Large area photon sieve

A photon sieve and large-area technology, applied in the field of photon sieves, can solve problems such as difficulty in increasing the diameter of photon sieves

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

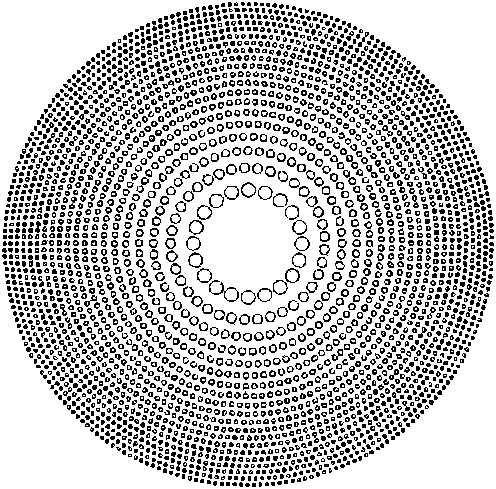

[0038] Embodiment 1: A photon sieve with a new structure, diameter Φ=100mm, focal length f=500mm, working wavelength λ=632.8nm.

[0039] If the design method of the traditional photon sieve is adopted, the photon sieve required by this embodiment will have a period of 3940 rings, and the minimum aperture diameter will be 0.00318mm, such as image 3 shown. These parameters clearly pose a great challenge to current manufacturing processes.

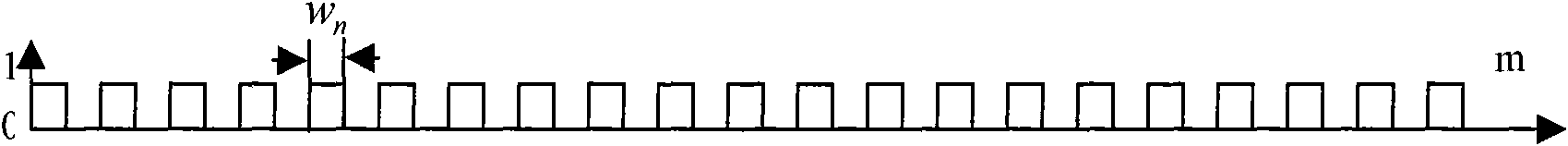

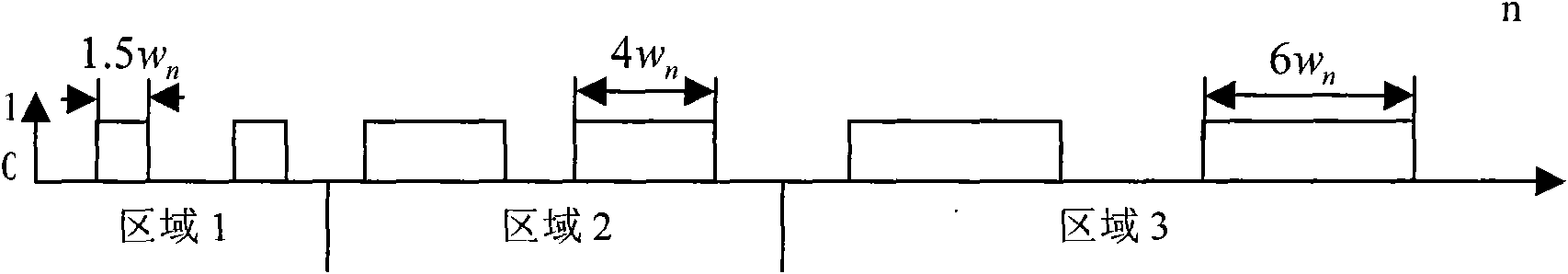

[0040] This example figure 2 As shown, the photon sieve is divided into three regions,

[0041]

[0042] in w n = λf 2 r n is the small hole diameter of the photon sieve before merging (the small hole diameters of the three regions are respectively enlarged to 1.5, 4, and 6 times of the original), λ is the working wavelength, f is the focal length of the new photon sieve, f n is the d...

Embodiment 2

[0049] For a photon sieve with f=500mm, D=50mm, and λ=632.8nm, the design scheme of the photon sieve of the present invention is adopted. Using the Gaussian density modulation function, after calculation, m=987 rings are divided into 3 areas, the number of rings after partitioning is 159, and the merging periods are 3, 5, and 8 respectively, as shown in the table below

[0050]

[0051] After optimization, σ f = 1.505, μ = 0, c = 0.8 and h = 2.75

[0052] With the new design scheme, the minimum hole diameter is changed from 63.28um to 279.07um.

Embodiment 3

[0054] For the photon sieve with f=500mm, D=50mm, λ=405nm, we use a new photon sieve design scheme. Using the Weber density modulation function, after calculation, m=1542 rings are divided into 4 areas, the number of rings after partitioning is 219, and the merging periods are 3, 5, 8, and 10 respectively, as shown in the table below

[0055]

[0056] In this embodiment, the density function is a Weibull function,

[0057] f ( r n ) = c α β f ( r n h · β f ) α - 1 e - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com