Precision machining technological equipment and machining method for blade of aviation engine

An aero-engine and process equipment technology, applied in metal processing equipment, metal processing mechanical parts, positioning devices, etc., can solve the problems of low work efficiency, complex production preparation, poor pouring and melting conditions, etc., to improve processing efficiency and The effect of high quality, high level of automation and novel process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

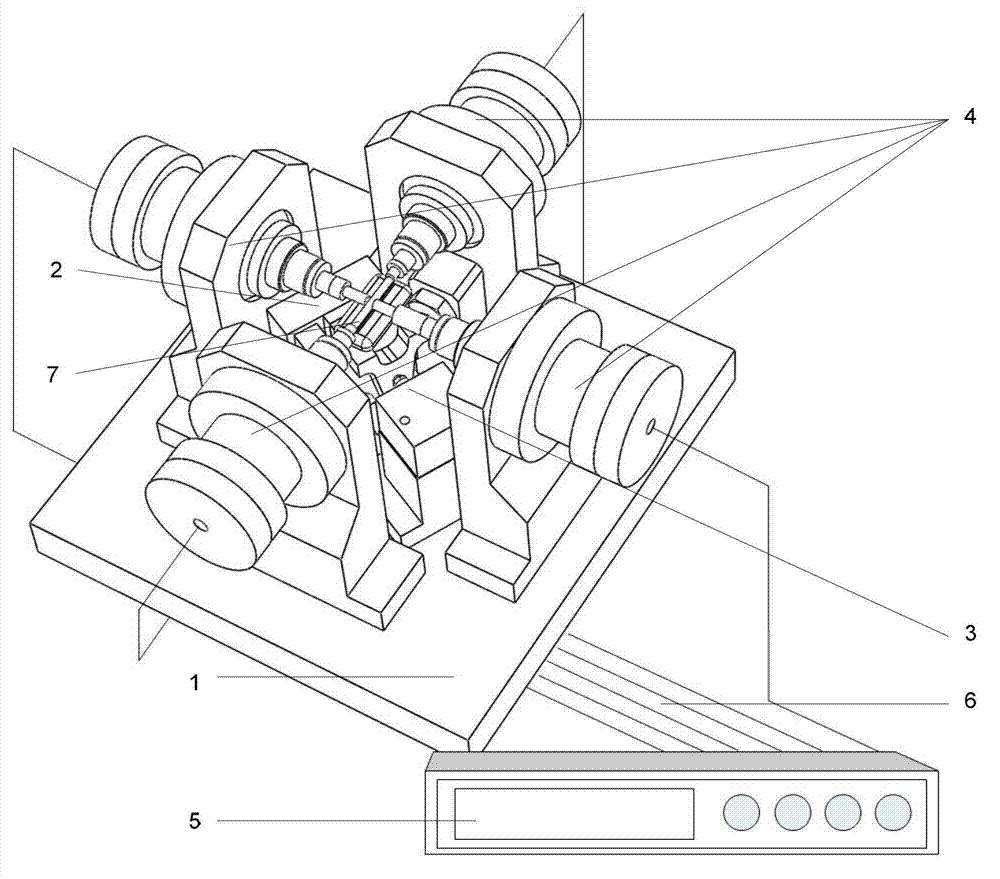

[0021] Such as figure 1 As shown, the present invention is a precision machining process equipment for aeroengine blades, including a positioning device 2 fixed on the base table 1, a clamping device 3 and an auxiliary support device 4, and the positioning device 2 is used for the curved surface of the blade blade Positioning, the clamping device 3 is used to clamp the blade body, the auxiliary supporting device 4 is fixed on the outside of the positioning device 2 and the clamping device 3, the working head of the auxiliary supporting device 4 is directly connected to the tenon of the blade 7 part contact; the main controller 5 controls the hydraulic cylinders on the clamping device 3 and the auxiliary support device 4 through the control circuit 6 .

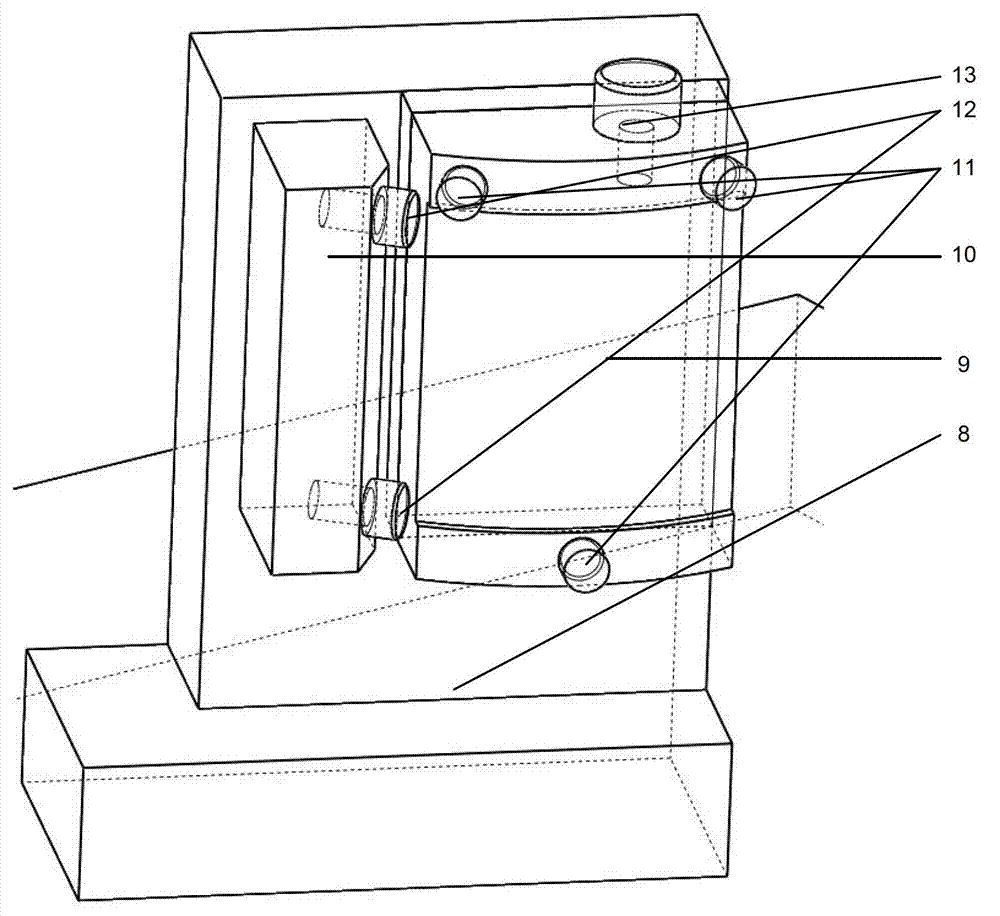

[0022] Such as figure 2 As shown, the positioning device 2 includes a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com