Laser direct-write photoetching system based on photon sieve

A laser direct writing and lithography system technology, applied in the field of laser direct writing lithography, can solve the problems of incompatibility, low production efficiency, unable to meet the needs of large-scale production, etc., and achieve high resolution, high production efficiency and low cost Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

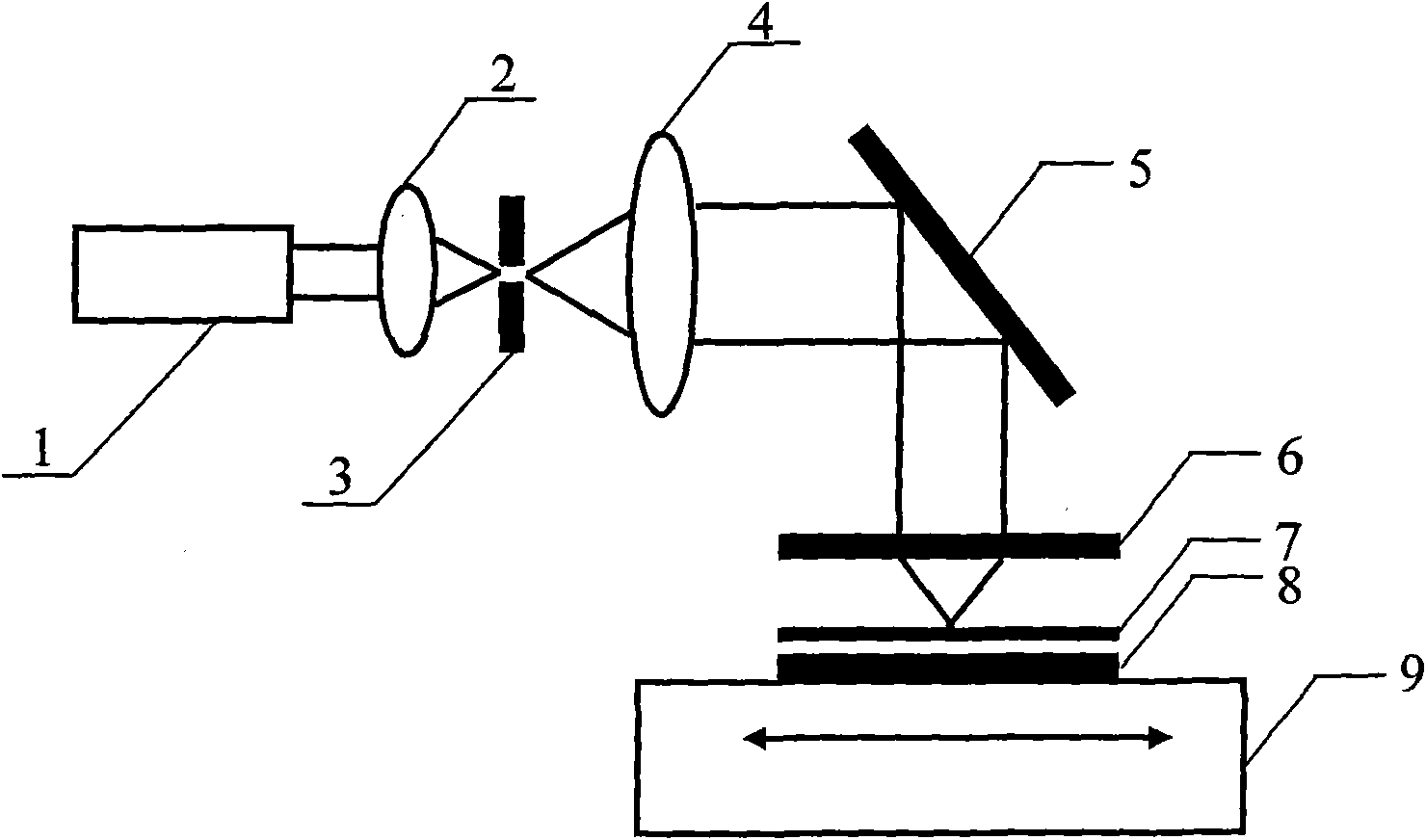

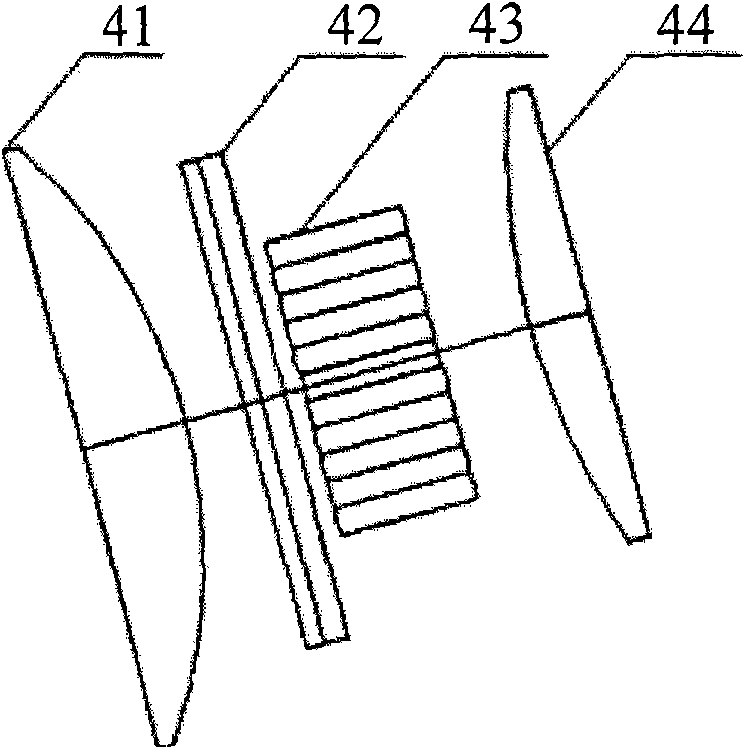

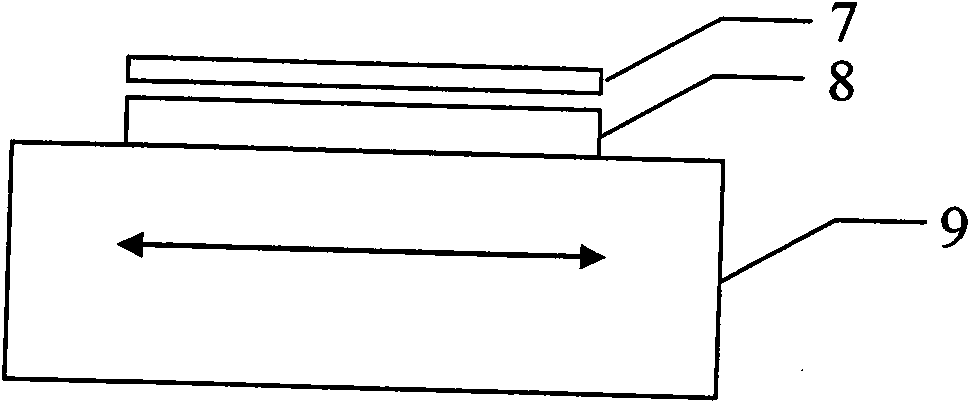

[0017] like figure 1 As shown, the present invention includes an exposure light source 1, a lens 2, a spatial filter device 3, a uniform collimation lens group 4, a mirror 5, a photon sieve 6, a photoresist 7, a substrate 8 and a scanning workpiece table 9, and the substrate 8 Placed on the scanning workpiece table 9; after the exposure light source 1 is gathered by the lens 2, it becomes uniformly collimated parallel light after passing through the spatial filter device 3 and the uniform collimation lens group 4, and then reflected by the reflector 5 onto the photon sieve 6, The photonic sieve has good focusing ability and focuses on the substrate 8 coated with photoresist 7. The scanning workpiece table 9 is an X, Y precision workpiece table. The precision workpiece table is realized according to the position and structure data of the required photolithography pattern provided by the computer. Precise control of the relative motion between the photonic sieve and the substrat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com