Laminated machine and electrical core laminated mechanism

A stacking machine and stacking technology, applied in the direction of non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of increasing equipment cost, affecting response speed, reducing stacking efficiency, etc., to reduce equipment cost, response time reduction, reduced motion interference or poor fit effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

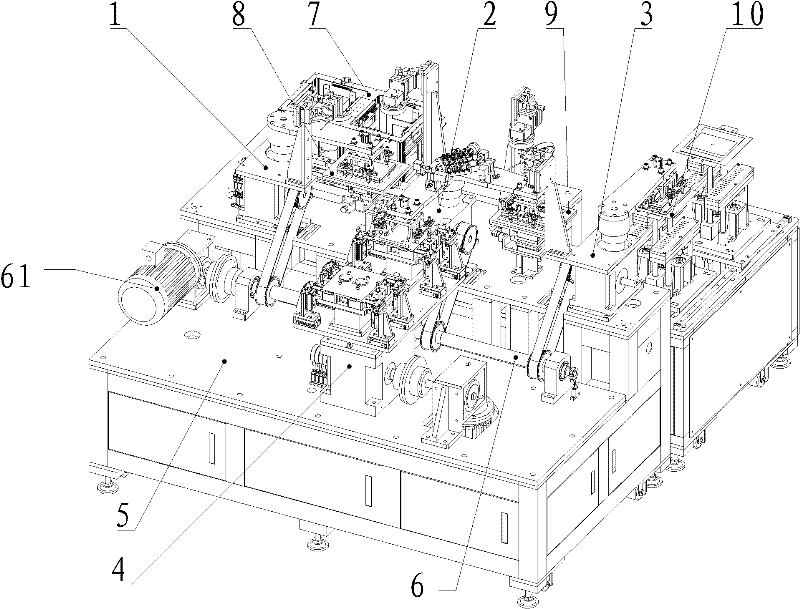

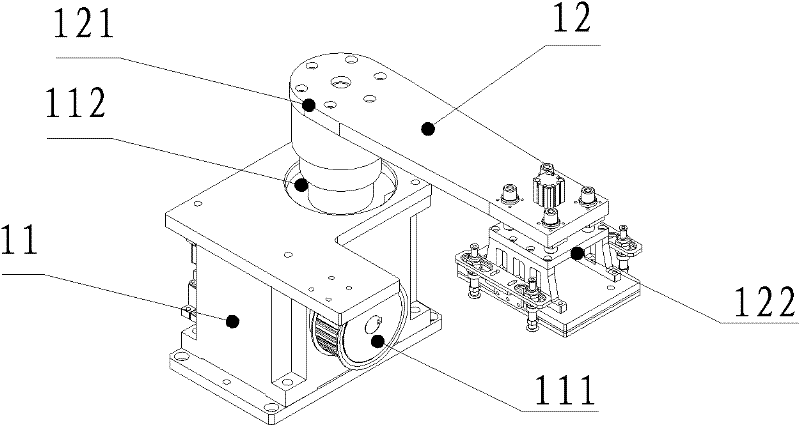

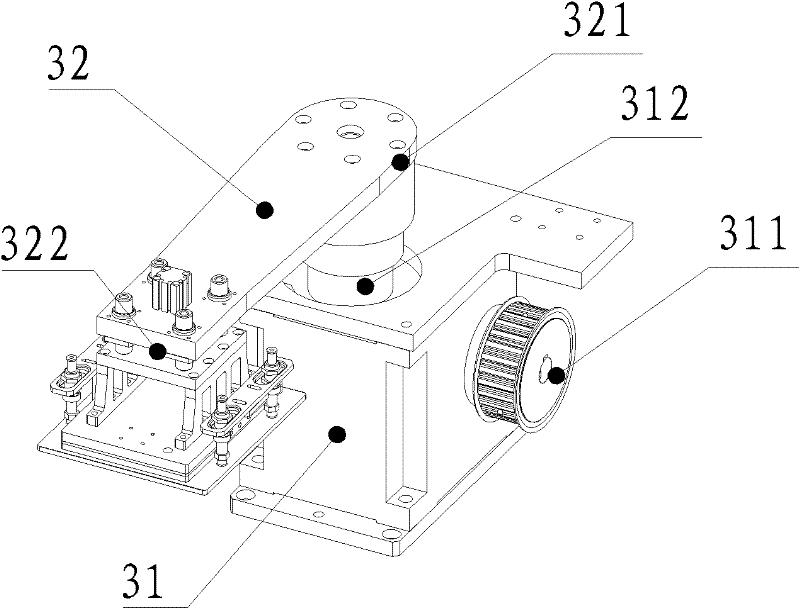

[0024] Please refer to figure 1 , the stacker of the present embodiment comprises the first magazine 7, the second magazine 10, the first positioning platform 8, the second positioning platform 9, the stacking platform 4 with at least one stacking position 41, the first material taking The manipulator 1, the second reclaiming manipulator 3, the lamination manipulator 2 and the lamination driving assembly may also include a base 5 for supporting and fixing the above components.

[0025] The first material box 7 and the second material box 10 are respectively used to provide different types of material sheets to be stacked, such as in the lamination process of power lithium battery cells, the first material box 7 provides the positive electrode sheet, and the second material box 10 provides the negative electrode sheet, and the two material boxes can be set in fixed positions respectively, and can also be set in the transmission mechanism so as to transport the material sheet fr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com