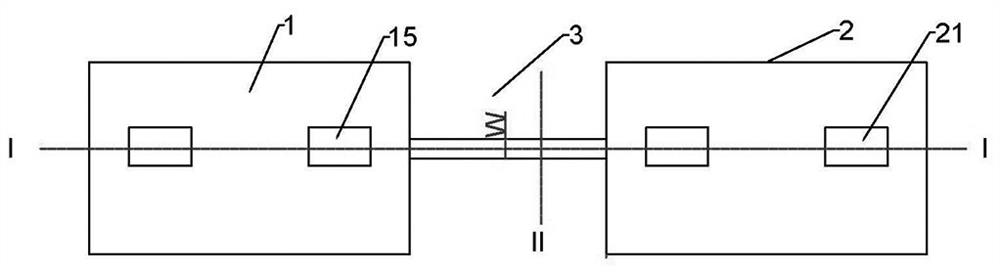

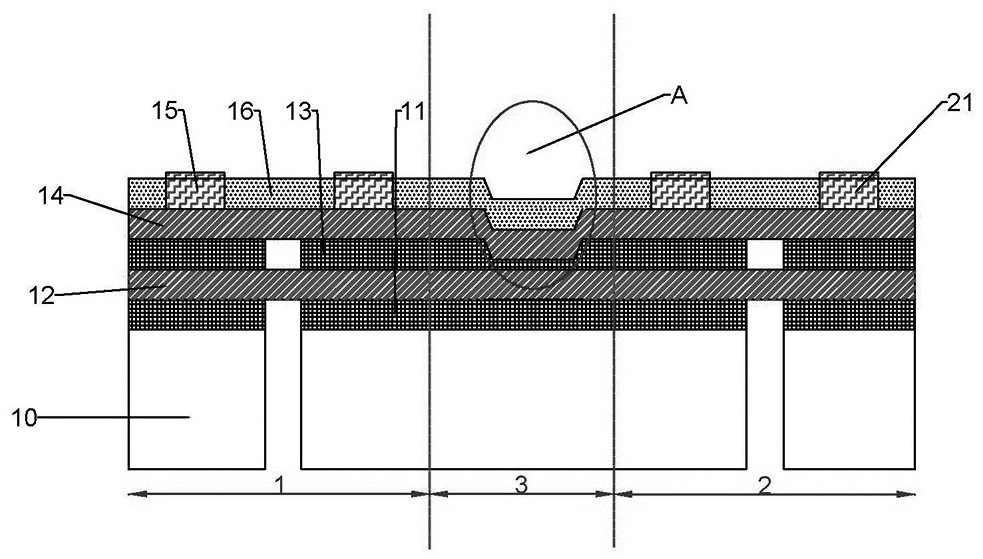

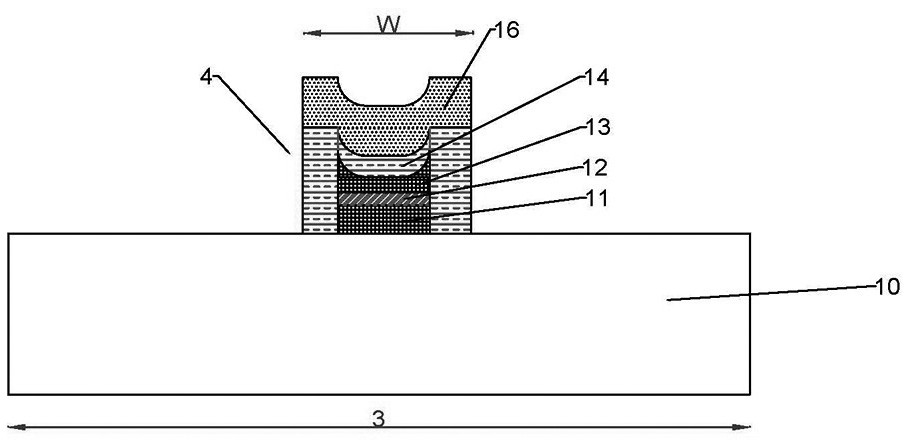

Inter-chip conductive bridge structure and manufacturing method thereof

A manufacturing method and conductive bridge technology, applied in the direction of microstructure technology, microstructure devices, manufacturing microstructure devices, etc., can solve the problems of conductive bridge short circuit, photoresist missing shape, photoresist deformation, etc., to avoid short circuit or open circuit, improve test efficiency, and reduce misjudgment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0044] In the following description, numerous specific details are given in order to provide a more thorough understanding of the invention, however, it will be apparent to those skilled in the art that the invention may be practiced without one or more of these details.

[0045] In other examples, in order to avoid confusion with the present invention, some technical features known in the art are not described. It should be understood that the present invention can be implemented in different forms and should not be construed as being limited to the implementations set forth herein. Rather, these embodiments are provided so that this disclosure will be thorough and complete, and will fully convey the scope of the invention to those skilled in the art.

[0046] In the drawings, the size and relative sizes of layers and regions may be exaggerated for clarity, and like reference numerals designate like elements throughout.

[0047] It should be noted that if there is a directional...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com