Detection method and system for silicon-based module defects of photovoltaic power station

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

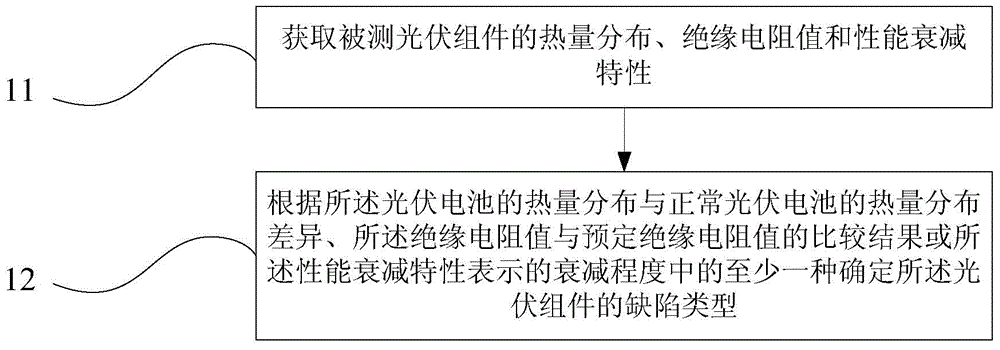

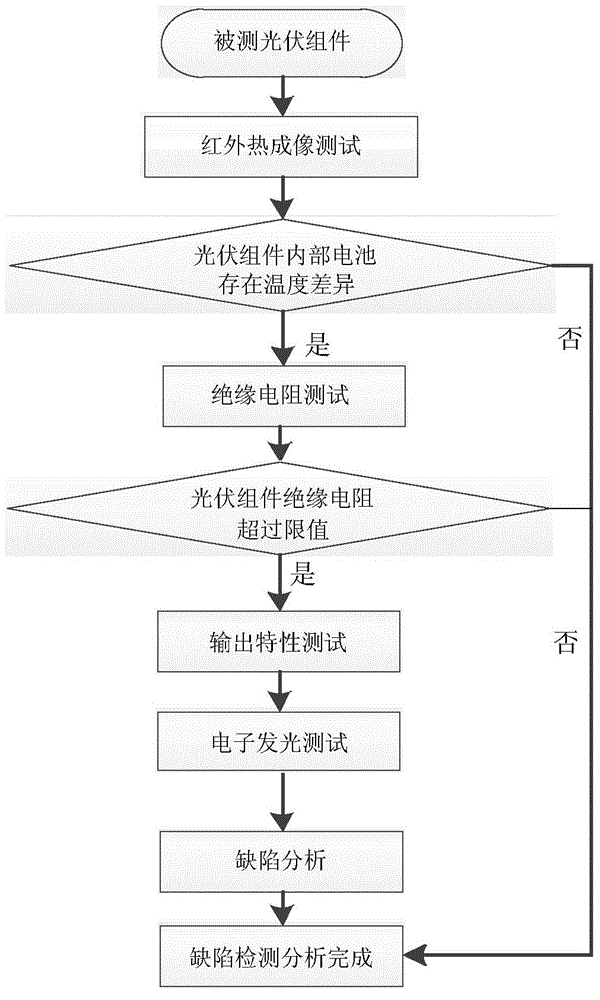

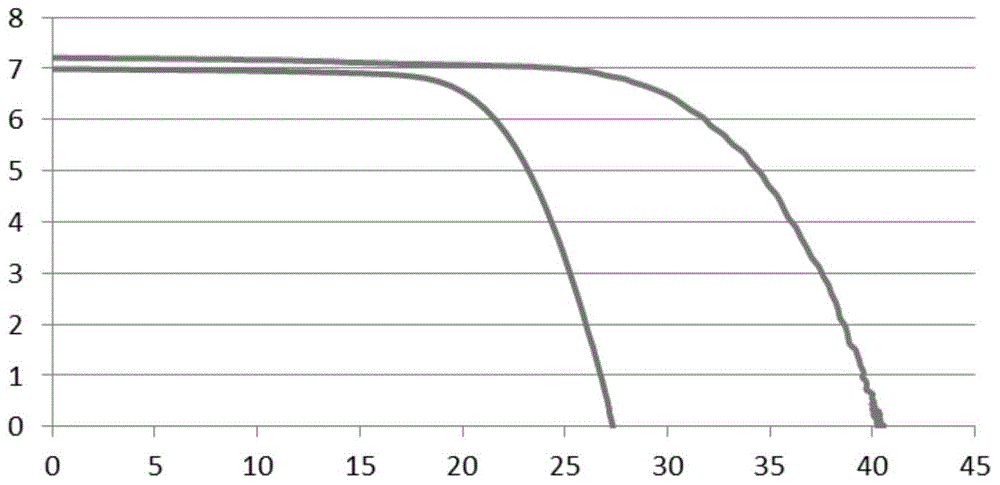

Method used

Image

Examples

Embodiment Construction

[0038] During the production, manufacture, on-site installation and operation of existing photovoltaic modules, their raw materials, packaging process and external factors will cause dominant or recessive defects or failures of photovoltaic modules. Among them, most of the defects are difficult to find under the condition of visible light. The current on-site testing standards for photovoltaic modules mainly rely on on-site test methods to check the photovoltaic modules one by one. Maintenance plays a role in promoting. Therefore, this specific implementation method proposes a detection scheme for silicon-based photovoltaic modules that are widely used in large-scale ground photovoltaic power plants, and can quickly and efficiently locate the type of defective components, and can also effectively explain the defects. The method of generating the cause is of great significance to the future maintenance of photovoltaic power plants, the standardization of the installation process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com