Defect detection system for extreme ultraviolet lithography mask

A technology for extreme ultraviolet lithography and defect detection, applied in the field of extreme ultraviolet lithography mask defect detection system, to achieve the effects of small size, easy processing, and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

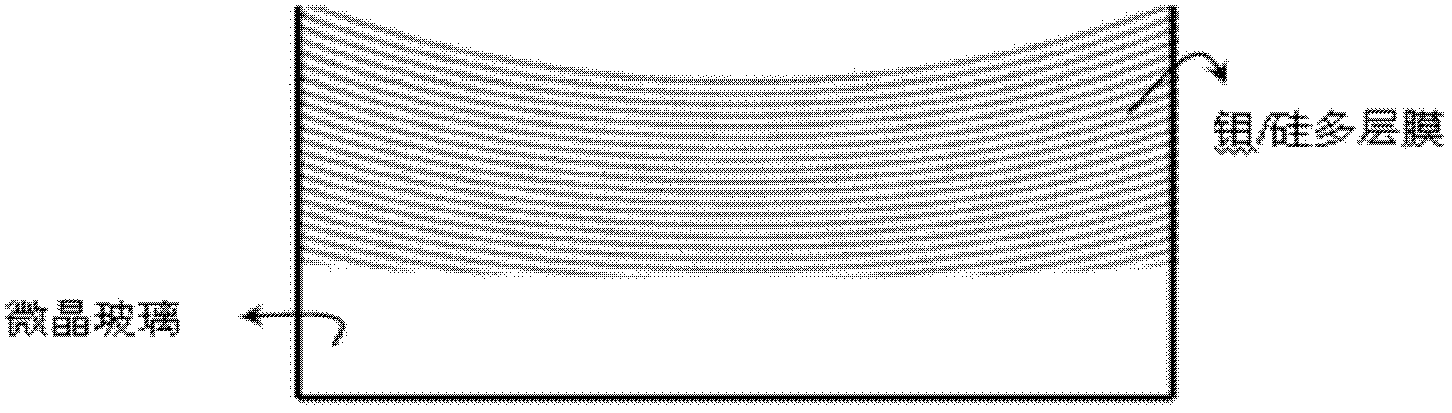

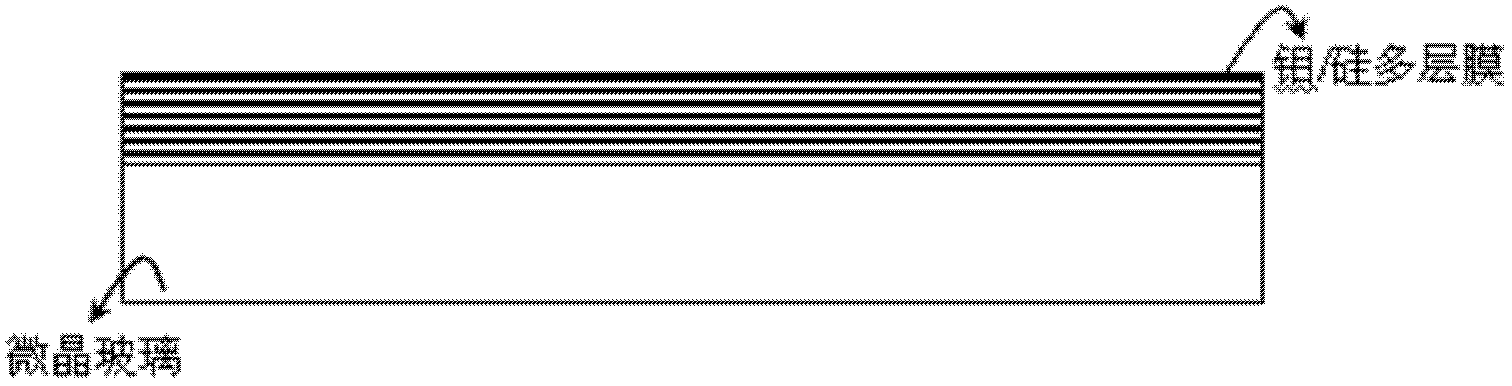

[0022] The EUV lithography mask defect detection system provided by the present invention uses a photon sieve instead of a traditional Schwarzchild objective to realize imaging of the mask in the EUV band, thereby detecting defects on the mask.

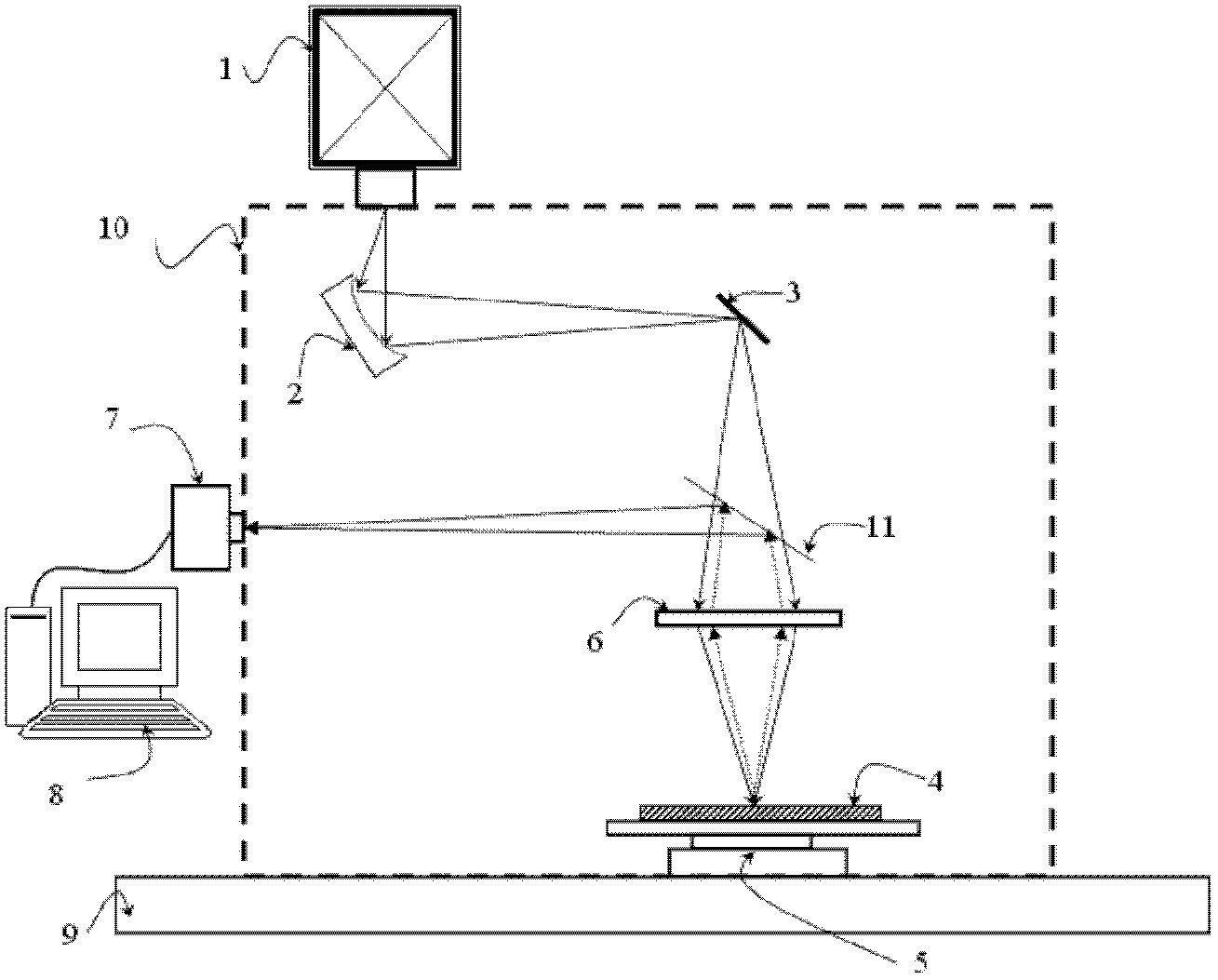

[0023] like figure 1 as shown, figure 1 It is a schematic structural diagram of an extreme ultraviolet lithography mask defect detection system according to an embodiment of the present invention. The extreme ultraviolet lithography mask defect detection system is oriented to the detection of mask defects in extreme ultraviolet lithography at the 22nm node, and specifically includes extreme ultraviolet lithography. Light source 1, extreme ultraviolet light transmission system (i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| power | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com