Large-aperture imaging photon sieve and production method thereof

A manufacturing method and technology of photon sieves, applied in optics, diffraction gratings, optical elements, etc., can solve the problems of inability to manufacture large-diameter imaging photon sieves, achieve suppression of sidelobe effects and advanced diffraction, increase resolution, and focus imaging sharp effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

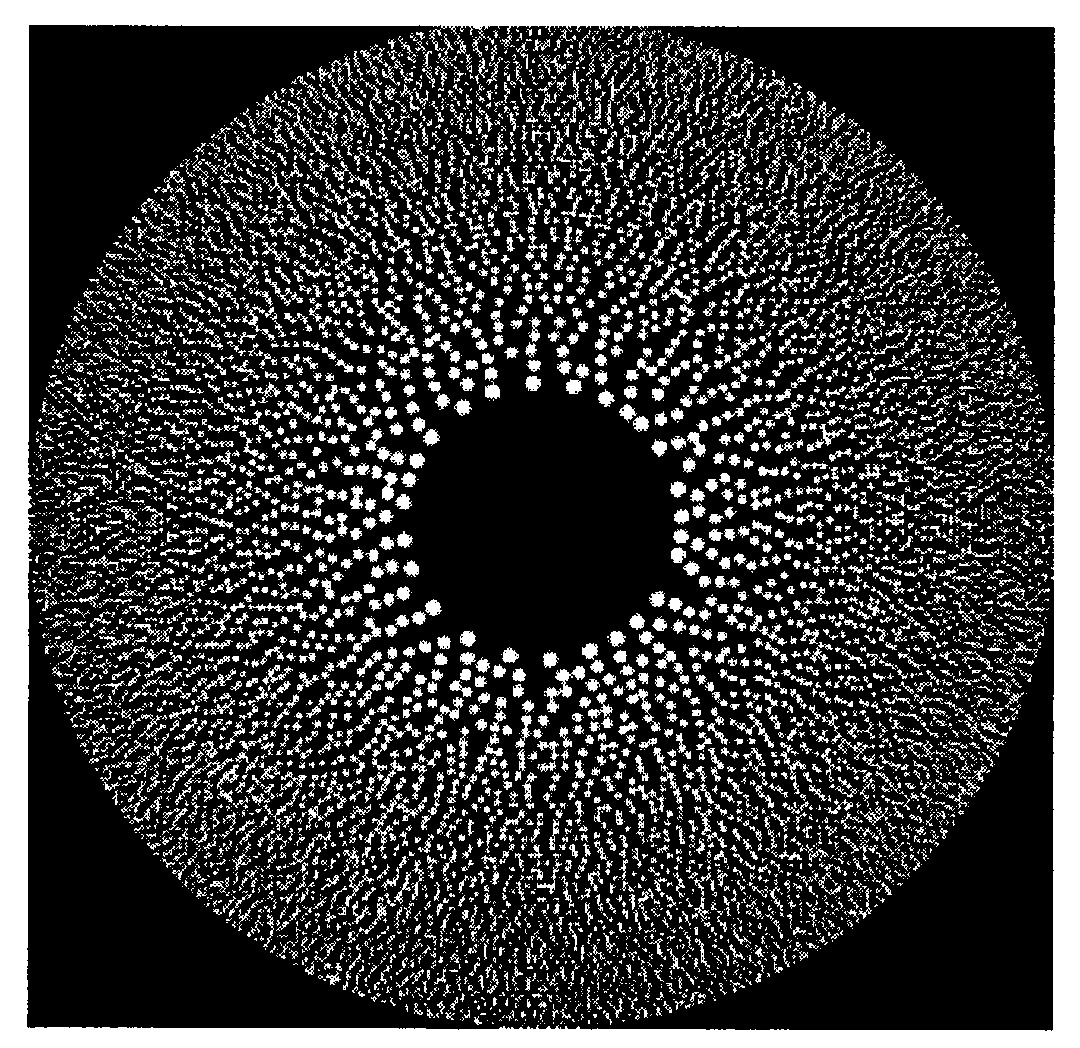

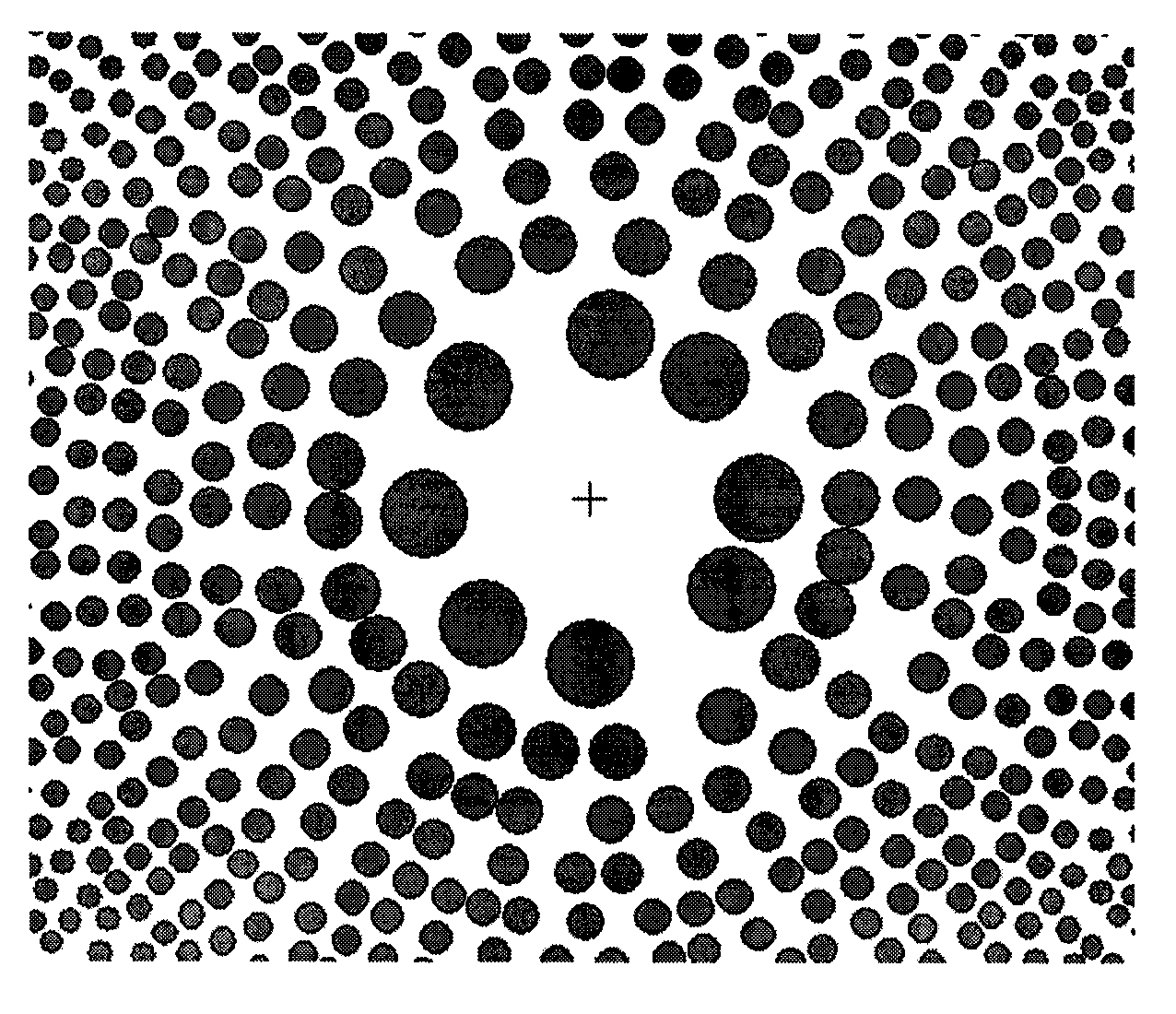

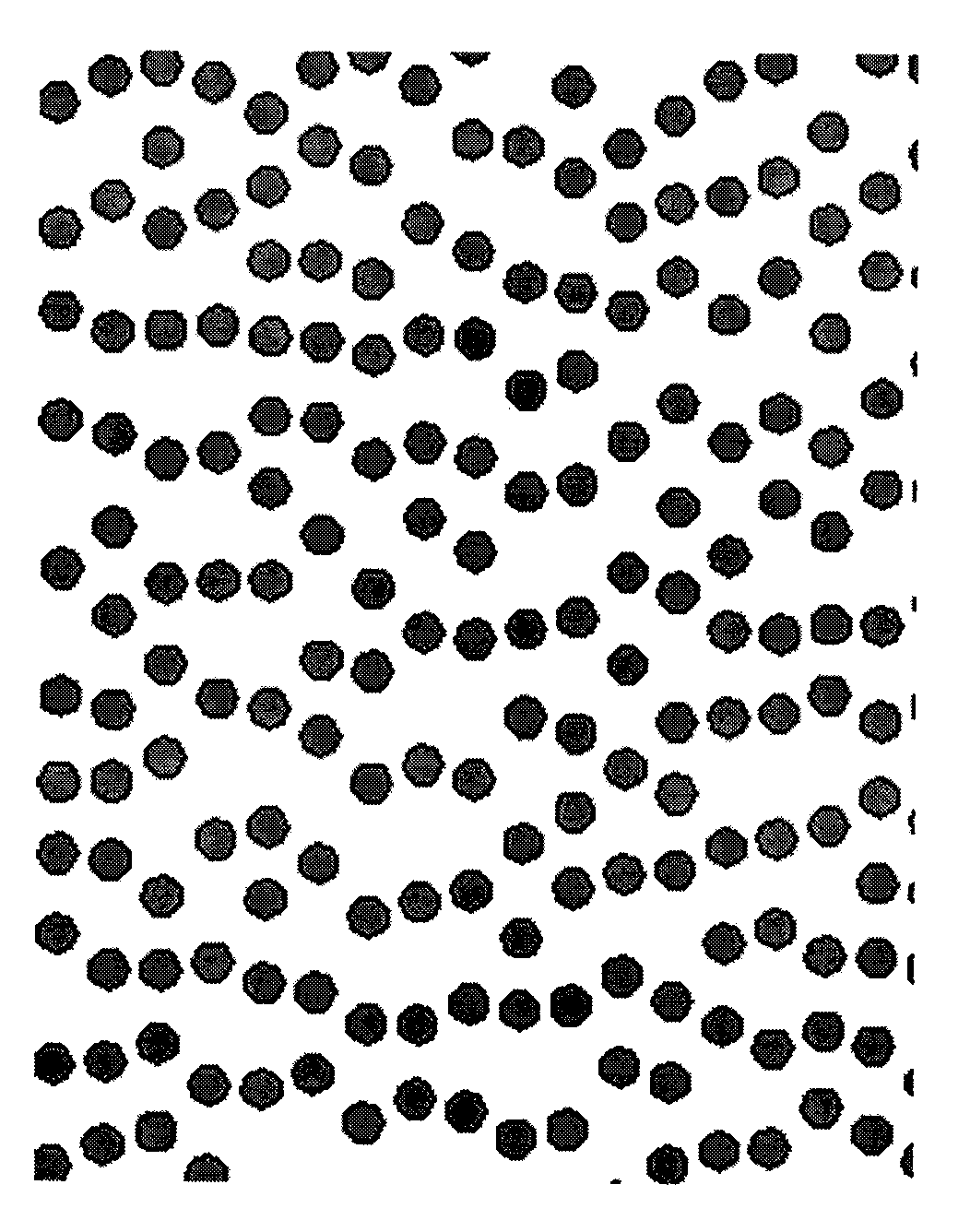

[0035] An embodiment of the present invention provides a large-diameter imaging photon sieve, which includes a light-transmitting quartz substrate and an opaque metal chromium film plated thereon. The material of the light-transmitting substrate can also be ordinary glass or plexiglass. Optical material, the material of the opaque metal thin film can also be opaque metals such as gold, aluminum or copper; On the described opaque metal chromium thin film, some light-transmitting small holes are randomly distributed; the diameter of the quartz substrate The diameter of the photon sieve is 10cm, the diameter of the photon sieve is 80mm, the number of rings is 3000, the wavelength is 355nm, the focal length is 0.939m, the diameter of the light-transmitting hole on the outermost ring is 5μm, and the characteristic size is 3.33μm. Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com