greek ladder photon sieve, a function of a multi-focal-plane different-point spread function of a singledevice is achieved, anisotropic Airy disks and vortex focuses are included, and the method can be applied to focusing and imaging from X rays to a terahertz waveband in a coherent light field. A first focus and a third focus are anisotropic Airy disks, different resolutions in different directions can be achieved for an input object, and the resolution of the object in the interested direction can be improved; the second focus is the vortex focus, the vortex focus can be used for optical capture; in addition, radial Hilbert transform can be achieved based on spiral phase filtering when the vortex focus is used for imaging, and edge enhancement of an amplitude and a phase object is realized.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Method for manufacturing array phase zone photon sieve dodging device

InactiveCN102681170AAchieve refocusUniformity achievedDiffraction gratingsPhotomechanical exposure apparatusDirect writingOptical glass

The invention discloses a method for manufacturing an array phase zone photon sieve dodging device, which is implemented by using a large-scale integrated circuit technology and a plane photoetching technology. The method comprises the following steps of: manufacturing a master plate by using an electron beam direct-writing method; transferring patterns of the master plate onto optical glass coated with photoresist with a contact-type photoetching method; and etching the patterns transferred onto the photoresist of the optical glass into the optical glass by using an inductive coupling plasma etching technology. The method disclosed by the invention can be used to realize wavefront flattening on a Gaussian light beam and other uneven non-planar wavefront light beams, realize dodging of the light beams and also realize approximately-planar light beams.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com