Material surface film coating device

A coating device and transmission technology, applied in the field of materials, can solve problems such as cumbersome adjustment procedures and inability to achieve fast thread cutting, and achieve the effects of improving operation technology, avoiding operation errors, and improving integrity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

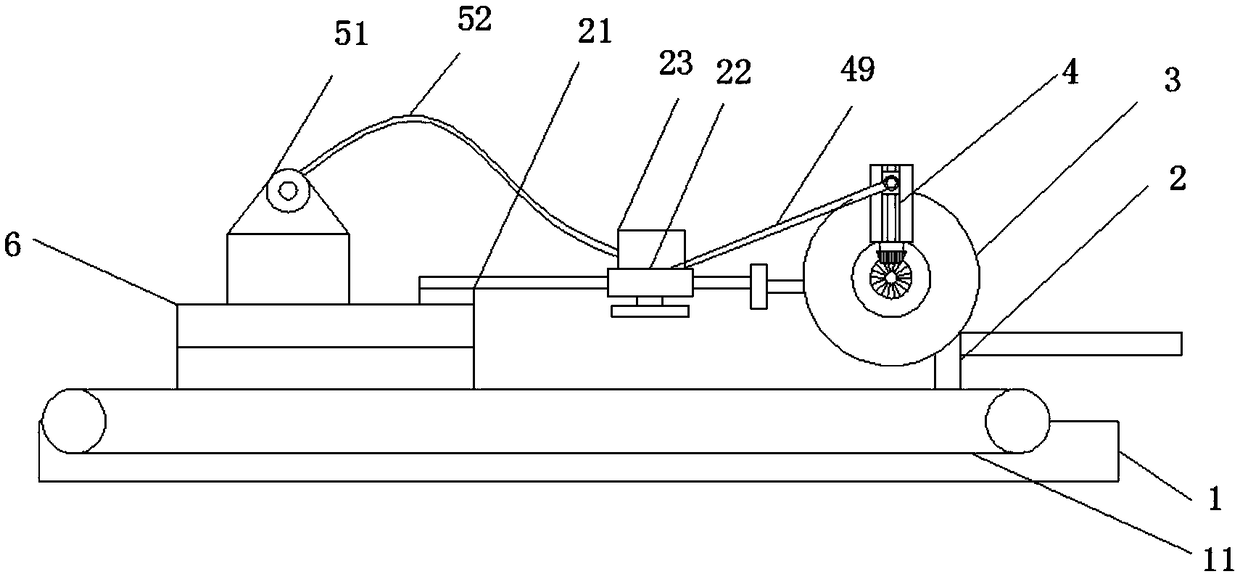

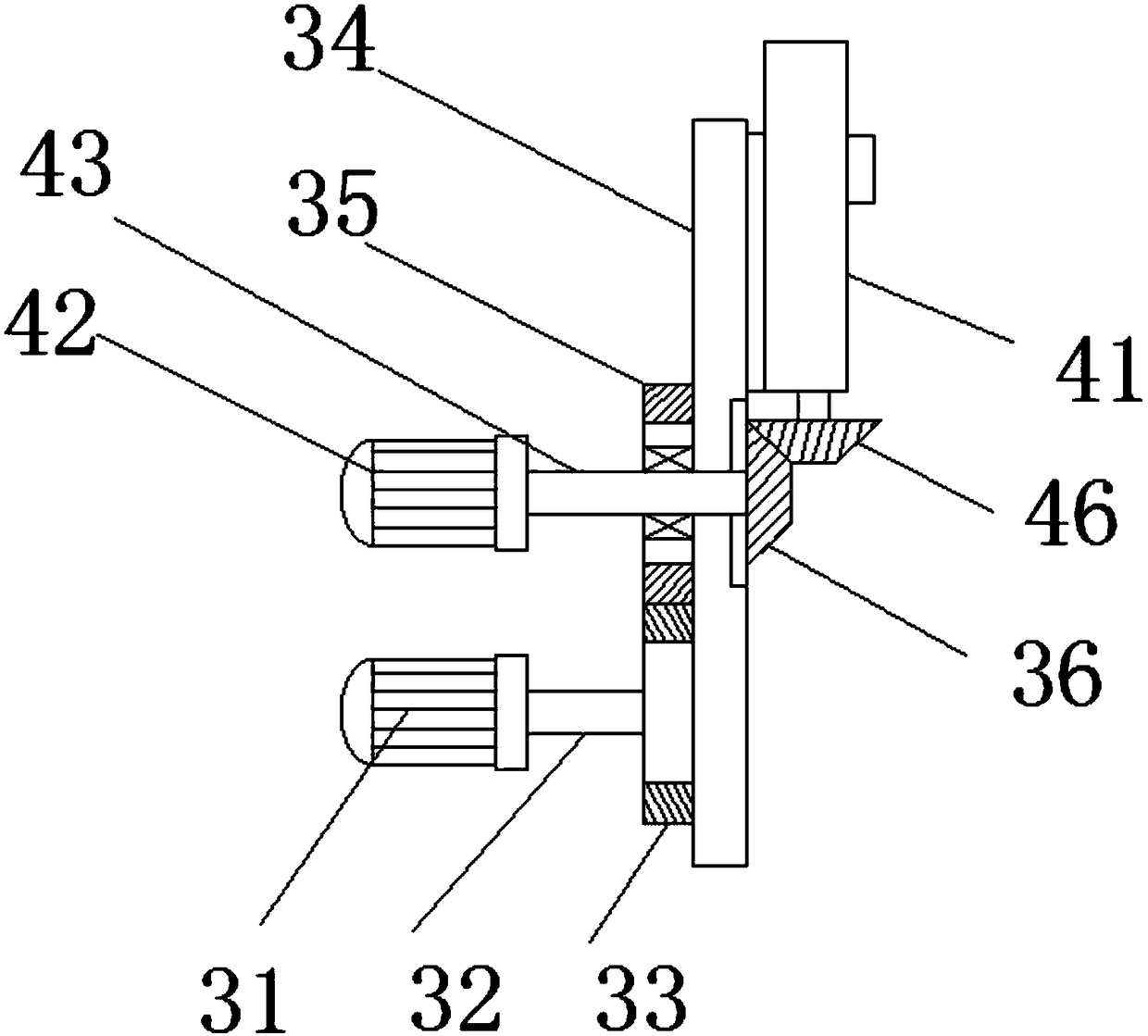

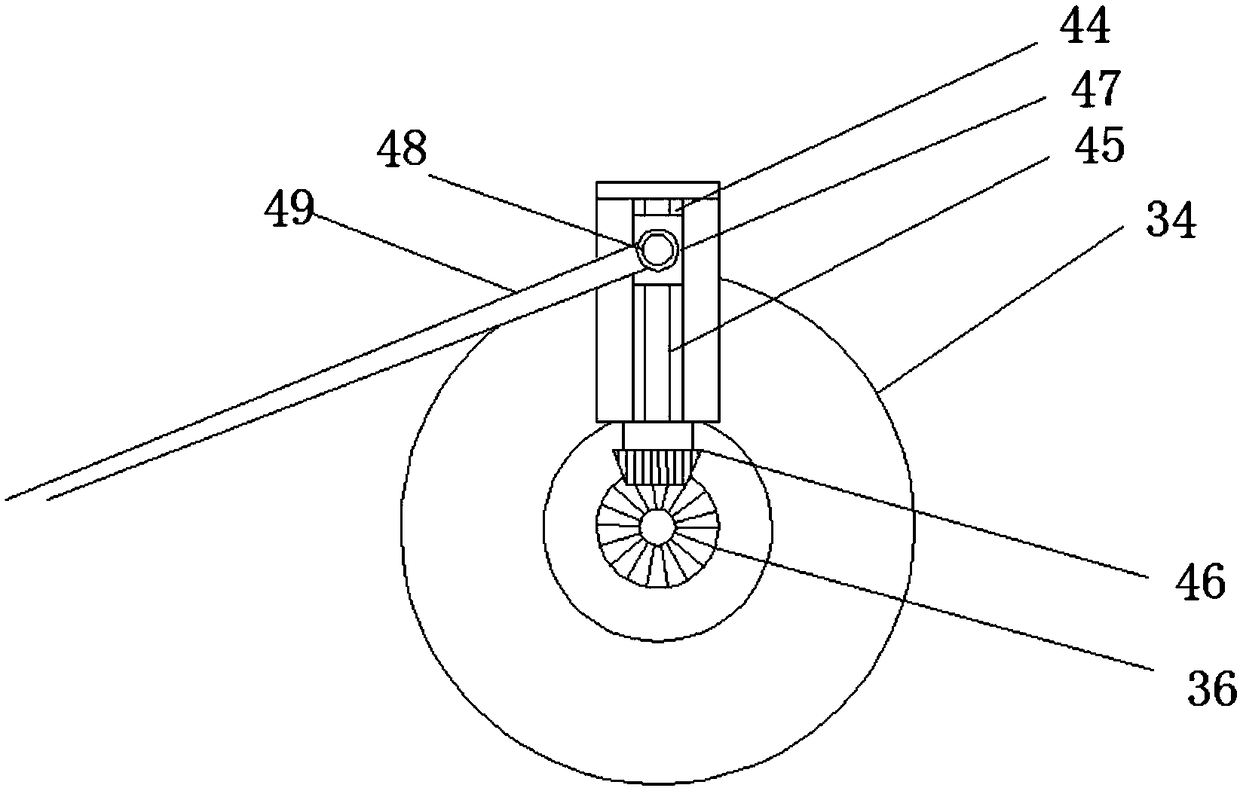

[0024] see Figure 1~3 , a material surface coating device, including a base 1, a transmission belt 11 is installed on the base 1, a transmission frame 2 is mounted on the base 1, and the transmission frame 2 is located on the transmission belt 11 Above, a slide bar 21 is installed horizontally on the transmission frame 2, a slide block 22 is installed on the slide bar 21, a spraying device 23 is installed on the slide block 22, and a synchronous installation is installed on the transmission frame 2. There is a first transmission mechanism 3, and a second transmission mechanism 4 is mounted on the first transmission mechanism 3. The first transmission mechanism 3 includes a transmission disc 34, and the rear side of the transmission disc 34 is provided with a first motor 31 , the first motor 31 is installed on the transmission frame 2, the first motor 31 is equipped with a transmission gear 33 through the first rotating shaft 32, the transmission gear 33 is not connected with ...

Embodiment 2

[0029] see Figure 4 , as a further optimization of Embodiment 1, on the basis of it, the front end of the transmission belt 11 is equipped with a limit frame 6, and the middle position of the top plate of the limit frame 6 is installed with a transmission threaded rod 61 transversely, and the transmission thread Rod 61 is a two-way threaded rod, the thread directions of the left and right sections of the transmission threaded rod 61 are opposite, and the left and right ends of the transmission threaded rod 61 are equipped with transmission sleeves 62, and the bottom ends of the transmission sleeves 62 are all equipped with limit plate 63, a transmission motor 67 is installed on the side wall of the limit frame 6, and the transmission threaded rod 61 is connected with the motor shaft of the transmission motor 67 through a coupling.

[0030] When working, start the transmission motor 67, thereby driving the transmission threaded rod 61 to rotate, and drive the transmission slee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com