Cement concrete curing method

A technology for cement concrete and concrete curing agent, applied in ceramic molding machines, manufacturing tools, etc., can solve the problem that the drying and water loss of concrete is not significantly improved, the shrinkage-reducing component and the film-forming component of the curing agent interact with each other, and the concrete is not considered. The surface water state and other problems can achieve the effect of excellent shrinkage curing effect, saving maintenance cost and excellent concrete mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

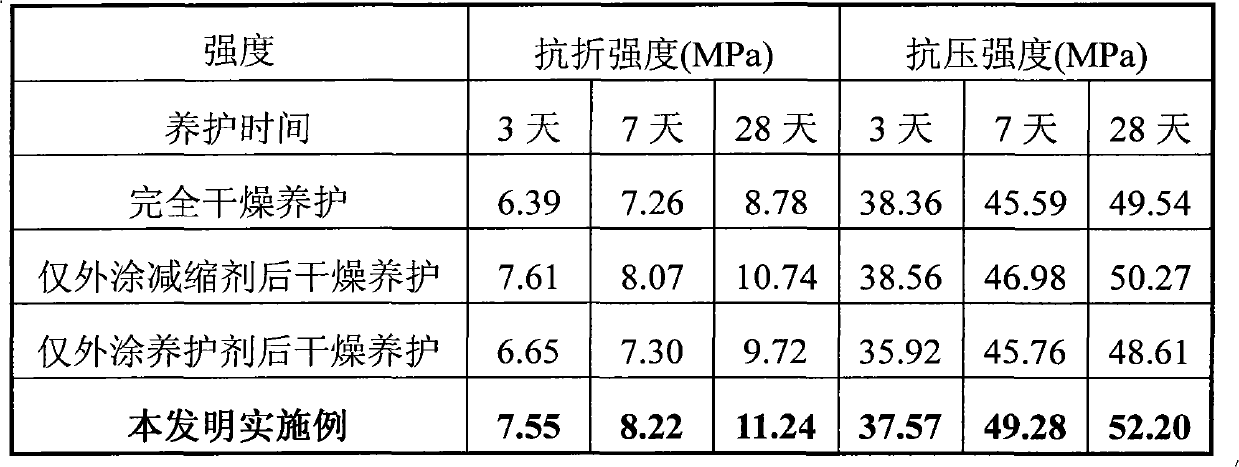

[0013] Example: When curing the concrete, directly use the shrinkage reducing solution (where the mass ratio of shrinkage reducing agent and water is 1:1, and the penetrating agent accounts for 1% of the above two mass ratios. The shrinkage reducing agent is Grace Eclipse Floor type shrinkage reducing agent, and the penetrating agent is used TF-107B type alcohol ether phosphoric acid monoester alkali resistant penetrating agent) at 0.15kg / m 2 Spray the concrete surface with the saturated surface and dry the concrete surface, and spray the concrete curing agent (acrylic emulsion curing agent) on the concrete surface when there is no large area of liquid shrinkage reduction solution visible on the concrete surface. In the above process, if the surface of the concrete is dry during curing, the concrete must be pre-wetted with the above-mentioned shrinkage reduction solution for not less than 60 minutes to make the internal moisture content reach the saturated surface dry state.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com