Compound photon sieve for large-caliber imaging and manufacturing method thereof

A production method and photonic sieve technology, which are applied in the photoengraving process, optics, diffraction grating and other directions of the pattern surface, can solve the problems of reducing the amount of layout data, unable to produce large-diameter imaging photonic sieves, etc., and achieve the suppression of side lobe effects and The effect of advanced diffraction, imaging contrast enhancement, sharp focal spot

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

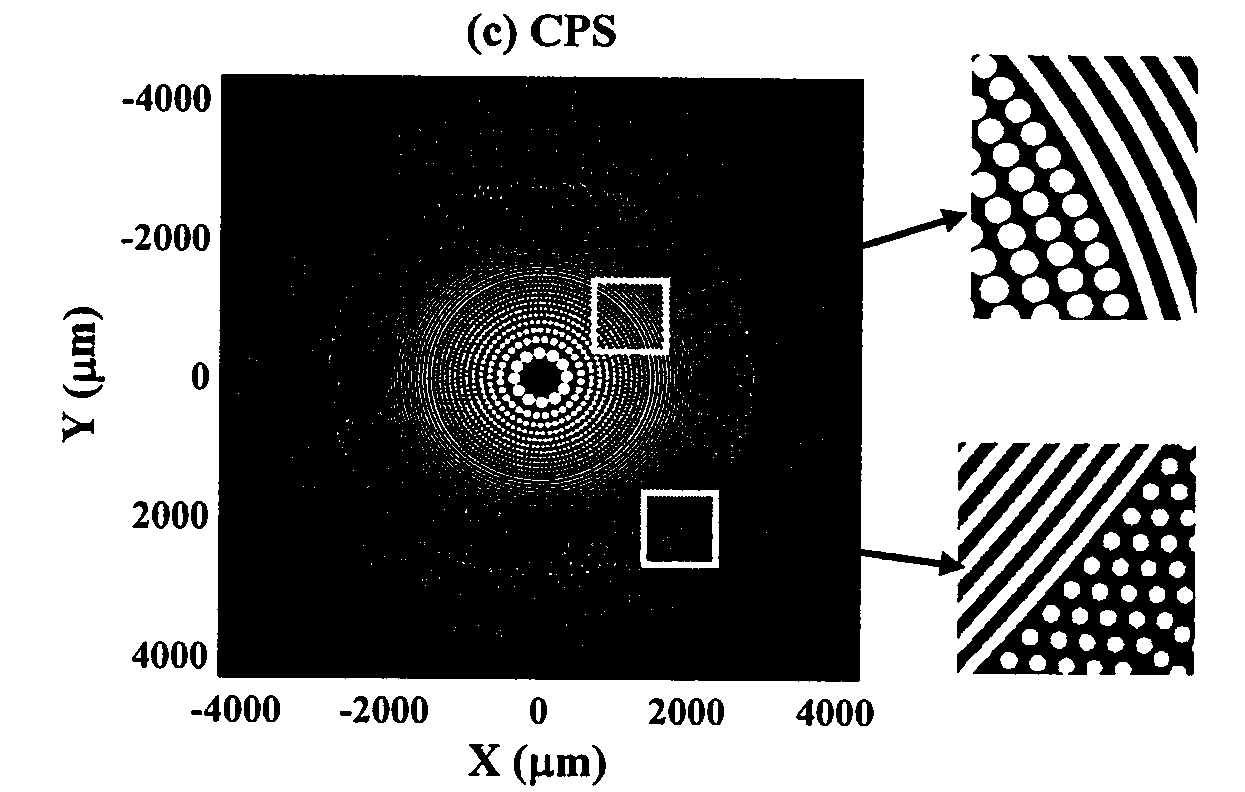

[0044] A composite photon sieve, including a light-transmitting quartz substrate and an opaque metal chromium film plated on it, the material of the light-transmitting substrate can also be light-transmitting materials such as ordinary glass or plexiglass, and the light-impermeable The material of the metal film can also be opaque metals such as gold, aluminum or copper;

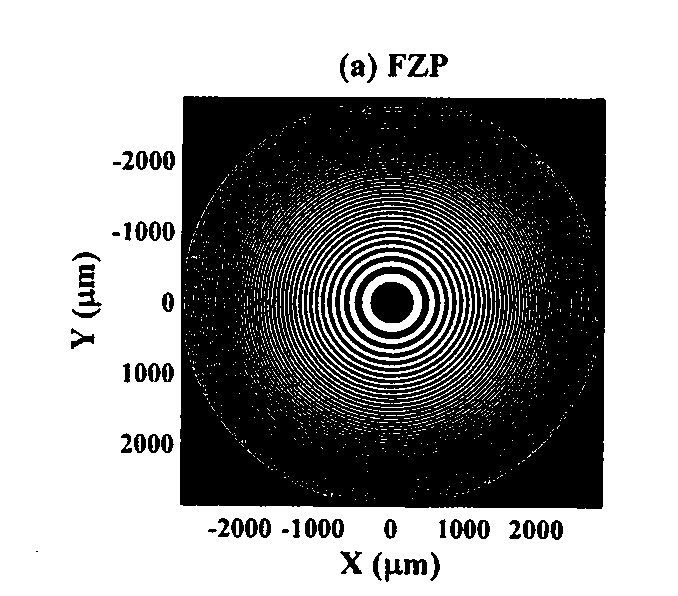

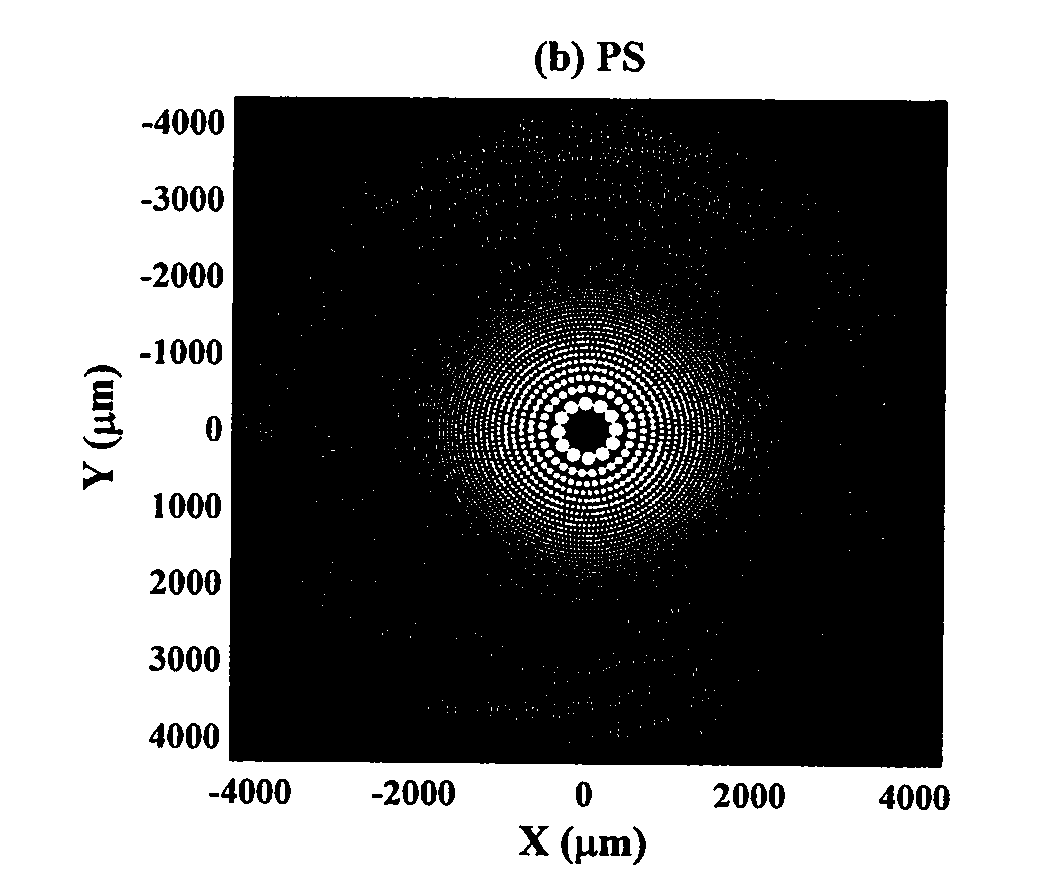

[0045] A series of light-transmitting annular zones and some light-transmitting small holes are distributed on the opaque metal chromium film; the diameter of the quartz substrate is 10cm, the diameter of the photon sieve is 17.75mm, the number of annular zones is 370 rings, and the wavelength is 355nm, the focal length is 0.3m, the diameter of the ligh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com