Compound type photon sieve

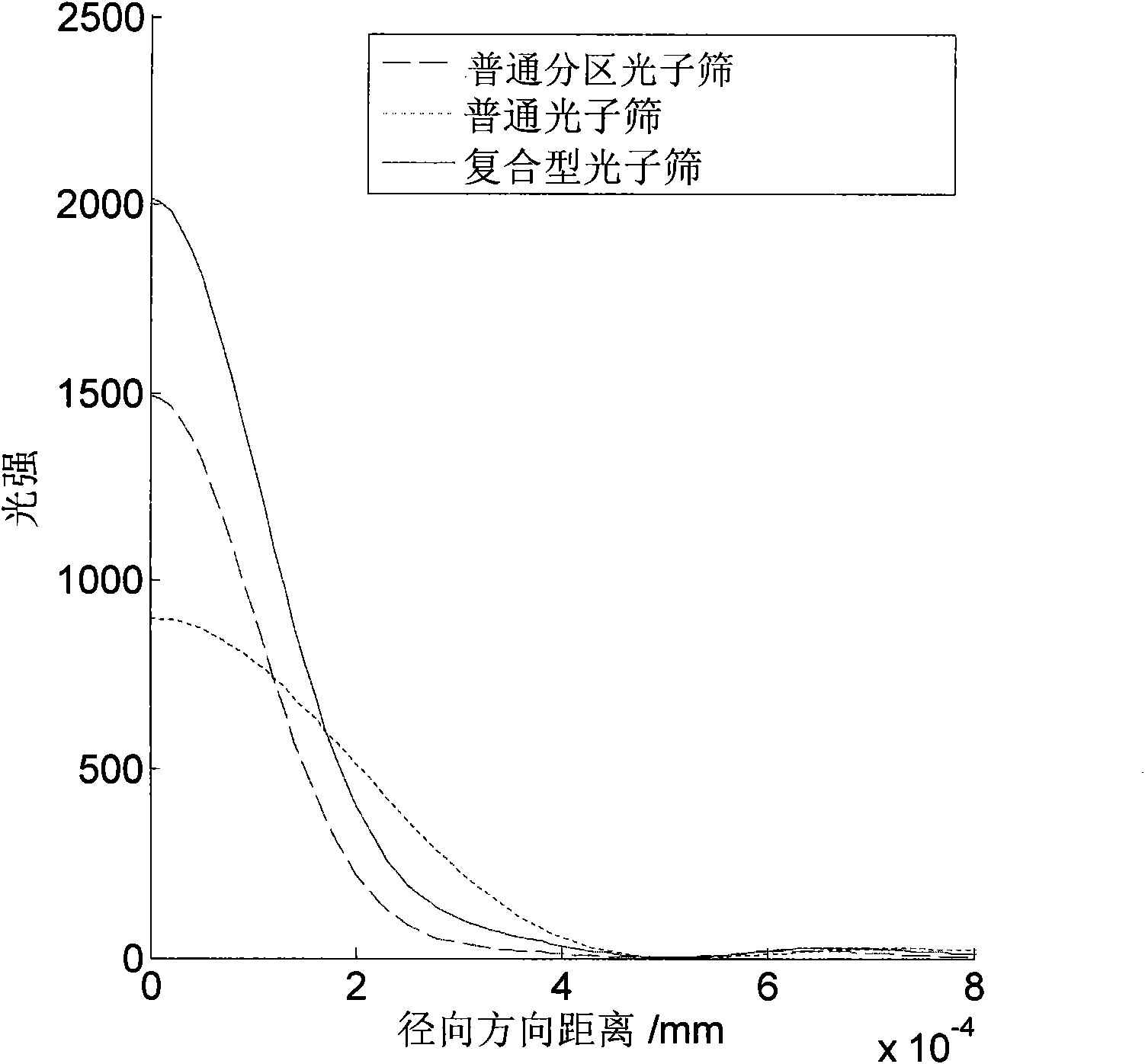

A photon sieve and composite technology, applied in the direction of diffraction grating, etc., can solve the problems of difficult to obtain aperture and low diffraction efficiency, and achieve the effect of improving resolution and main spot energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

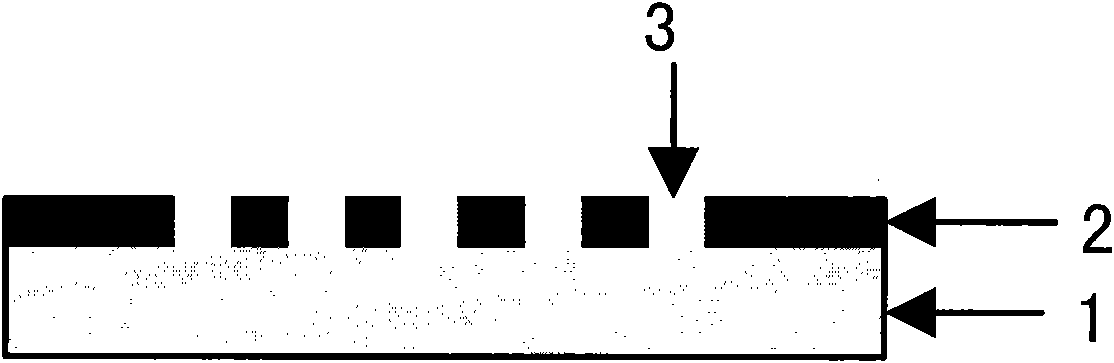

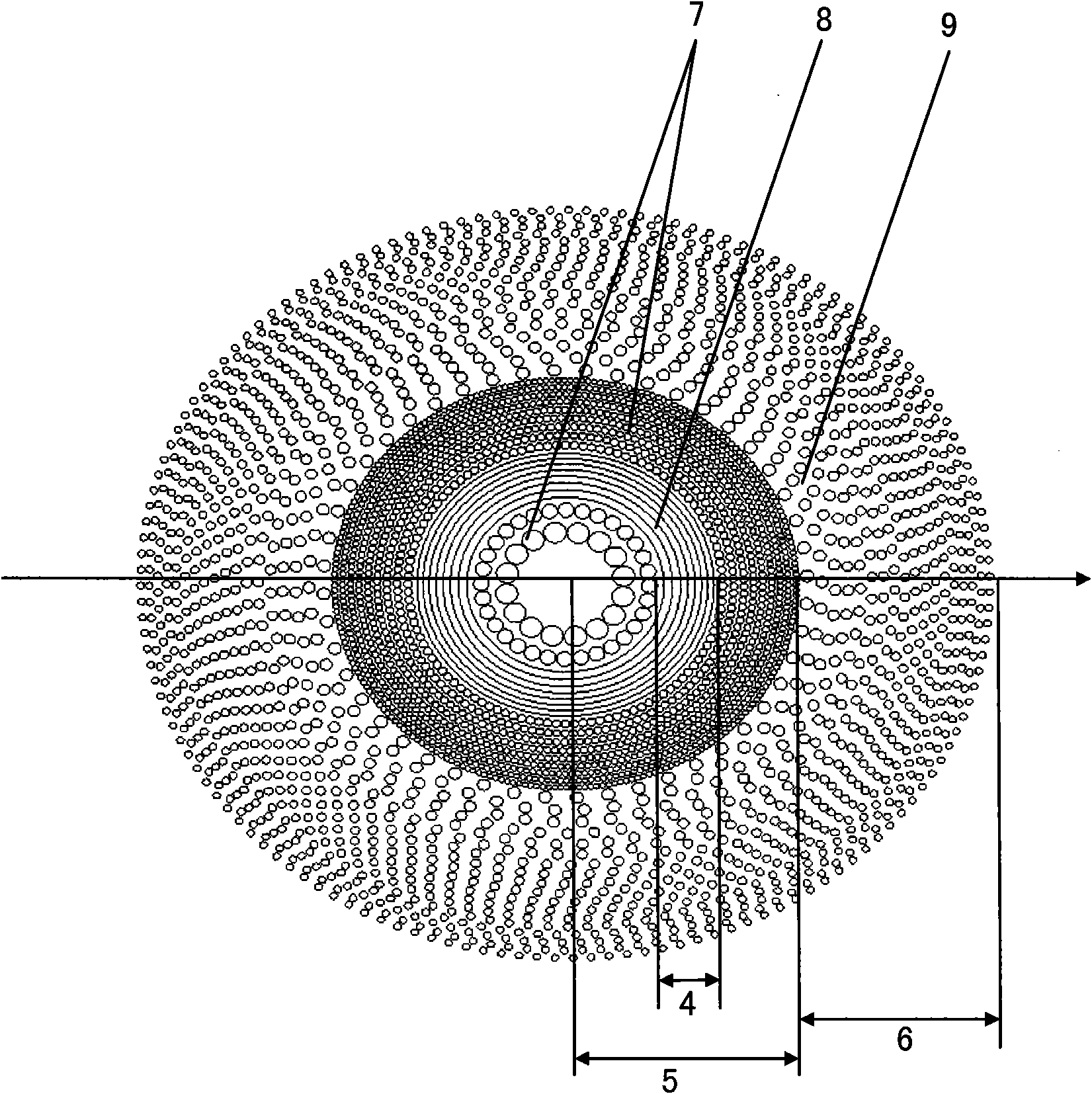

[0010] This example figure 1 and figure 2 Contains transparent medium 1, metal layer 2 and microstructure 3, metal layer 2 is plated on transparent medium 1, and required microstructure 3 is etched on metal layer 2, along the radius of transparent medium 1 from inside to outside The direction of the transparent medium 1 is divided into different regions based on the minimum line width of the microfabrication, and the regions include the band region 4, the first region 5, and the second region 6 all have multiple sets of microstructures 3. Between the two groups of microstructures 3 in the first area 5, there is a wave zone 4, each group of microstructures 3 is composed of ring-shaped distributions with different radii a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com