Method for manufacturing array phase zone photon sieve dodging device

A technology of photon sieve and light homogenizer, which is applied in the field of annular photon sieve light homogenizer in part of the array, can solve the problems of high requirements for designers, low cost, large transmission loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

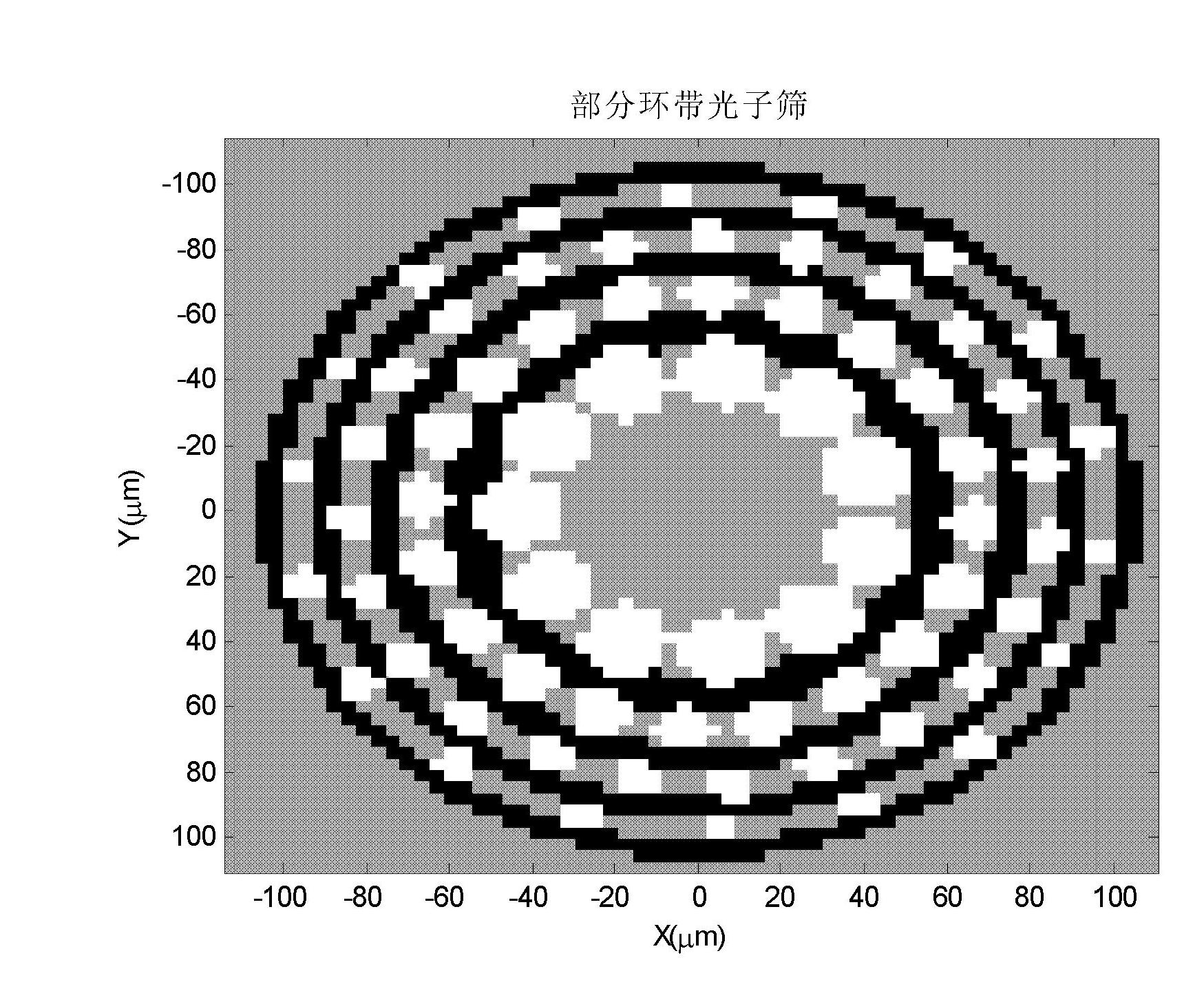

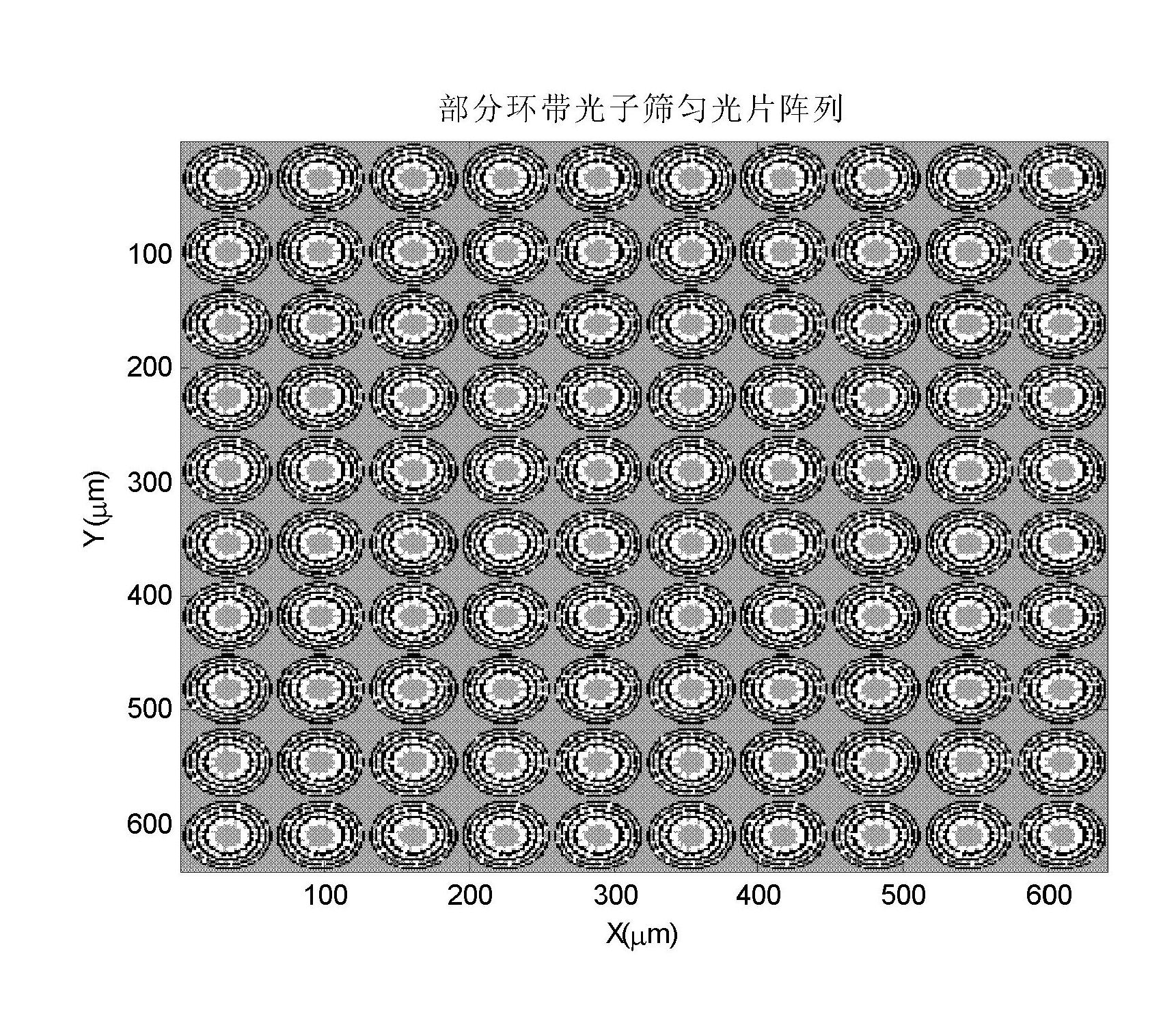

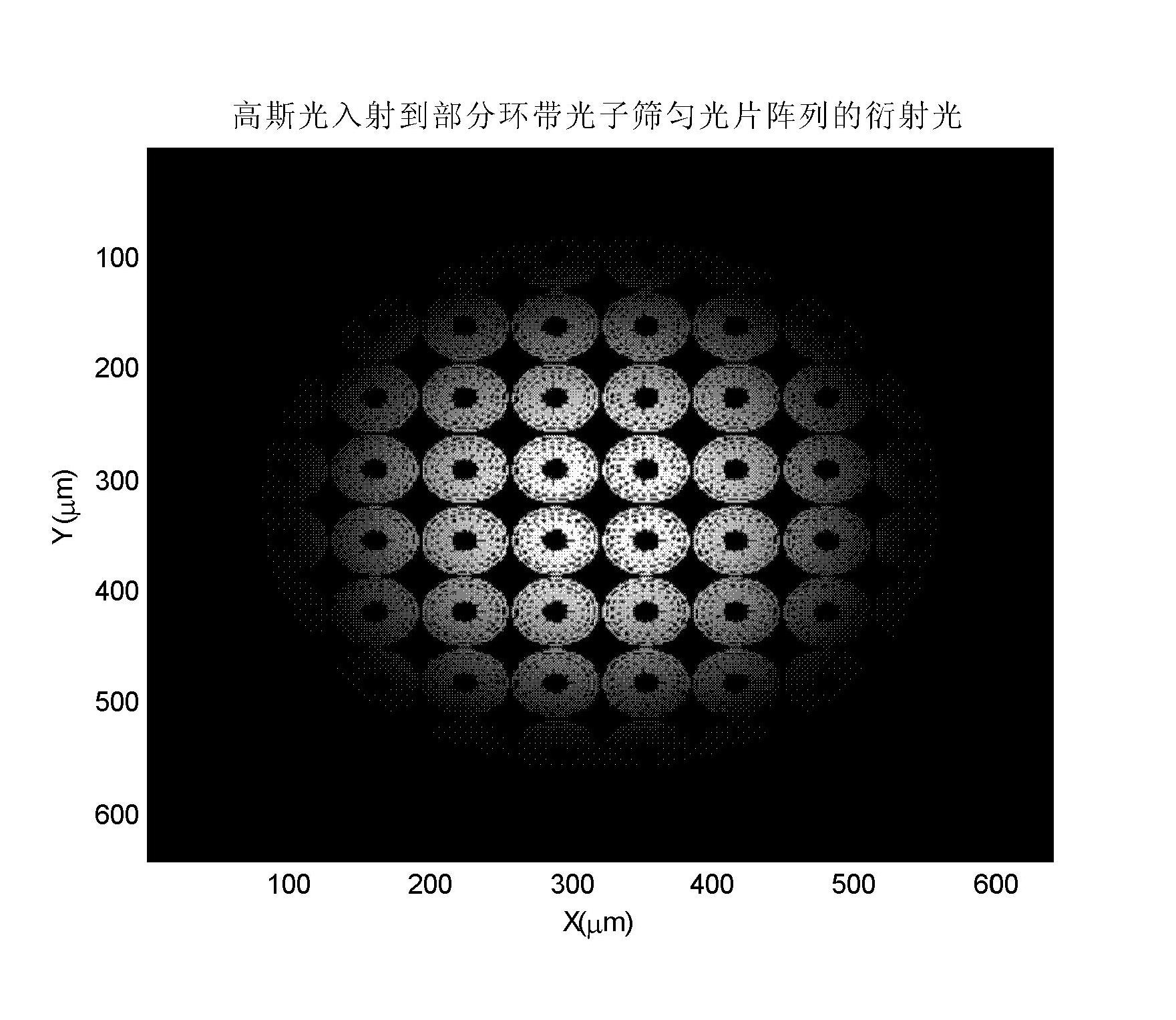

[0038] The photon sieve homogenizer with an annular ring in the array is a new type of diffractive optical phase element, that is, a phase plate. The phase plate is placed before or after the diffraction-limited lens to correct the far-field diffraction light field of the laser beam, that is, to homogenize the light, and to achieve a diffracted beam that is closer to the plane wavefront than the irregular wavefront of the incident beam (such as a Gaussian beam). The invention provides the design structure of the ring-band photon sieve homogenizer in the array part, and carries out relevant simulation experiments. Experiments have verified that the wavefront flattening of the Gaussian beam can be achieved by using the part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com