Magnetic control sputtering equipment

A magnetron sputtering and equipment technology, applied in the field of magnetron sputtering equipment, can solve the problems of multiple equipment space, occupation, increase the volume of the process chamber, etc., to save operating costs, save processing costs, and reduce equipment volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

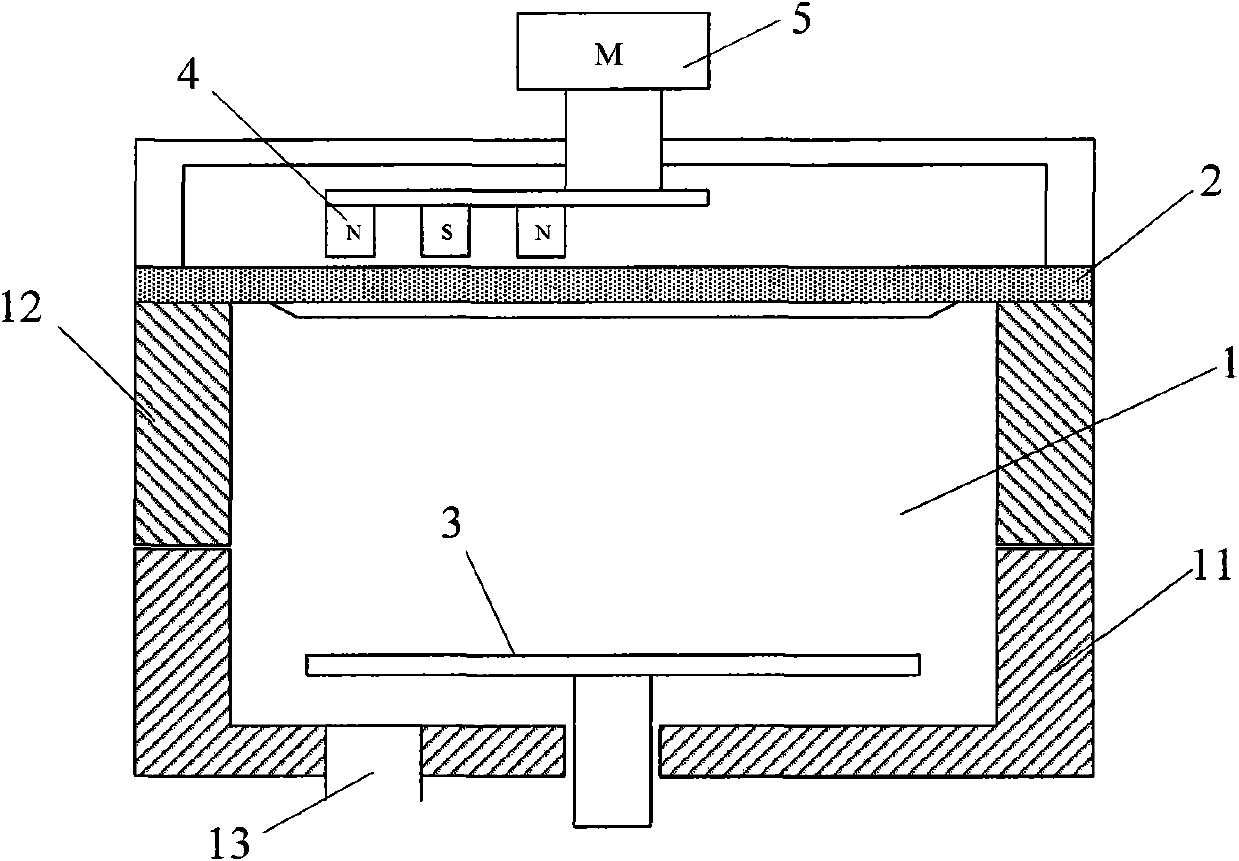

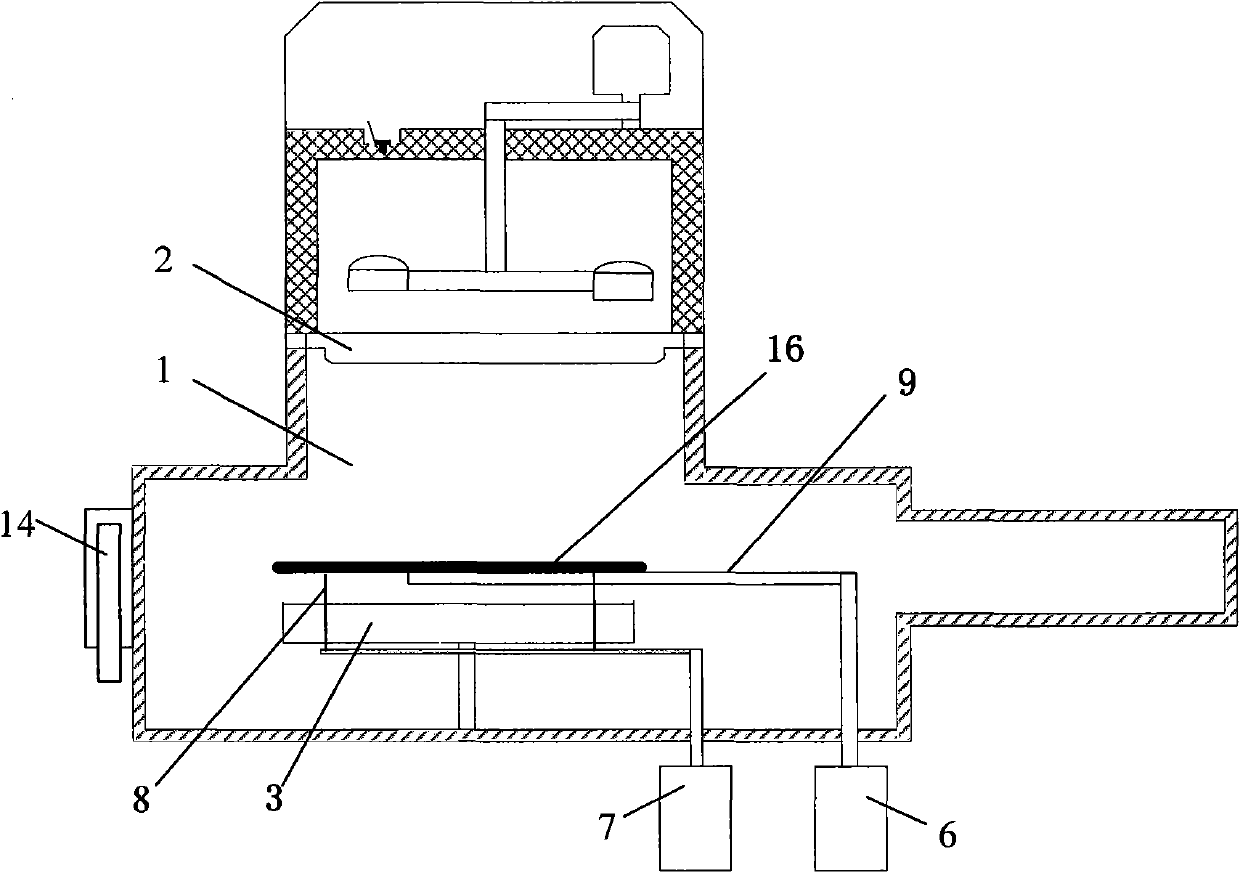

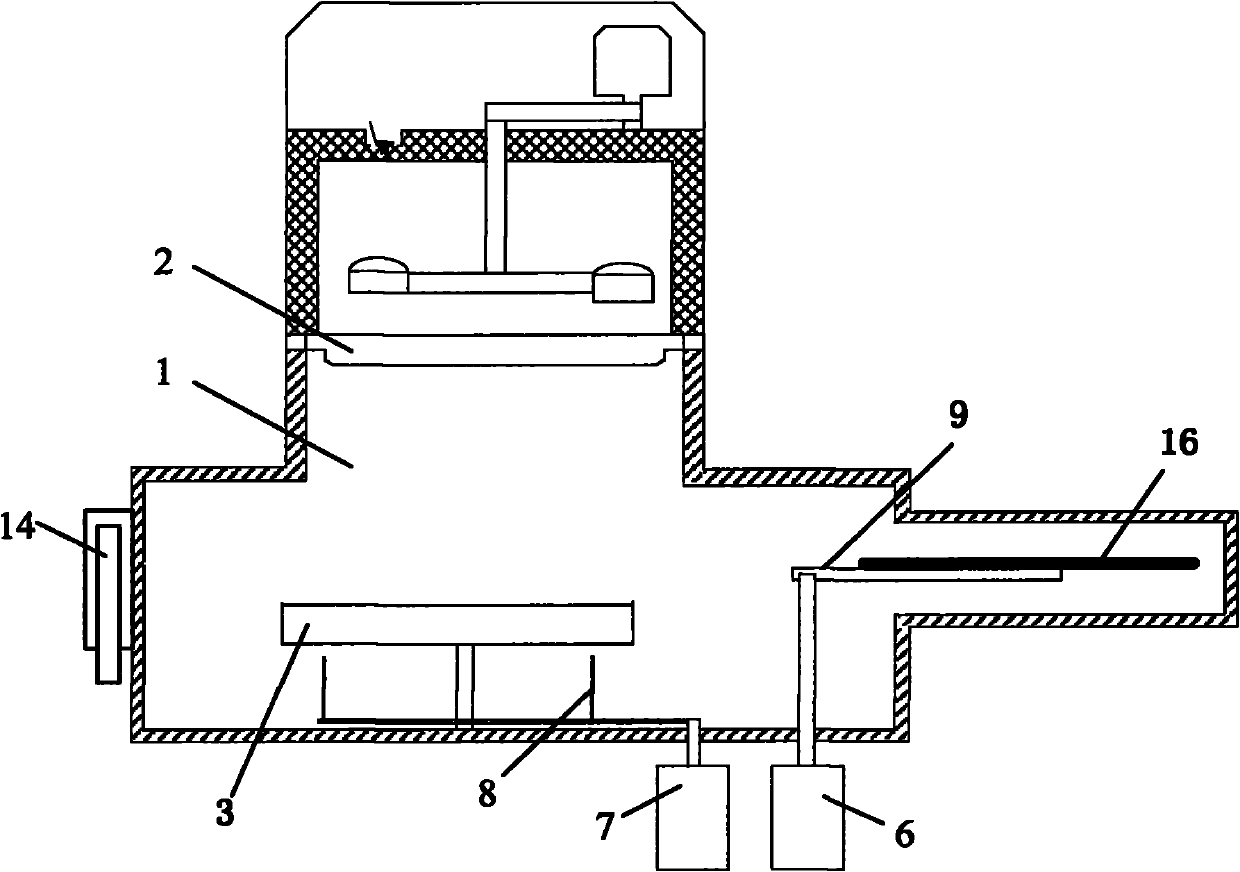

[0028] In order to enable those skilled in the art to better understand the technical solution of the present invention, the magnetron sputtering equipment provided by the present invention will be described in detail below with reference to the accompanying drawings.

[0029] The magnetron sputtering equipment provided by the present invention includes at least one process chamber, a target and a substrate carrying device arranged inside the process chamber; in addition, it also includes at least one shielding plate. When removing the oxide on the surface of the target material, the substrate carrying device is protected by means of the above-mentioned shielding disc to prevent the fallen oxide particles from falling on the surface of the substrate carrying device and causing pollution; and, after removing the target material oxide, the The shielding disk is stored outside the process chamber. In a specific embodiment, the above-mentioned magnetron sputtering equipment furthe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com