Photon sieve and manufacturing method thereof

A production method and technology of photon sieves, applied in optics, diffraction gratings, optomechanical equipment, etc., can solve the problems of low diffraction efficiency of photon sieves, and achieve improved diffraction efficiency, increased transmittance, surface plasmon polarization and surface Effect of Plasma Coupling Enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

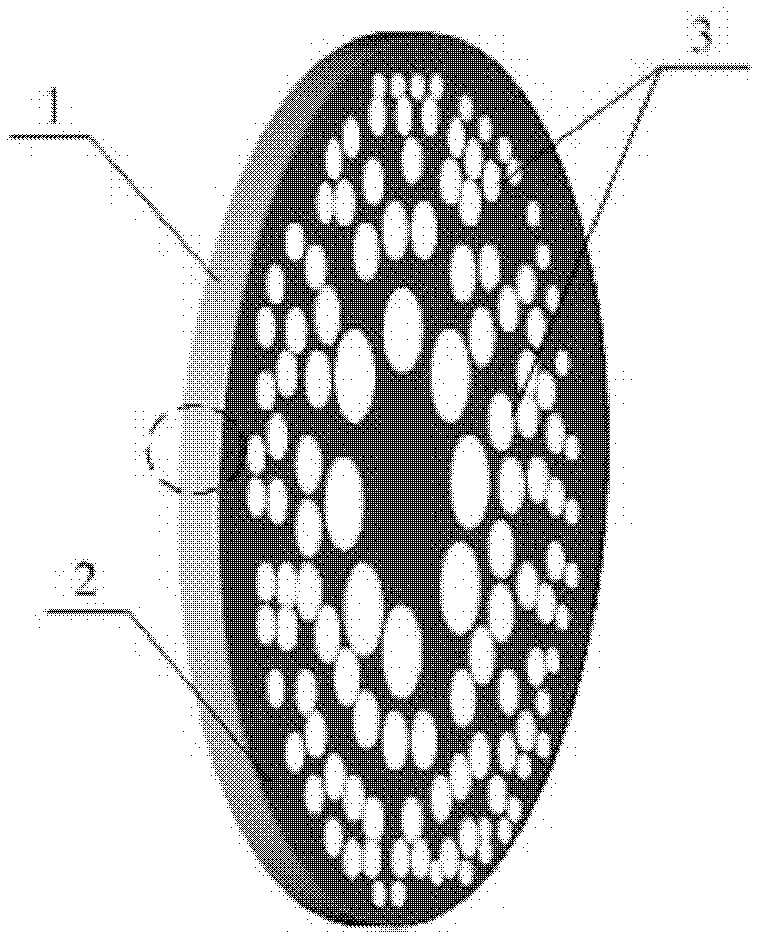

[0037] refer to figure 1 , figure 1 It is a schematic diagram of the structure of the photonic sieve provided by the present invention, the photonic sieve includes: a light-transmitting substrate 1; 2 includes a multilayer metal film and a dielectric film arranged alternately; a plurality of small holes 3 arranged on the opaque multilayer film 2 and distributed in a plurality of rings, and a plurality of small holes on each ring 3 are distributed randomly and do not overlap each other.

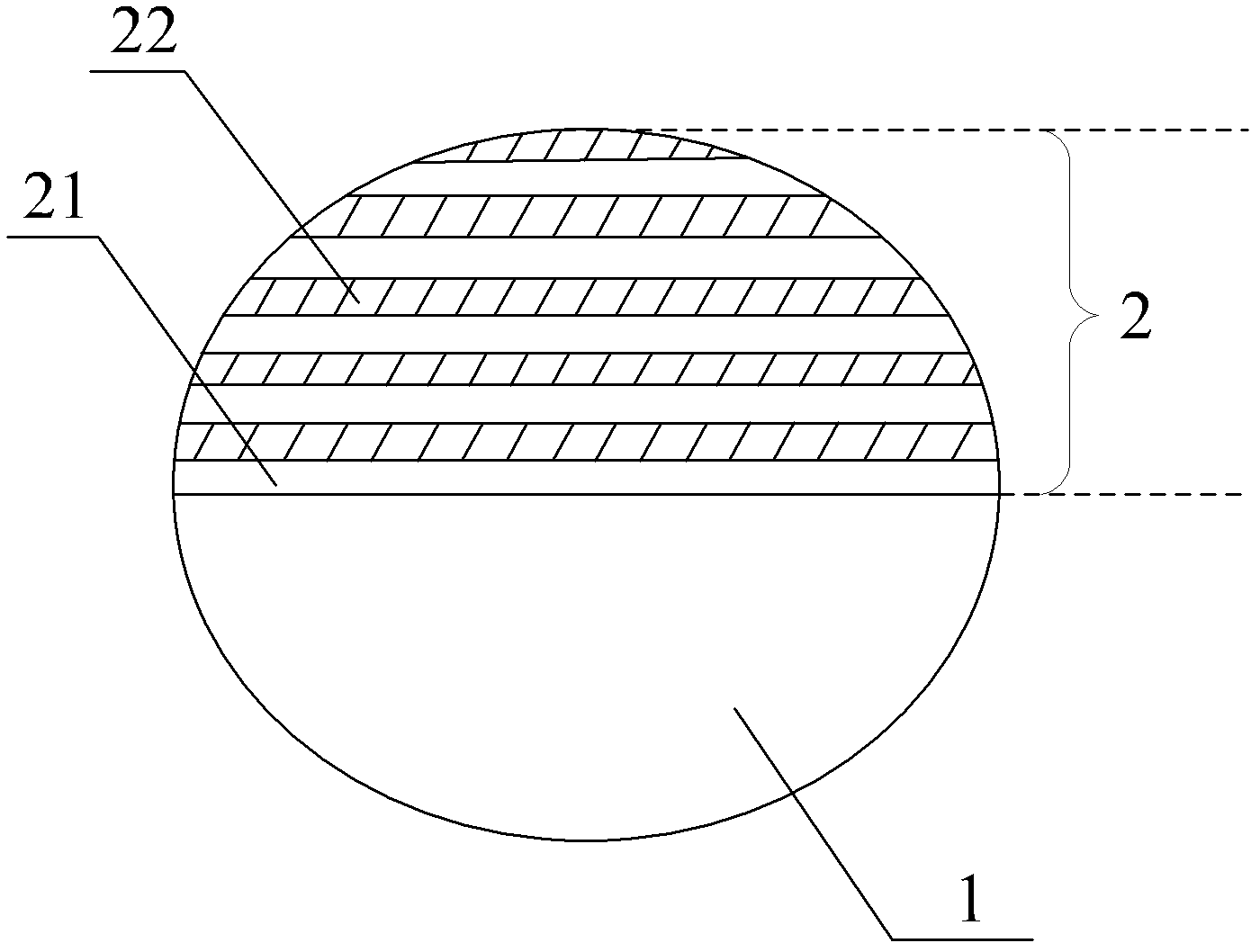

[0038] In order to more clearly describe the positional relationship between the light-transmitting substrate 1 and the opaque multilayer film 2 on it, the figure 1 The part of the dotted line frame in the middle is partially enlarged, and the obtained cross-sectional schematic diagram is as follows figure 2 as shown, figure 2 The figure shows a light-transmitting substrate 1 and an opaque multi-layer film 2 on the light-transmitting substrate 1 . The light-impermeable multi-layer film 2...

Embodiment 2

[0049] The photon sieve provided by the present invention has been described in detail above, and the manufacturing method of the photon sieve is introduced below.

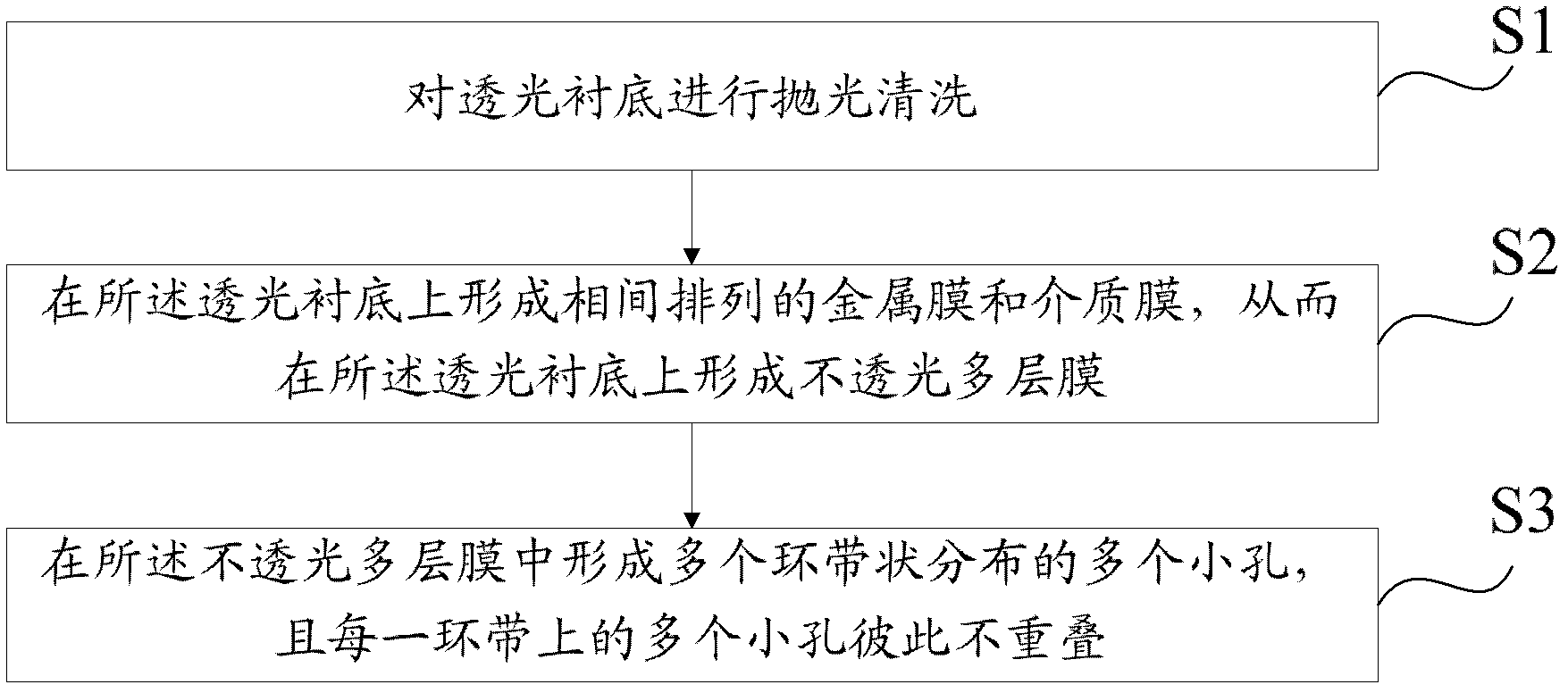

[0050] refer to image 3 , image 3 It is a schematic flow chart of the photon sieve manufacturing method provided by the present invention, and the method specifically includes the following steps:

[0051] Step S1: Polishing and cleaning the transparent substrate.

[0052] First, a light-transmitting substrate is selected, and the light-transmitting substrate is polished and cleaned. The light-transmitting substrate is selected as a quartz substrate, the thickness of the quartz substrate is 1.5mm, and the diameter is 25.4mm, and the transmittance of the light-transmitting substrate is greater than 85% under the irradiation of an applied wavelength of 405nm. After the light-transmitting substrate is polished and cleaned, the roughness of the light-transmitting substrate is less than 0.5 nm, and the flatness is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com