Short-wavelength efficient stable high-reflectivity metal laser welding system

A laser welding, short-wavelength technology, used in laser welding equipment, welding equipment, metal processing equipment and other directions, can solve the problem of low laser welding efficiency, and achieve the effect of improving equipment use efficiency, welding speed, and improving welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

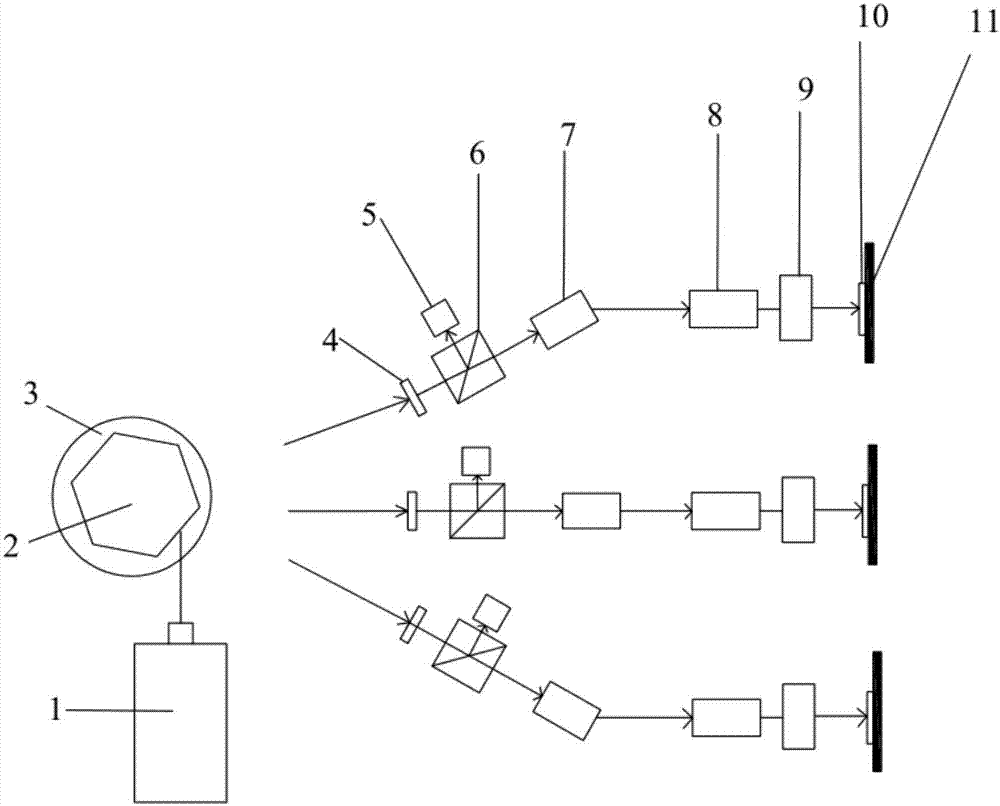

[0036] The structure diagram of the laser welding system of the present invention is as follows figure 1 As shown, a laser welding system for highly reflective metals is provided with a laser 1, a polygonal mirror 2, and several component optical paths in sequence; the split optical path includes an optical attenuation device, a laser transmission mirror group 7, a beam shaping mirror group 8, and a laser focusing lens. Group 9 also includes a laser collector 5, and the light attenuation device includes a half-wave plate 4 and a polarization beam splitter cube 6 arranged in sequence, and the polygon mirror 2 is rotated by a high-speed motor 3; the laser light emitted by the laser 1 shines on the rotating polygon mirror 2 The scanning laser beam is formed on the upper part, and the scanning laser beam can enter the optical path of several components, and finally realize the welding of the first weldment 10 and the second weldment 11.

[0037]In this embodiment, a 40W laser 1 is...

Embodiment 2

[0043] This embodiment is basically the same as Embodiment 1, except that when the laser wavelength is 400nm, the process parameters when welding the laser are: the pulse width range is 10ms, the pulse repetition frequency is 10Hz, and the final diameter of each component optical path is 120 μm The focused spot of light can finally realize the welding of weldment 1 and weldment 2.

Embodiment 3

[0045] This embodiment is basically the same as Embodiment 1, the difference is that: when the laser wavelength is 100nm, the laser 1, the polygon mirror 2 and some component optical paths are placed in an inert gas (such as Ar gas), and the process parameters when welding the laser are : The pulse width range is 30ns, the pulse repetition frequency is 200kHz, and the focused spot with a diameter of 100μm is obtained, and finally the welding of the first weldment and the second weldment is realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com