A LED display module detection device and detection method thereof

A technology of LED display screen and detection device, which is applied in the direction of measuring device, testing optical performance, and material analysis by optical means, can solve the problems of high missed detection rate, high missed detection rate and high missed detection rate, and achieve Improve supplier monitoring, improve production quality, and improve the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

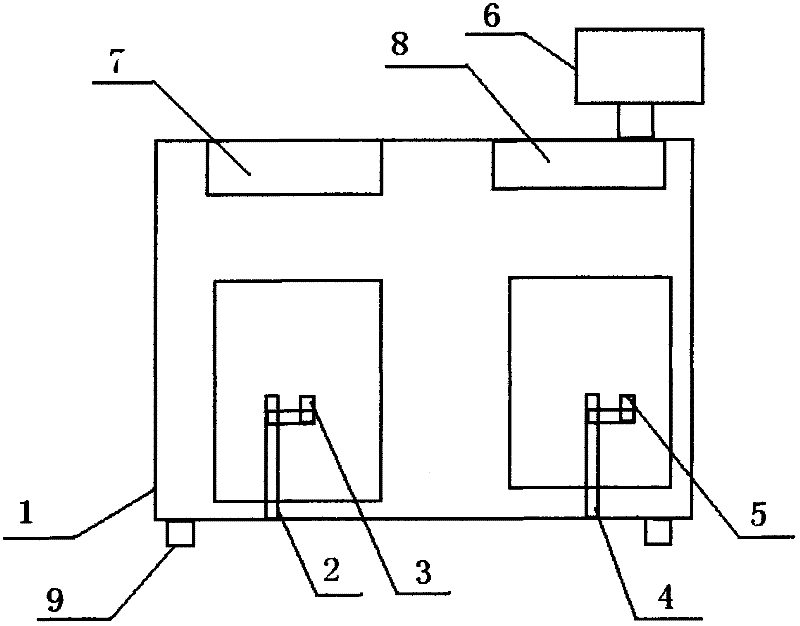

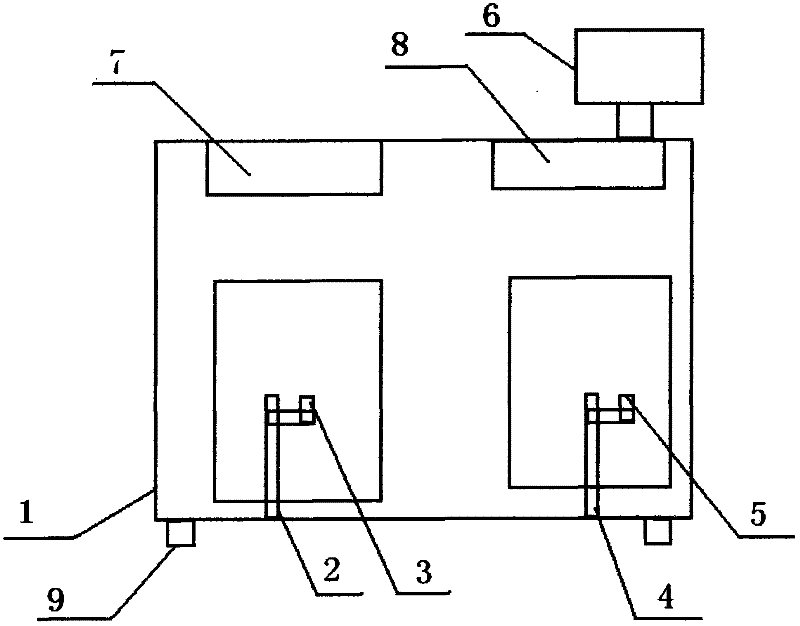

[0058] Refer to attached picture figure 1

[0059] A LED display module detection device, comprising a detection device body 1, a first lifting platform 2 and a second lifting platform 4 arranged on the inner base of the detection device body 1, and a first camera device 3 is arranged on the first lifting platform 2 , The second camera device 5 is set on the second lifting platform 2, and an output detection and display unit placement platform 7 is set on the detection device body operating table directly above the first camera device 3, directly above the second camera device 5 A display unit placement platform 8 to be tested is arranged on the operating table of the detection device body, and a display platform 6 and a display unit detection system are also arranged on the detection device body.

[0060] In the LED display module detection device, the display unit detection system includes a package control unit, a detection unit and a judgment unit;

[0061] The control u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com