Device used for changing objective lens of microscope

A technology of microscopes and objective lenses, applied in microscopes, optics, instruments, etc., can solve problems such as inability to drive by motors, and achieve the effect of avoiding collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

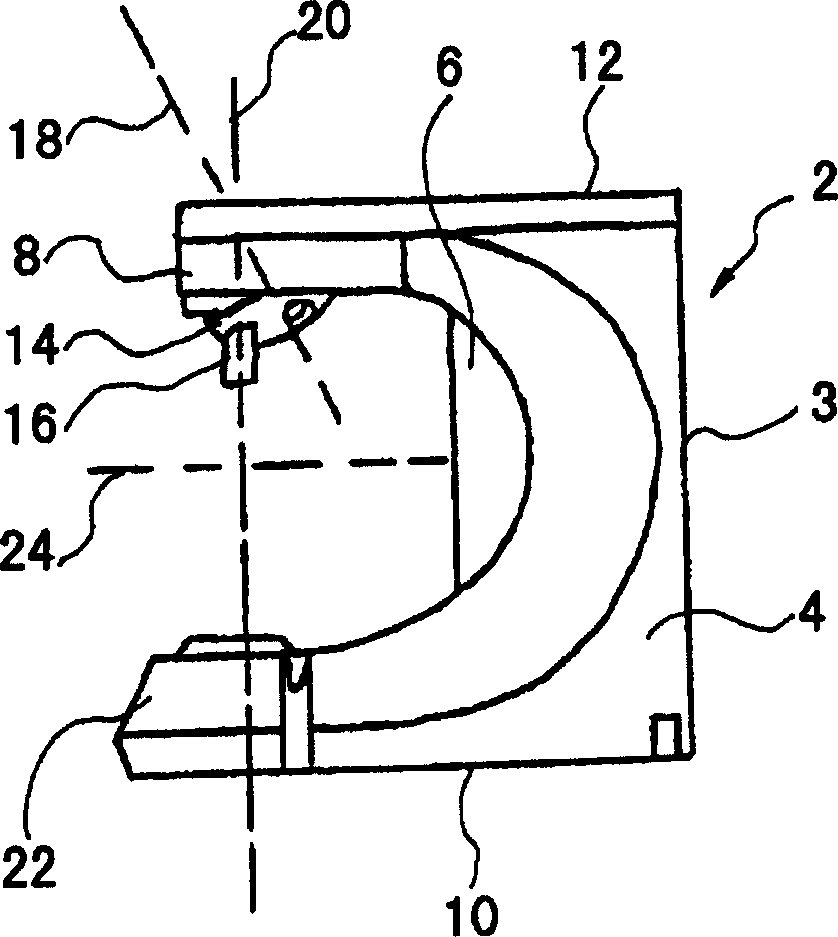

[0021] figure 1 Indicates a microscope according to the prior art. The microscope comprises a stand 2 defined by first and second side walls 4 and 6 and an end wall 8 . The first and second side walls 4 and 6 are also connected to each other by the rear wall 3 . The microscope also includes a base 10 and a head 12 . Installed in the head 12 is an objective turret 14, which supports several objective lenses 16 that can be rotated or rotated to the working position by the objective turret 14. The objective turret 14 rotates around a rotation axis. The objective 16 in the working position defines an optical axis 20 . An illumination device 22 for illuminating an object (not shown) lying on the stage plane 24 can be arranged, for example, on the base 10 of the microscope. The axis of rotation 18 and the optical axis 20 are arranged apart such that the plane defined by them is parallel to the first or second side wall 4 or 6 of the microscope.

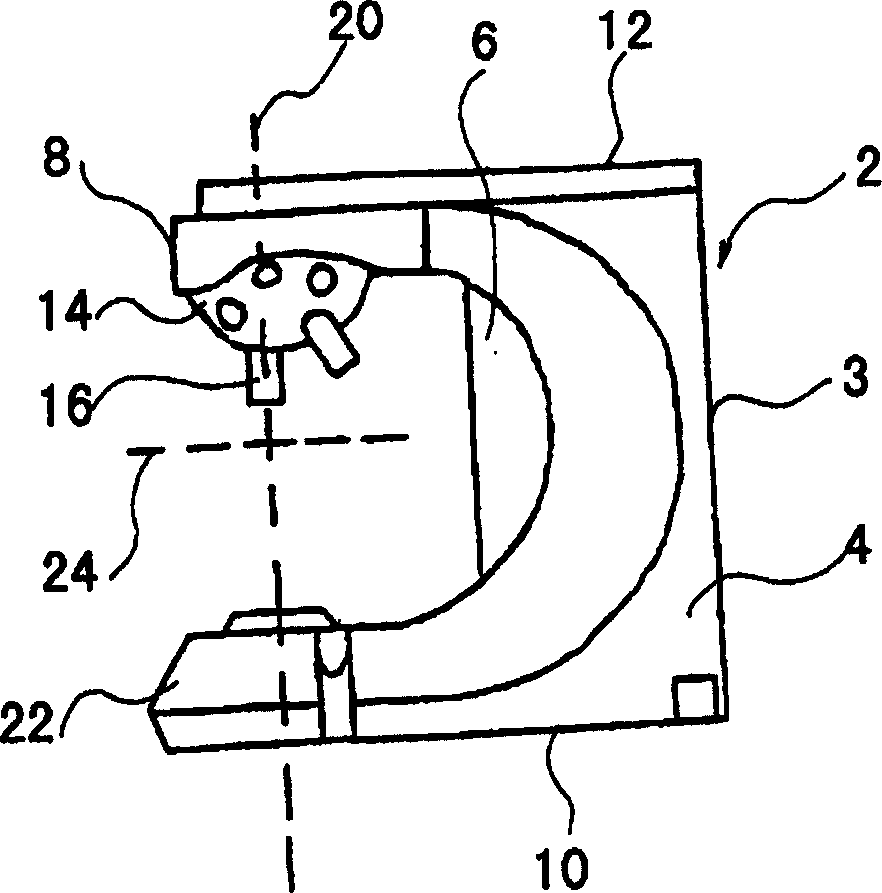

[0022] figure 2 Designating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com