Wear-resistant alloy material and plasma surfacing welding process of shield tunneling machine wear-resistant cutter ring

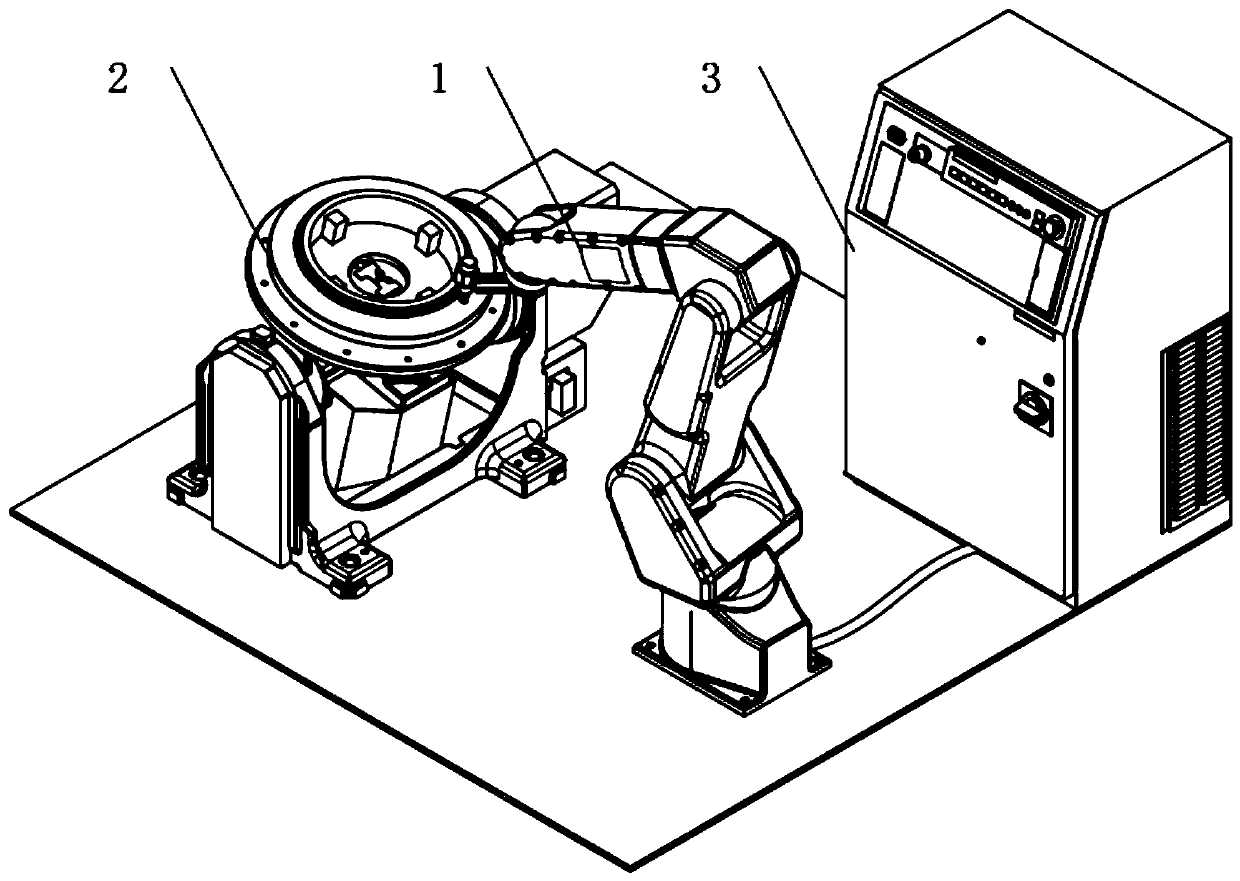

A wear-resistant alloy, plasma stack technology, applied in the field of shield cutting tools, can solve the problems of low production efficiency, poor quality stability, poor wear resistance, etc., to reduce excavation costs, high density and toughness, and increase wear resistance. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

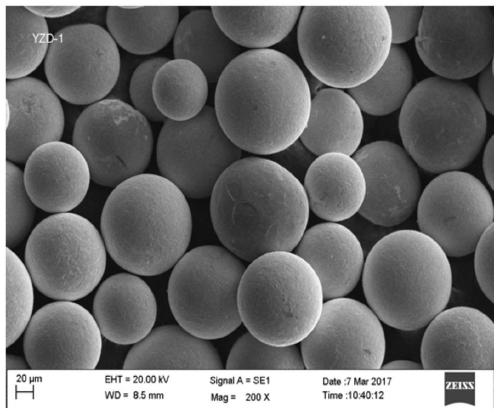

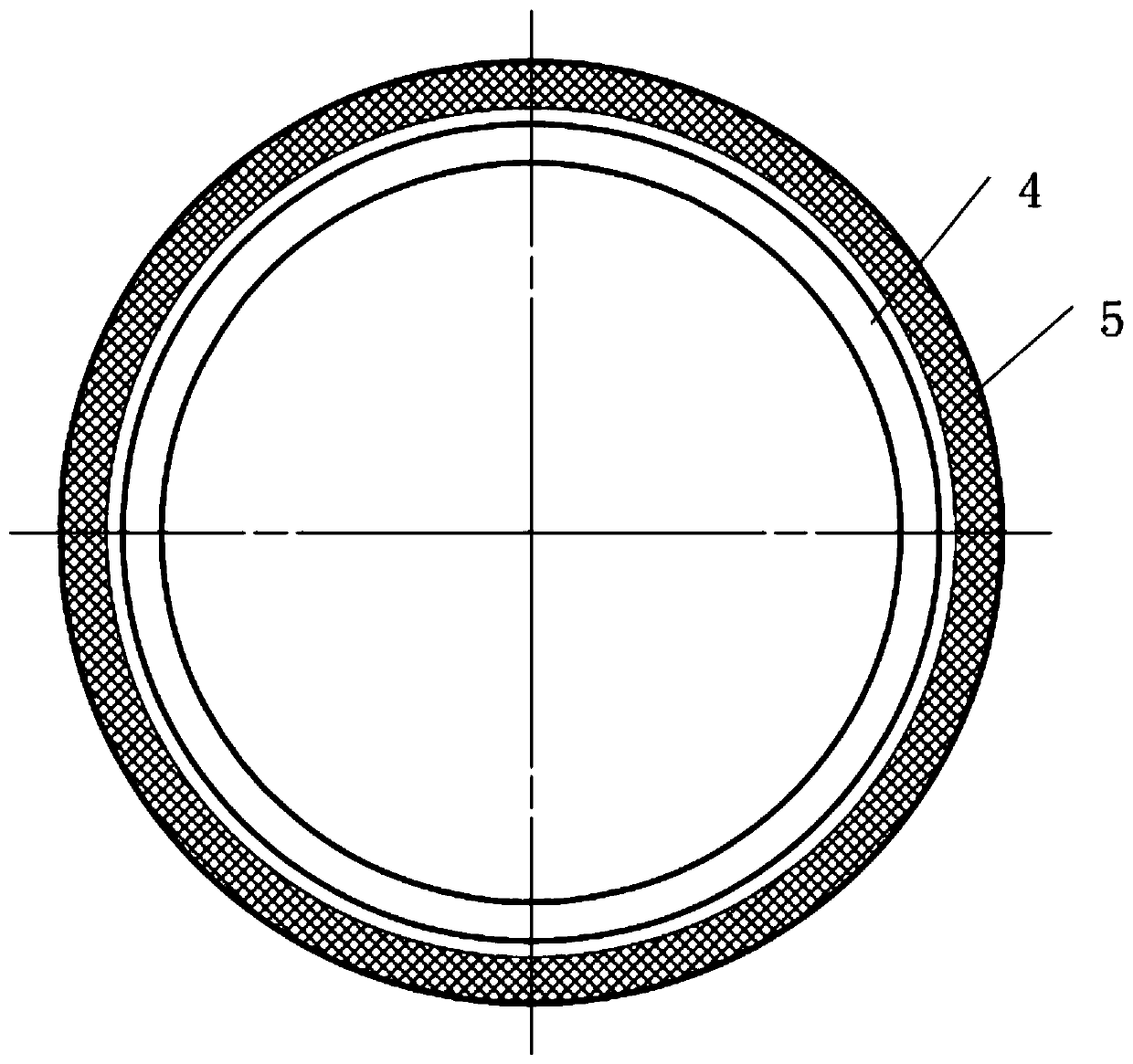

[0056] A wear-resistant alloy material comprises NiCrBSi alloy and spherical cast tungsten carbide, the mass percentage of the NiCrBSi alloy is 35%, and the mass percentage of the spherical cast tungsten carbide is 65%. This setting can improve the wear resistance of the cutter ring of the shield machine and prolong the service life of the cutter ring.

[0057] The wear-resistant alloy material of the present embodiment is carried out reciprocating sliding wear test and sliding compound wear test:

[0058] ①Reciprocating sliding wear test: the number of reciprocating frictions N=2000 times, the wear scar width of the surfacing layer in this embodiment is 0.39mm, and the H13 mold steel commonly used in the prior art has a wear scar width of 0.67mm. It can be seen from the comparison that this embodiment The alloy material has better wear resistance.

[0059] ② Punching-sliding compound wear test: the number of impact wear N=15000 times, the impact zone and sliding zone of the ...

Embodiment 2

[0075] A wear-resistant alloy material comprises NiCrBSi alloy and spherical cast tungsten carbide, the mass percentage of the NiCrBSi alloy is 45%, and the mass percentage of the spherical cast tungsten carbide is 55%. This setting can improve the wear resistance of the cutter ring of the shield machine and prolong the service life of the cutter ring.

[0076] The wear-resistant alloy material of the present embodiment is carried out reciprocating sliding wear test and sliding compound wear test:

[0077] ① Reciprocating sliding wear test: the number of reciprocating frictions N = 2000 times, the wear scar width of the surfacing layer in this embodiment is 0.37mm, and the H13 mold steel commonly used in the prior art has a wear scar width of 0.67mm. It can be seen from the comparison that this embodiment The alloy material has better wear resistance.

[0078] ② Punching-sliding compound wear test: the number of impact wear N=15000 times, the impact zone and sliding zone of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com