Patents

Literature

54results about How to "Improve workmanship" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

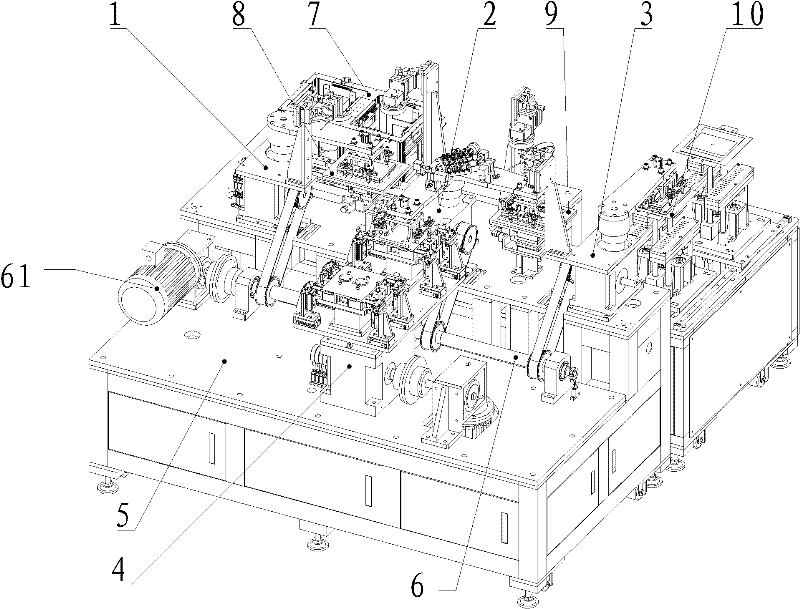

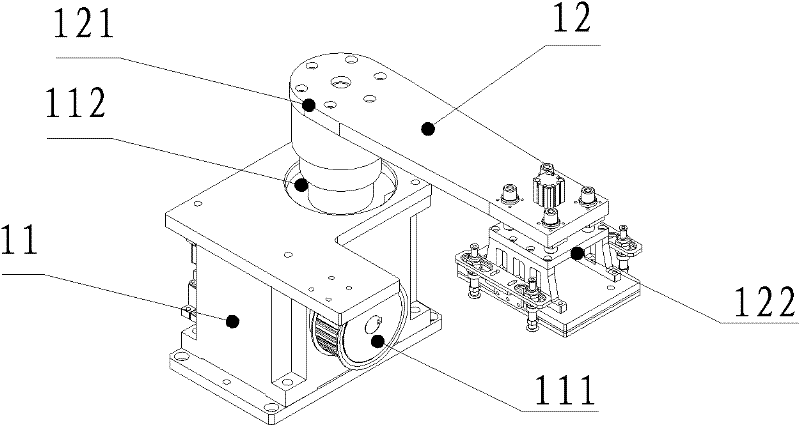

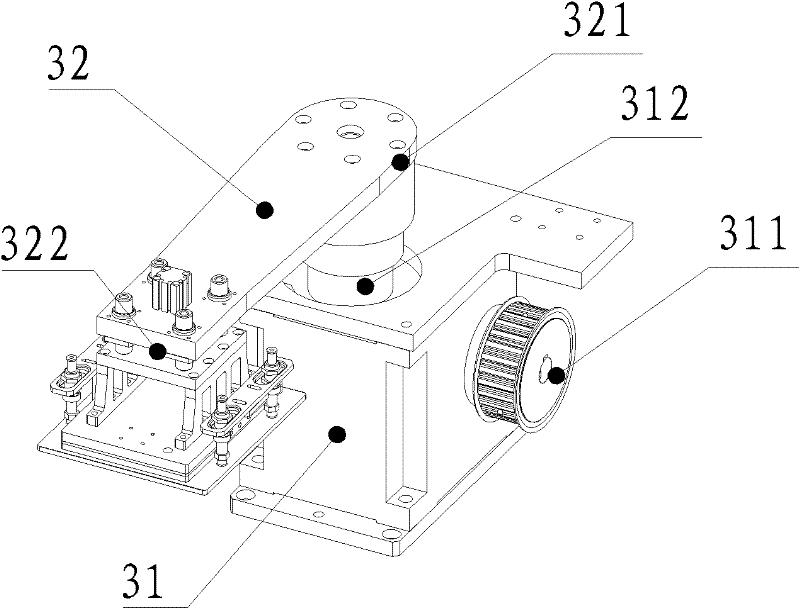

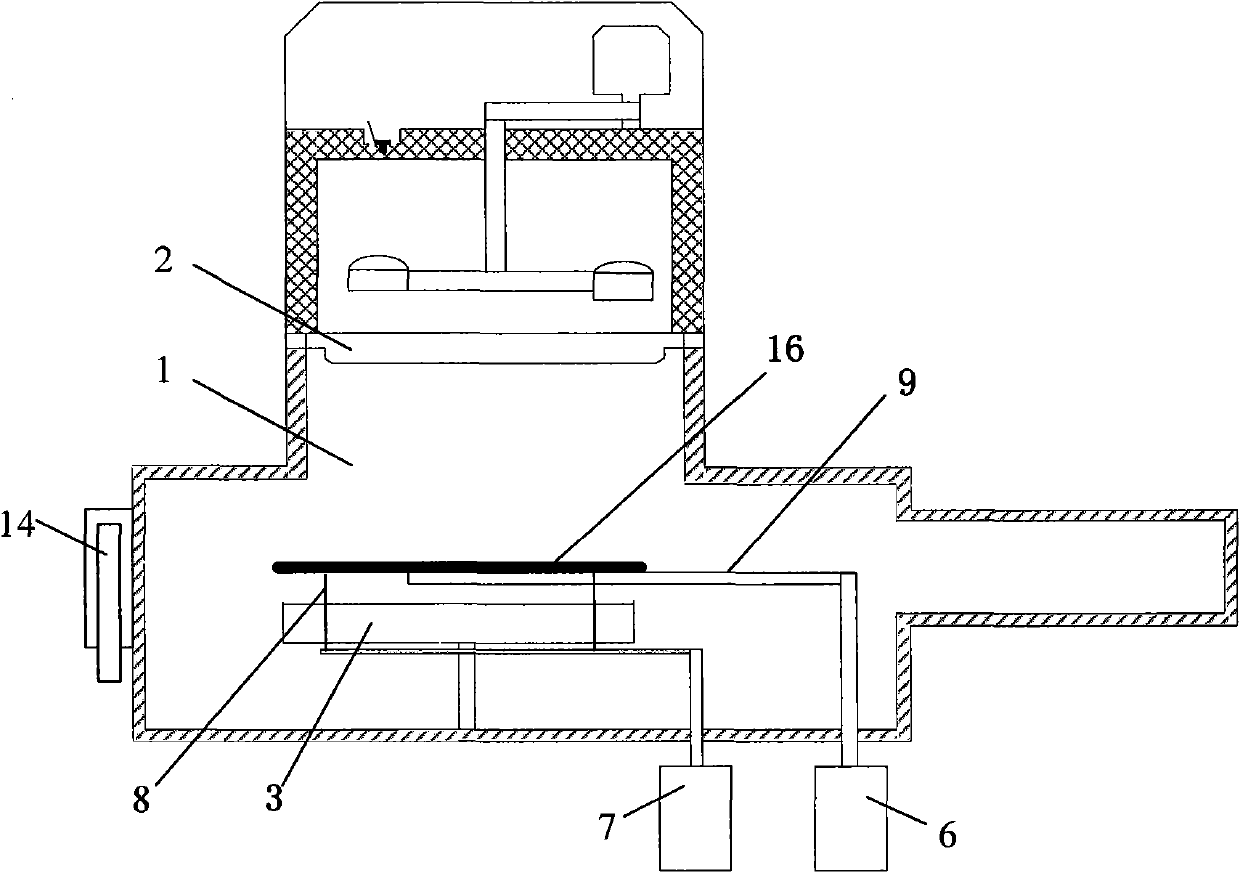

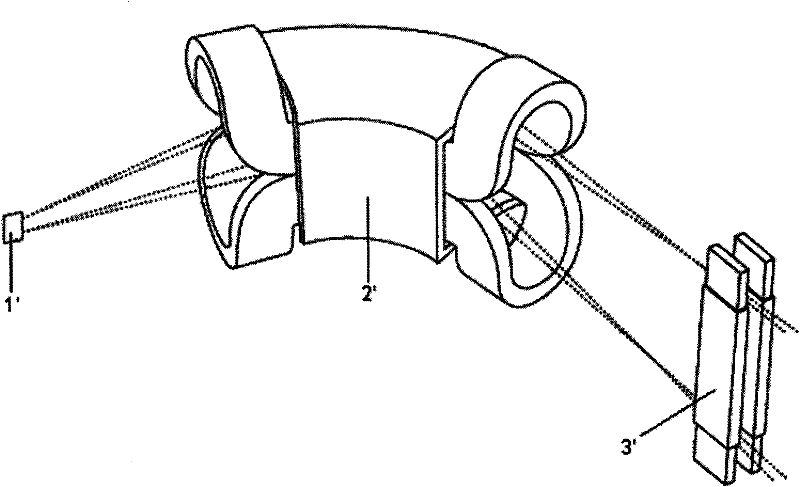

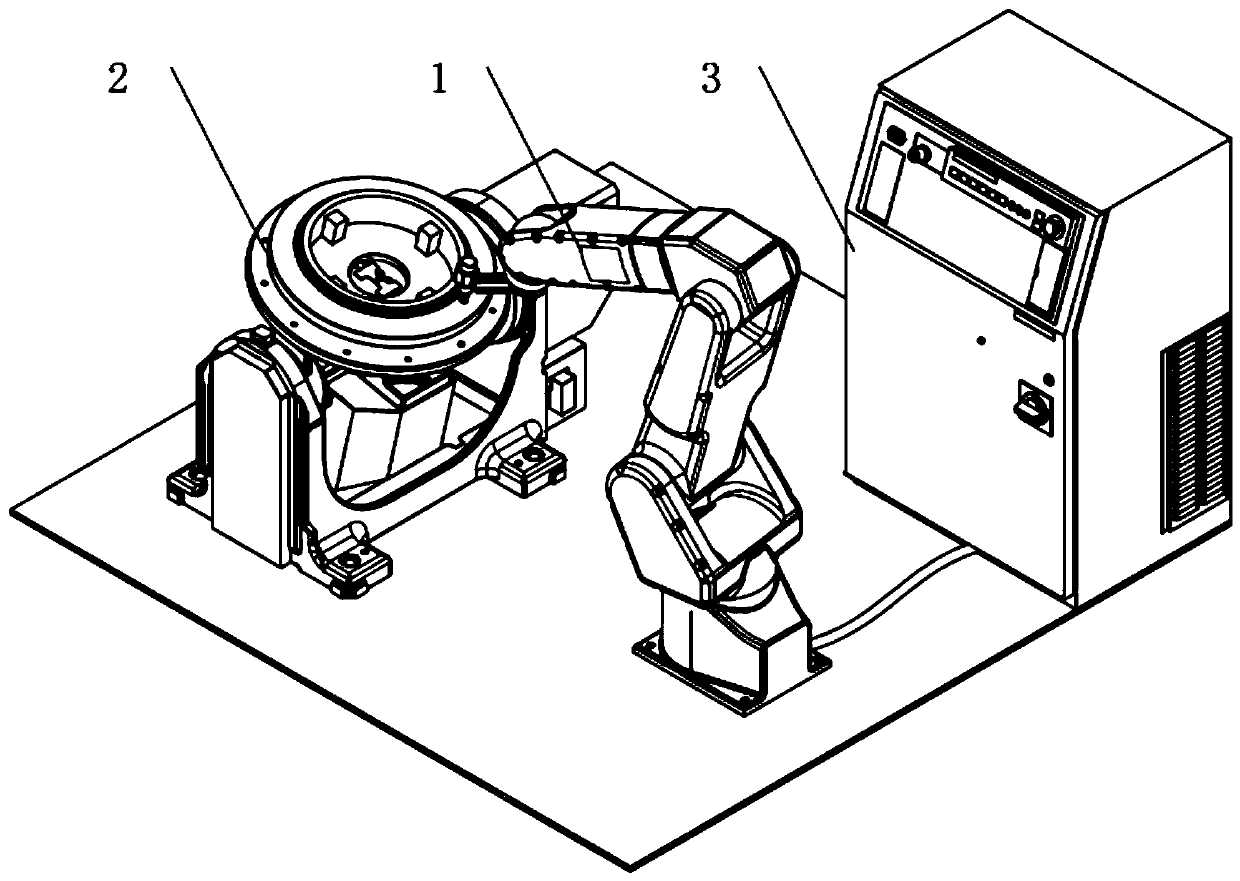

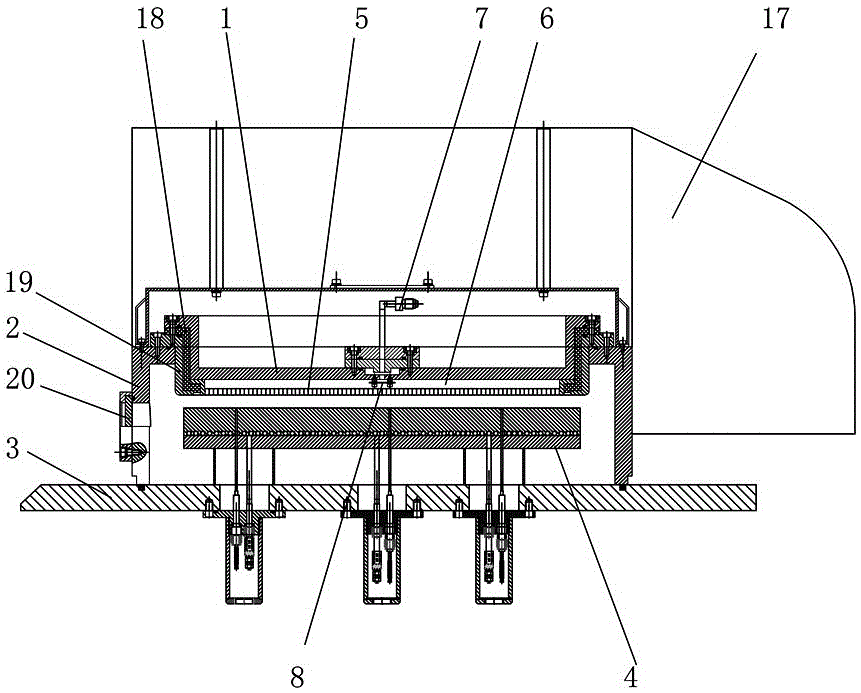

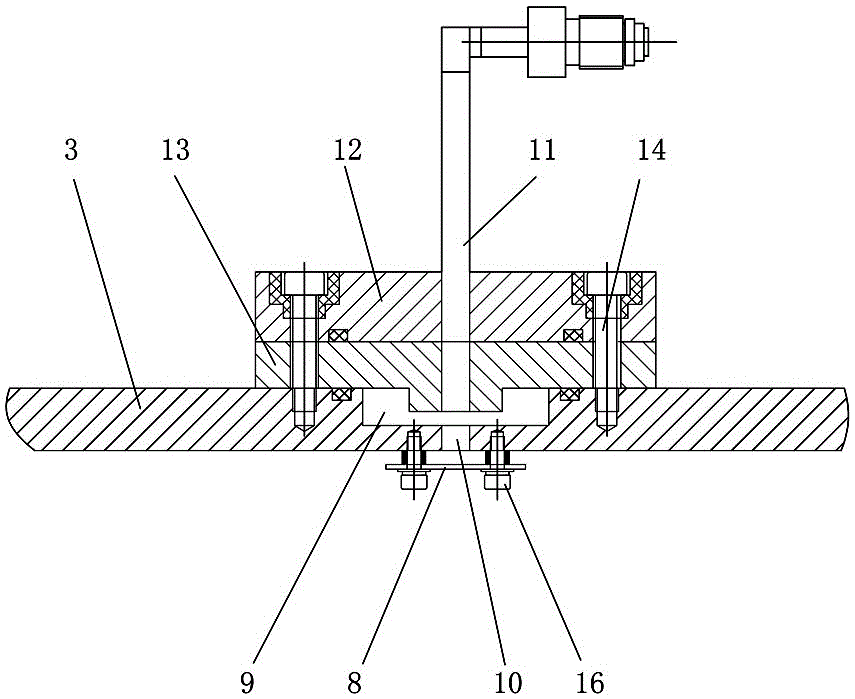

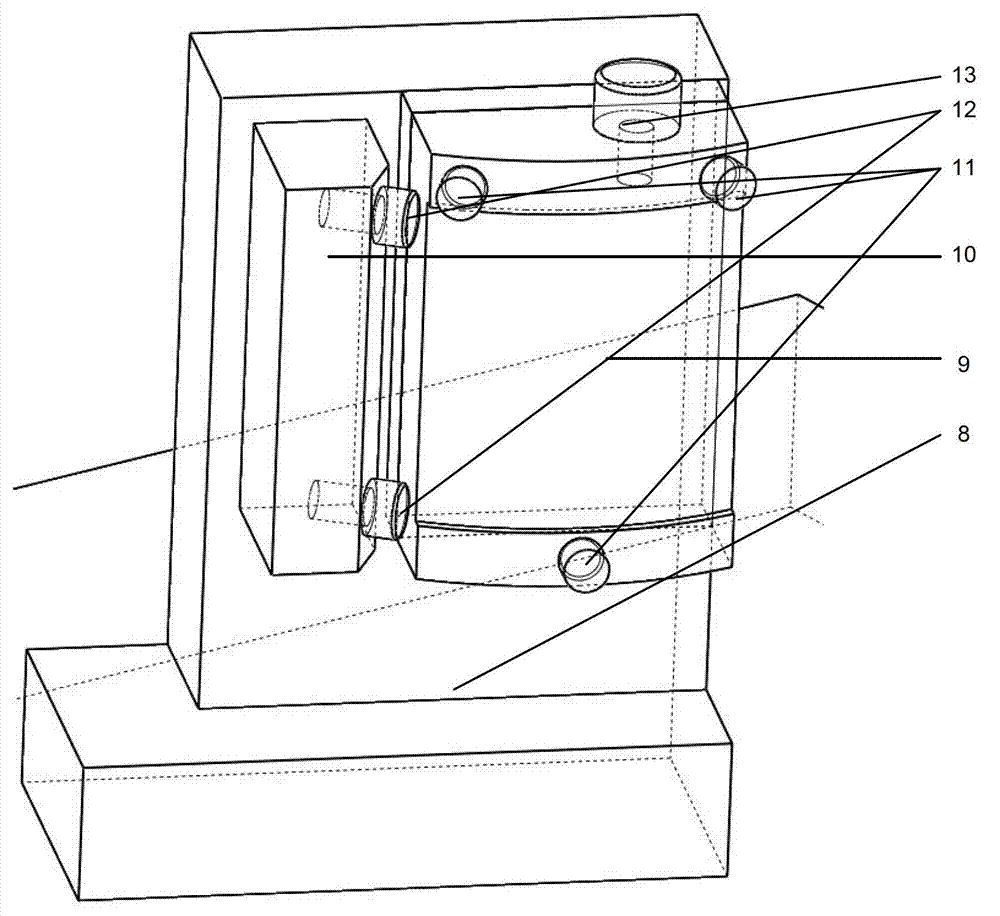

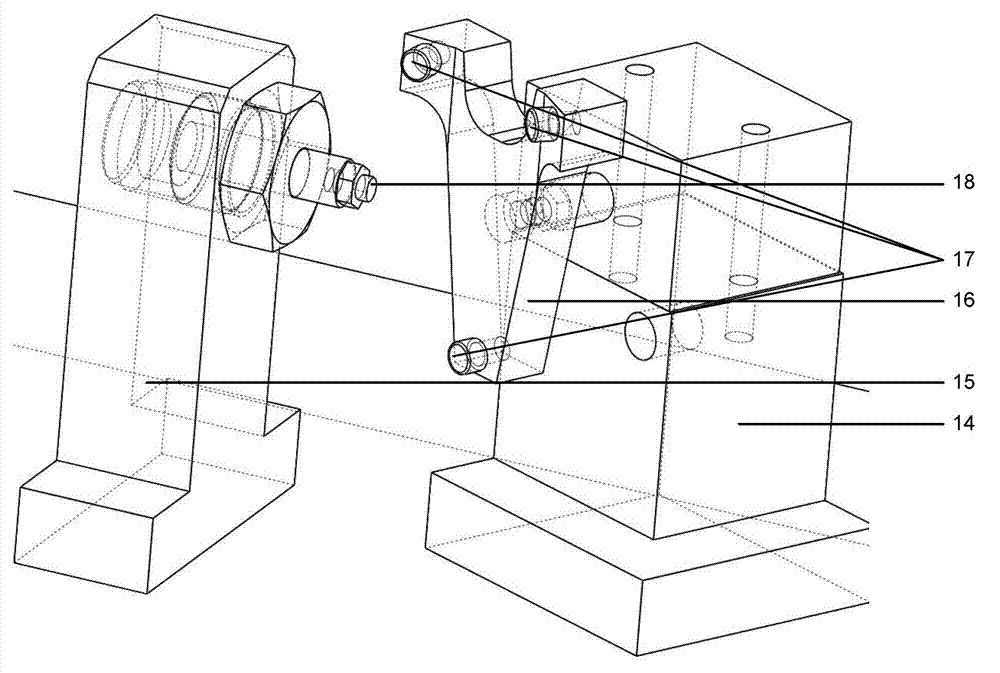

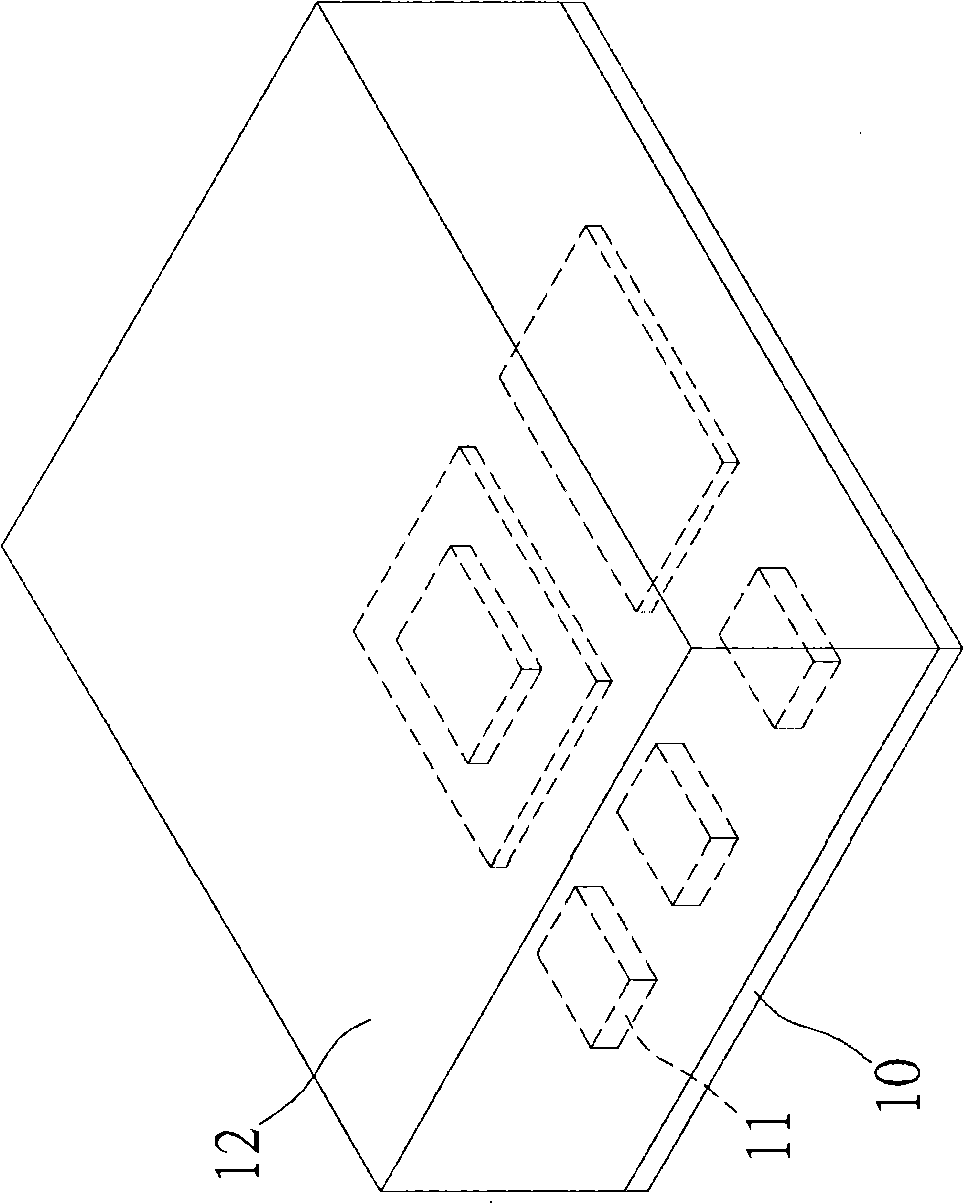

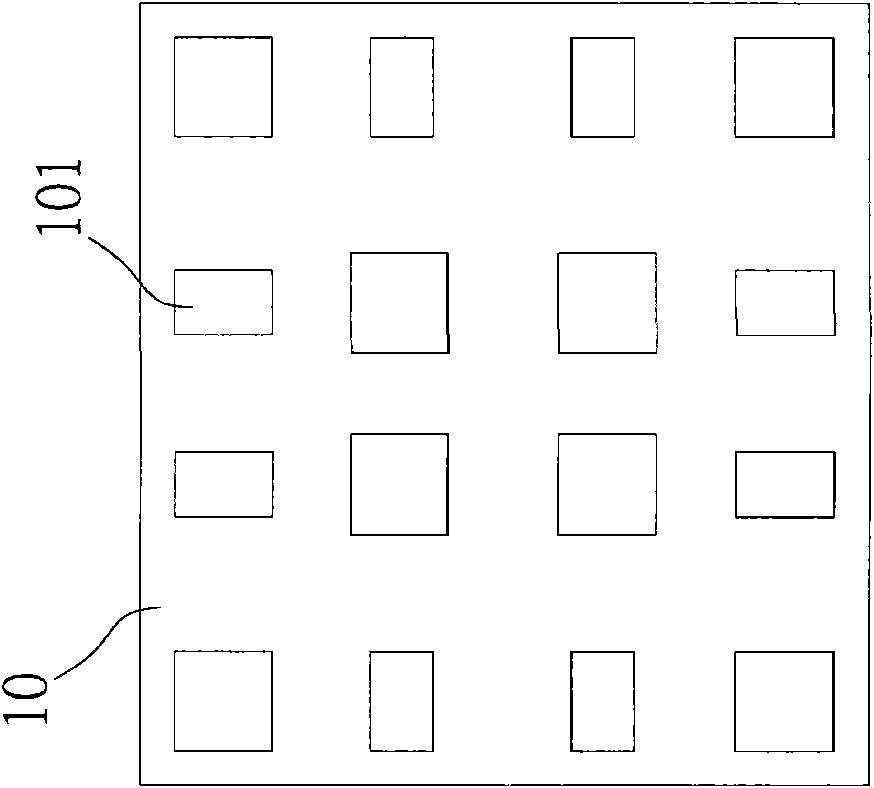

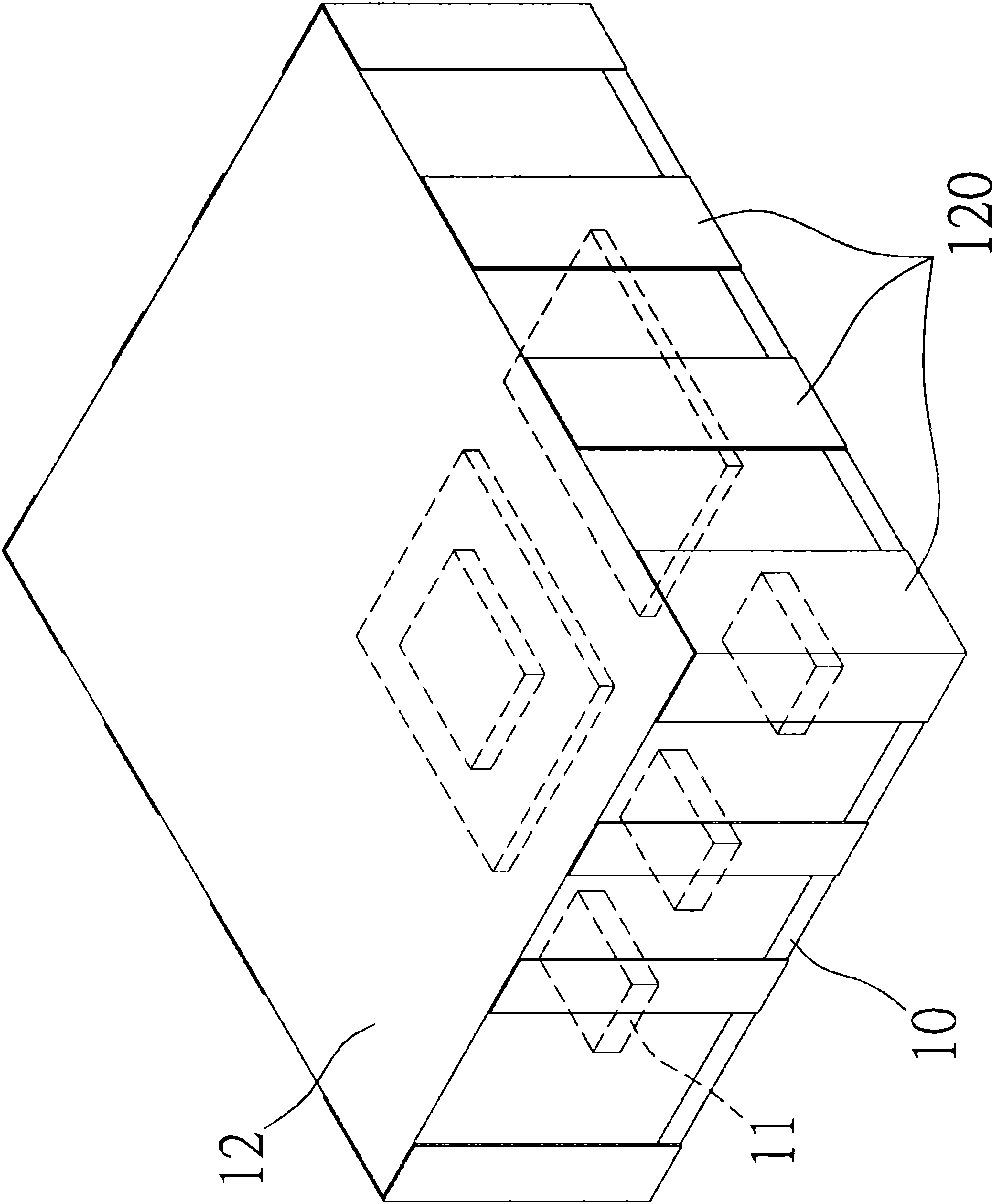

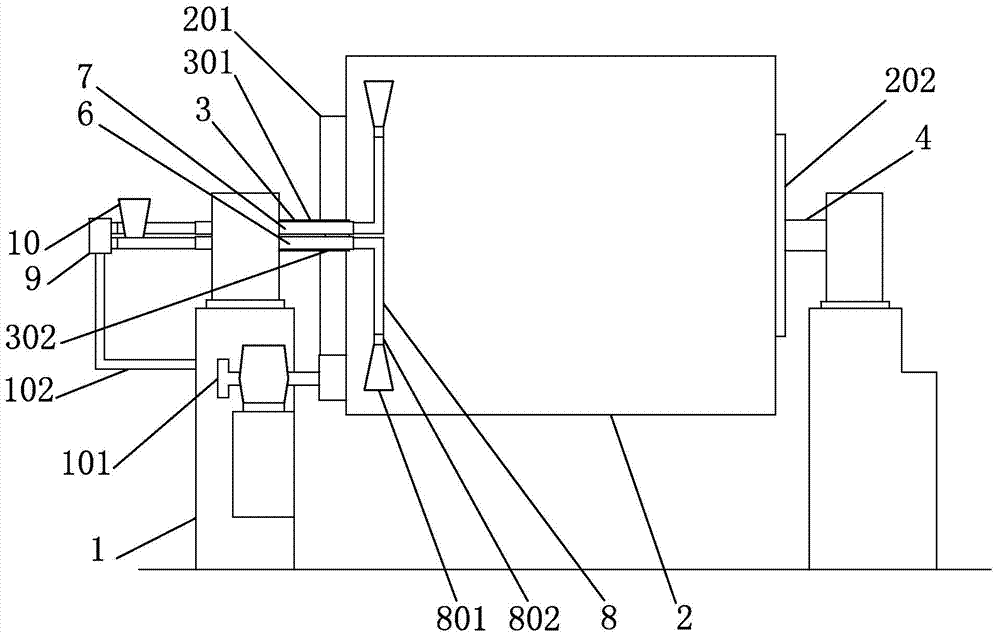

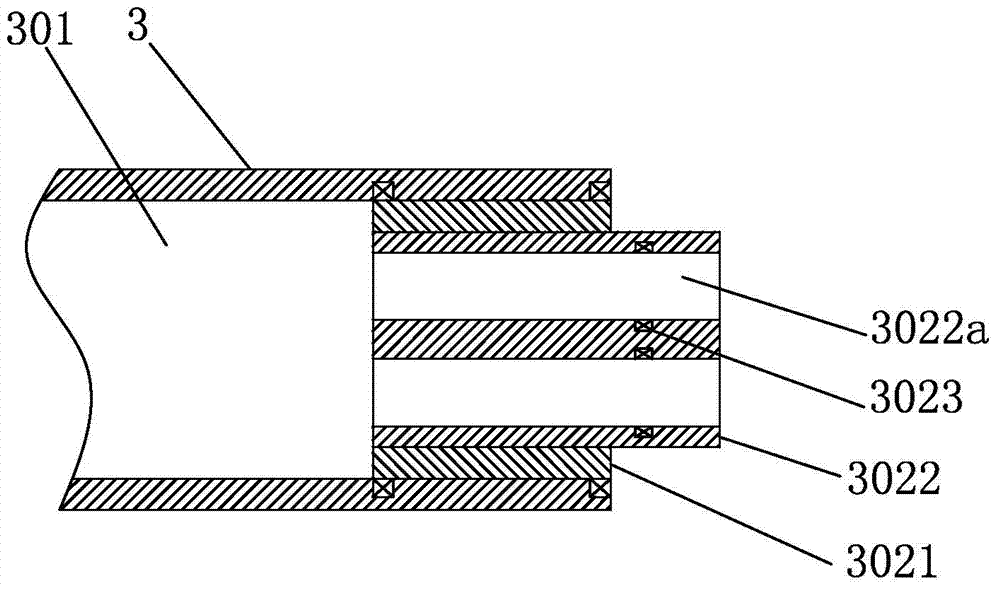

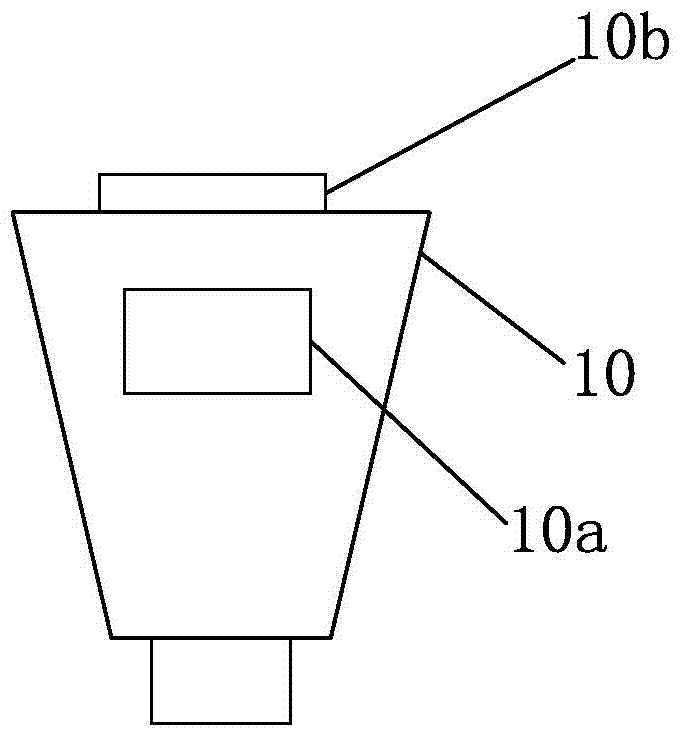

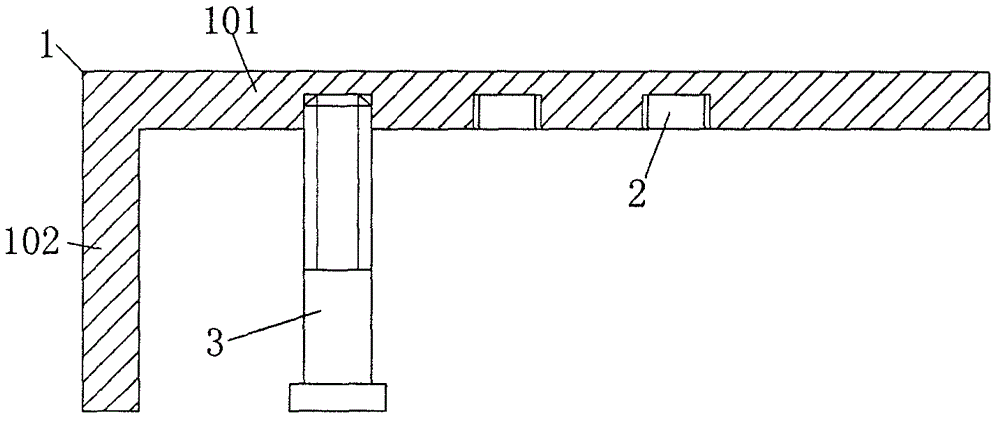

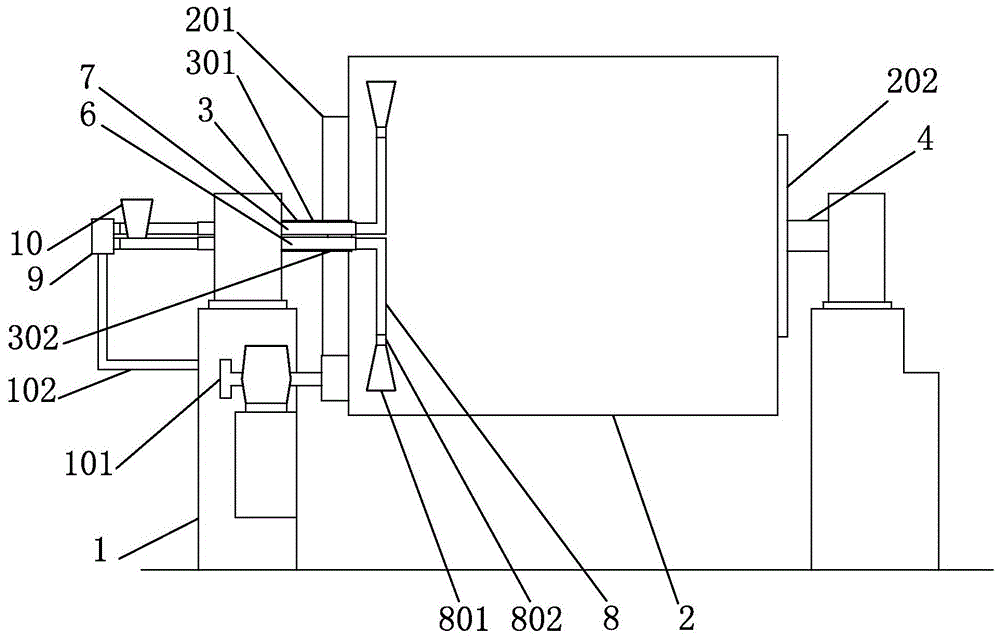

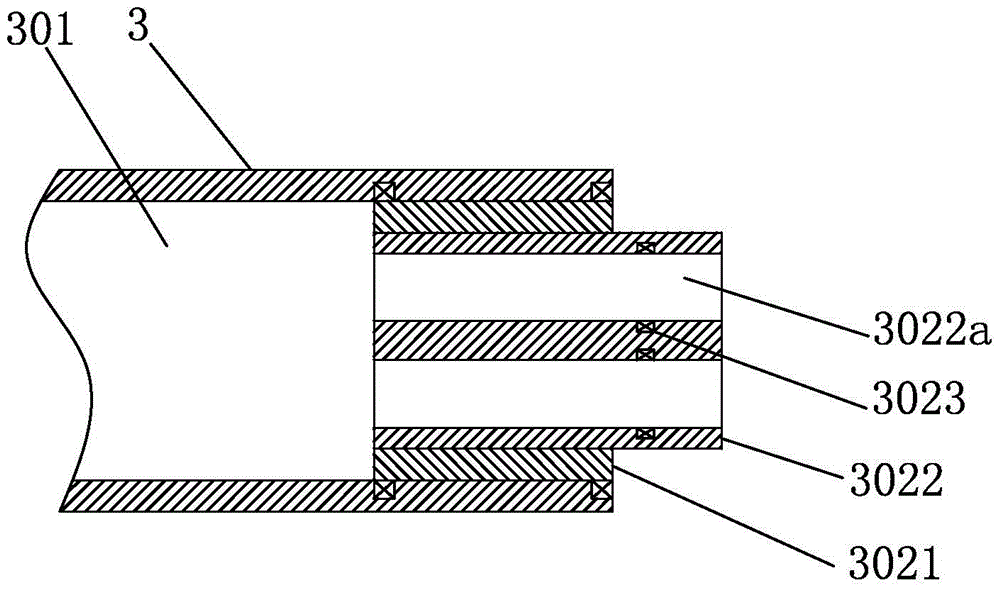

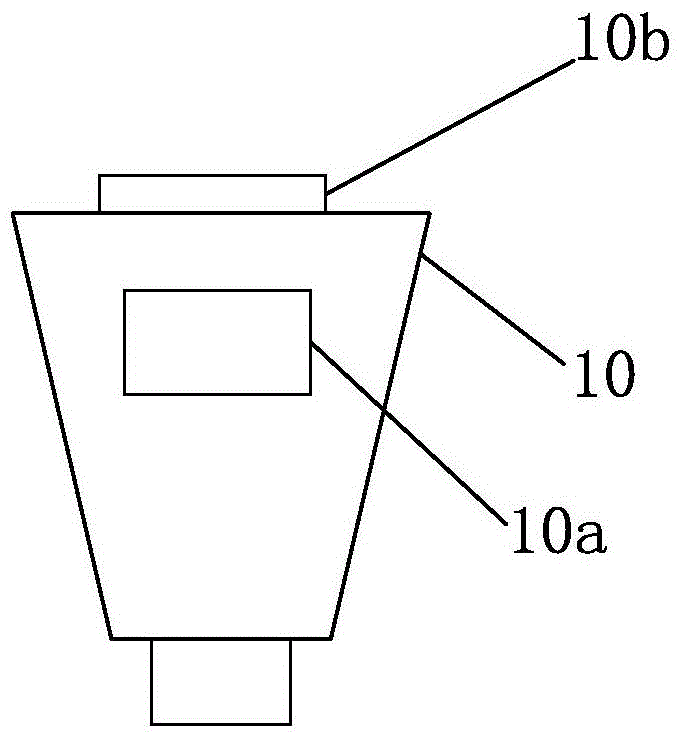

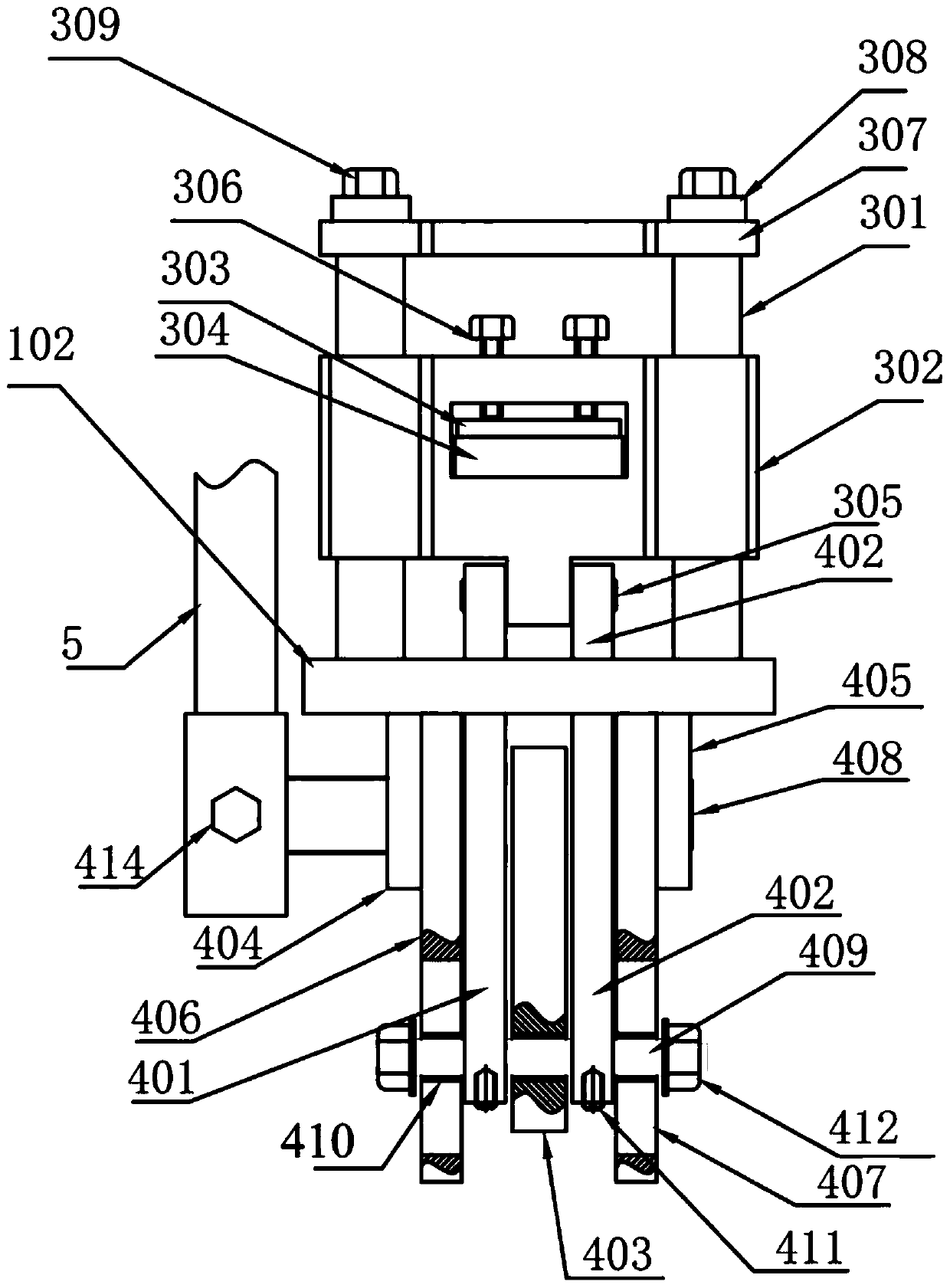

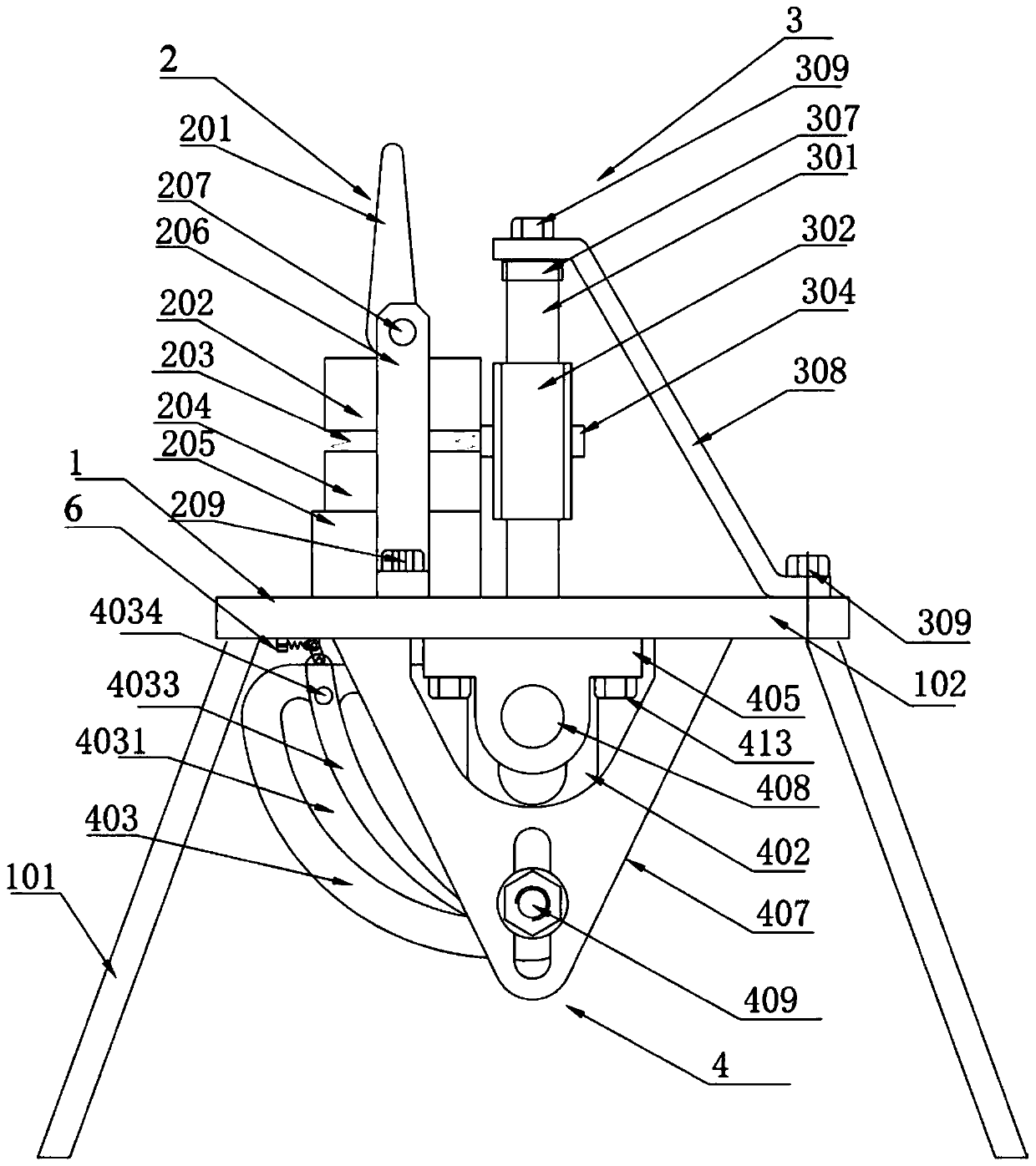

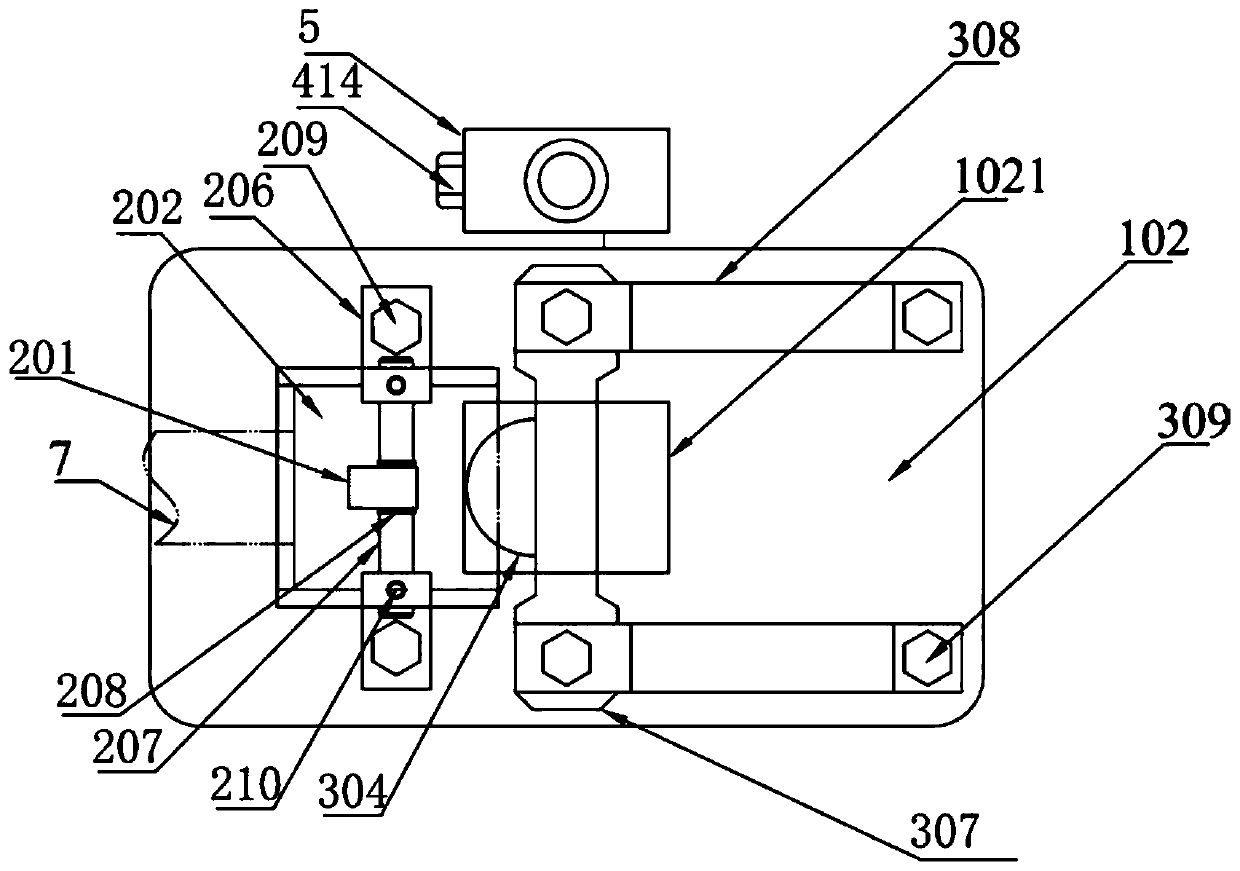

Laminated machine and electrical core laminated mechanism

ActiveCN102412419AReduce in quantityShort response timeFinal product manufactureElectrolyte accumulators manufactureEngineeringManipulator

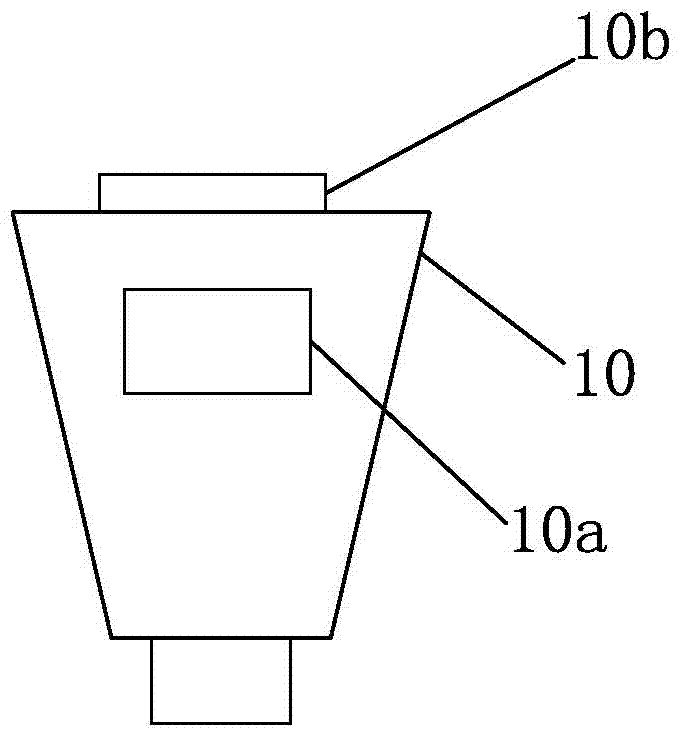

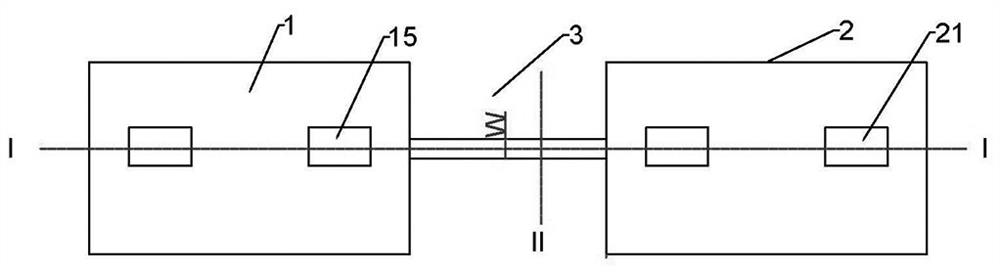

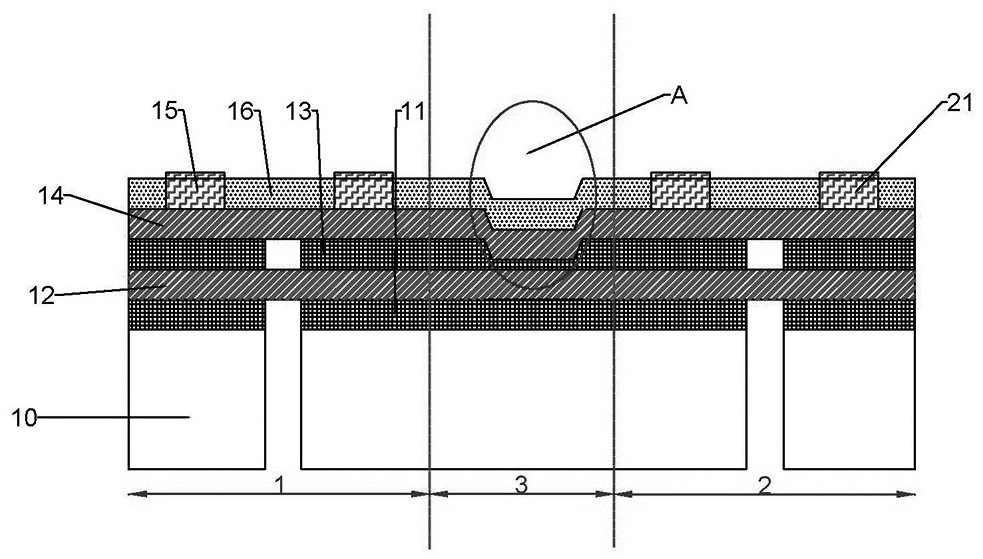

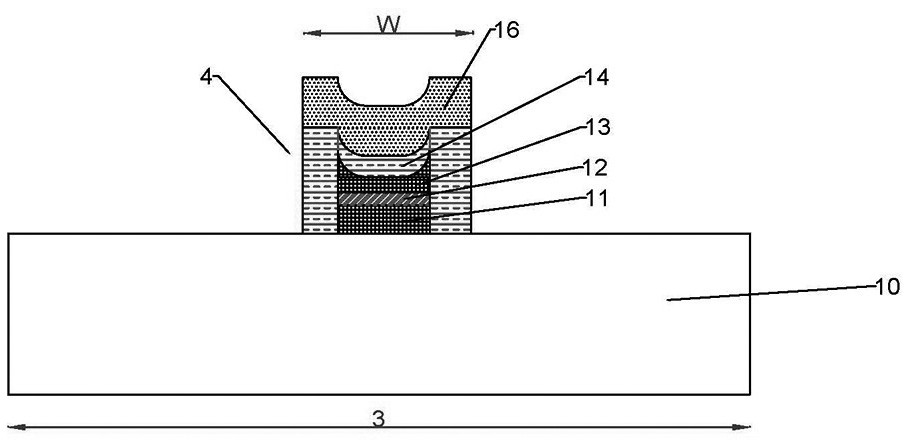

The invention discloses a laminated machine and an electrical core laminated mechanism, the laminated machine comprises a first material box, a second material box, a first positioning bench, a second positioning bench and a laminated bench possessing at least one lamination position, and also comprises a first material taking manipulator used for moving a first material sheet of the first material box to the first positioning bench, a second material taking manipulator used for moving a second material sheet of the second material box to the second positioning bench, a laminated manipulator used for moving the first material sheet of the first positioning bench, and / or the second material sheet of the second positioning bench to the laminated position, and a laminated drive component used for driving the first material taking manipulator, the second material taking manipulator and the laminated manipulator. The laminated machine employs laminated drive component with same power supply for driving the first laminated drive component, the second laminated drive component and laminated manipulator to realize the operation of material taking, moving and laminating. The lamination efficiency and technology quality can be effectively enhanced, the equipment cost can be reduced, and the technology can be simplified.

Owner:肇庆兆阳装备技术有限公司

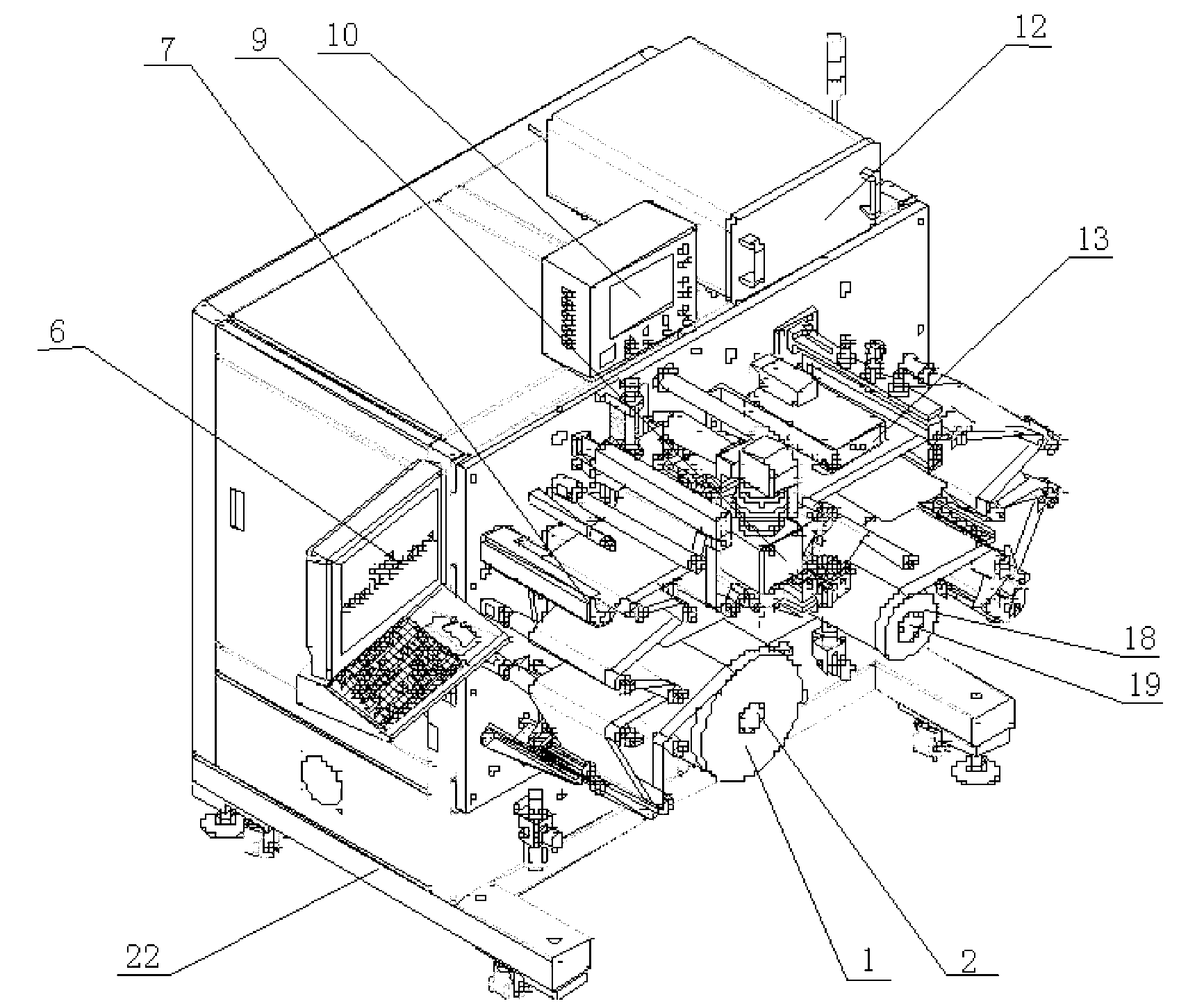

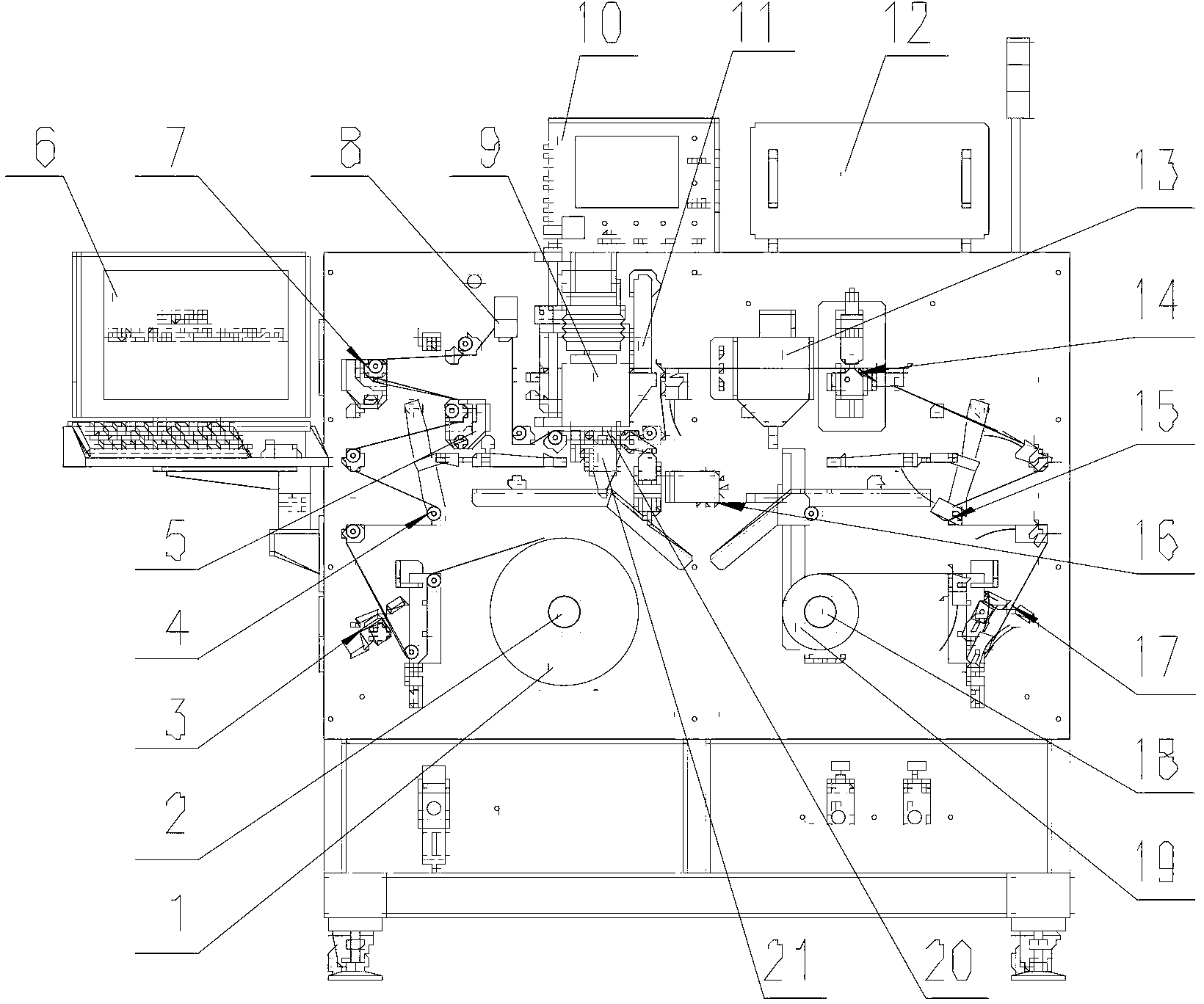

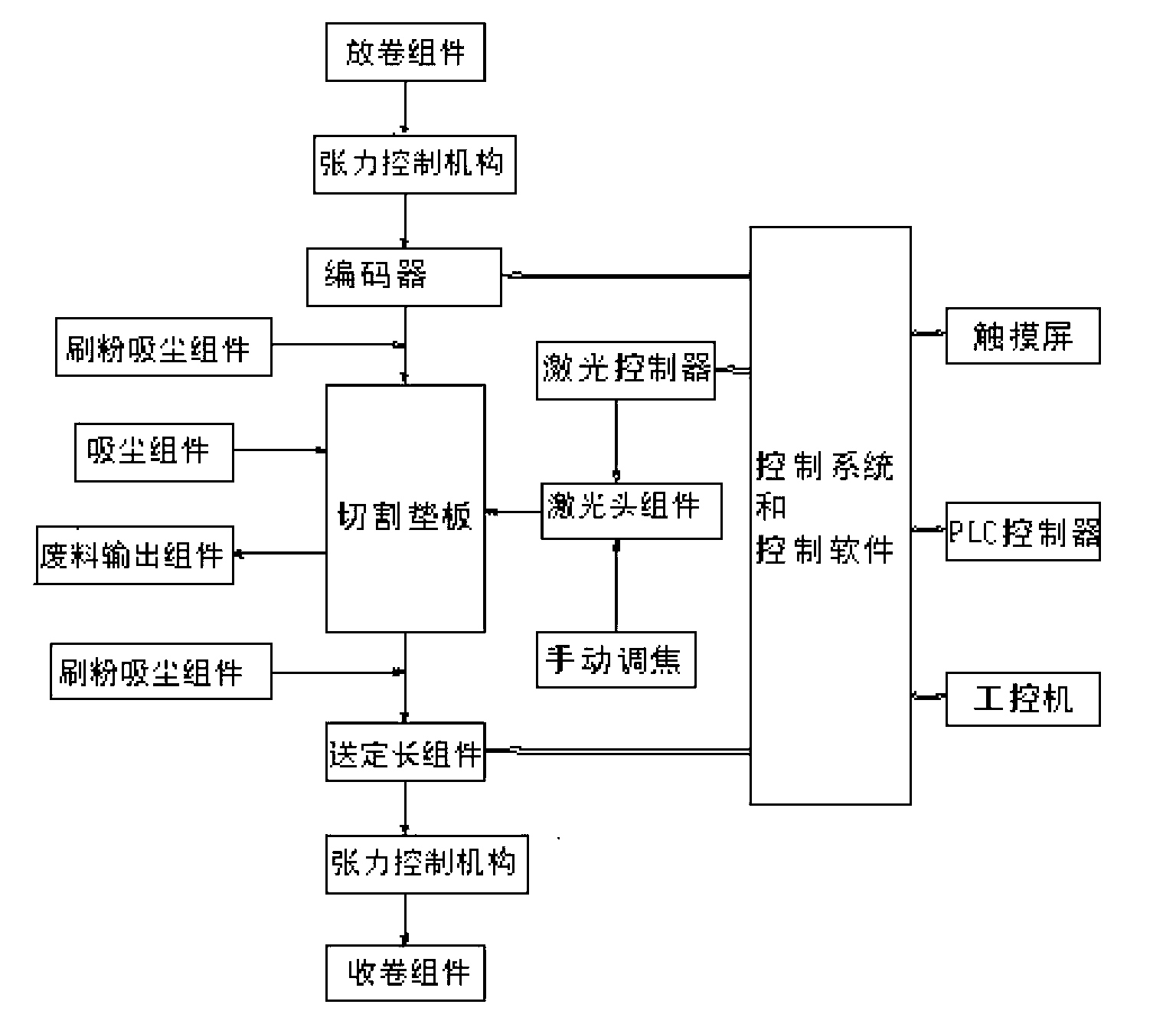

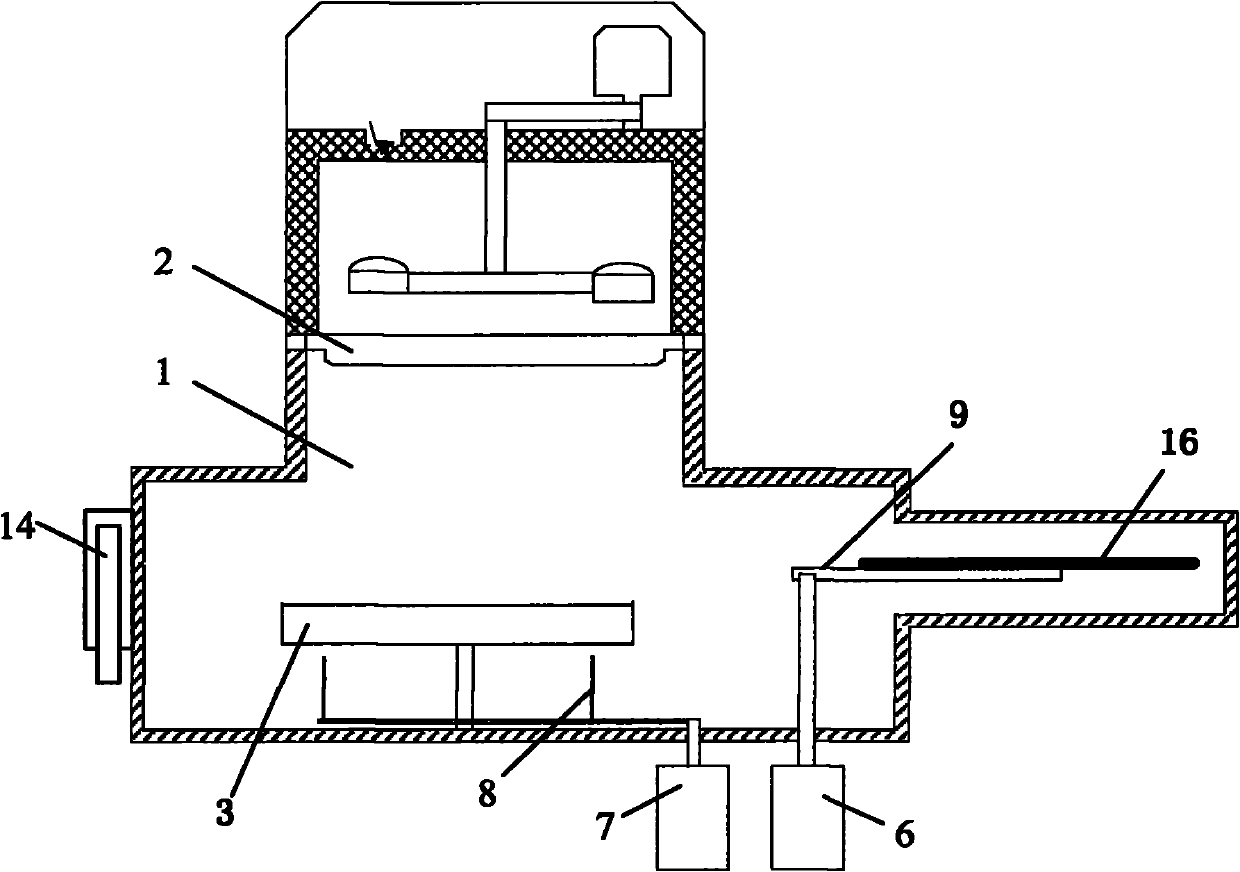

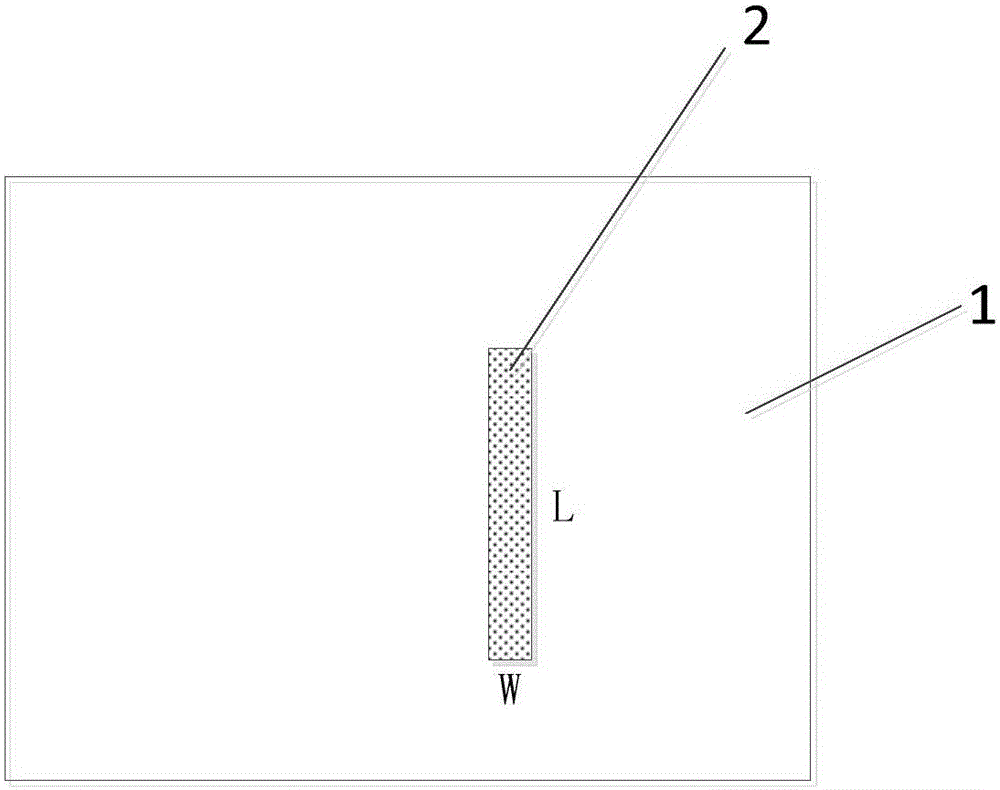

Terminal forming machine and method for pole piece of lithium battery

The invention discloses a terminal forming machine and method for a pole piece of a lithium battery. The terminal forming machine comprises an unwinding component (2), a cutting base plate (20), a laser cutting head (9), a winding component (18) and a control system, wherein the cutting base plate (20) is placed on a pole piece motion path between the unwinding component (2) and the winding component (18), the laser cutting head (9) is arranged over the cutting base plate (20), and the control system is connected with the unwinding component (2), the laser cutting head (9) and the winding component (18) through signals. The terminal forming machine and method have the advantages that the pole producing process quality is remarkably improved, the consistency of a battery cell is guaranteed, the pole producing efficiency is improved, and subsequent handling of the pole producing process is facilitated.

Owner:GEESUN AUTOMATION TECH

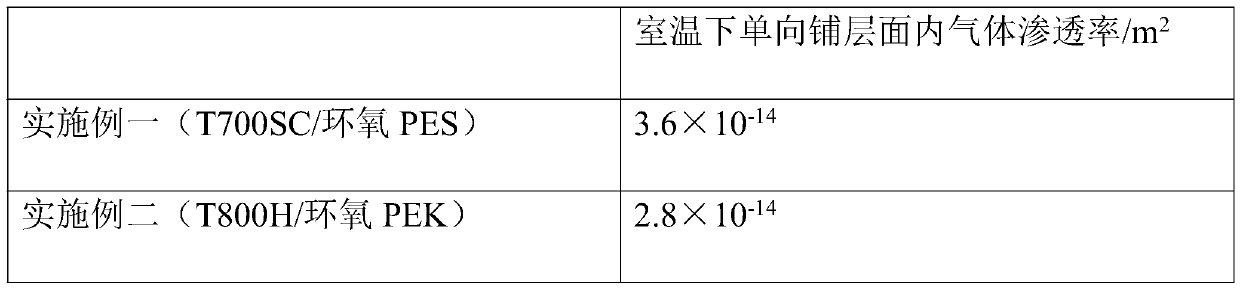

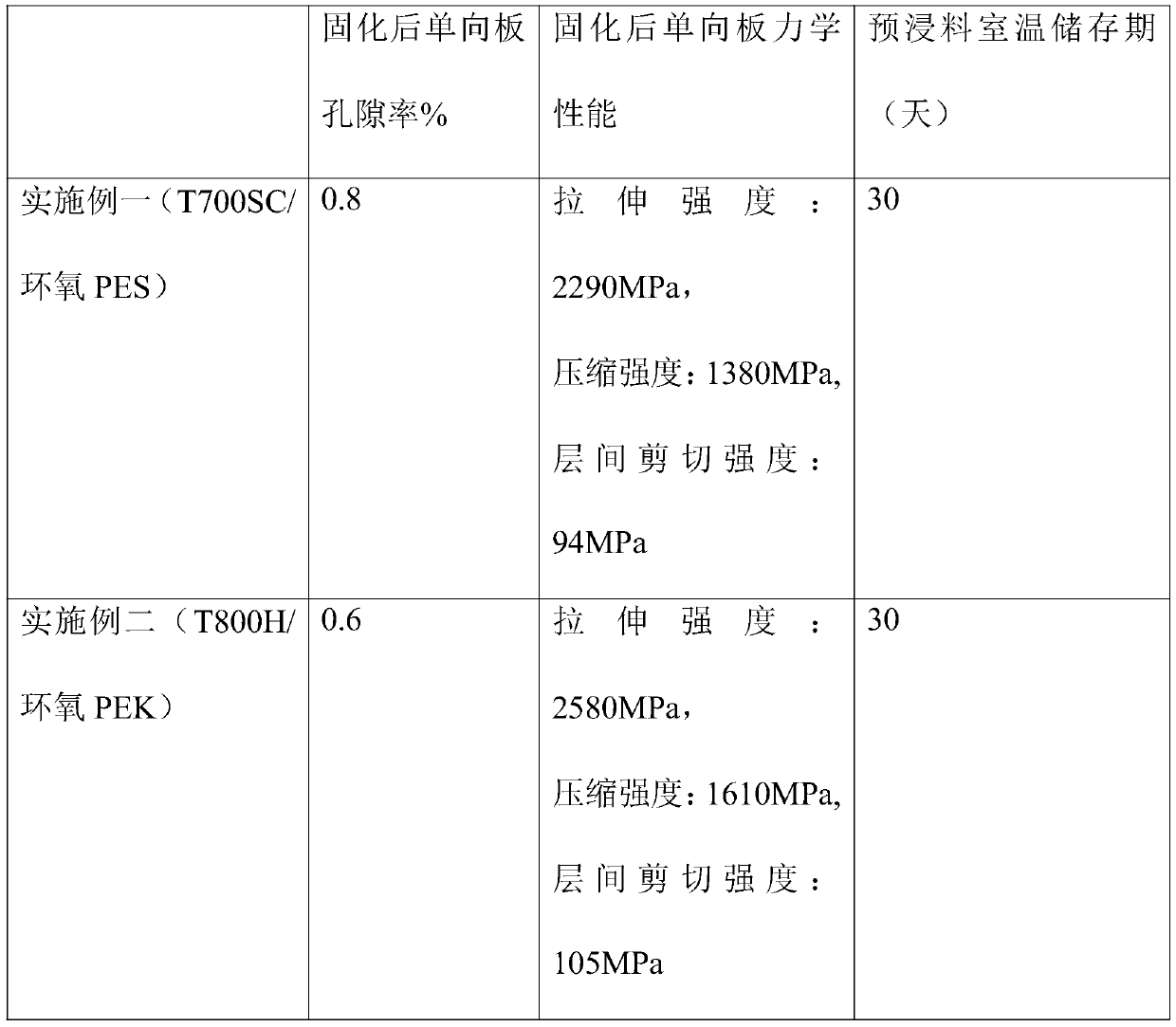

Preparation method of carbon fiber/toughened epoxy resin prepreg for vacuum bag forming process

The invention discloses a preparation method of a carbon fiber / toughened epoxy resin prepreg for a non-autoclave vacuum bag forming process. According to the method, the dissolution degree and the particle size of a curing agent and a toughening agent in epoxy resin are controlled by controlling a resin formula, the particle sizes of the curing agent and the toughening agent and process conditionsfor resin system configuration, and meanwhile, two modification effects are achieved: 1, the resin system is toughened; and 2, the requirements of a non-autoclave process on the viscosity of the resin in the prepreg and a room-temperature storage period are met. The prepared epoxy resin system is prepared into a rubber film, the carbon fiber / epoxy resin prepreg is further prepared by adopting a rubber film calendering method, and the semi-impregnated prepreg (unsaturated impregnated prepreg) is obtained by controlling the pressure and temperature during compounding of the rubber film and carbon fibers.

Owner:BEIHANG UNIV

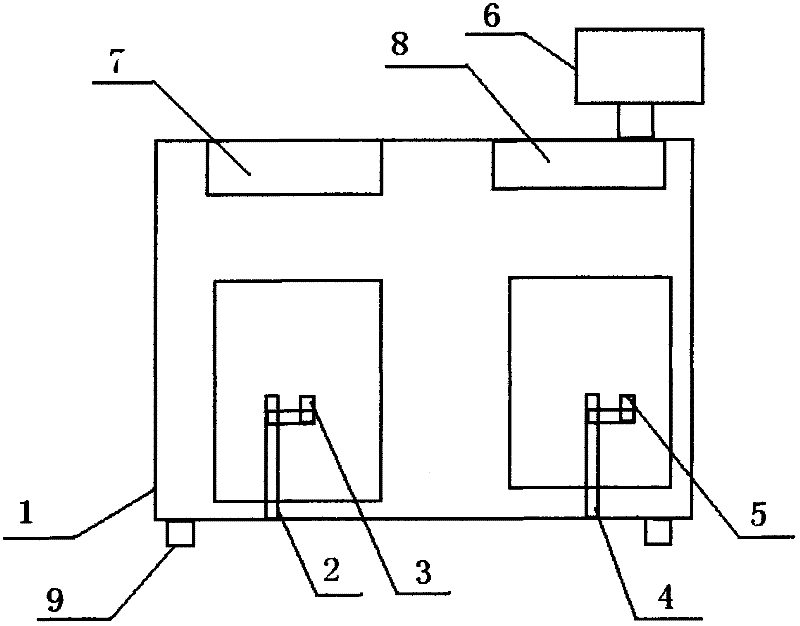

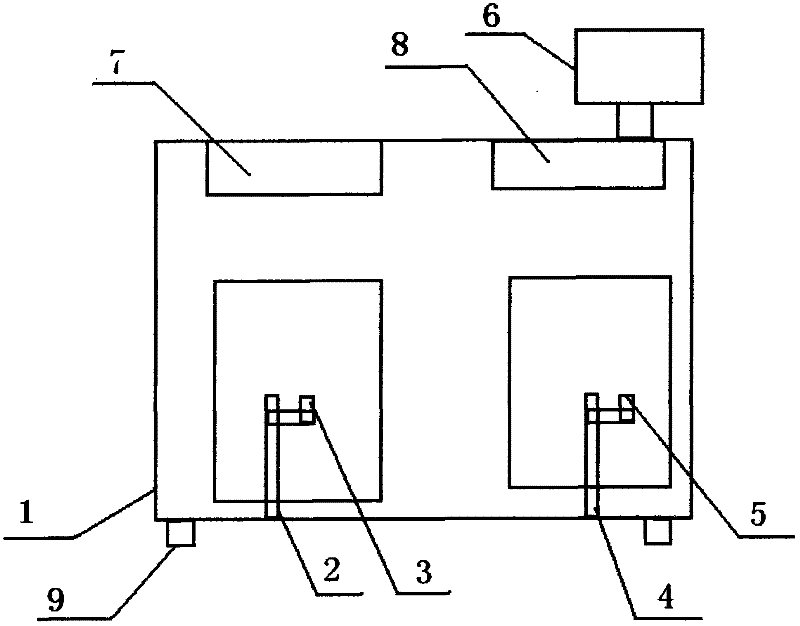

A LED display module detection device and detection method thereof

InactiveCN102288543AComprehensive monitoringImprove craftsmanshipMaterial analysis by optical meansTesting optical propertiesLED displayComputer engineering

The invention discloses an LED display module detection device and a detection method thereof. An LED display module detection device comprises a detection device body, a first lifting platform and a second lifting platform arranged on a base inside the detection device body , the first camera device is set on the first lifting platform, the second camera device is set on the second lifting platform, and an output detection display unit is placed on the operating table of the detection device body directly above the first camera device. A platform for placing a display unit to be tested is set on the operating table of the detection device body directly above the second camera device, and a display platform and a display unit detection system are also set on the detection device body.

Owner:深圳中科光华科技有限公司

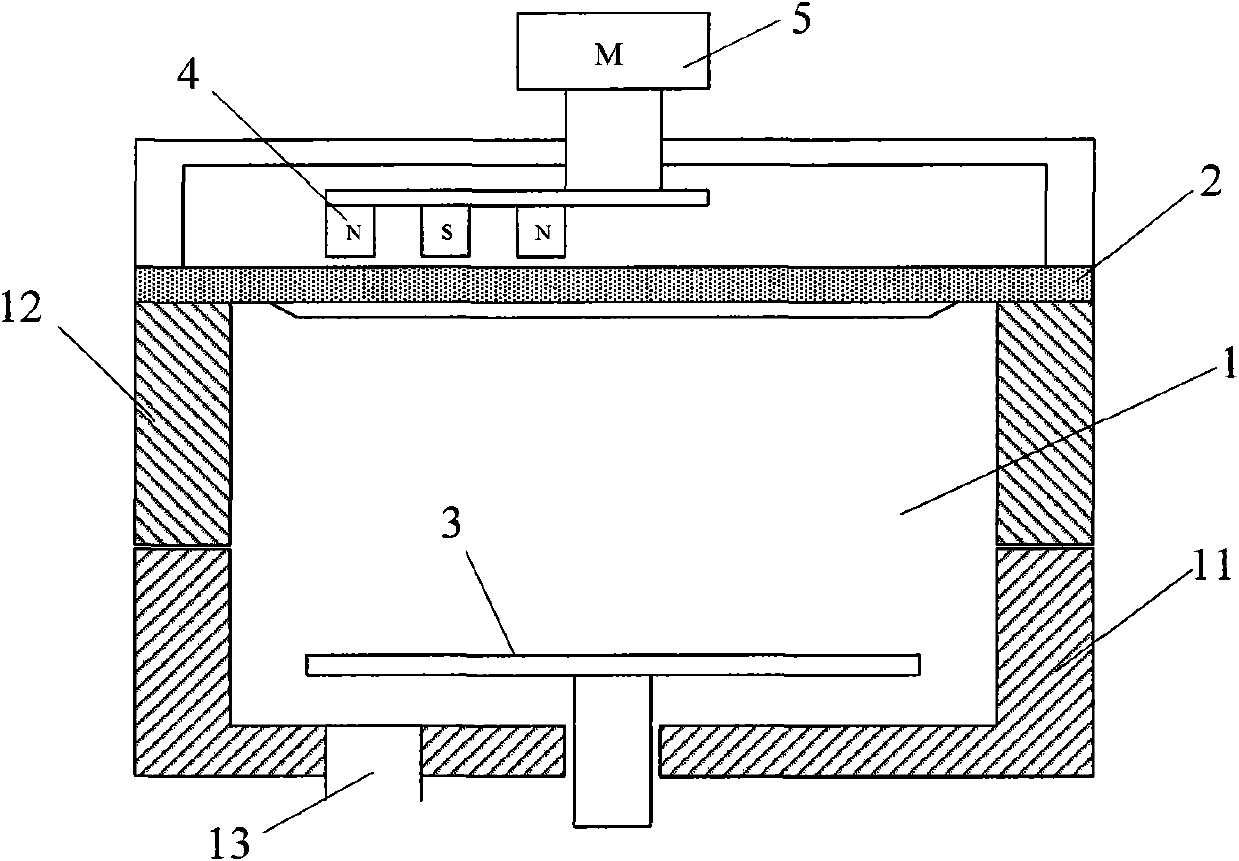

Magnetic control sputtering equipment

InactiveCN102560388AEffective coverageAvoid pollutionVacuum evaporation coatingSputtering coatingSputteringProcess quality

The invention provides magnetic control sputtering equipment which comprises at least one process cavity, a target material, a substrate bearing device and at least one shielding disc, wherein the target material and the substrate bearing device are arranged at the inner part of the process cavity, and the shielding disc is stored at the outer part of the process cavity. When the oxide on the surface of the target material is removed, the shielding disc is transferred to the inner part of the process cavity so as to protect the substrate bearing device from being polluted. According to the magnetic control sputtering equipment, the shielding disc is stored at the outer part of the process cavity, so that the inner structure and the volume of the process cavity can be effectively simplified, and the shielding disc can be shared by a plurality of process cavities, so that the equipment processing and running cost can be reduced effectively; and the influence on the process environment caused by the shielding disc and a driving device of the shielding disc can be avoided, thereby being benefit to the acquisition of the better process quality.

Owner:BEIJING NAURA MICROELECTRONICS EQUIP CO LTD

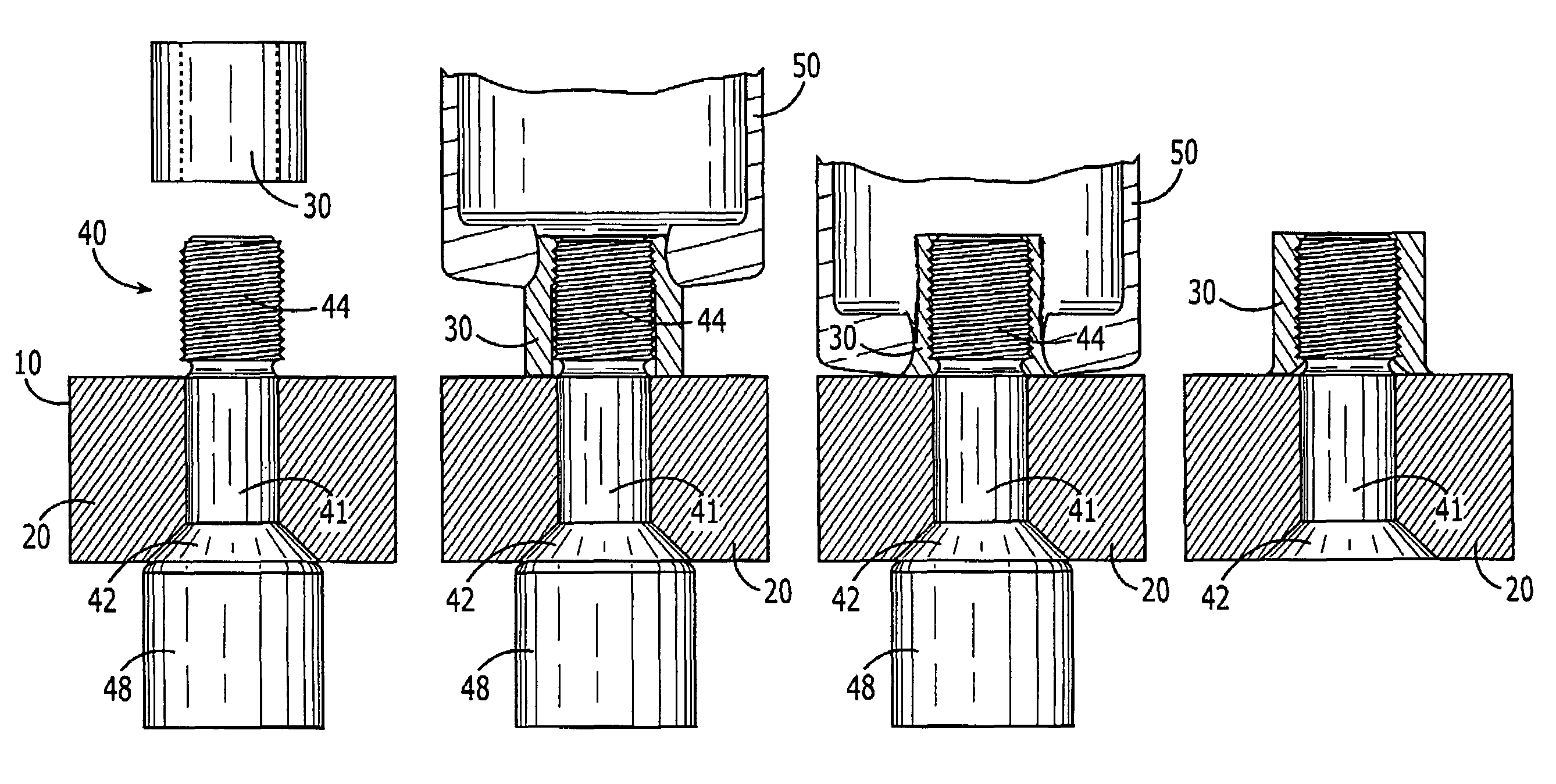

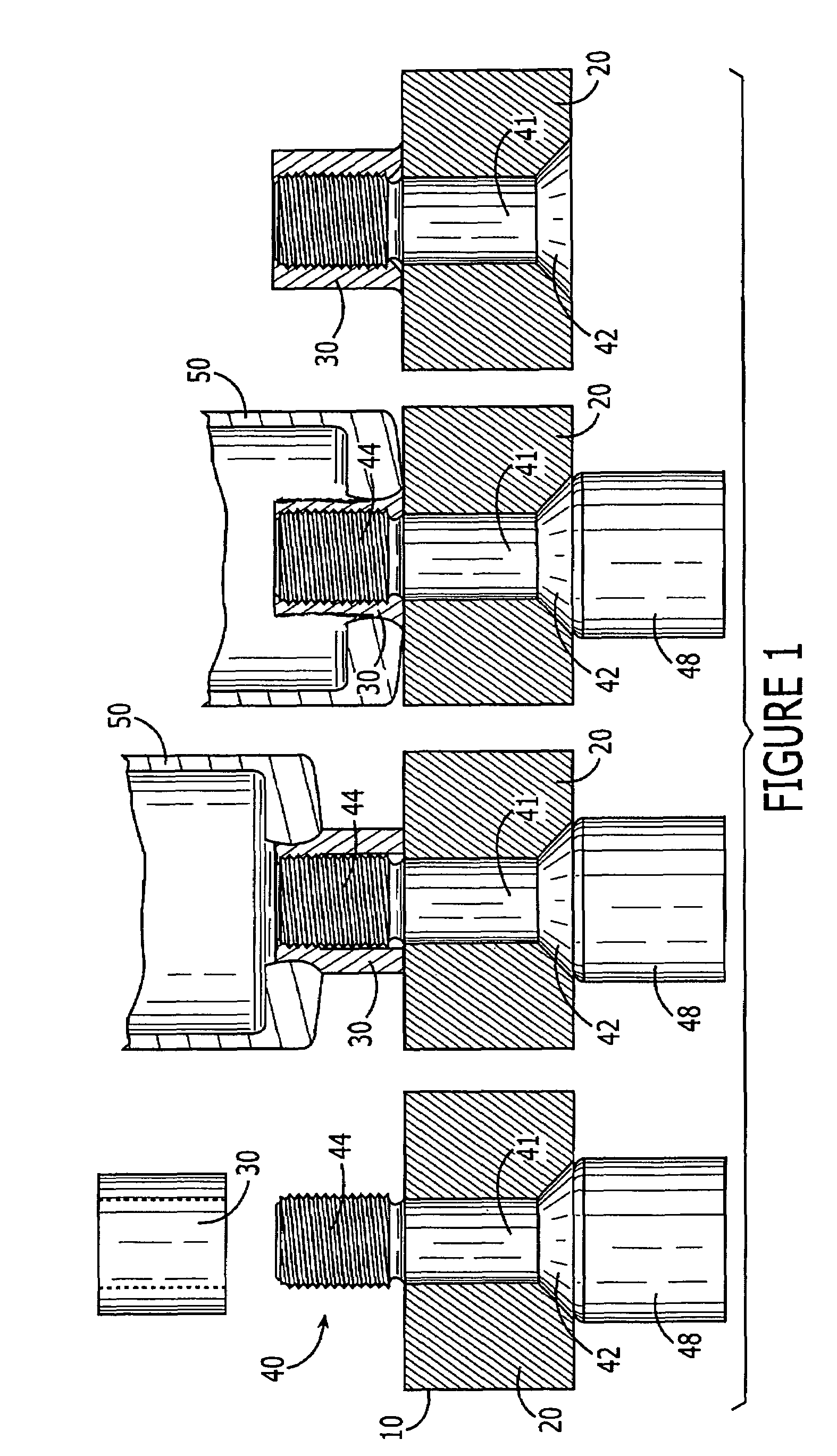

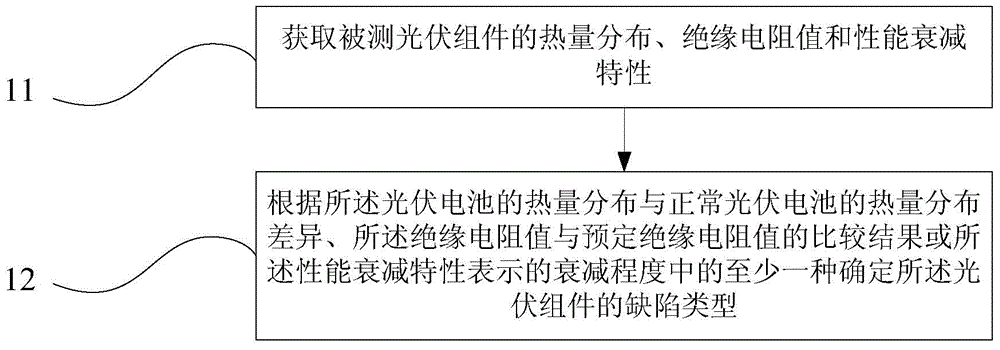

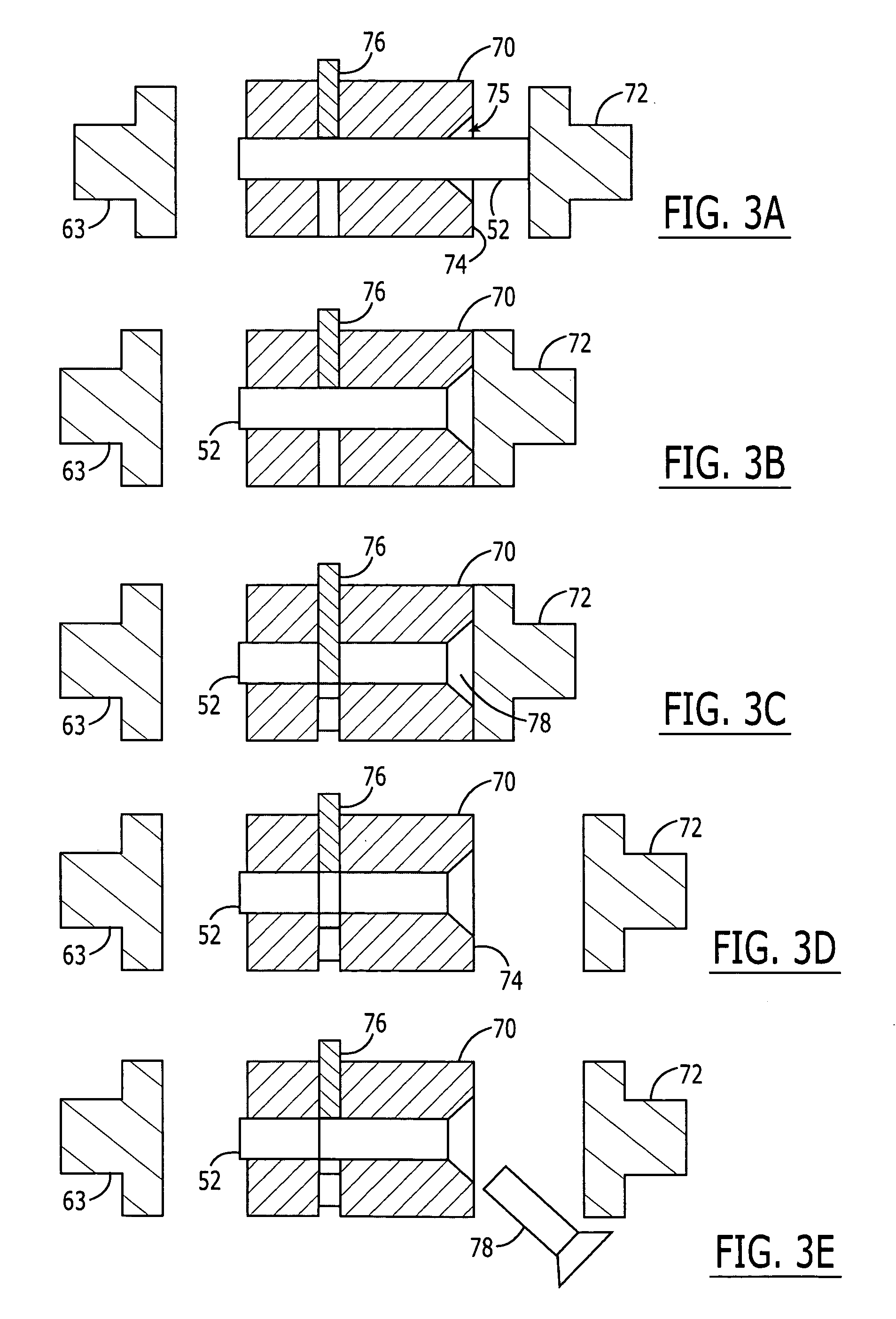

Hybrid fastening system and associated method of fastening

A hybrid fastening system comprising a female fastener component, i.e., swage collar, fabricated from a titanium or titanium-alloy material, preferably Ti-3A1-2.5V, and a mating titanium or titanium-alloy material male fastener component, i.e., threaded pin, each preferably pre-coated with an organic coating material comprising an organic, phenolic resin. The threaded pin component is installed through two or more structural components to be joined. The swage collar component is then deformed or swaged onto the threads of the pre-coated threaded pin component to achieve the same, if not improved, fastener / joint performance characteristics of existing lockbolt systems using aluminum-alloy material swage collar components.

Owner:THE BOEING CO

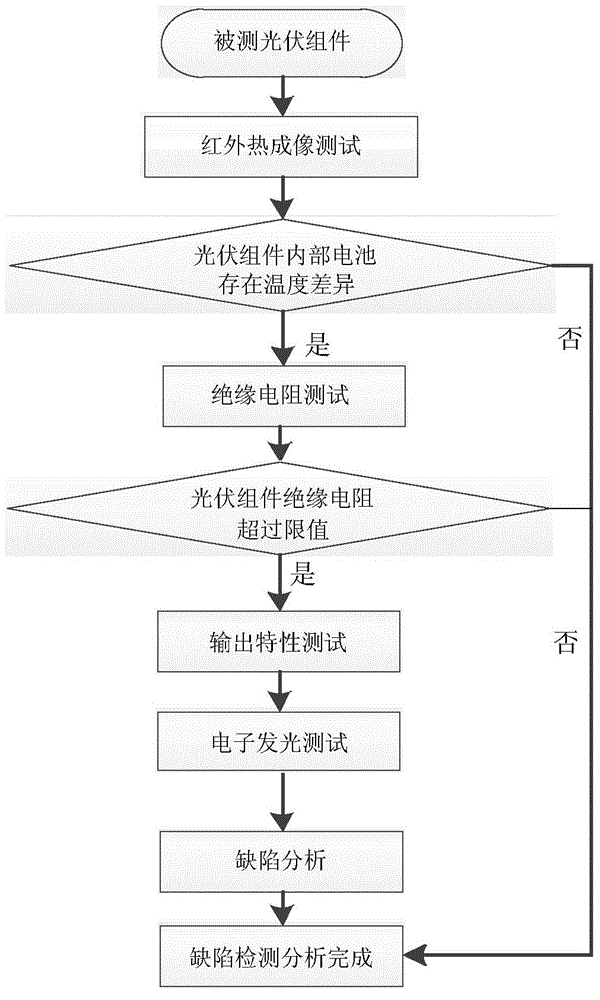

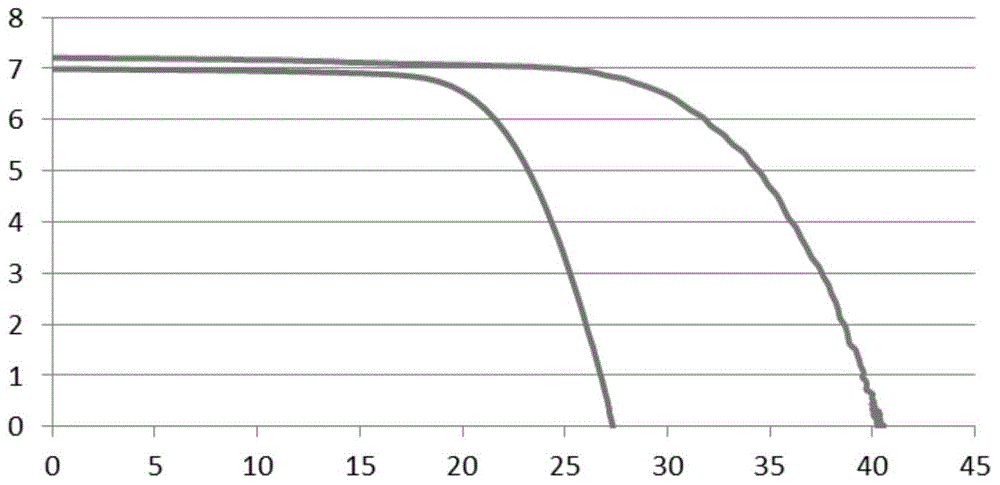

Detection method and system for silicon-based module defects of photovoltaic power station

InactiveCN105790711AStandardize the construction and installation processImprove production process and quality controlPhotovoltaic monitoringPhotovoltaic energy generationInsulation resistanceHeat distribution

The invention provides a detection method and system for silicon-based module defects of a photovoltaic power station, and belongs to the technical field of photovoltaic power station detection. The detection method comprises the steps of obtaining heat distribution, an insulation resistance value and a performance attenuation characteristic of a tested photovoltaic module; and determining the defect type of the photovoltaic module according to any least one kind of the difference between the heat distribution of the photovoltaic cell and the heat distribution of a normal photovoltaic cell, or the comparison result between the insulation resistance value and a predetermined insulation resistance value, or the attenuation degree represented by the performance attenuation characteristic. According to the detection method provided by the invention, a set of defective photovoltaic module detection method applicable to onsite application is established; meanwhile, the internal defects of a track module can be effectively found in time by the detection method, so that efficient maintenance of the photovoltaic power station can be carried out in a targeted mode; the construction and installation process of the photovoltaic power station can be standardized; the production process and the quality control of manufacturers can be improved; and the long-term stable operation of the photovoltaic power station can be ensured.

Owner:STATE GRID CORP OF CHINA +1

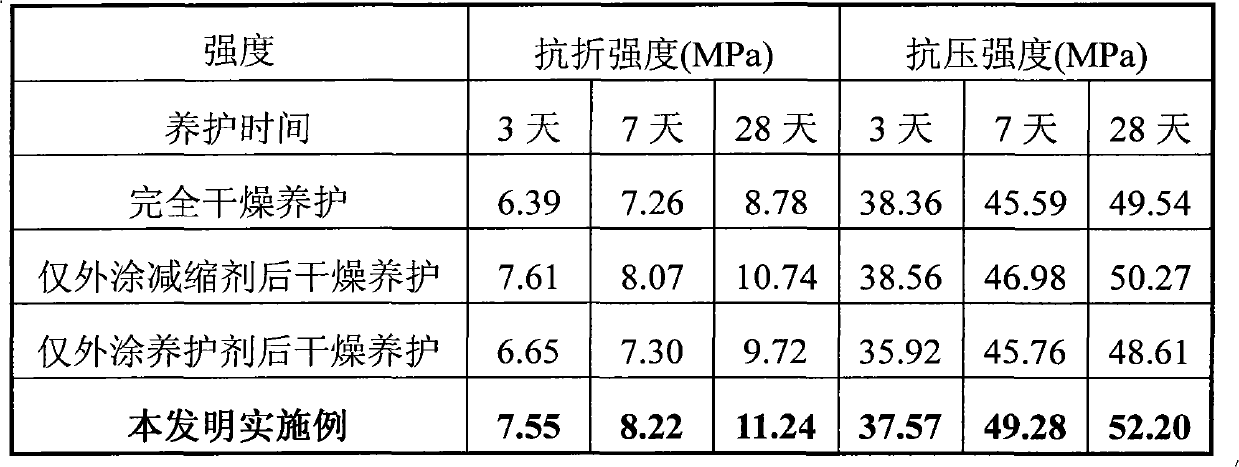

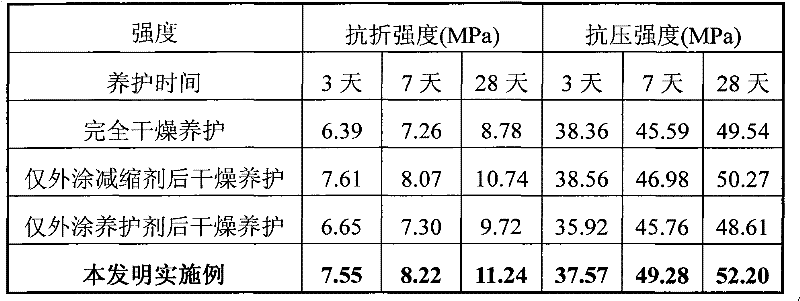

Cement concrete curing method

InactiveCN101767370ASmall shrinkageImprove mechanical propertiesCeramic shaping apparatusReducing agentMaterials science

The invention discloses a cement concrete curing method which is characterized in that: concrete shrinkage reducing solution is directly sprayed or coated on the concrete surface during curing process; when no liquid shrinkage reducing solution remains on the concrete surface, concrete curing agent is sprayed on the concrete surface. In the method, the shrinkage reducing solution is firstly sprayed, and then the concrete curing agent is sprayed, therefore the efficacy loss situation caused by mutual interference of the shrinkage reducing agent and curing agent is avoided, the volatilization of shrinkage reducing agent and the water dispersion of concrete interior are prevented after the curing agent is filmed, and the concrete shrinkage and crack prevention effects are further reinforced; compared with prior art, the cement concrete curing method effectively prevents the concrete shrinkage and crack, reinforces the cement hydration effect and improves the curing effect.

Owner:CHONGQING UNIV

Chemical palladium plating method for back through hole metallization seed layer of semiconductor

InactiveCN105551956ASimple processImprove workmanshipSemiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingSputteringSemiconductor materials

The invention discloses a chemical palladium plating method for a back through hole metallization seed layer of a semiconductor. The chemical palladium plating method comprises the steps: palladium ions and a reducing agent have a strong oxidation-reduction reaction with a semiconductor material and a metal surface in the highly acidic environment, and then a layer of palladium seed crystals is replaced on the semiconductor material and the metal surface; in a palladium chemical plating solution, palladium metal continuously precipitate on the palladium seed crystals by utilizing self-excitation of the plating solution, thereby obtaining a back through hole metallization seed layer formed by a palladium metal layer with a certain thickness on the semiconductor material and the metal surface. Compared with the traditional metal seed layer sputtering technique, the chemical palladium plating method provided by the invention has the advantages of simple process, great technical quality, high yield, wide application range, low costs and the like, and also has excellent market application prospect.

Owner:NO 55 INST CHINA ELECTRONIC SCI & TECHNOLOGYGROUP CO LTD

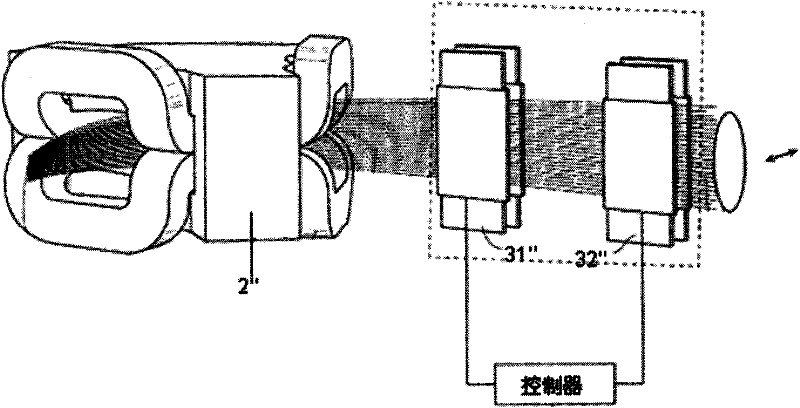

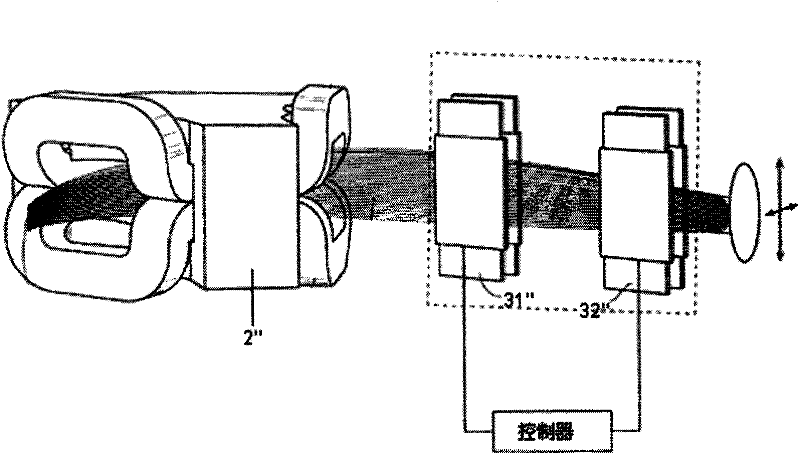

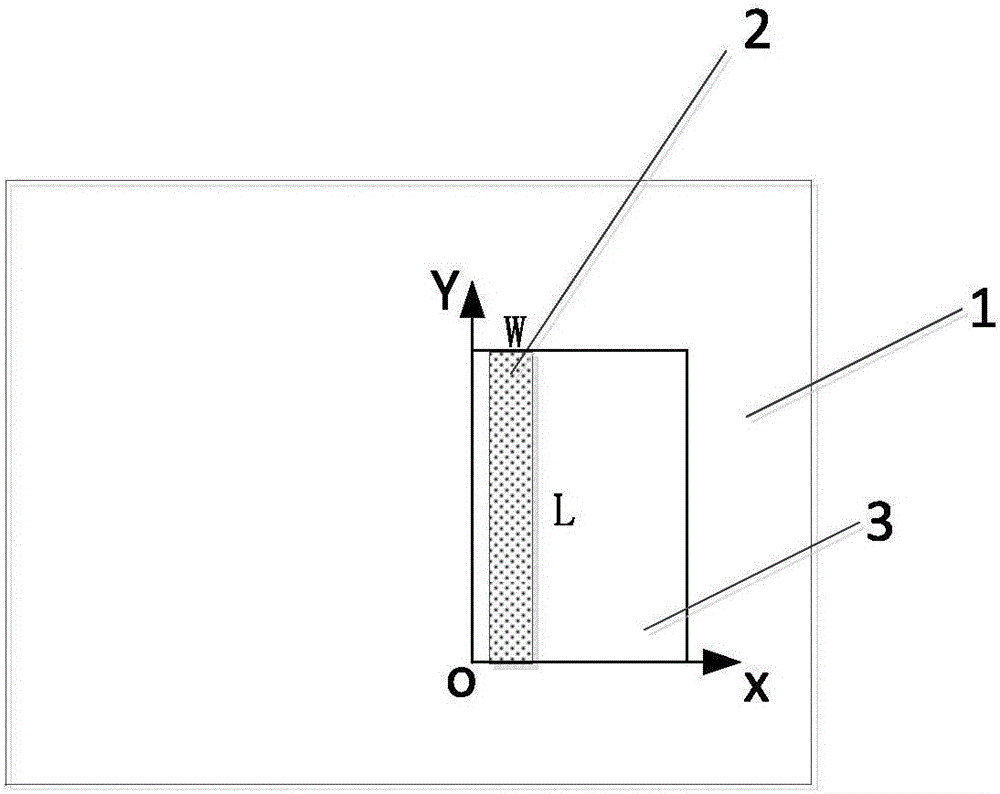

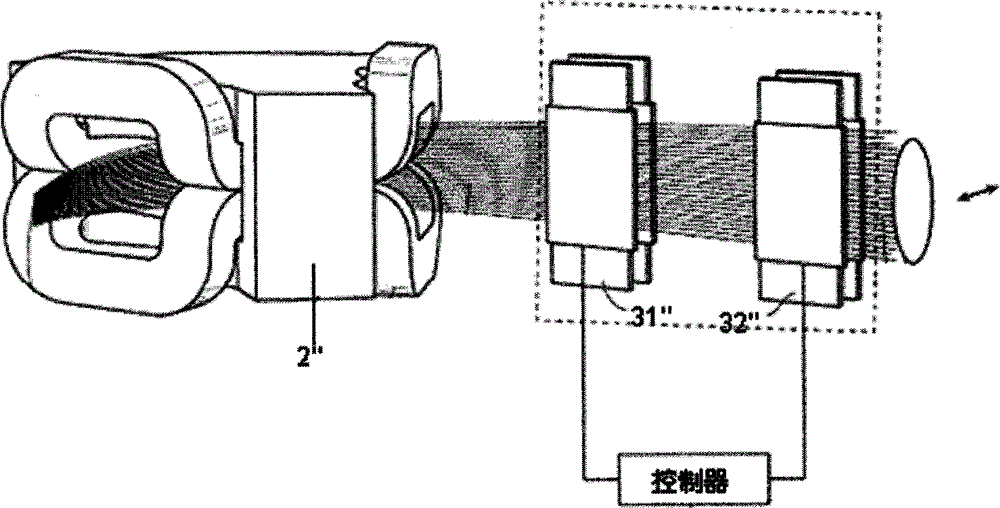

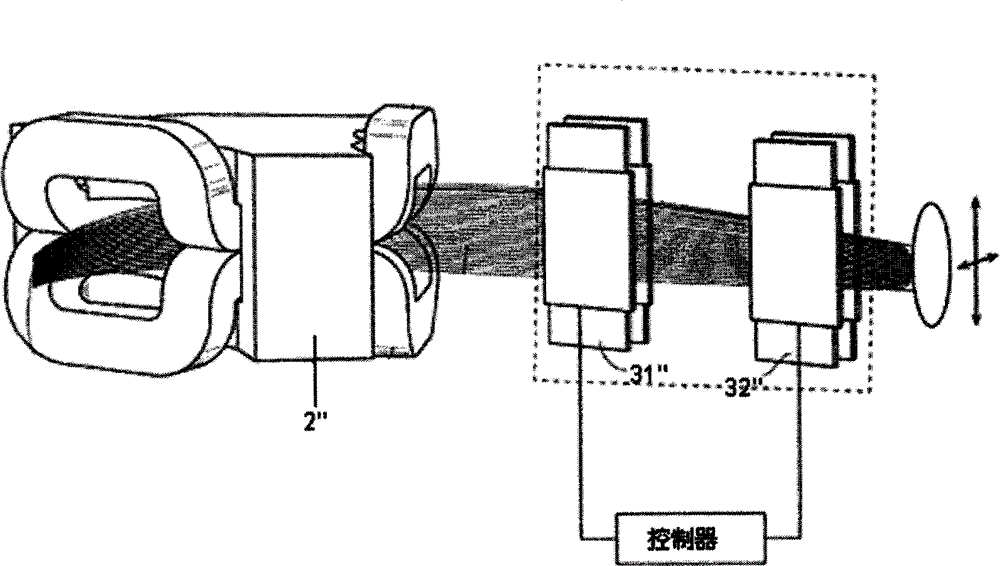

Ion implantation system and method

ActiveCN102194637AImprove uniformityAccurate angle adjustmentElectric discharge tubesIon beamUltimate tensile strength

The invention discloses an ion implantation system. The system comprises an ion source and an extractor, wherein a mass analyzing magnet, a correcting magnet and a workpiece scanning device are arranged on the transmission path of the ion beams in sequence. The system also comprises a scanning magnet arranged on the upper stream of the correcting magnet and a beam current measuring device arranged in the implantation position, wherein the scanning magnet is used for scanning the passing ion beams so as to ensure distribution of the ion beams which are arranged in the implantation position and in the preset energy range in the ion beam scanning direction to cover the workpiece; and the beam current measuring device is used for measuring the intensity and angle distribution of the beam current in the scanning direction of the ion beams. The invention also discloses an ion implantation method realized by the ion implantation system. The system and the method have the following positive effects: accurate control of the implantation angle uniformity and implantation intensity uniformity of the ion beams can be realized; the production cost is lowered; and the process flows are simplified.

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

Wear-resistant alloy material and plasma surfacing welding process of shield tunneling machine wear-resistant cutter ring

InactiveCN110421242AImprove wear resistanceExtended service lifePlasma welding apparatusAlloyShield tunneling

The invention belongs to the technical field of shield cutters, and particularly relates to a wear-resistant alloy material and a plasma surfacing welding process of a shield tunneling machine wear-resistant cutter ring. The problems of poor wear resistance, low production efficiency and poor quality stability of a shield tunneling machine cutter ring in the prior art are solved. According to thetechnical scheme, the wear-resistant alloy material comprises NiCrBSi alloy and spherical cast tungsten carbide, wherein the mass percentage of the NiCrBSi alloy is 35%-45%, the mass percentage of thespherical cast tungsten carbide is 55%-65%, the plasma surfacing welding process comprises a. cleaning treatment, b. preheating treatment, c. adjusting of surfacing welding process parameters of a welding machine, d. positioning of a welding gun, e. surfacing starting, and f. heat preservation and cooling. The wear resistance of the shield tunneling machine cutter ring is improved, the service life of the cutter ring is prolonged, the consumption of the cutter ring and the workload of equipment maintenance are reduced, and the unit excavation cost is reduced. The material is suitable for manufacturing the shield tunneling machine wear-resistant cutter ring.

Owner:中德云岭(成都)科技有限公司

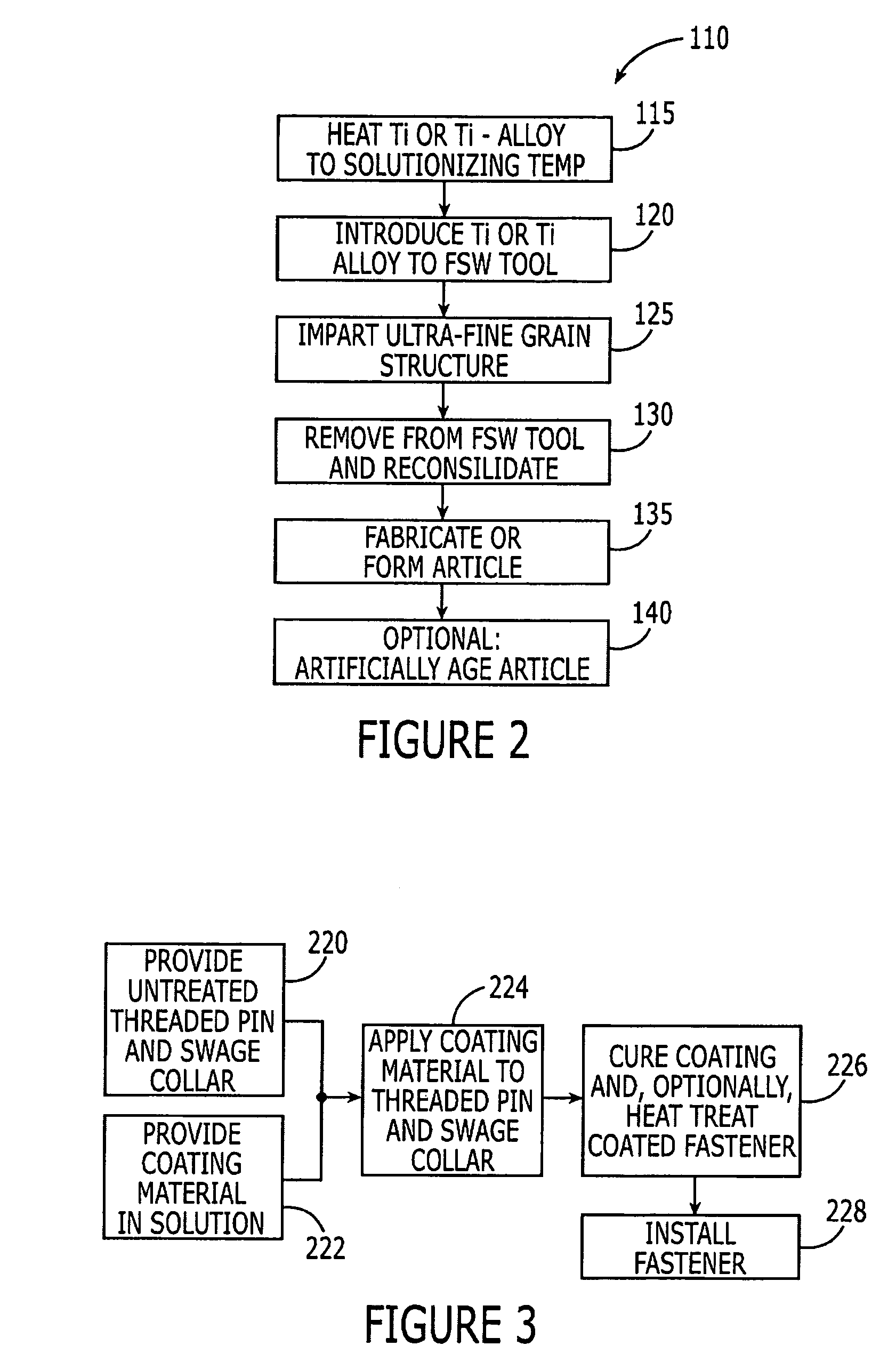

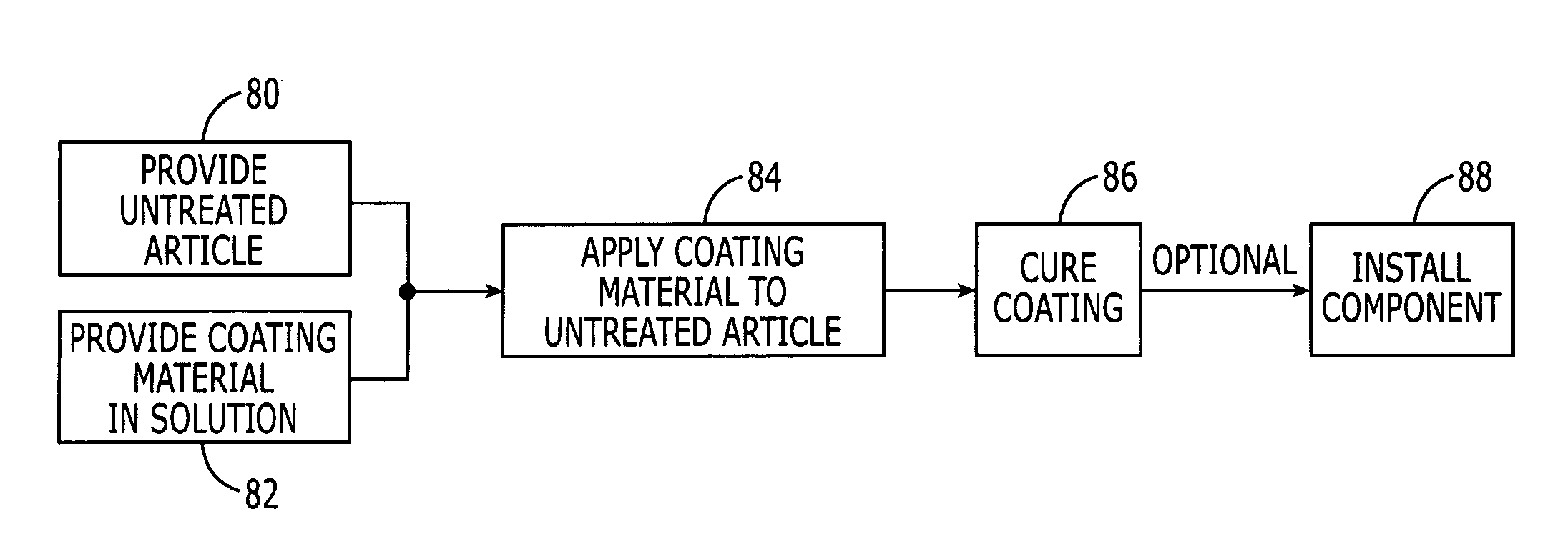

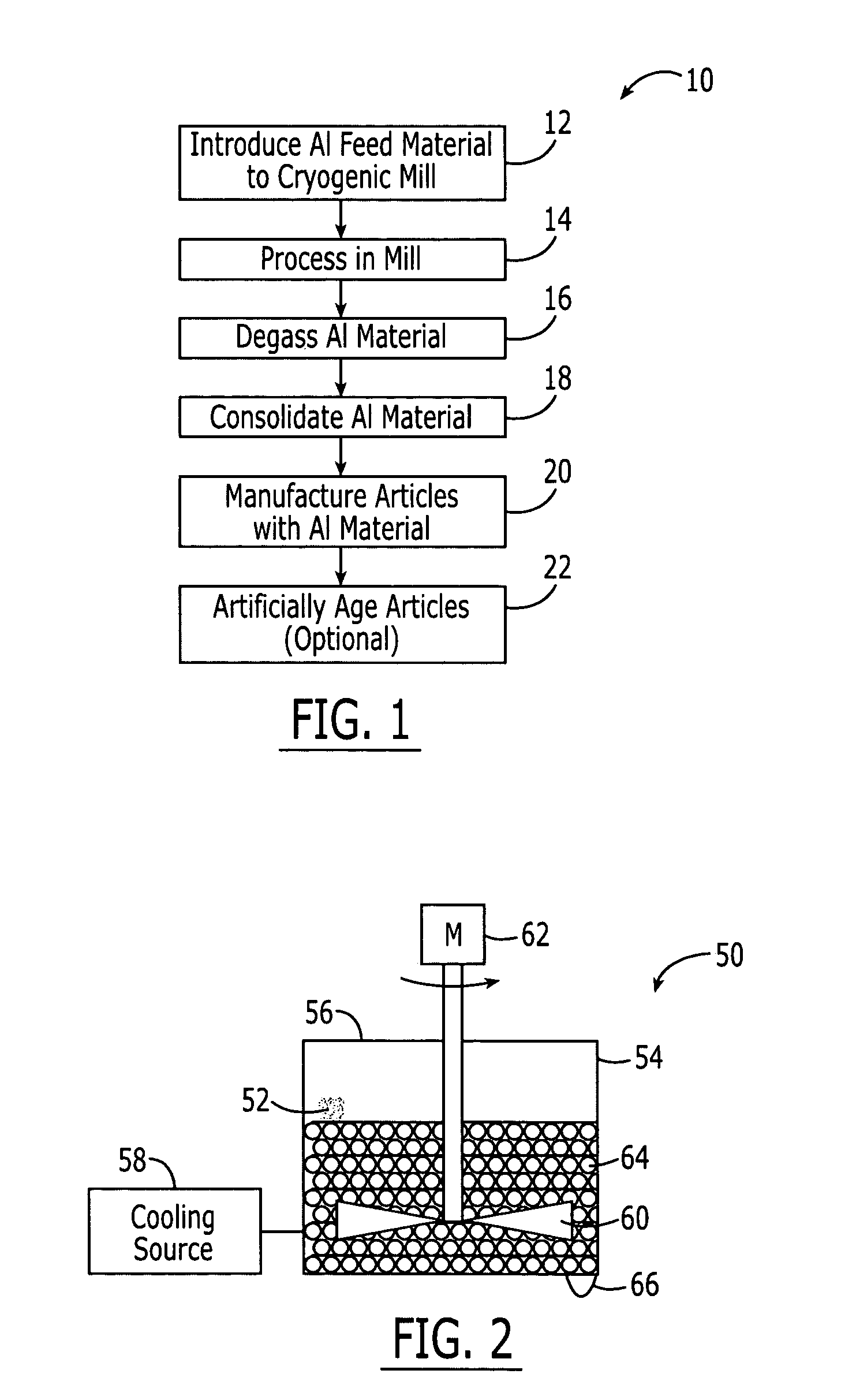

Method for preparing pre-coated, ultra-fine, submicron grain high-temperature aluminum and aluminum-alloy components and components prepared thereby

ActiveUS20060237134A1Improves fatigue life and corrosion resistanceImprove workmanshipRivetsSynthetic resin layered productsCrystalliteUltra fine

The invention is a high-strength, pre-coated, aluminum or aluminum-alloy component comprising an aluminum or aluminum-alloy article having ultra-fine, submicron grain microstructure and an organic coating of phenolic resin applied to the surface of the article. The article is prepared from a coarse grain aluminum or aluminum-alloy material that is cryomilled into an ultra-fine, submicron grain material, degassed, and densified. The densified material is formed into an article, and coated with an organic coating containing phenolic resin prior to installation or assembly.

Owner:THE BOEING CO

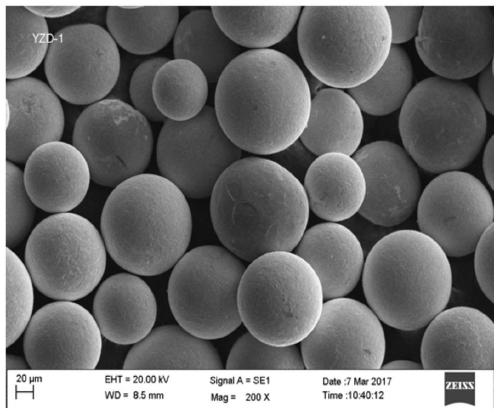

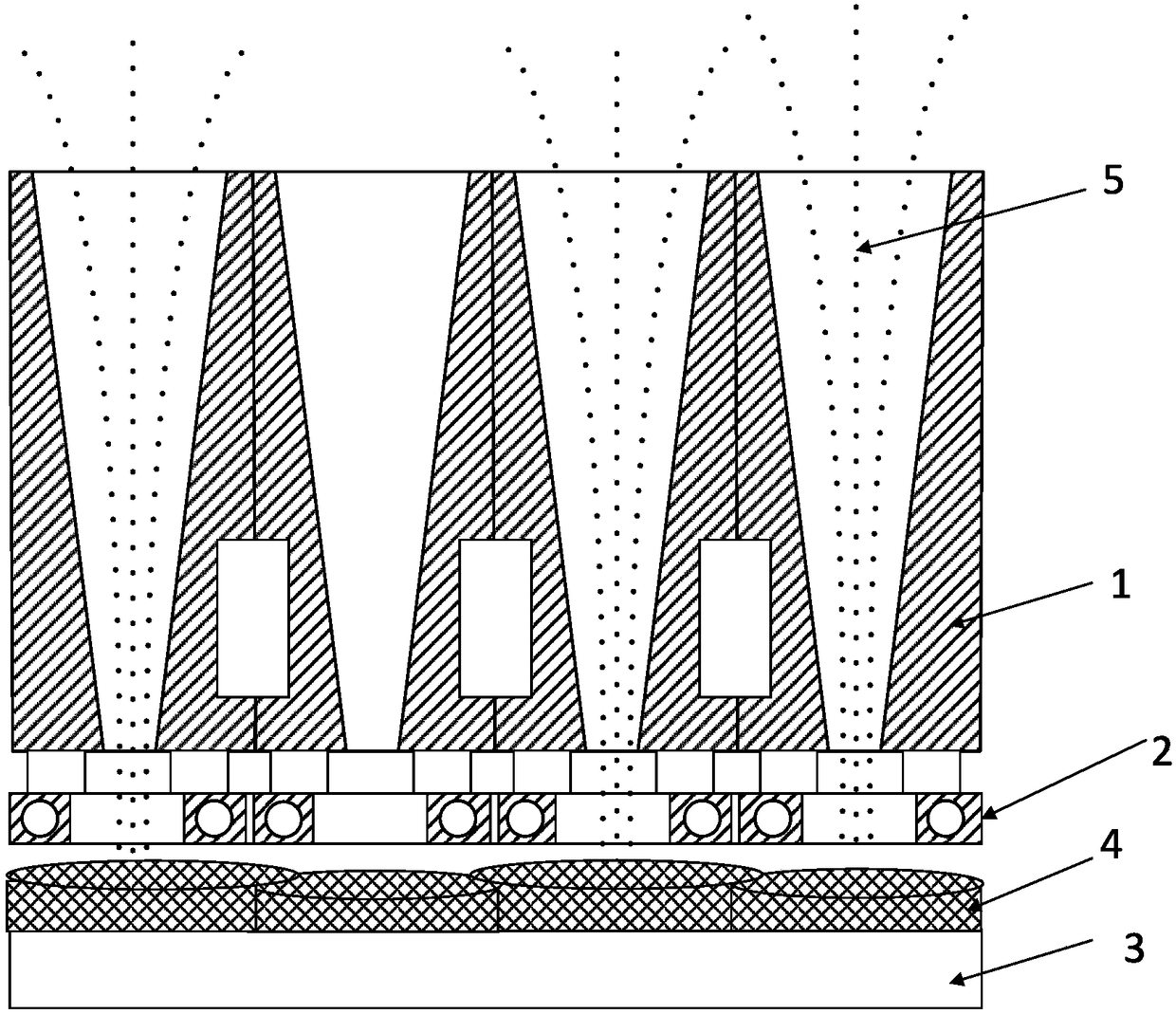

Three-dimensional printing formation method based on induction heating and used for metal nanopowder

ActiveCN108380871ALow molding temperatureEliminate molding thermal stress problemsMaterial nanotechnologyAdditive manufacturing apparatusNanometreUltra fine

The invention provides a three-dimensional printing formation method based on induction heating and used for metal nanopowder. The three-dimensional printing formation method based on induction heating and used for the metal nanopowder comprises the steps that CAD data files, a formed substrate, the metal nanopowder and a nanopowder jet array plate for three-dimensional printing formation of a part are prepared; internal block-by-block filling is conducted on each closed outline pattern of each layer of slice; the formed substrate and a formed part are kept at a preset temperature through heating in a vacuum formation cavity; and slice data of the current slice are obtained, corresponding powder delivery nozzle jet valves are controlled to be opened according to corresponding small blocksformed after the current slice is cut, solidification occurs while the metal nanopowder is molten and molten metal is leveled, and the thicknesses of the corresponding small blocks are increased by acertain degree. According to the three-dimensional printing formation method based on induction heating and used for the metal nanopowder, the process thinking that the temperature of the formed substrate and the formed part is kept below the melting point of the blocks and above the melting point of the metal nanopowder is ingeniously utilized, a high-energy beam for assisting melting is not needed, and three-dimensional formation of ultra fine and ultra-high-speed parts is achieved based on the metal nanopowder.

Owner:山东承坤信息科技有限公司

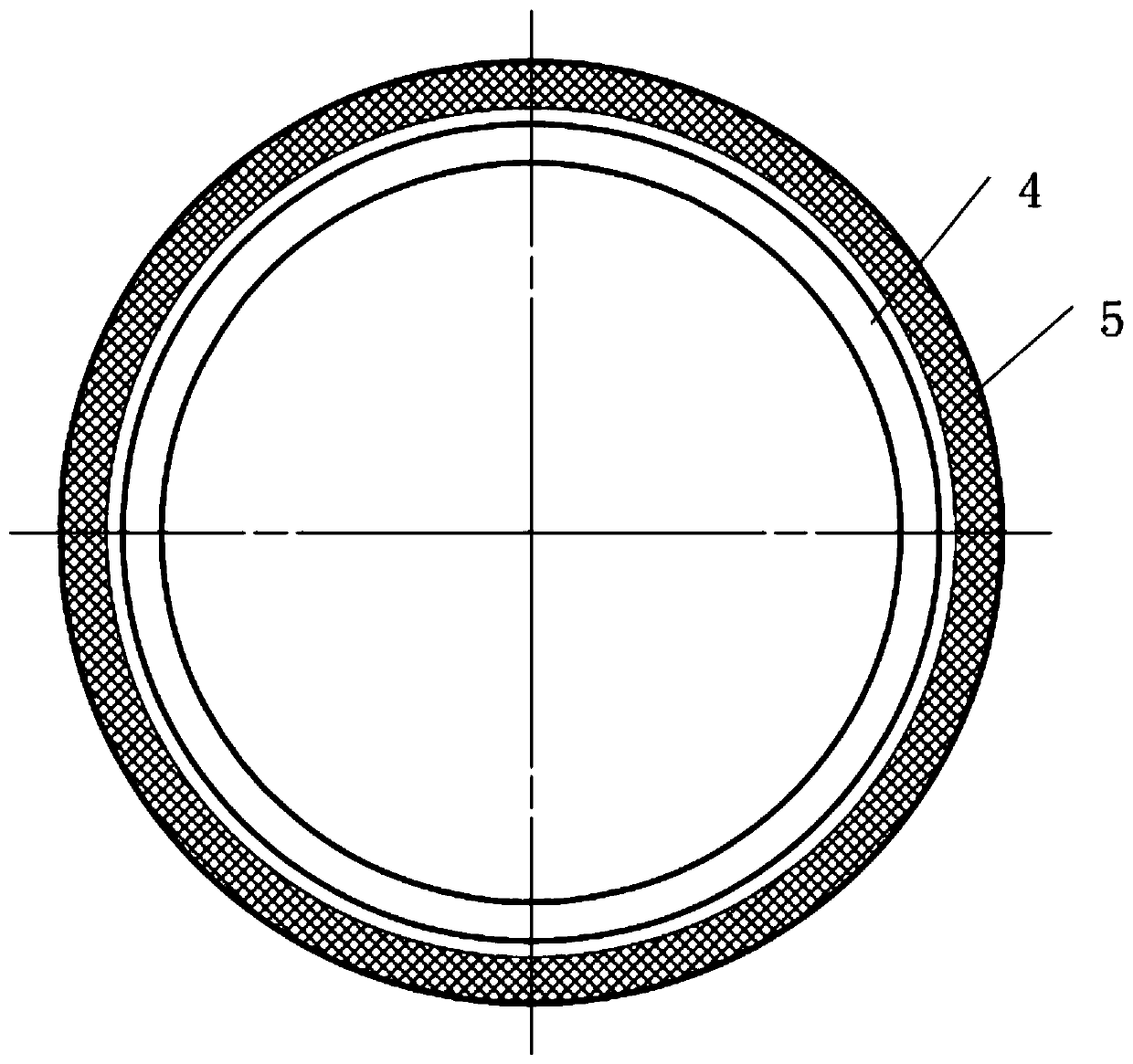

Reaction cavity and semiconductor processing equipment

ActiveCN105088193AEnter fastImprove film qualityChemical vapor deposition coatingSemiconductor materialsEngineering

The invention discloses a reaction cavity. The reaction cavity comprises a closed cavity body and a flat plate heater assembly, wherein the cavity body consists of a lower spacer, a side wall and an upper cover plate, the flat plate heater assembly is arranged in the cavity body, a flow equalizing plate is arranged between the upper cover plate and the flat plate heater assembly, a flow equalizing cavity is formed between the flow equalizing plate and the upper cover plate, an air inlet assembly is arranged on the upper cover plate, an air outlet of the air inlet assembly is communicated with the flow equalizing cavity, and an air flow baffle is arranged in a position which is of a certain distance from the air outlet of the air inlet assembly. The technical gas of the reaction cavity is equalized twice before entering the reaction cavity. The reaction cavity has the advantage that the technical gas enters at a high speed and is evenly distributed. The technical quality is improved, and the film forming quality of a semiconductor material is improved. As the technical gas directly enters the reaction cavity from the top of the cavity, the speed that the technical gas enters the reaction cavity is increased.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

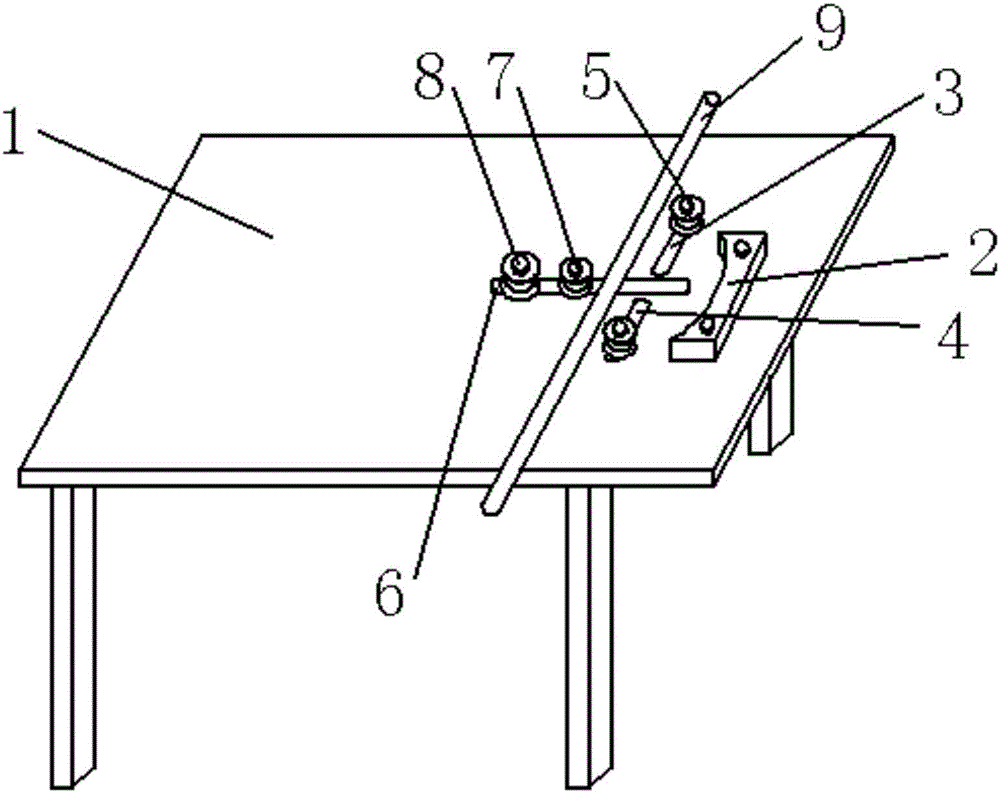

Wire holding and bending setter

InactiveCN106532560AEasy to operateImprove work efficiencyApparatus for overhead lines/cablesProcess qualityControl engineering

The invention discloses a wire holding and bending setter, which comprises an operation platform, a fixed bracket, a right groove, a left groove, holding and moving wheels, a top groove, a top moving wheel, a setting wheel, an air cylinder and a control switch, wherein the fixed bracket is arranged at the inner side of one edge of the upper part of the operation platform; a concave arc wire protection surface is arranged at the inner side of the fixed bracket; the longitudinal top groove is arranged in the center of the inner side of the fixed bracket; a top moving arm is arranged at the lower of the top groove and is sequentially provided with the top moving wheel and the setting wheel; transverse left groove and right groove are formed in the left side and the right side, close to the fixed bracket, of the top groove respectively; a left moving arm and a right moving arm are arranged at the lower parts of the left groove and the right groove respectively; the holding and moving wheels are arranged on the left moving arm and the right moving arm respectively; the air cylinder provides the left moving arm, the right moving arm and the top moving arm with power; and the moving arms are controlled to move through the control switch. The wire holding and bending setter is simple in operation and high in work efficiency, and can be quickly completed by one person at present from 2-3 persons in the past, and the process quality of a product is good through perfect cooperation of the holding and moving wheels, the top moving wheel and the setting wheel.

Owner:聊城市光明电力服务有限责任公司 +2

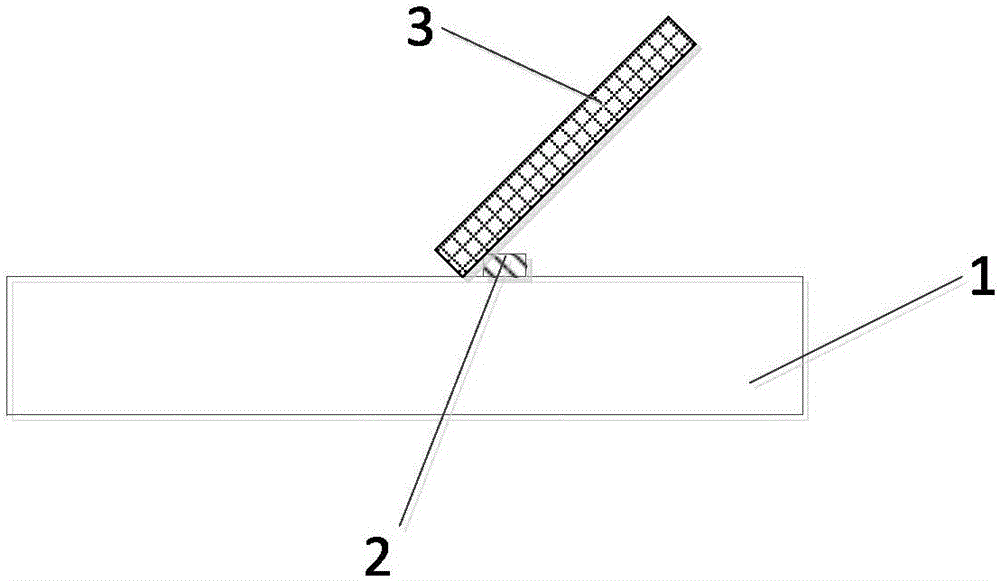

Extrusion forming laser welding brazing method

ActiveCN106077862ASpread evenlyEasy to overflowSoldering apparatusWelding/soldering/cutting articlesMelting tankLaser beams

The invention provides an extrusion forming laser welding brazing method. The extrusion forming laser welding brazing method comprises the steps that (1) a solder powder strip is paved in a to-be-welded position of a lower welding block in advance; (2) a first end of an upper welding block is placed in the position, close to the solder powder strip, on the lower welding block, and a 0 to 60-degree included angle space is formed between the upper welding block and the lower welding block; (3) laser beams obliquely shoot from the included angle space, and the laser beams are focused on the solder powder strip to form a strip-shaped brazing molten pool; (4) a second end of the upper welding block is pressed downwards, the strip-shaped brazing molten pool is pushed to be spread on a welding surface between the upper welding block and the lower welding block, and the upper welding block completely fits the lower welding block; and (5) solder is solidified to form a welding connector. According to the extrusion forming laser welding brazing method, the laser beams are utilized to melt solder to form the strip-shaped brazing molten pool, the liquid solder is pushed to be spread on a to-be-welded surface through extrusion, bubbles in the molten pool are released, the metallurgy reaction of a welding brazing connector is sufficient, the technological quality of the welding brazing connector is good, and the mechanical property is high.

Owner:苏州奥钦商贸有限公司

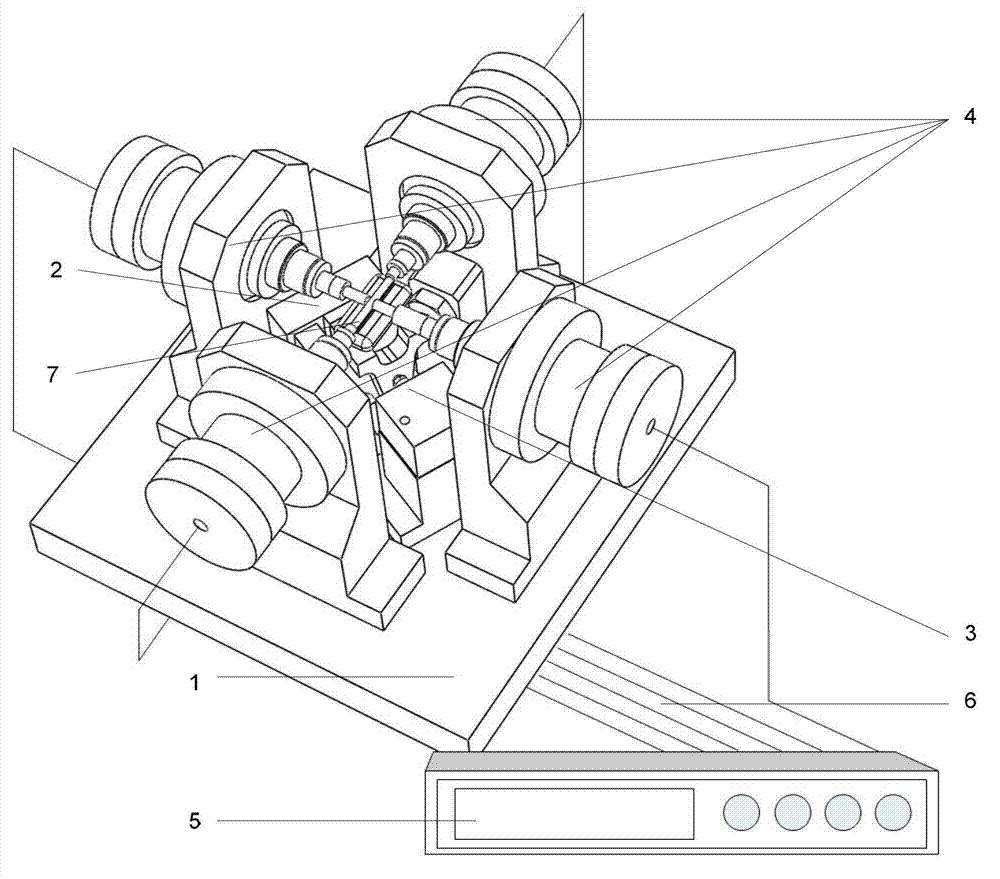

Precision machining technological equipment and machining method for blade of aviation engine

ActiveCN102975061BAvoid pouringAvoid meltingPositioning apparatusMetal-working holdersAviationHydraulic cylinder

The invention discloses precision machining technological equipment for a blade of an aviation engine. The precision machining technological equipment comprises a positioning device, a clamping device and an auxiliary supporting device, wherein the positioning device, the clamping device and the auxiliary supporting device are fixed on a foundation table top, the positioning device is used for positioning of a curved surface of a blade body, the clamping device is used for clamping the blade body, the auxiliary supporting device is fixed outside the positioning device and the clamping device, a working head of the auxiliary supporting device directly contacts a tenon portion of the blade, and a master controller controls each hydraulic cylinder on a tool through a control loop. According to the precision machining technological equipment, the blade body provided with a thin wall and the curved surface is directly positioned and clamped for machining the tenon, and therefore continuous mechanical operation and machining can be achieved in production of the blade, and working efficiency and machining quality can be improved.

Owner:TSINGHUA UNIV +1

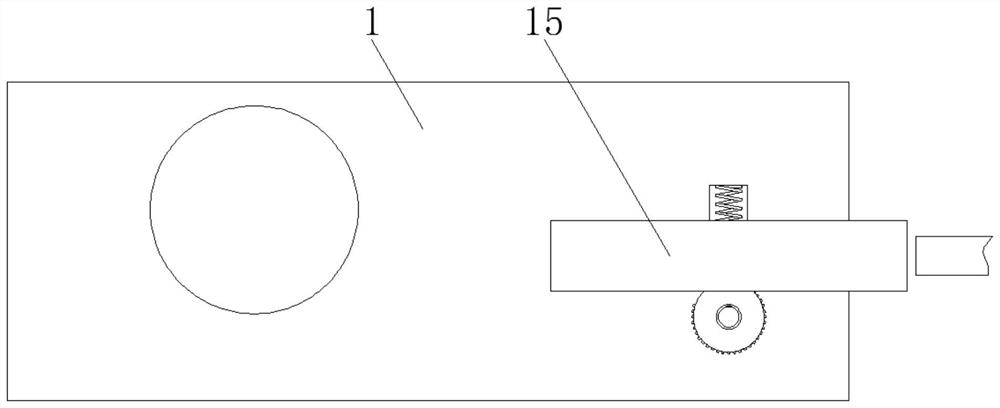

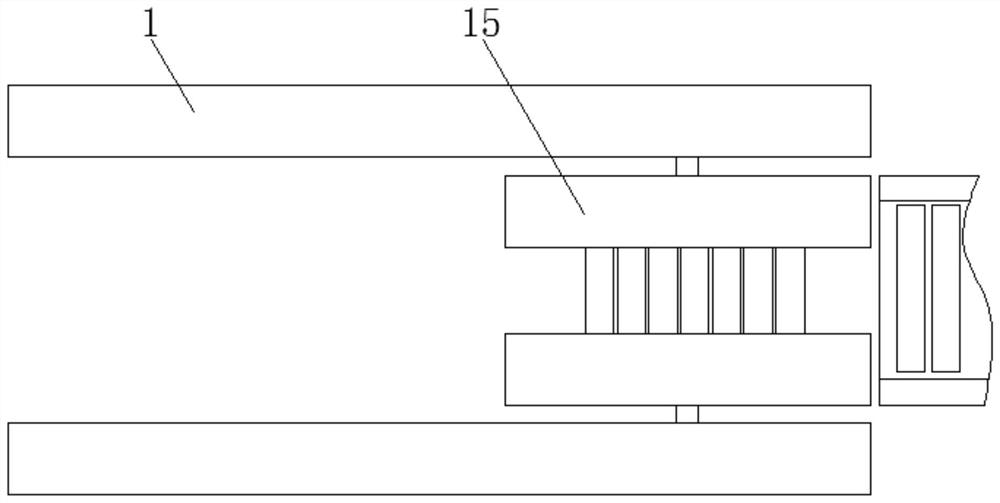

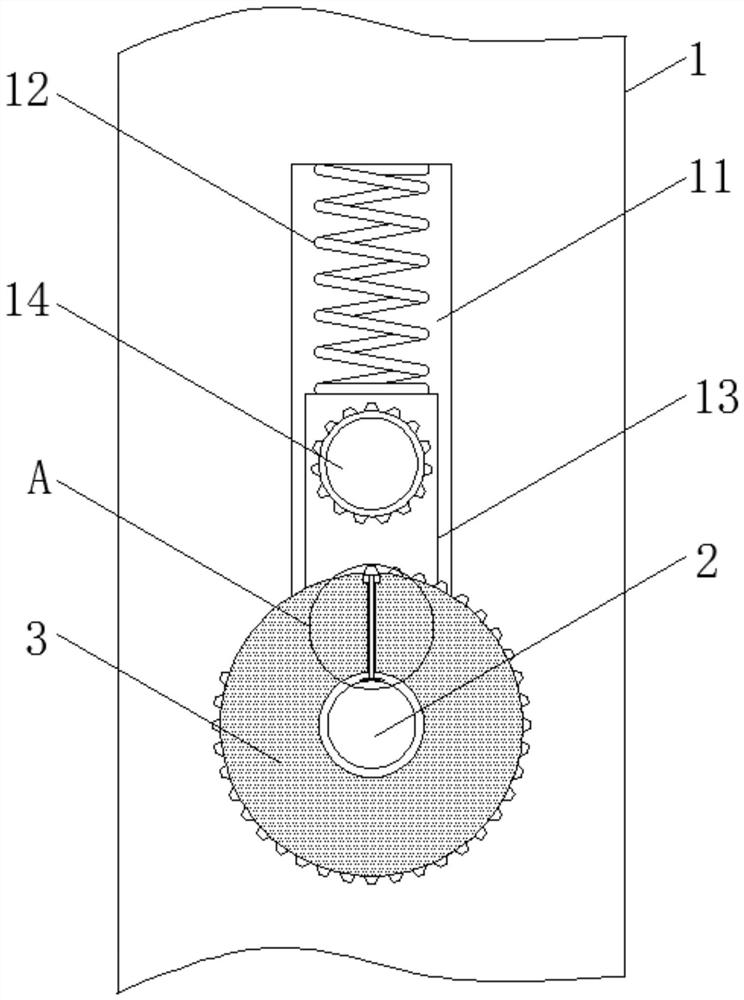

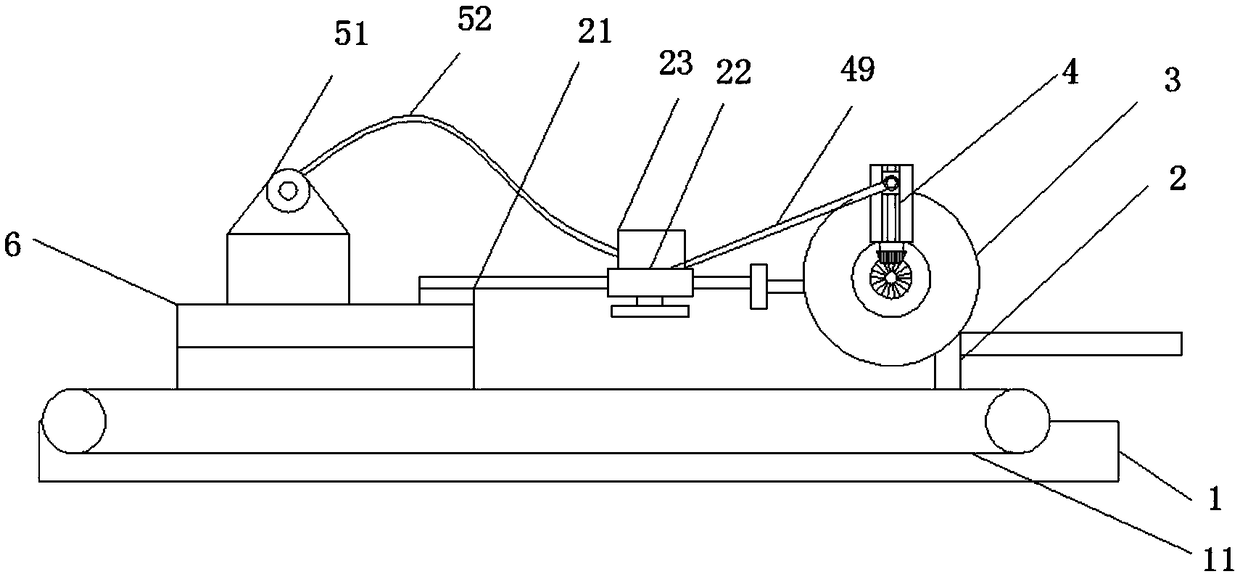

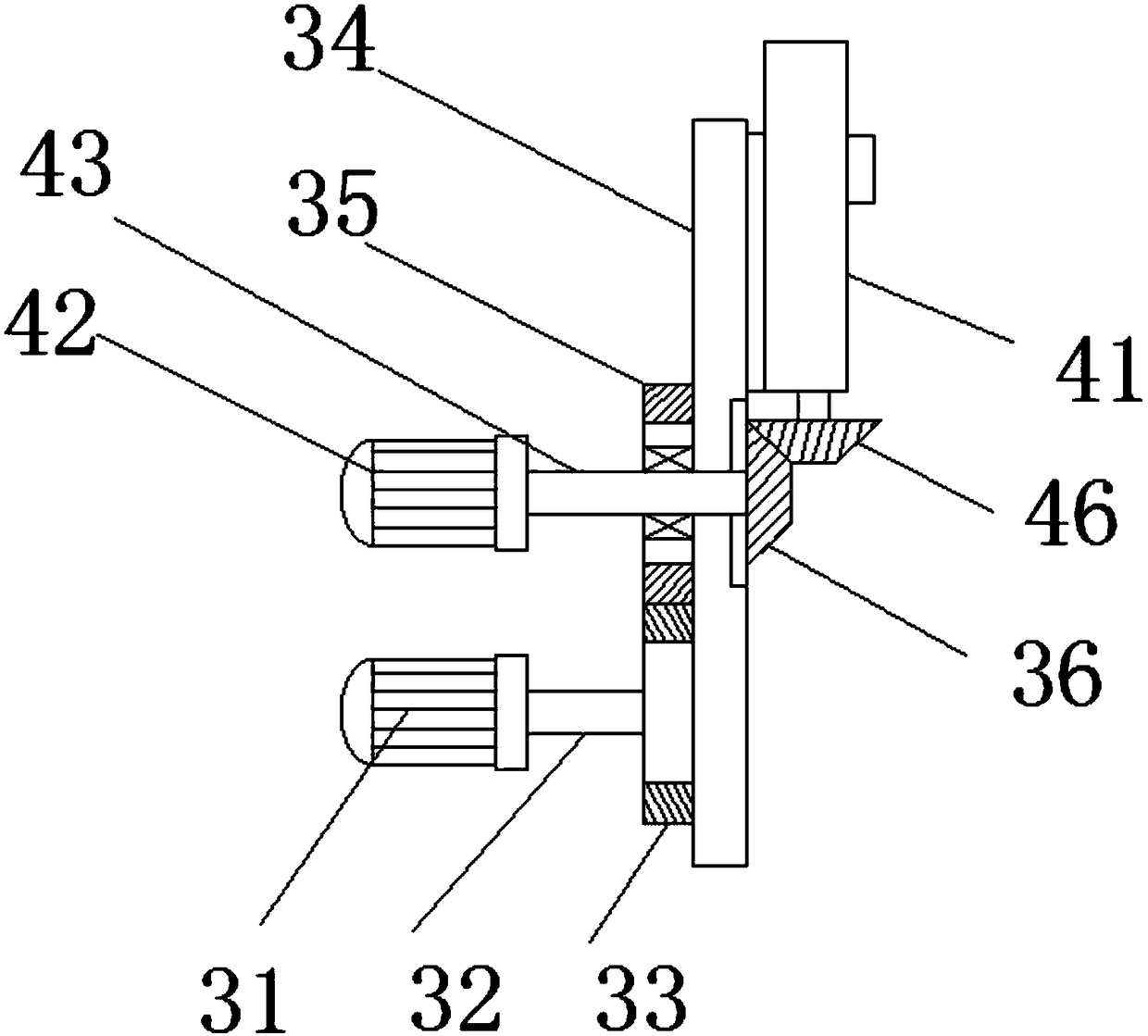

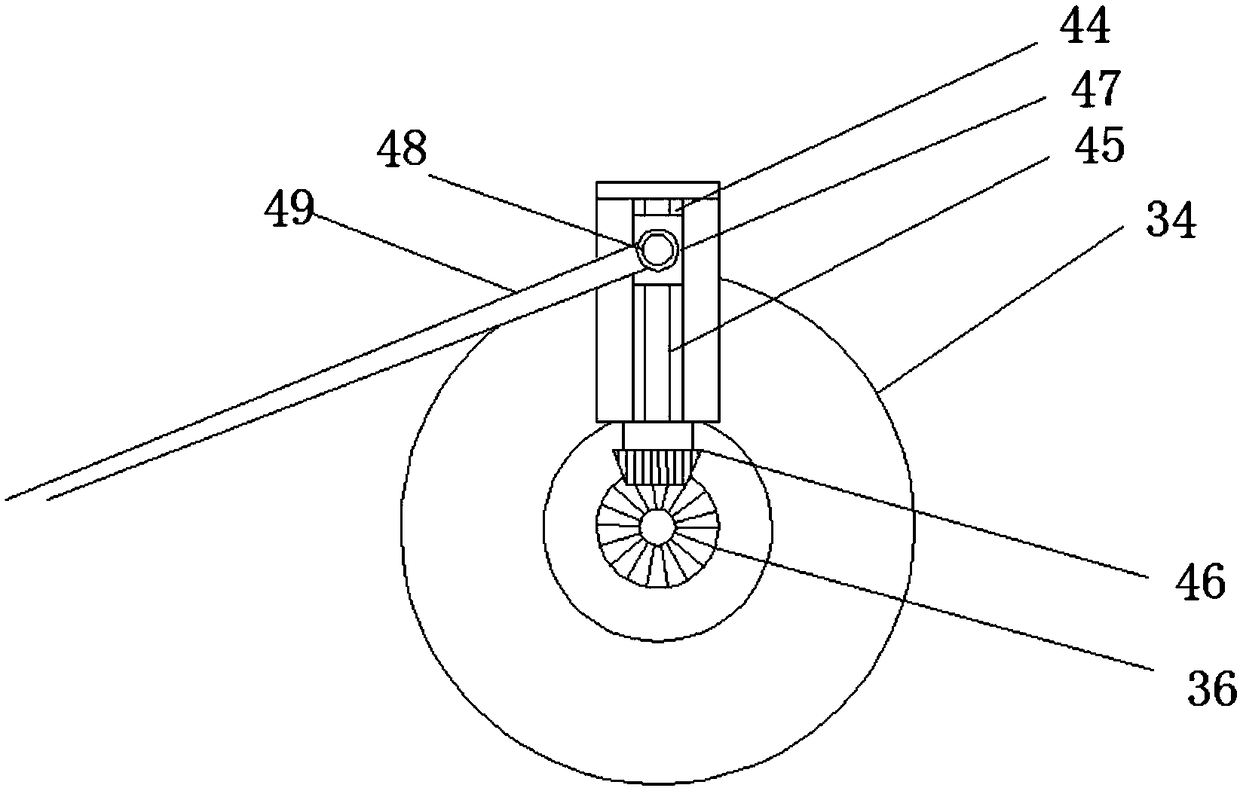

Automatic arranging, winding and binding mechanism for lithium battery pack production

InactiveCN111682253AImprove workmanshipImprove work efficiencyPrimary cell manufactureAssembling battery machinesAdhesive beltGear drive

The invention discloses an automatic arranging, winding and binding mechanism for lithium battery pack production. The automatic arranging, winding and binding mechanism for lithium battery pack production comprises two side plates; a power shaft extending to the front face of the rear side plate is arranged on the back face of the rear side plate in a penetrating mode; a power gear is rotationally installed on the front face of the rear side plate; a compression groove is formed in the top of the power gear; a compression spring is fixedly connected into the compression groove, and movable teeth are fixedly connected with the top of the compression spring. According to the automatic arranging, winding and binding mechanism for lithium battery pack production, a tray is mounted on the leftside of a conveying belt; after lithium batteries on the conveying belt enter a containing groove, the power gear drives the tray to rotate, an adhesive tape is wound on the surface of the tray, a blade cuts off the adhesive tape after the adhesive tape rotates by three and a half circles, and the device resets; and therefore automatic arrangement and packaging of the lithium batteries are achieved, the working process is improved, working efficiency is improved, and expanded production is facilitated.

Owner:蔡钰烨

Material surface film coating device

InactiveCN109453932AQuick TangentImprove workmanshipLiquid spraying apparatusEngineeringMechanical engineering

The invention discloses a material surface film coating device. The material surface film coating device comprises a base seat, the base seat is provided with a transmission rack in an erected manner,the transmission rack is synchronously provided with a first transmission mechanism, the first transmission mechanism is provided with a second transmission mechanism in an erected manner, the firsttransmission mechanism comprises a transmission disc, the rear side of the transmission disc is provided with a first motor, the first motor is installed on the transmission rack and provided with a transmission gear through a first rotating shaft, the rear side wall of the transmission disc is provided with a driven gear, the second transmission mechanism comprises a lifting groove, and the lifting groove is installed on the front plane of the transmission disc. According to the material surface film coating device, by means of mutual coordination of helical gear transmission and screw threadtransmission, operations adapting to materials of different sizes can be achieved, relative to process production, the effect of cutting lines rapidly is achieved, and the operation process is greatly improved.

Owner:HENAN HUANQIU AVIATION EQUIP TECH CO LTD

Electronic packaging structure and manufacturing method thereof

InactiveCN101635265AHigh degree of integrationConvenient detection of processing conditionsPrinted circuit assemblingSemiconductor/solid-state device detailsEngineeringElectronic component

The invention discloses an electronic packaging structure and a manufacturing method thereof. The electronic packaging structure comprises a main substrate, wherein a plurality of circuit wires are arranged on the main substrate; and an electronic element module, wherein at least one conducting solder pad is arranged on the bottom face of the electronic element module and a plurality of conducting circuits are arranged on one side face of the electronic element module. The conducting solder pad and the conducting circuits are electronically connected with the circuit wires. By using the structure, the electronic element module can be repeatedly stacked upwards to form an ultra-integrated electronic packaging structure.

Owner:ANHUI HAIHUA CHEM

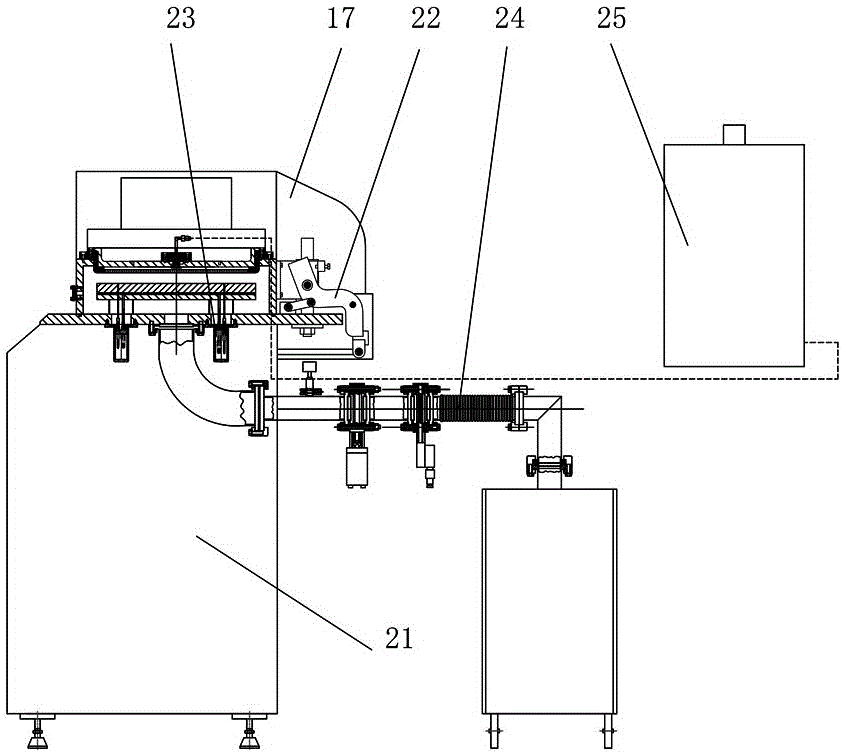

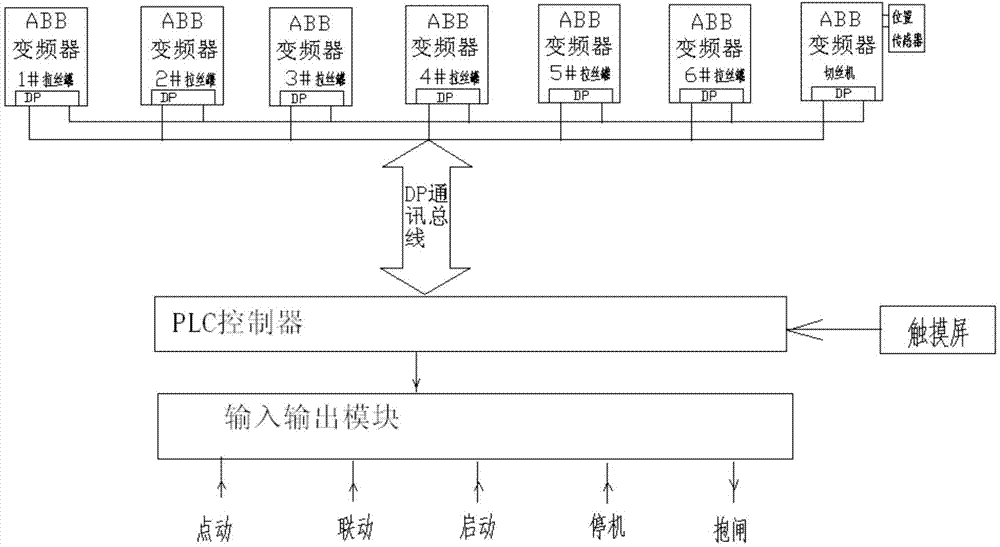

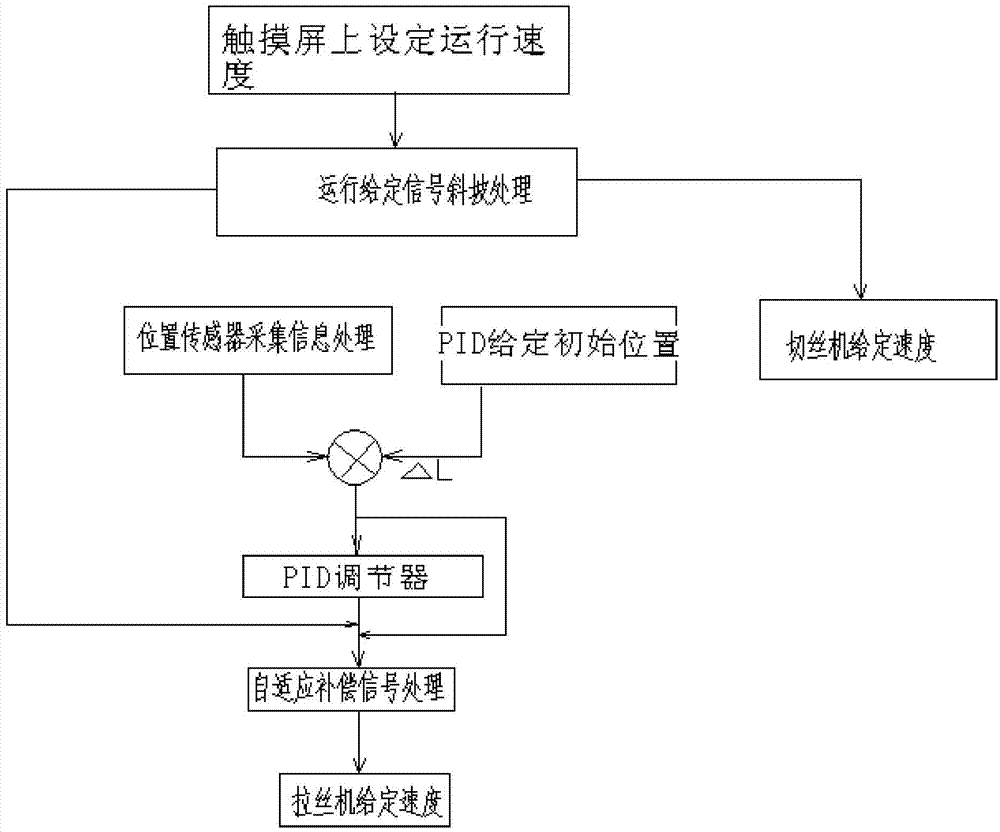

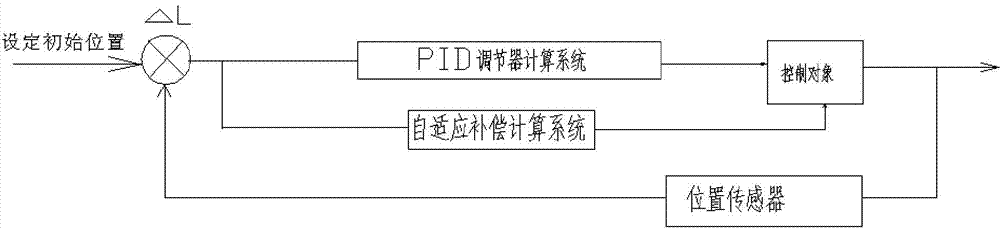

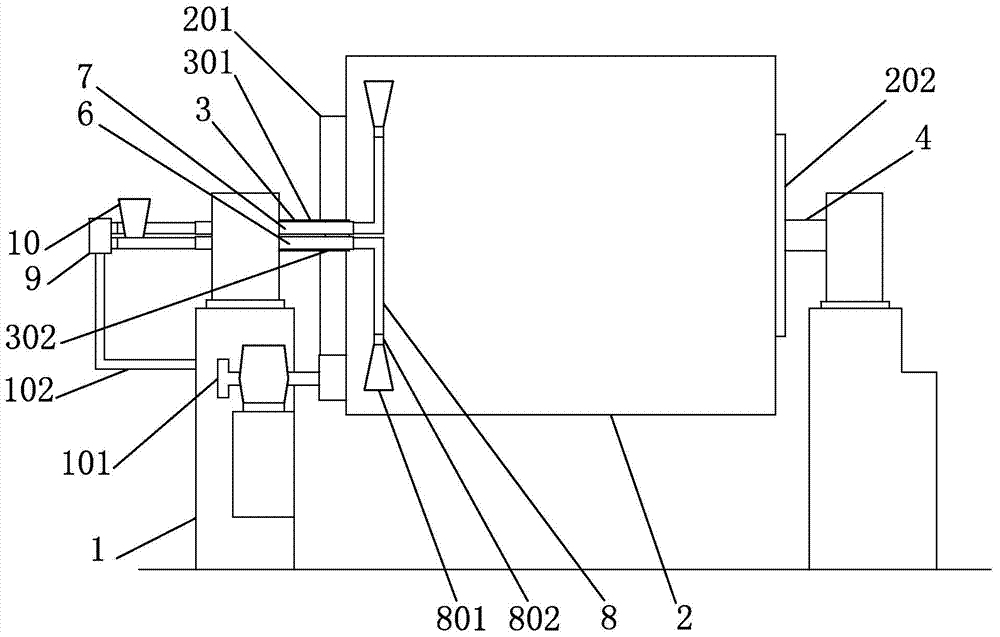

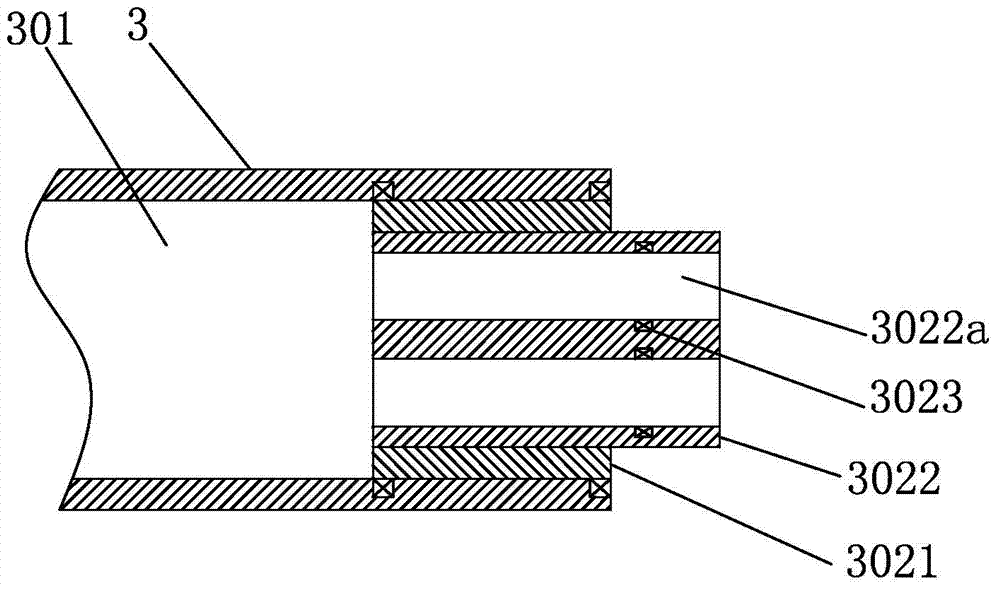

Linear wire drawing machine and high-speed wire cutting machine continuous production integrated device and control method

ActiveCN104731077ARealize integrated continuous productionImprove workmanshipWelding/cutting media/materialsTotal factory controlElectricityControl system

The invention provides a linear wire drawing machine and high-speed wire cutting machine continuous production integrated device. The linear wire drawing machine and high-speed wire cutting machine continuous production integrated device comprises a linear wire drawing machine, a wire cutting machine and a control system controlling the speed of the linear wire drawing machine and the speed of the wire cutting machine. A tension swinging arm is installed between the linear wire drawing machine and the wire cutting machine, and a position sensor is installed at the tension swinging arm. The control system comprises a PLC. The PLC is connected with communication modules of all wire drawing tank frequency converters of the wire drawing machine and communication modules of a wire cutting machine frequency converter through communication buses. The PLC is electrically connected with a touch screen, the position sensor and an input / output module. By means of the linear wire drawing machine and high-speed wire cutting machine continuous production integrated device, linear wire drawing machine and high-speed wire cutting machine integrated continuous production is achieved, matching of the speeds of the two machines can be quickly and accurately adjusted in real time, it can be guaranteed that the lengths of core wires cut by the high-speed wire cutting machine are equal, and the technological requirement for core wire linearity can be met; meanwhile, the technical quality of the core wires is improved, efficiency is improved, and energy is saved.

Owner:TIANJIN GOLDEN BRIDGE WELDING MATERIALS GRP

Circulation-type drum

InactiveCN104120201AReal-time detection of temperatureReal-time detection of concentrationLeather/skins/hides/pelt chemical treatment apparatusWater storageEngineering

The invention discloses a circulation-type drum which comprises a rack and a hollow drum body, wherein a large gear and an attached disc are respectively arranged at two ends of the drum body; a speed reduction mechanism which is connected with the large gear is arranged on the rack; the large gear is connected with a first rotating shaft; the attached disc is connected with a second shaft; a through hole is formed inside the first rotating shaft along the center of the axis; one end, connected with the large gear, of the first rotating shaft, is communicated with the inner cavity of the drum body; a water inlet tube and a water outlet tube are arranged inside the through hole; a sealing component is arranged at one end, communicated with the inner cavity of the drum body, of the first rotating shaft; the water inlet tube and the water outlet tube respectively penetrate through the sealing component and stretch into the inner cavity of the drum; a water guide tube is connected with one end (stretching into the inner cavity of the drum body) of each of the water inlet tube and the water outlet tube; the other ends of the water inlet tube and the water outlet tube respectively penetrate through the through hole and are communicated with a valve; the valve is connected with the rack through a support rod; a water storage bucket which is communicated with the tube cavity is arranged on the water inlet tube. By adopting the drum, processing liquid can be detected in real time.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

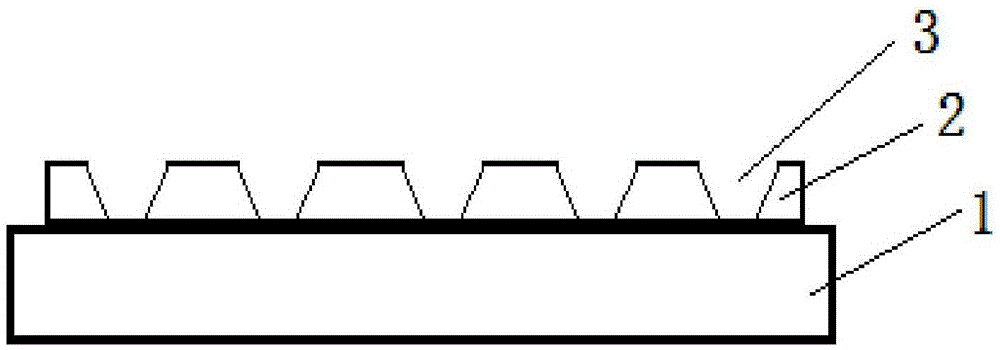

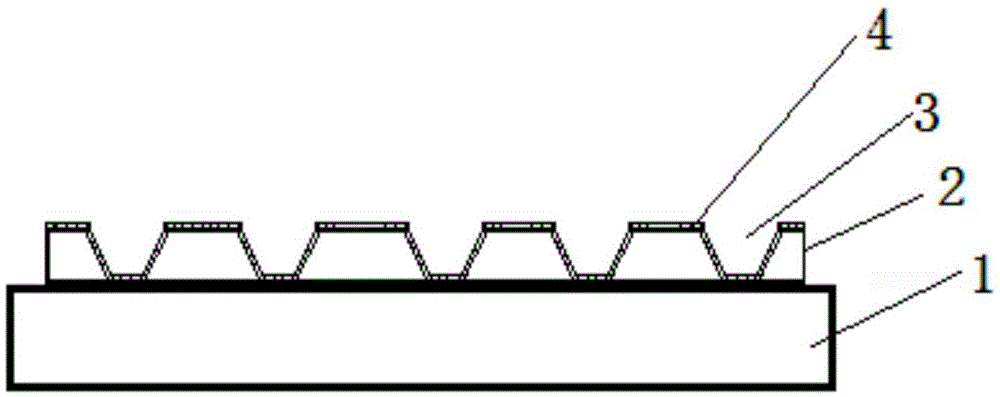

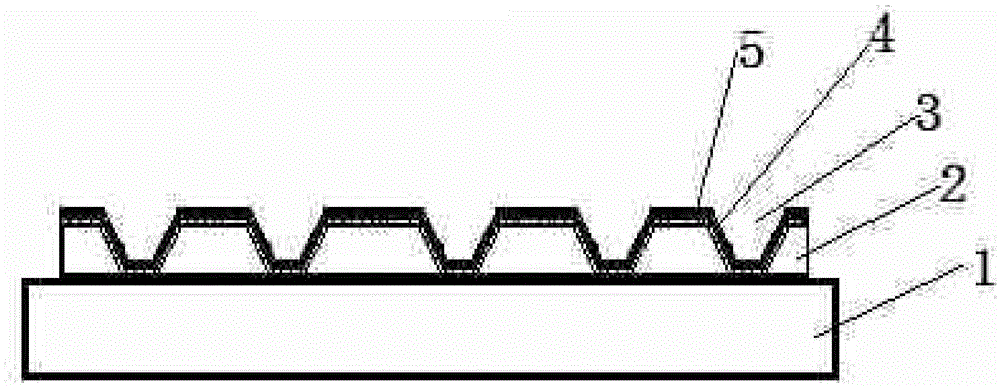

Inter-chip conductive bridge structure and manufacturing method thereof

PendingCN113800463AValid reservationImprove performanceTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesStructural engineeringProtection layer

The invention discloses an inter-chip conductive bridge structure and a manufacturing method thereof. An opening can be etched in at least one of a to-be-etched layer and a layer structure in a bridging area, a curved surface is arranged below the opening, the curved surface at least comprises a pair of surfaces with two non-right-angle adjacent edges, preferably, the curved surface is a surface with fillets, the opening can prevent the photoresist in the opening from being thrown out, and when the photoresist is coated and developed, the opening can ensure that the photoresist on the top surface of the layer structure is effectively reserved with proper thickness and width and better morphology, so that when the photoresist layer is used as a mask to etch the layer to be etched to form a conductive bridge, the photoresist can effectively protect the layer structure and the to-be-etched layer on the top surface of the layer structure, so that the required shape and width of the conductive bridge are achieved, the performance is reliable, short circuit or open circuit of the formed conductive bridge is avoided, and the product manufacturing yield and the test accuracy are further improved.

Owner:深圳市德金元科技有限公司

High-efficiency circular type drum

InactiveCN104120202AReduce resistanceImprove activity efficiencyLeather/skins/hides/pelt chemical treatment apparatusPipingEngineering

The invention discloses a high-efficiency circular type drum which comprises a machine frame and a hollow drum body, wherein a large gear and an auxiliary disc are respectively arranged at two ends of the drum body; a deceleration mechanism connected to the large gear is arranged on the machine frame; the large gear is connected to a first rotating shaft; the auxiliary disc is connected to a second rotating shaft; elastic devices are uniformly distributed on the inside surface of the drum body along the axial direction of the drum body; the elastic devices are connected to a separate type wide plate; the separate type wide plate can generate elastic rotation around the elastic devices; a through hole is arranged in the first rotating shaft along the axis; one end of the first rotating shaft connected with the large gear is communicated with the cavity of the drum body; a water inlet pipe and a water outlet pipe are arranged in the through hole; a sealing component is arranged at one end of the first rotating shaft communicated with the cavity of the drum; the water inlet pipe and the water outlet pipe respectively pass through the sealing component and stretch into the cavity of the drum; and one ends of the water inlet pipe and the water outlet pipe stretching into the cavity of the drum are respectively connected to a water guide pipe. The high-efficiency circular type drum disclosed by the invention is difficult to tear hides, low in working resistance and higher in efficiency, and is capable of simultaneously detecting a processing solution in real time.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

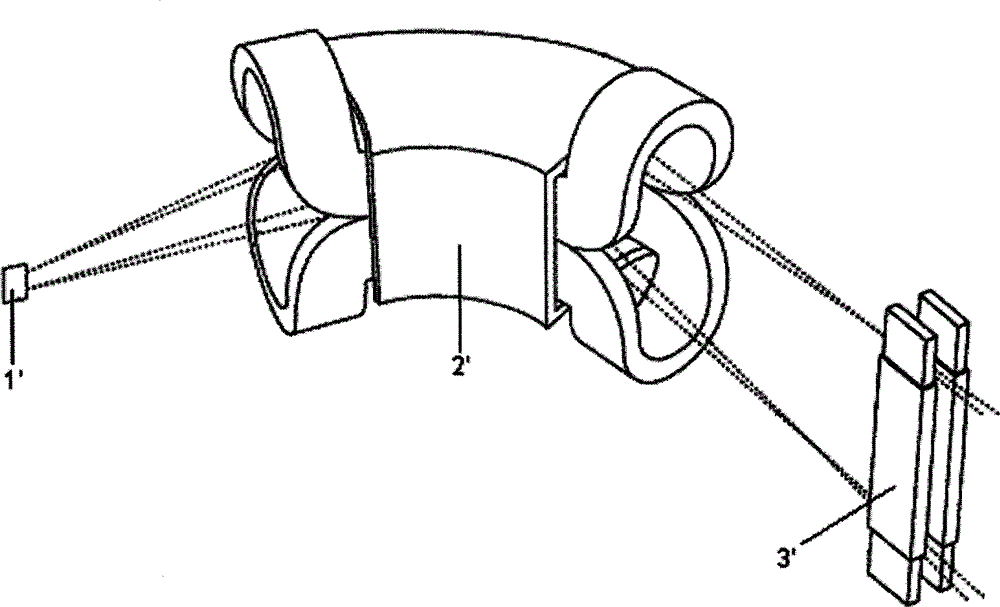

Adjustable cable bending spanner

InactiveCN104589254ARelieve fatigue strengthReduce in quantitySpannersWrenchesProcess qualityEngineering

The invention relates to an adjustable cable bending spanner which effectively resolves the problem that the part needing bending is not easy to operate in the installation process of large cables in the prior art. According to the scheme, the adjustable cable bending spanner comprises an L-shaped spanner, wherein the L-shaped spanner is composed of a handle and an action rod at the front end of the handle, a plurality of threaded holes are formed in the axial direction of the inner wall of the handle of the L-shaped spanner at intervals, the hole centers of the threaded holes and the axis of the action rod are on the same horizontal plane, and adjustable bearing levers are screwed in the threaded holes. The adjustable cable bending spanner can relieve the fatigue degree of workers, relieve labor intensity, increase the safety coefficient in the construction process, reduce the number of workers taking part in the work, be operated only by one person, and improve the cable engineering process quality.

Owner:国网河南襄城县供电公司

A circulating leak-proof drum

InactiveCN104120203BTemperature controlControl concentrationLeather/skins/hides/pelt chemical treatment apparatusGear wheelEngineering

The invention discloses a circular leakage-proof drum which comprises a rack and a hollow drum body, wherein a gear wheel and a secondary disc are arranged at the two ends of the drum body respectively; the rack is provided with a retarding mechanism connected with the gear wheel; the gear wheel is connected with a first rotary shaft; the secondary disc is connected with a second rotary shaft; a bearing seat is arranged at the two ends of the rack respectively; the first rotary shaft and the second rotary shaft are connected with the bearing seats respectively; a through hole is formed in the first rotary shaft along the axis, and the end of the first rotary shaft connected with the gear wheel is communicated with a drum inner cavity; a water inlet pipe and a water outlet pipe are arranged in the through hole; a sealing component is arranged at the end of the first rotary shaft communicated with the drum inner cavity; and the water inlet pipe and the water outlet pipe pass through the sealing component respectively and stretch into the drum inner cavity. The circular leakage-proof drum disclosed by the invention can detect the treating fluid in real time while collecting the treating fluid leaking from the drum to prevent pollution.

Owner:QINGDAO R & D INST XIAN JIAOTONG UNIV

Ion implantation system and method

ActiveCN102194637BImprove uniformityAccurate angle adjustmentElectric discharge tubesIon beamUltimate tensile strength

Owner:KINGSTONE SEMICONDUCTOR LIMITED COMPANY

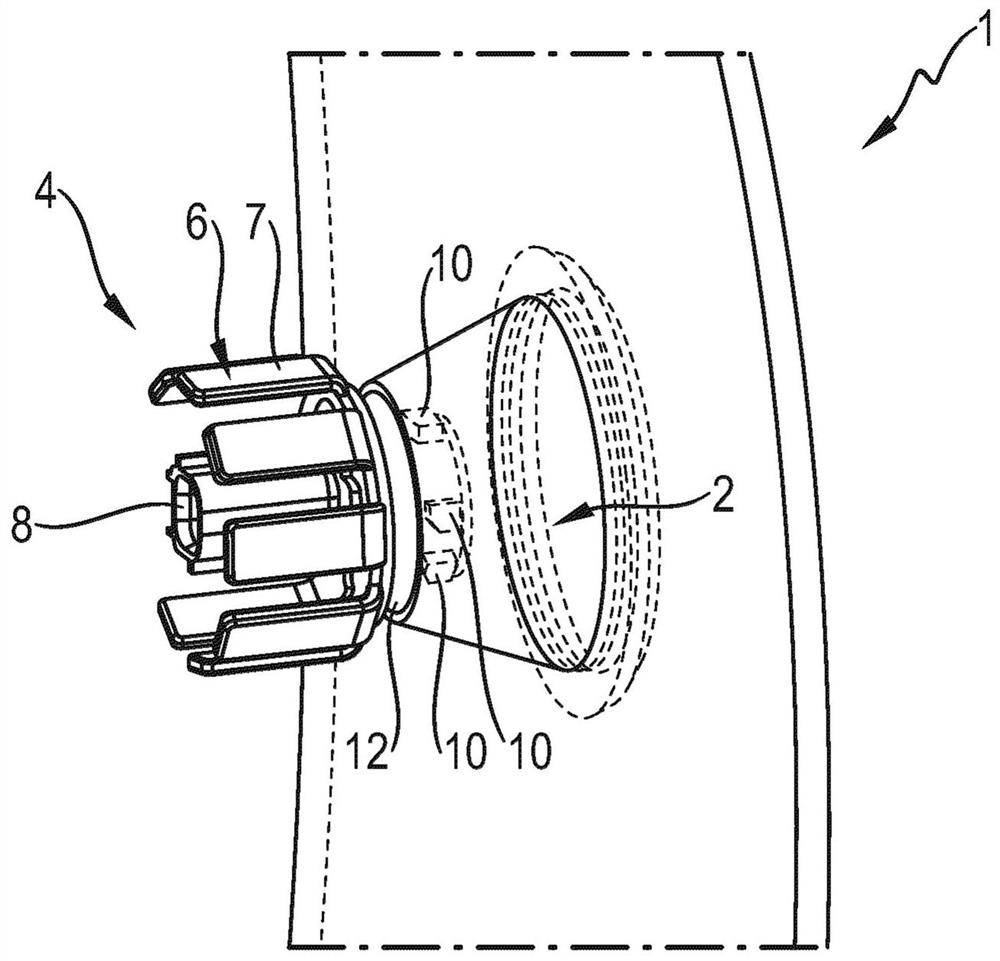

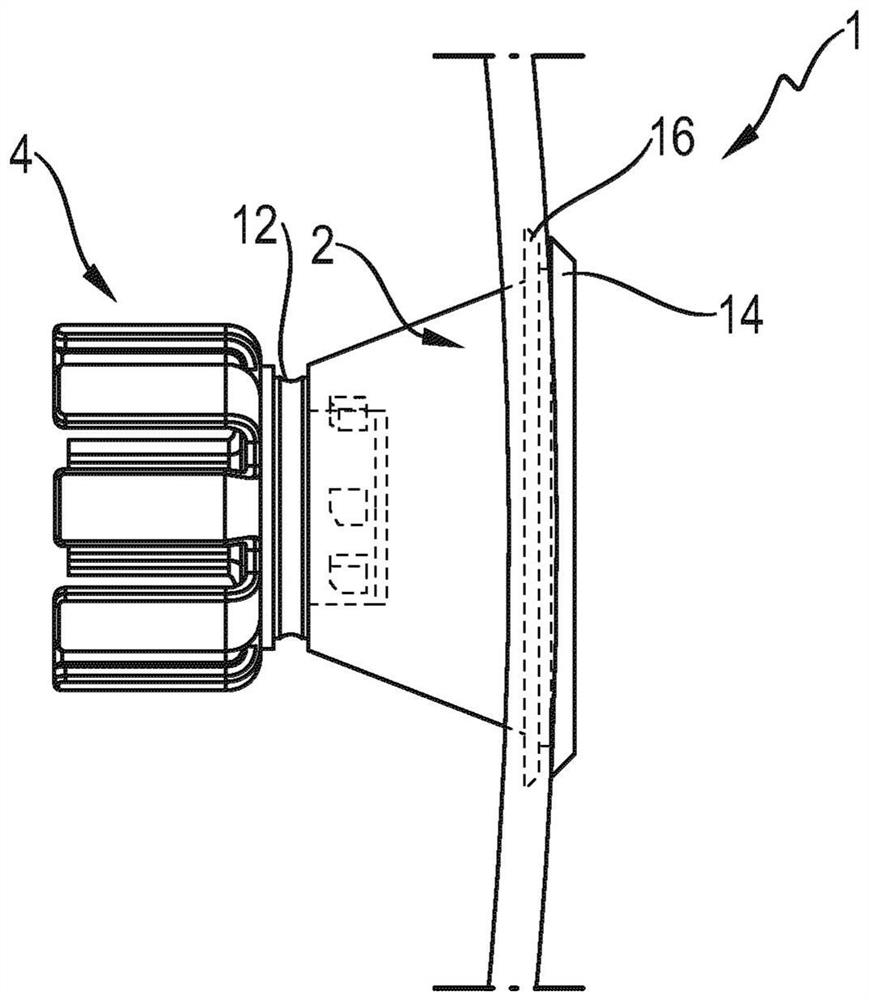

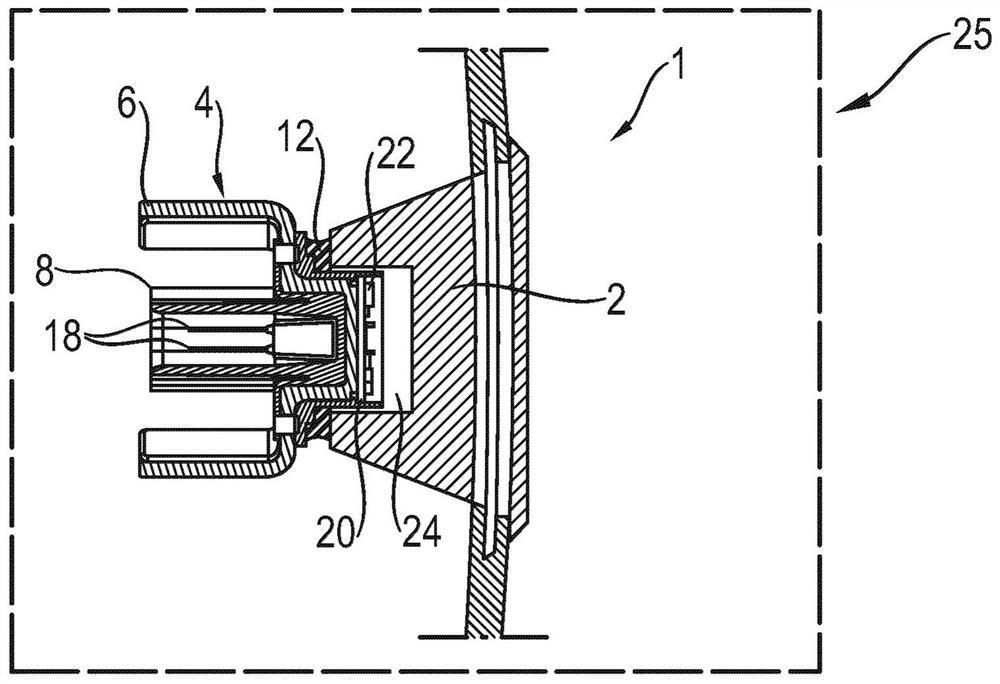

Vehicle component, vehicle and method

PendingCN113811716AEasy to assembleImprove workmanshipVehicle headlampsLighting and heating apparatusControl theoryMechanical engineering

Owner:OSRAM CONTINENTAL GMBH

A steel pipe punching and shearing machine

Owner:SEPCO ELECTRIC POWER CONSTR CORP

Cement concrete curing method

InactiveCN101767370BSmall shrinkageImprove mechanical propertiesCeramic shaping apparatusReducing agentMaterials science

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com