Stratified fluid monitoring and sampling device based on pressure pulse

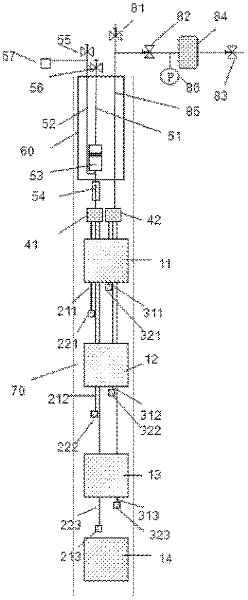

A technology of pressure pulse and sampling device, applied in measurement, wellbore/well components, earthwork drilling, etc., can solve the problems of data value lag, inability to understand the state of underground multiphase fluid, inability to take gas samples, etc., to reduce The effect of the number of pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

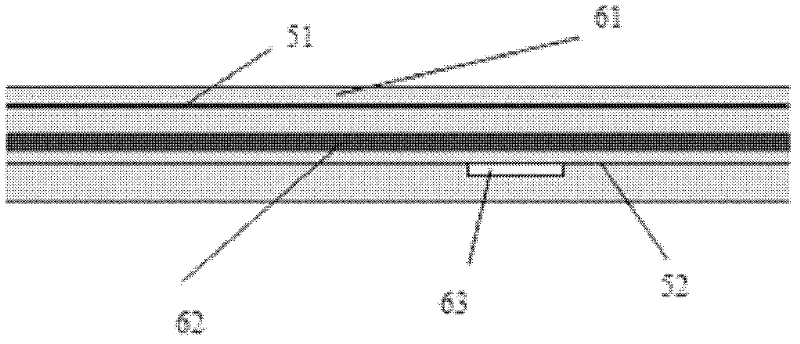

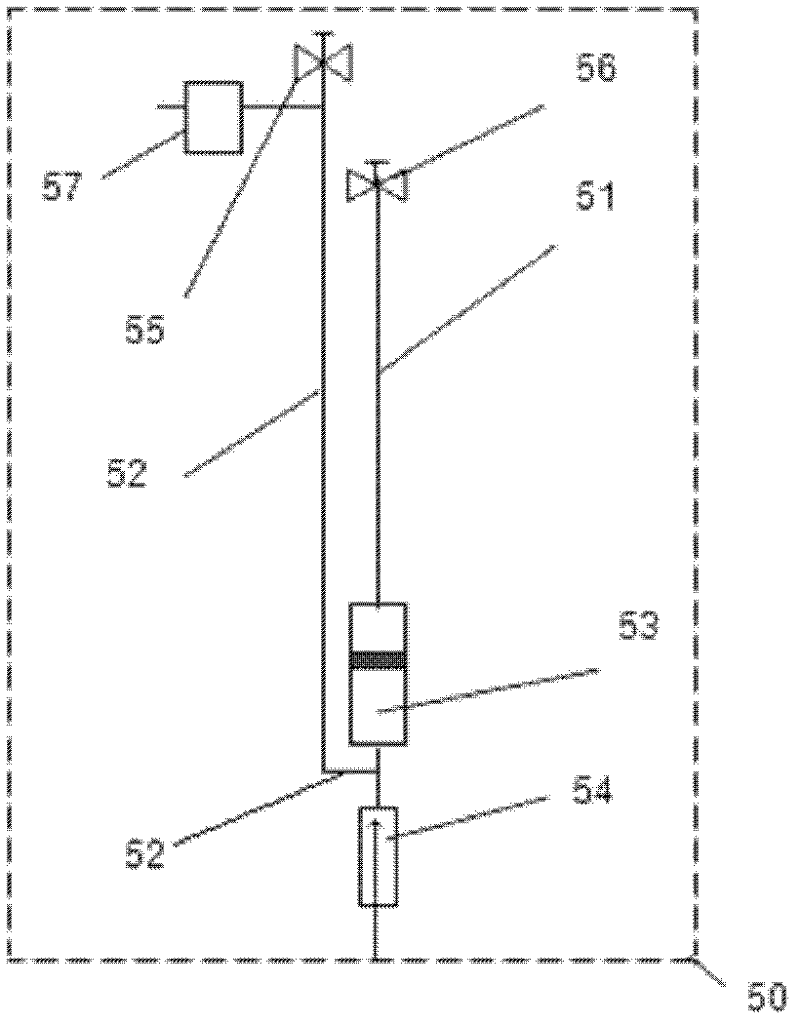

Method used

Image

Examples

Embodiment example

[0184] Inner Mongolia Tongliao CO 2 The saline layer storage test site used two-layer pressure pulse fluid monitoring and sampling devices to analyze and sample the groundwater and gas fluids. The sampling conditions were good. The sampling depth of the lower layer was 250-220m, and the depth of the upper layer was 160-120m. Carry out pulse monitoring, the results are as follows Figure 8 As shown, as the gas migrates to the location of the monitoring well, the pressure pulse data has changed significantly. By comparing the calibration data, the ratio of underground gas to liquid can be inferred; The system takes about 70L of other samples (standard condition). The water samples taken out were decompressed and analyzed after the sampling device, and the fluid conditions under underground conditions were synthesized by software, and the sampling results were good. The change of underground gas saturation is monitored by pressure pulse, and obvious saturation change is detecte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com