Wire holding and bending setter

A technology of forming machine and wire, applied in the direction of overhead line/cable equipment, etc., can solve the problem of labor and labor in holding and bending the wire, and achieve the effect of good product process quality, simple operation and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

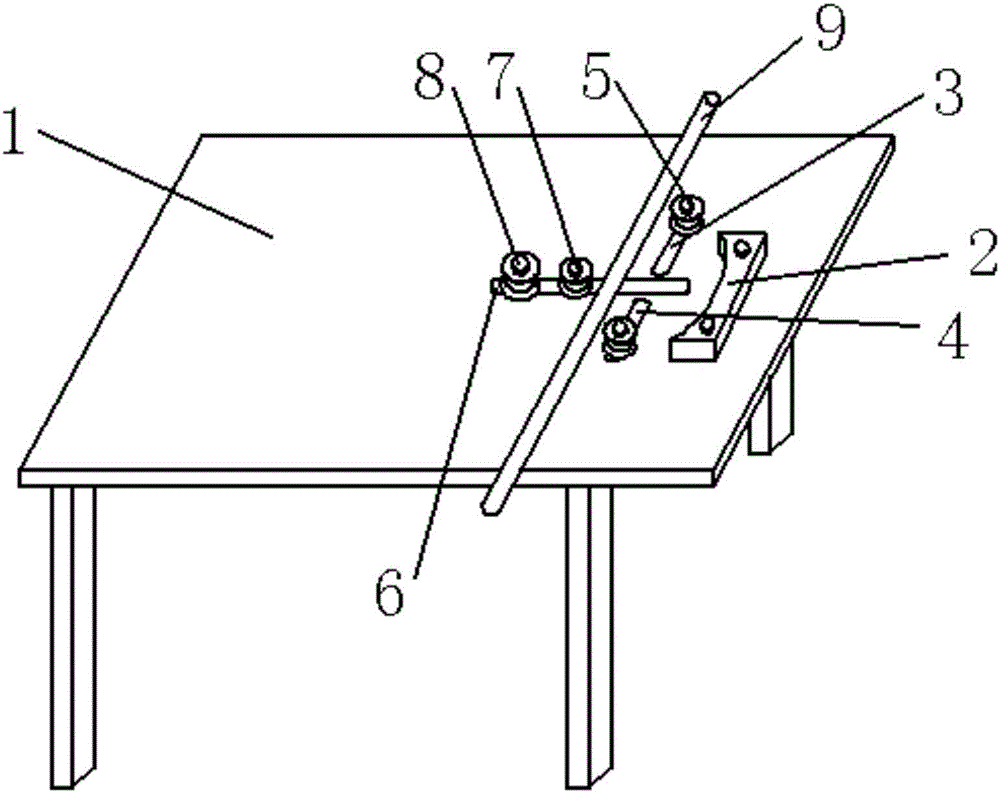

[0015] The technical solution adopted by the present invention to realize its technical purpose is as shown in the figure: including operating platform 1, fixed bracket groove 2, right groove 3, left groove 4, grip wheel 5, top groove 6, top driving wheel 7, Shaping wheel 8, cylinder, control switch;

[0016] The operating platform 1 is square, with four brackets on the bottom, a fixed bracket 2 on the inner side of the upper edge, and a concave arc-shaped wire protection surface on the inner side of the fixed bracket 2; a longitudinal top groove 6 is provided in the center of the inner side of the fixed bracket 2 , the bottom of the top groove 6 is provided with a top movable arm, and the top movable arm is sequentially provided with a top driving wheel 7 and a shaping wheel 8; the top groove 6 is provided with a horizontal left groove 4 on the left side near the end of the fixed bracket groove 2, and the left groove The distance between 4 and the top groove 6 close to the en...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com